Hummer H1 (1992-1998). Manual — part 45

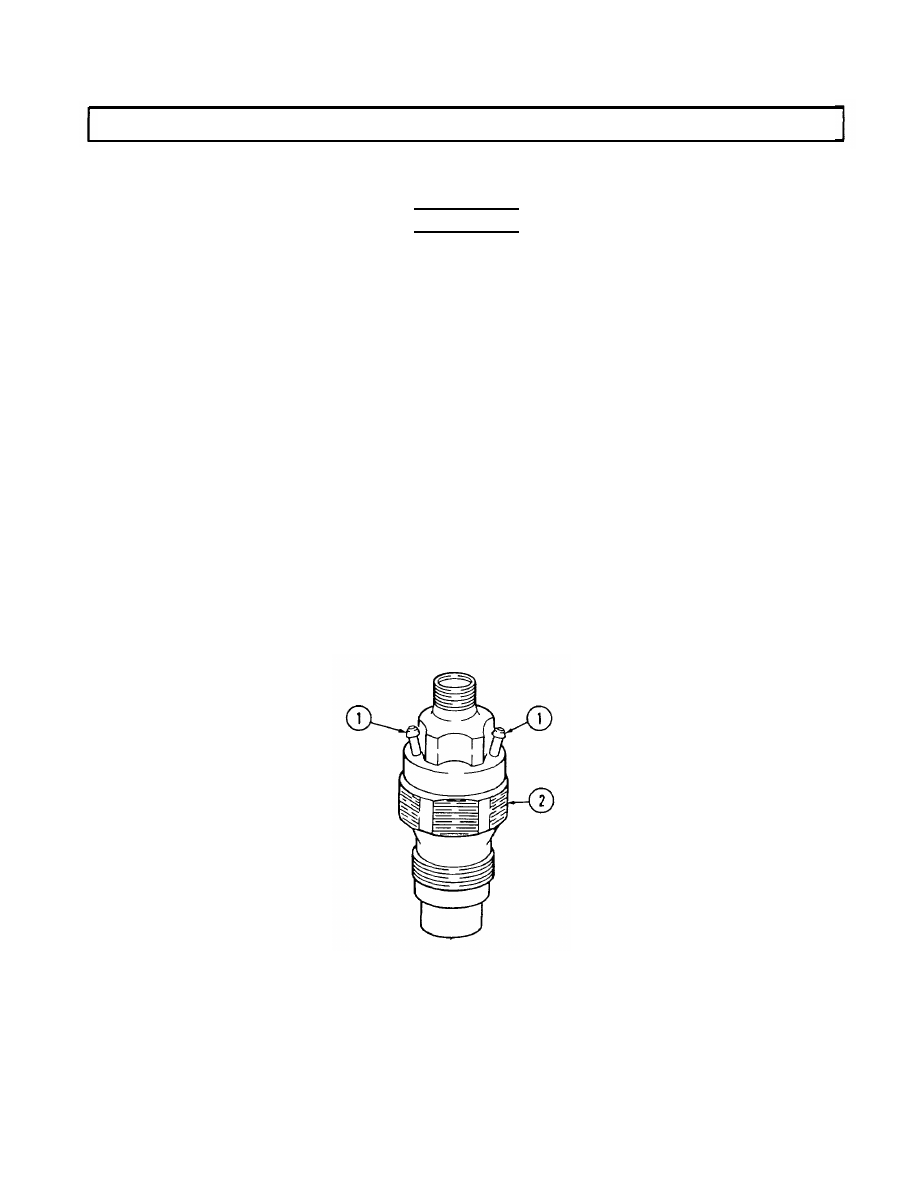

2-37. FUEL INJECTION NOZZLE REPAIR (Cont’d)

3. Leakage test.

(a) Open shutoff valve to pressure gauge one additional turn.

WARNING

Compressed air used for cleaning purposes will not exceed 30 psi

(207 kPa). Use only with effective chip guarding and personal

protective equipment (goggles/shield, gloves, etc.).

(b) Blow-dry end of nozzle (2).

NOTE

A pressure of 1,400 psi (9,653 kPa) must be maintained for

10 seconds while checking for nozzle leakage.

(c) Depress lever on tester until pressure gauge reads 1,400 psi (9,653 kPa) and observe tip

of nozzle (2). If a droplet forms and drops off the nozzle (2) in 10 seconds or less, replace

nozzle (2).

4. Chatter test.

(a) Close shutoff valve to pressure gauge.

(b) Depress lever on tester slowly, noting whether a chattering noise can be heard.

NOTE

Faster lever movement may cause nozzle to hiss or squeal rather

than chatter; this is acceptable.

(c) If no chatter is heard, increase speed of lever movement on tester until nozzle (2) chatters.

If no chatter is heard, replace nozzle (2).

2-143

2-38. WATER PUMP REPAIR

This task covers:

a. Disassembly

c. Inspection

b. Cleaning

d. Assembly

INITIAL SETUP

Tools

Manual References

General mechanic’s tool kit:

automotive (Appendix E, Item 1)

Materials/Parts

Equipment Conndition

Engine disassembIed into subassemblies

Pipe sealing compound (Appendix B, Item 17)

Sealing compound (Appendix B, Item 18)

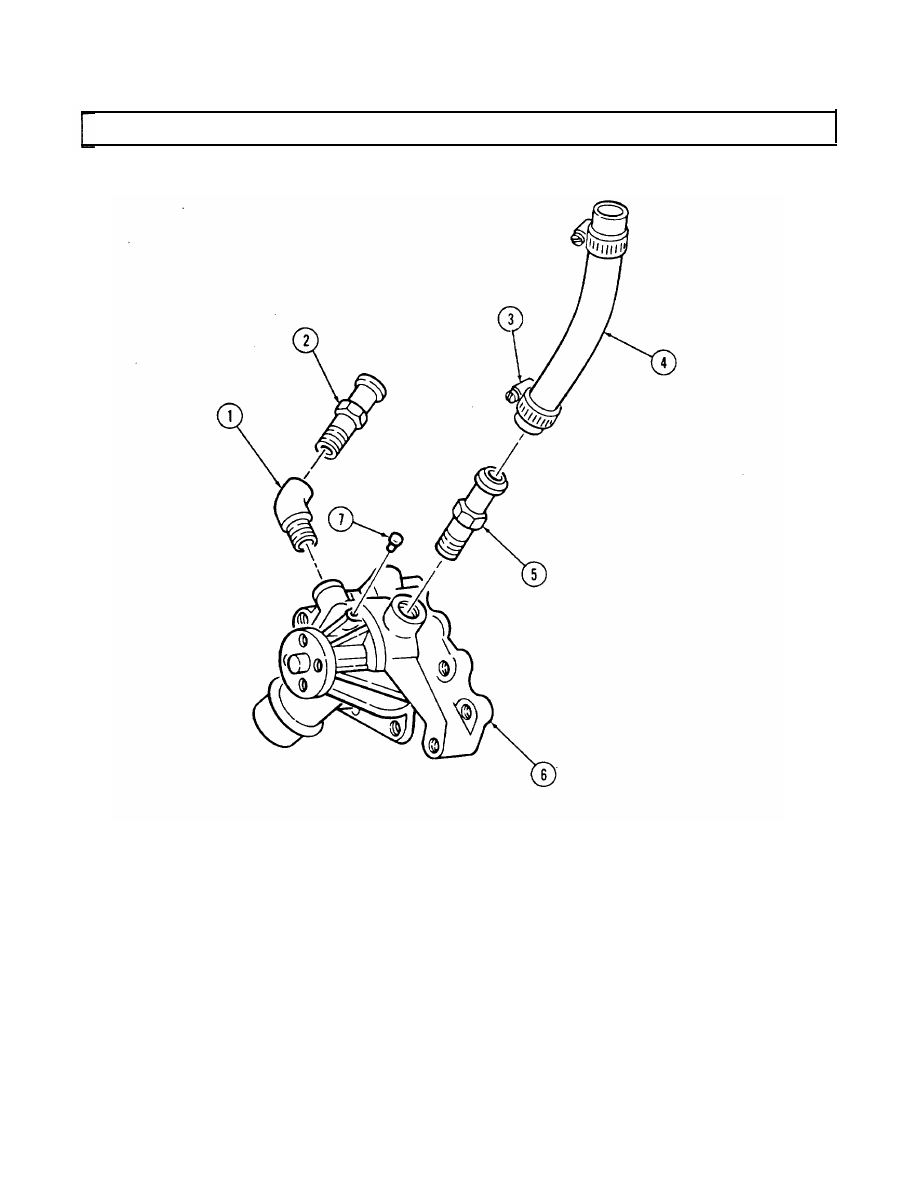

a. Disassembly

NOTE

Perform steps 1 through 3 if replacing water pump or damaged parts.

1. Loosen hose clamp (3) and remove bypass hose (4) from bypass hose adapter (5).

2. Remove 450 adapter (1) and heater hose nipple (2) from water pump (6).

3. Remove bypass hose adapter (5) from water pump (6).

b. Cleaning

Clean all components in accordance with para. 2-9.

c. Inspection

NOTE

For general inspection instructions, refer to para. 2-10.

1. Inspect heater hose nipple (2), 45° adapter (l), and bypass hose adapter (5) for thread damage.

Replace if threads are damaged.

2. Inspect water pump (6) for cracks and wear. Replace if cracked or worn.

3. Inspect threaded holes in water pump (6) for damage. Replace water pump (6) if threads are

damaged.

4. Inspect bypass hose (4) for damage. Replace if damaged.

5. Inspect water pump rivet (7) for damage or looseness. Replace if damaged or loose. Apply sealing

compound to replacement rivet prior to installation.

d. Assembly

1. Coat threads on 45° adapter (1) and heater hose nipple (2) with pipe sealing compound and install

in pump (6).

2. Coat threads on bypass hose adapter (5) with pipe sealing compound and install in water pump (6).

3. Install bypass hose (4) on bypass hose adapter (5) and secure with hose clamp (3).

NOTE

Perform step 4 if water pump was replaced.

4. Apply sealing compound to water pump rivet (7) and install in water pump (6).

2-144

2-38. WATER PUMP REPAIR (Cont’d)

2-145

2-39. WATER CROSSOVER REPAIR

This task covers:

a. Disassembly

c. Inspection

b. Cleaning

d. Assembly

INITIAL SETUP:

Tools

Manual References

General mechanic’s tool kit:

automotive (Appendix E, Item 1)

Equipment Condition

Materials/Parts

Engine disassembled

Water crossover gasket (Appendix D, Item 19)

Pipe sealing compound (Appendix B, Item 17)

into subassemblies

NOTE

In some cases, flanged head fasteners maybe present instead of

standard fasteners and washers. In all cases, washers should be

used when replacing a flanged head fastener with a standard

fastener.

a. Disassembly

1. Remove capscrew (6), stud (5), two washers (4), water outlet (7), thermostat (9), and gasket (8) from

water crossover (11). Discard gasket (8).

NOTE

Only perform steps 2 through 4 if replacing water crossover or

damaged parts.

2. Remove glow plug controller (1).

3. Remove temperature switch (3).

4. Remove de-airation nipple (2), bypass hose nipple (10), and heater hose nipple (12) from water

crossover (11).

Clean all components in accordance with para. 2-9.

NOTE

For general inspection instructions, refer to para. 2-10.

1. Inspect water crossover (11) and water outlet (7) for damage. Replace if damaged.

2. Inspect all threaded holes in water crossover (11) for thread damage. Replace if threads are

damaged.

3. Inspect heater hose nipple (12), de-airation nipple (2), and bypass hose nipple (10) for damage.

Replace if damaged.

4. Inspect glow plug controller (1), thermostat (9), and temperature switch (3) for damage. Replace

if damaged.

2-146

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст