Hummer H1 (1992-1998). Manual — part 39

2-140.4 Change 1

2-35.1. (6.5L) FUEL INJECTION PUMP (DB2831-5209) CALIBRATION (Cont’d)

3.

Set the throttle lever in correct low-idle position prior to calibration using vacuum valve block

gauge. The low-idle screw must be at 34 ± 2 degrees as measured between vertical centerline of

throttle shaft bushing bore and throttle connection stud.

4.

Flush pump with calibrating oil to remove metal chips and possible contamination.

5.

Before mounting pump on test stand, check driveshaft for freedom of rotation in housing. Pump

should be mounted securely in the appropriate adapter, and the intermediate coupling should be

checked for freedom of movement.

6.

Connect supply and return lines securely.

7.

Install high-pressure injection lines. Use copper gaskets or steel washers where required. Leave fuel

line connections at the pump and nozzles loose.

8.

Apply 17.6 volts to electric shutoff solenoid and operate pump at 1000 rpm (WOT) for 10 minutes to

bring to operating temperature and clear air from system.

9.

Tighten all connections securely. Check connections for leaks while operating.

10.

Set transfer pump pressure at 2000 rpm (WOT) for 60-62 psi (414-427 kPa). Test stand boost should

be set at 5 ± 0.5 psi (34.5 ± 3.4 kPa).

11.

Set return oil flow to 225-375 cc/minute at 2000 rpm (WOT).

12.

Measure housing pressure:

(a)

Check housing pressure at 650 rpm. With throttle shaft in low idle position, pressure should

be 8-12 psi (55-83 kPa).

(b)

Energize housing pressure cold advance solenoid with 17.6 volts. Housing pressure should be

0-1 psi (0-7 kPa).

13.

With governor cover removed and throttle shaft in low-idle position, set min.-max. governor

assembly for 7-9 mm

3

/stroke at 650 rpm (fuel reading with cover installed).

NOT E

If low-idle screw adjustment is required, refer to step 3. Adjust-

ment is ± 1 turn from the point in step 3.

14.

At 650 rpm, adjust low-idle screw for 13-15 mm

3

/stroke for the remainder of the setting and checking

procedures.

15.

During and at the completion of all settings, ensure face cam-to-throttle shaft end play measures

0.004-0.006 in. (0.10-0.15 mm) between throttle shaft spacer and housing.

16.

At 3500 rpm (WOT), rotate face cam to its maximum lift position in contact with the cam roller.

17.

Adjust trimmer screw at 3500 rpm (WOT) for 4.25 degrees cam advance and set fuel delivery to

45.5-46.5 mm

3

/stroke.

18.

Set guide stud for 46.5 mm

3

/stroke at 3800 rpm (WOT). Tighten guide stud nut to 80-90 lb-in.

(9-10 N

•

m) and check dimension from top of nut to top of guide stud for 0.425 in. (10.80 mm)

maximum.

19.

Set throttle for 21.5-23.5 mm

3

/stroke at 3200 rpm and rotate face cam to obtain 5.00 degrees cam

advance.

20.

Tighten face cam screw to 28-30 lb-in. (3 N

•

m) and check face cam retention.

(a)

Put 0.005-in. (0.127 mm) feeler gauge between throttle shaft mylar washer and housing boss.

(b)

Put throttle shaft in idle position. Squeeze throttle shaft and face cam tightly toward each

other and rotate face cam as lower roller rests approximately in middle at lowest step. Tighten

screw to 30 lb-in. (3 N

•

m) with torx bit and remove feeler gauge.

21.

Set total throttle travel. With throttle in low-idle position, align zero degree mark on protractor

with center of rib on rocker lever. Move throttle to WOT and adjust maximum travel screw to

80-84 degrees.

NOT E

Any changes to pump or settings after this point will require

retesting of pump, starting with step 12.

Change 1 2-140.5

2-35.1. (6.5L) FUEL INJECTION PUMP (DB2831-5209) CALIBRATION (Cont’d)

22.

Fuel delivery measurement:

(a)

In order to minimize variations between readings due to residual oil in the graduates, the

following timed cycle should be used:

(1)

Draw

(2)

Settle 30 seconds

(3)

Drain 30 seconds

(4)

Draw

(5)

Settle 30 seconds

(6)

Read graduates

(7)

Repeat cycle and average readings

(b)

Check points:

(1)

At 1500 rpm (WOT), de-energize electric shutoff solenoid. Delivery should be 4 mm

3

/stroke

maximum.

(2)

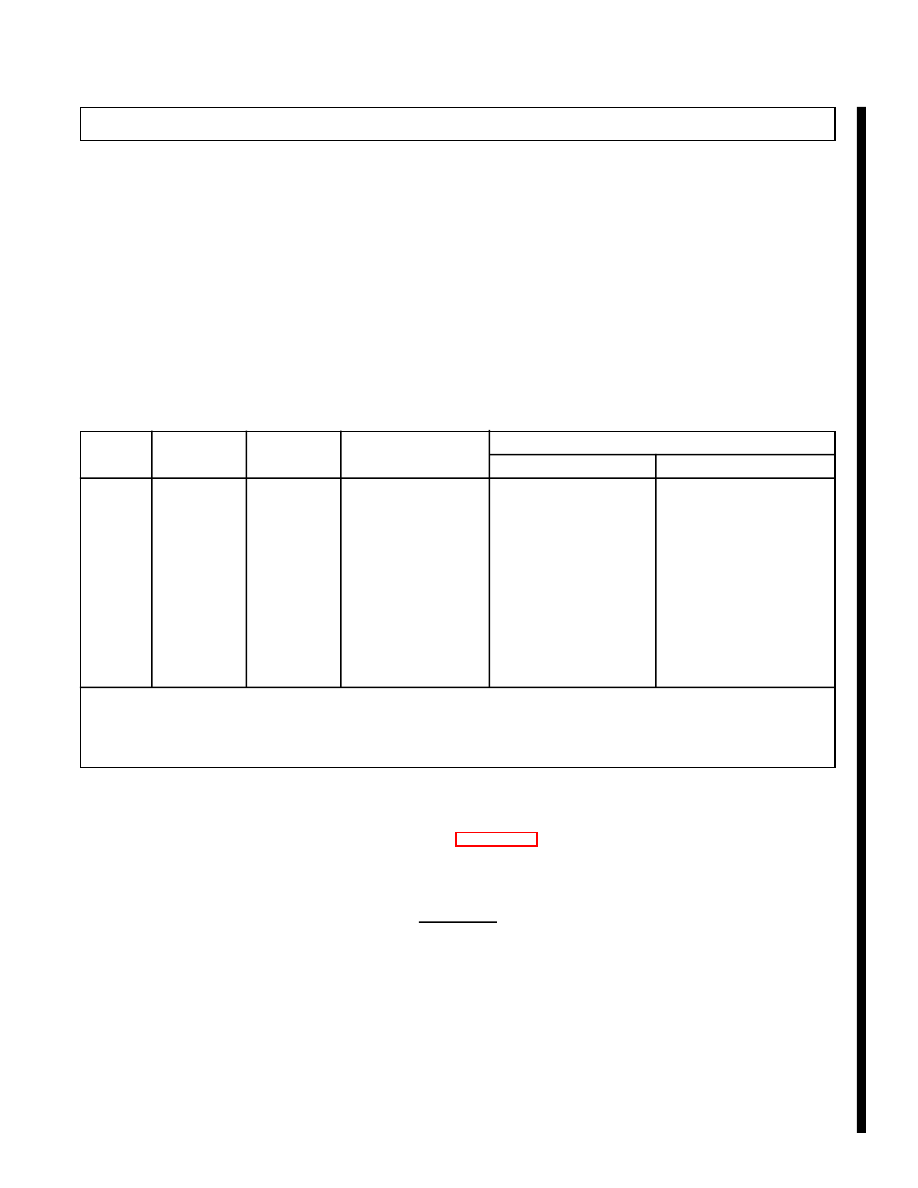

Re-energize electric shutoff solenoid and check delivery against the chart below.

23.

Disconnect pump and mount in holding fixture.

24.

Using air timing gauge, check pump timing. Set to +1.00 degree ± 0.50 degree.

25.

Tighten all fasteners to specifications. Refer to para. 2-32d.

26.

Apply sealing compound as follows:

(a)

Apply one drop at interface of maximum travel screw and locknut.

CAUTION

Do not allow sealing compound to enter gap between face cam and

housing. Binding of the throttle shaft may result.

(b)

Apply one drop to threaded end of face cam screw where it protrudes from face cam.

(c)

Apply one drop to interface of servo advance adjusting screw and rocker lever, ensuring sealing

compound does not enter hex recess of screw.

27.

Install tamper-proof cap on guide stud.

THROTTLE

MM

3

/

CAM MOVEMENT

PRESSURE

RPM

POSITION

STROKE*

(DEGREES)

TRANSFER PUMP

HOUSING

150

Low idle

26 min.

16 psi (110 kPa) min.

0-12 psi (0-83 kPa)

400

WOT

36.5 min.

400

WOT**

4 max.

400

Low idle***

700

Low idle

12-16

1.0 min.

8-12 psi (55-83 kPa)

700

Low idle

****

0-1 psi (0-7 kPa)

2000

WOT

51.5 max.

60-62 psi (414-427 kPa)

3200

ADJ

21.5-23.5

4.0-6.0

3500

WOT

44.5-47.5

3.75-4.75

3600

WOT

44 min.

3800

WOT

31.5 min.

4050

WOT

15 max.

125 psi (862 kPa) max.

* Maximum cylinder variation should be ± 6 mm

3

from the average flow of all cylinders.

** With electric shut-off solenoid de-energized.

*** Reset using low-idle screw.

**** Minimum of 1.25 degrees more than reading.

2-140.6

Change 1

2 - 3 5 . 2 . ( 6 . 5 L ) FUEL INJECTION PUMPS (DB2831-5485 OR DB2831-5079) CALIBRAT I O N

This task covers:

a.

Test Bench Requirements

c.

Injection Pump Check (Prior to Service)

b.

Injection Pump Information

d.

Injection Pump Settings (Following Pump Repair)

Test Equipment

Digital tachometer

Voltage source (variable)

Pressure gauge (0-160 psi, 1 psi increments)

Pressure gauge (0-30 psi)

Vacuum gauge (0-30 in. Hg)

Flowmeter with three-way valve

Temperature gauge (0°-250°F)

Zero-backlash coupling device

Calibrating nozzles and lines

Orifice 13211

Calibration stand

Materials/Parts

Calibrating fluid (Appendix B, Item 4)

Sealing compound (Appendix B, Item 19)

Manual References

a. Test Bench Requirements

The fuel injection pump requires a test bench capable of at least 2250 rpm shaft speed. The test bench

must be equipped with the following items:

(a) A zero-backlash coupling device.

(b) A digital tachometer.

(c) A variable voltage source.

(d) Test gauges:

(1) 0-160 psi (0-1103 kPa) pressure gauge calibrated in 1 psi increments to measure transfer pump

pressure. This gauge should be located as close as possible to the pump, with an in-line shutoff

valve located at the pump.

(2) 0-30 psi (0-206.9 kPa) pressure gauge to measure housing pressure.

(3)

0-30 in. Hg (0-101.3 kPa) vacuum gauge to measure transfer pump lift. This gauge should be in

the supply line to the pump, with a shutoff valve between the gauge and the oil source.

(4) A flowmeter for measuring return oil should be used with a three-way valve to permit the

flowmeter to be in use only during the return oil check.

(5) 0-250°F (-17.8-121.1°C) temperature gauge, located at the pump inlet, to monitor inlet

temperature.

INITIAL SETUP:

Tools

General mechanic’s tool kit:

automotive (Appendix E, Item 1)

Special Tools

Roller-to-roller setting tool

(Appendix E, Item 45)

Linkage gap tool (Appendix E, Item 49)

Automatic advance indicator

(Appendix E, Item 50)

Vacuum valve block gauge

(Appendix E, Item 51)

Protractor (Appendix E, Item 52)

Air timing gauge (Appendix E, Item 53)

Holding fixture (Appendix E, Item 46)

Torx drive (Appendix E, Item 42)

NOT E

The following calibration procedure applies to 6.5L turbocharged

fuel injection pumps. Refer to para. 2-34 for calibration of 1990

6.2L and above pumps and para. 2-33 for pre-1990 6.2L pumps.

Change 1

2-140.7

2 - 3 5 . 2 . ( 6 . 5 L ) FUEL INJECTION PUMPS (DB2831-5485 OR DB2831-5079) CALIBRATION (Cont’d)

b. Injection Pump Information

NOT E

All speeds are in engine rpm unless otherwise noted.

1.

Injection pump operating speed is half of engine speed.

2.

Injection pump rotation is counterclockwise.

3.

Injection pump is timed to the outlet port in the 10 o’clock position when viewed from the transfer

pump end.

(e)

Calibrating nozzles and injection lines:

(1)

Eight 0.020-in. (0.5 mm) orifice plate nozzles set at 1700 ± 25 psi (11,721 ± 172 kPa).

(2)

Eight 0.098-in. (2.5 mm) inside diameter by 25 in. (63.5 cm) long injection lines.

(f)

Calibrating fluid conforming to SAE J967, maintaining a temperature of 110°-115°F (43°-46°C)

at the pump inlet over all speed and load ranges.

(g)

Orifice fitting in the inlet line between the supply pump and shutoff valve, to maintain

constant fluid circulation and temperature.

c. Injection Pump Check (Prior to Service)

1.

Before mounting the pump on the test stand, check the drive shaft for freedom of rotation in the

housing. Pump should be mounted securely in the appropriate adapter, and the intermediate

coupling should be checked for freedom of movement.

2.

Connect supply and return lines securely.

3.

Install high-pressure injection lines. Use copper gaskets or steel washers where required. Leave fuel

line connections at the pump and nozzles loose.

4.

Apply 17.6 V to electric shutoff solenoid and operate pump at 2000 rpm wide-open throttle (WOT)

for 10 minutes to bring to operating temperature and clear air from system.

5.

Tighten all connections securely. Check connections for leaks while operating.

6.

Check fuel delivery at 650 rpm (low-idle). Fuel delivery should be 10-18 mm

3

/stroke. If fuel delivery

is not within the range specified, adjust low-idle screw. Turn screw clockwise to decrease or counter-

clockwise to increase fuel delivery.

7.

Check housing pressure at 650 rpm while applying 17.6 V to housing pressure cold-advance

solenoid. Housing pressure should be 0-1 psi (0-7 kPa) and 8-12 psi (55-83 kPa) when de-energized.

8.

Check electric shutoff solenoid for pull-in with 17.6 V maximum with throttle lever in low-idle

position at 400 rpm.

9.

Fuel delivery measurement:

(a)

In order to minimize variations between readings due to residual oil in the graduates, the

following timed cycle should be used:

(1)

Draw

(2)

Settle 30 seconds

(3)

Drain 30 seconds

(4)

Draw

(5)

Settle 30 seconds

(6)

Read graduates

(7)

Repeat cycle and average readings

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст