Hummer H1 (1992-1998). Manual — part 4

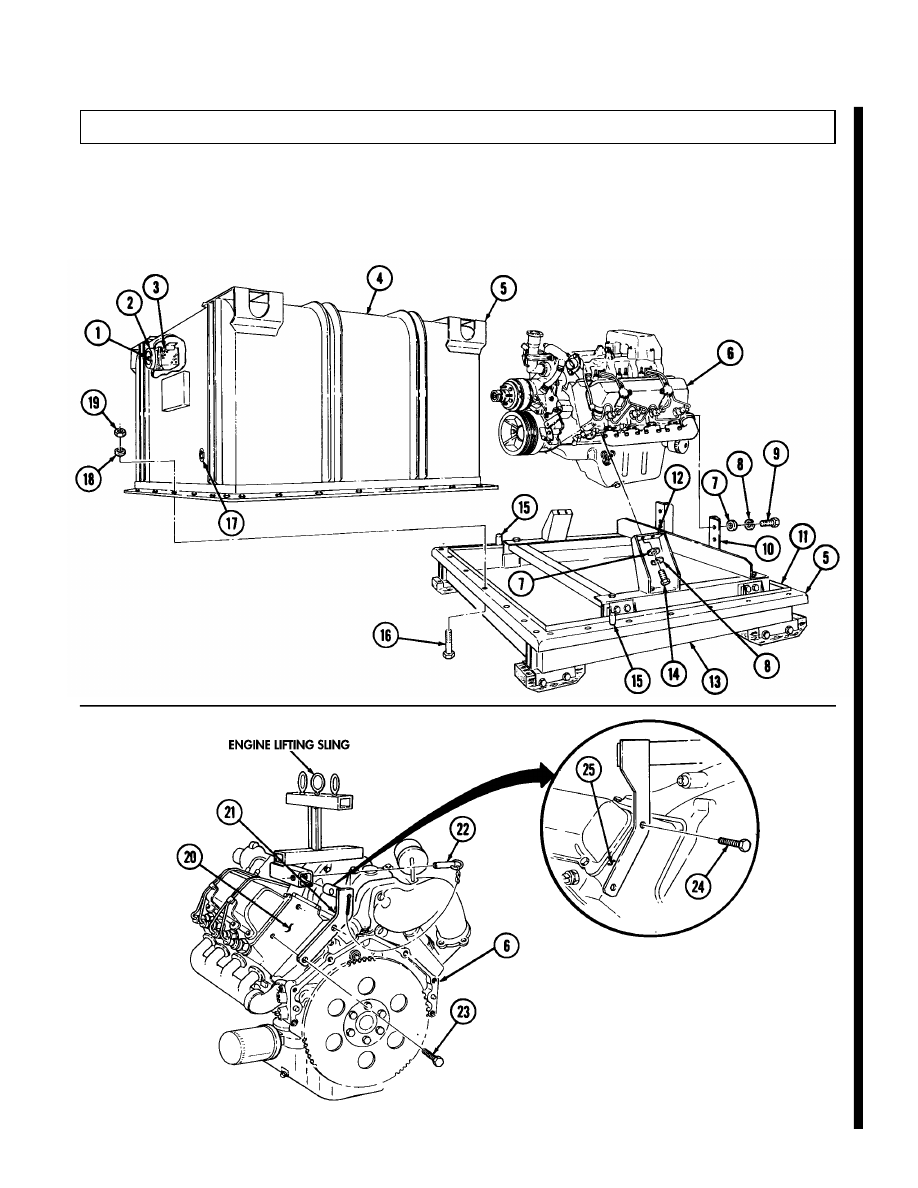

2 - 1 3 . 1 . ENGINE REPLACEMENT IN SHIPPING/STORAGE CONTAINER (Cont’d)

Change 1

2 - 7

NOT E

Ensure gasket is seated properly.

8.

Using alignment pins (15), position upper container (4) on gasket (11) and lower container (13).

9.

Install upper container (4) on lower container (13) with twenty-six capscrews (16), washers (18), and

nuts (19).

2-8

Change 1

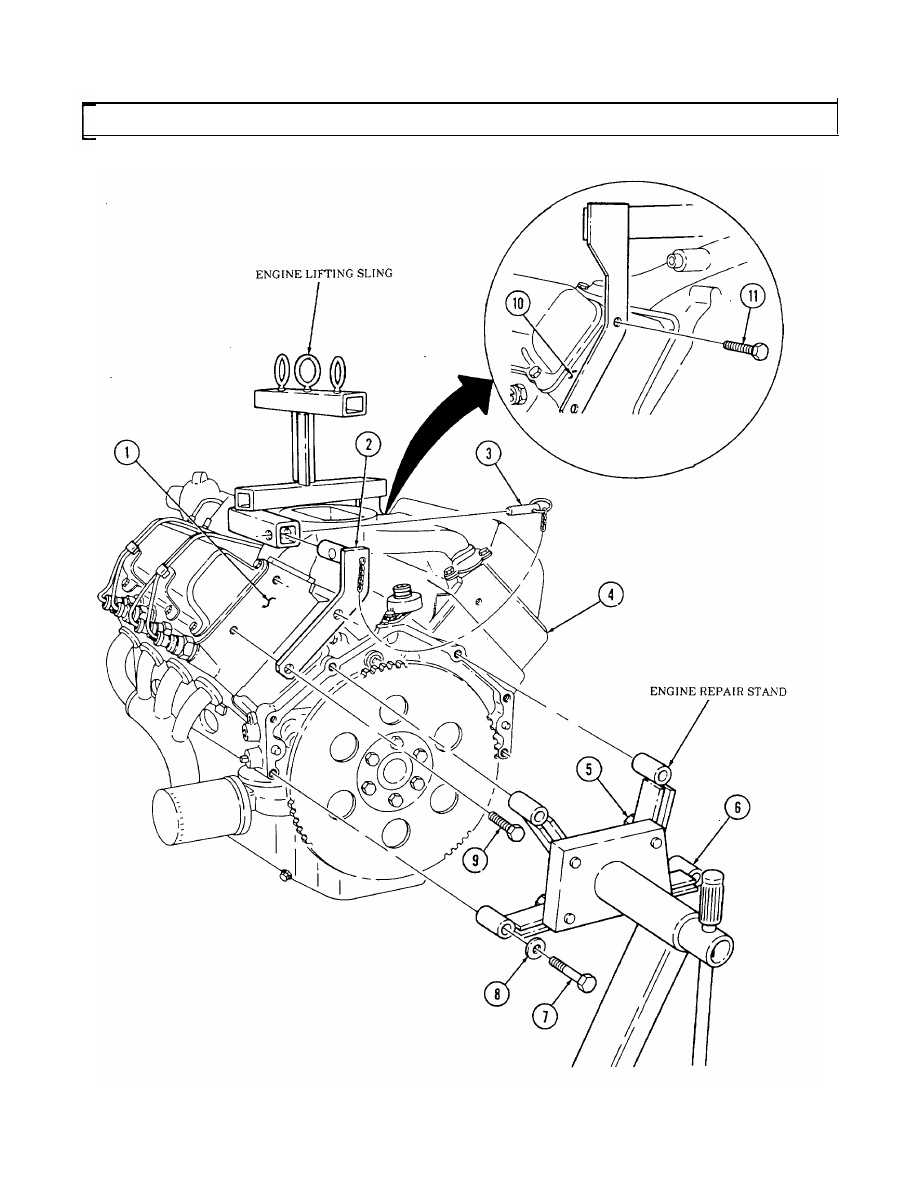

2 - 1 4 . MOUNTING ENGINE ON REPAIR STA N D

This task covers:

a.

Installation

b.

Removal

General Safety Instructions

Direct personnel to stand clear during hoisting

operation.

a. Installation

NOTE

Do not perform step 1 if engine lifting sling has been previously

installed.

1.

Position engine lifting sling on engine (4) and secure to right cylinder head (10) with two bolts (11).

Finger tighten bolts (11).

2.

Install sling bracket (2) to engine lifting sling with pin (3) and on left cylinder head (1) with two

bolts (9). Tighten bolts (9) and (11).

WARNING

Direct personnel to stand clear during hoisting operation. Failure

to do this may cause injury to personnel.

3.

Attach hoist to engine lifting sling and hoist engine (4) into position over engine repair stand.

4.

Loosen four capscrews (5) securing repair stand arms (6) on engine repair stand and align arms (6)

with holes in rear of engine (4).

5.

Install repair stand arms (6) to engine (4) with four washers (8) and capscrews (7).

6.

Tighten capscrews (5) and (7).

7.

Disconnect hoist and remove two bolts (11) and (9), engine lifting sling, and bracket (2) from

engine (4).

b. Removal

1.

Position engine lifting sling on engine (4) and secure to right cylinder head (10) with two bolts (11).

Finger tighten bolts (11).

2.

Install sling bracket (2) to engine lifting sling with pin (3) and on left cylinder head (1) with two

bolts (9). Tighten bolts (9) and (11).

3.

Attach hoist to engine lifting sling and hoist engine (4) to relieve pressure on engine repair stand.

4.

Remove four capscrews (7) and washers (8) from repair stand arms (6) and hoist engine away from

engine repair stand.

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix E, Item 1)

Special Tools

Engine repair stand (Appendix E, Item 2)

Engine lifting sling (Appendix E, Item 3)

2-14. MOUNTING ENGINE ON REPAIR STAND (Cont’d)

2-9

2-10

Change 1

2 - 1 5 . ENGINE DISASSEMBLY INTO SUBASSEMBLIES

This task covers:

a.

Fan Drive and Water Pump Pulley

b.

Crankshaft Pulley

c.

Torsional Damper

c.1. Wastegate Actuator

c.2. Wastegate Housing

c.3. Manifold-to-Turbocharger Exhaust Pipe

c.4. Turbocharger

d.

Exhaust Manifolds

e.

Intake Manifold

f.

Water Crossover

g.

Fuel Injection Lines

h.

Fuel Supply and Return Lines

i.

Modulator Link

j.

Rocker Arm Covers

k.

Rocker Arm Shafts and Pushrods

l.

Fuel Injection Nozzles

m.

Glow Plugs

n.

Cylinder Heads

o.

Valve Lifters

p.

Water Pump and Adapter Plate

q.

Fuel Injection Pump

r.

Timing Gear Cover

s.

Timing Chain and Drive Sprockets

t.

Oil Filter, Adapter, and Oil Pressure Sending Unit

u.

Oil Pan

v.

Oil Pump

w.

Fuel Pump

x.

Oil Pump Drive

y.

Camshaft

z.

Pistons and Connecting Rods

aa.

Flywheel

bb.

Crankshaft and Main Bearings

Personnel Required

One mechanic

One assistant

Equipment Condition

Engine mounted on repair stand (para. 2-14).

General Safety Instructions

• Do not perform this procedure near fire, flame,

or sparks.

• Gaskets installed on some 6.2L engines

assembled prior to 1991 may contain asbestos.

Gaskets should be disposed of IAW current

directives.

a. Fan Drive and Water Pump Pulley

NOT E

It may be necessary to apply compressed air to fan drive fitting. This disengages

fan drive and allows access to socket head capscrews.

1.

Position pry bar between water pump pulley (3) and crankshaft pulley (6) and apply pressure.

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix E, Item 1)

Puller (Appendix E, Item 19)

Cylinder ridge reamer (Appendix E, Item 11)

Dial indicator (Appendix E, Item 10)

Special Tools

Hydraulic valve lifter remover

(Appendix E, Item 4)

Injection nozzle socket (Appendix E, Item 5)

Glow plug socket (Appendix E, Item 6)

Hex-head driver, 6 mm (Appendix E, Item 7)

Hex-head driver, 8 mm (Appendix E, Item 8)

Hex-head driver, 5/16-in.

(Appendix E, Item 9)

NOT E

• Work area should be clean, well-ventilated, and free from blowing dirt and dust.

• In some cases, flanged head fasteners may be present instead of standard

fasteners and washers. In all cases, washers should be used when replacing a

flanged head fastener with a standard fastener.

• Disassembly procedures for pre-1990, 1990 and above 6.2L and 6.5L engines are

basically the same. Any differences in procedures are noted. Refer to para.

1-10 to determine engine model before ordering replacement parts.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст