Hummer H1 (2002+). Manual — part 274

_____________________________________________________

PCM/Tech 1 Scan Tool 29

®

05745159

DTC P0117 Engine Coolant Temperature

(ECT) Sensor Circuit Low Voltage

Circuit Description

The engine coolant Temperature (ECT) sensor is a thermistor

that controls signal voltage to the PCM. When the engine is

cold, the sensor resistance is high, therefore the PCM will see

high signal voltage. As the engine warms, sensor resistance be-

comes less and voltage drops. The voltage measured across the

thermistor is interpreted as a temperature. This is a type B

DTC.

Conditions for Setting the DTC

Engine coolant temperature greater than or equal to 151°C

(303°F) for 2 seconds.

Action Taken When the DTC Sets

• High idle

• No TCC

• Shift schedules will be affected.

Conditions for Clearing the MIL/DTC

• The PCM will turn the MIL off after three consecutive

trips without a fault condition.

• A History DTC will clear when forty consecutive

warm-up cycles that the diagnostic does not fail (coolant

temperature has risen 5°C (40°F) from start up coolant

temperature and engine coolant temperature exceeds

71°C (160°F) that same ignition cycle).

• Use of a Scan Tool.

Diagnostic Aids

Check harness routing for a potential short to ground. After en-

gine is started, the coolant temperature should rise steadily to

about 85°C (185°F). refer to “Intermittents” on page 14. A

“skewed” sensor could result in poor driveability complaints.

Test Description

Number(s) below refer to the step number(s) on the Diagnostic

Table.

2. This step determines if P0117 is a hard failure or an inter-

mittent condition.

3. This test will check the PCM and the wiring.

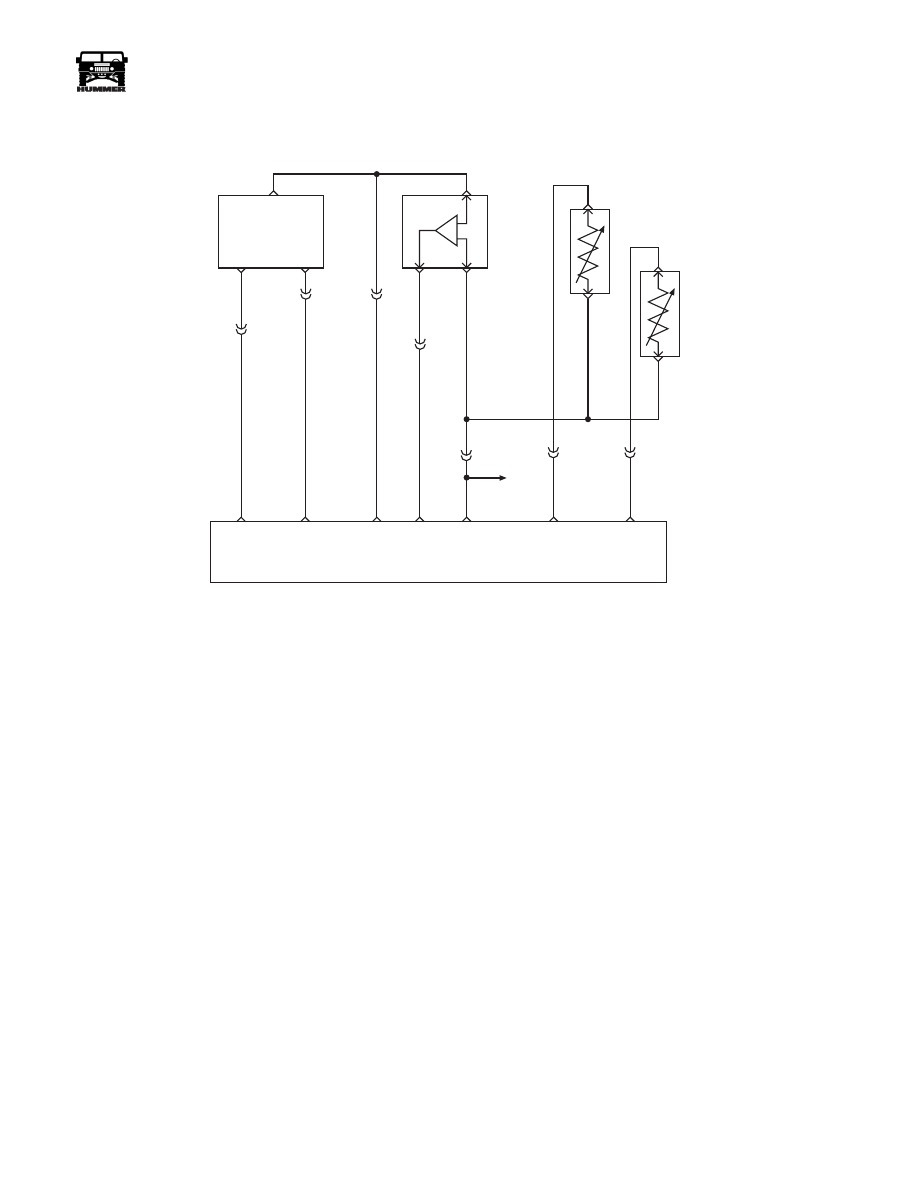

5 VOLT

REFERNCE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

CRANK

SHAFT

POSITION

SENSOR

(CKP)

A

B

B

A

B

B

A

A

C

C

C5-B12

C5-B5

C5-B9

BOOST/

BARO

PRESSURE

SENSOR

INTAKE AIR

TEMPERATURE

SENSOR (IAT)

ENGINE

COOLANT

TEMP

SENSOR

(ECT)

C5-B10

POWERTRAIN

CONTROL

MODULE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

5 VOLT

REFERENCE

BOOST

SENSOR

SIGNAL

SENSOR

GROUND

ECT

SENSOR

SIGNAL

IAT

SENSOR

SIGNAL

C29-A5

359 BK

C5-C4

C5-C5

C27-C1

C27-D13

C27-C14

C29-B12

349 YL

651 PP

350 LG

394 LB

359 BK

C5-B11

TO

TFT

SENSOR

357 TN

354 YL

9-S12-066

30

PCM/Tech 1 Scan Tool

_____________________________________________________

®

DTC P0117 - Engine Coolant Temperature (ECT) Sensor Circuit Low Voltage

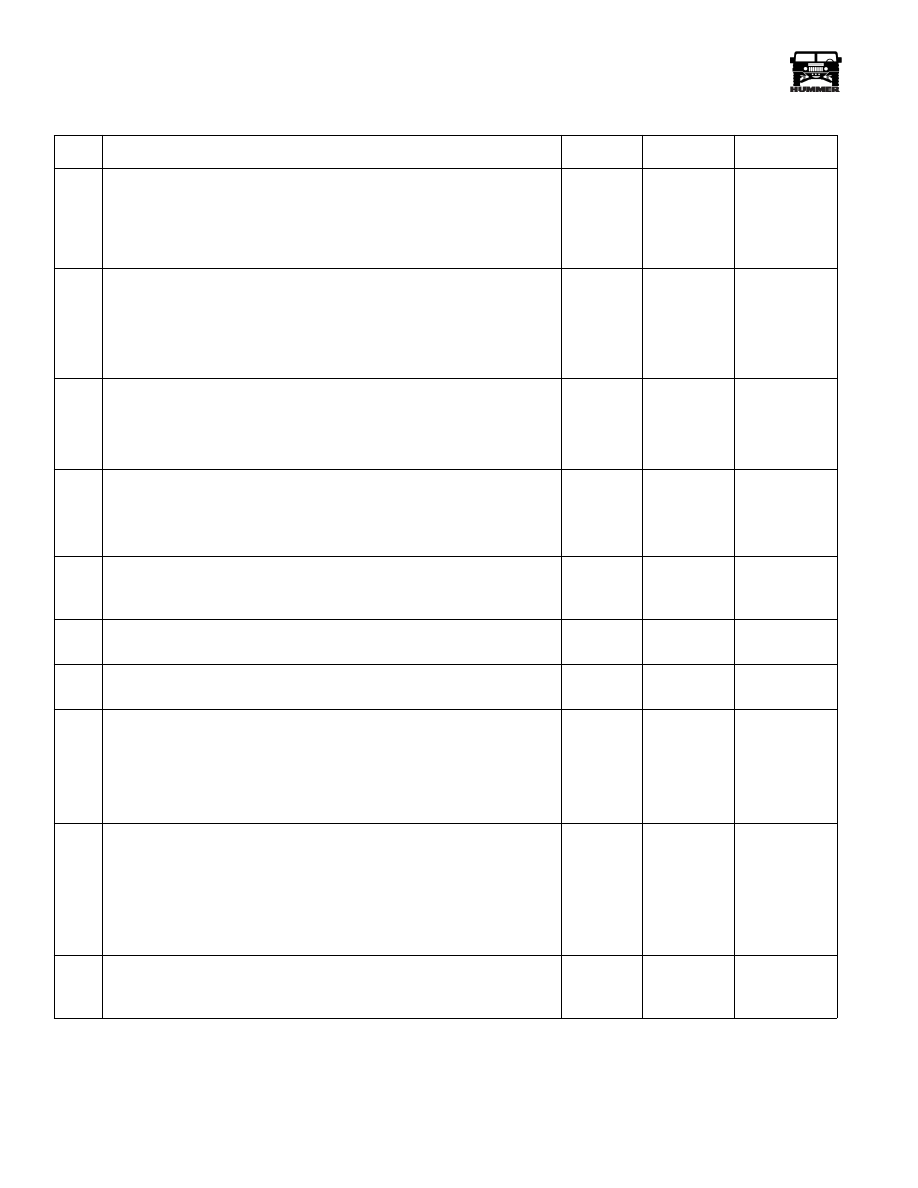

Step

Action

Value(s)

Yes

No

1

NOTE:

Before clearing DTC(s) use the Scan tool “Capture Info” to

record Freeze Frame and Failure Record for reference. This data

will be lost when “Clear Info” function is used.

Was the “On-Board Diagnostic (OBD) System Check” performed?

—

Go to Step 2 Go to OBD

System Check

2

1. Scan tool connected.

2. Start the engine.

3. Monitor the ECT display on Scan Tool.

Does the scan tool display ECT greater than or equal to the specified

value?

151°C

(303°F)

Go to Step 3 Go to Step 5

3

1. Turn the engine “OFF.”

2. Turn the ignition “ON.”

3. Disconnect the ECT sensor connector.

Does the scan tool display ECT less than or equal to the specified value?

-30°C

(-22°F)

Go to Step 7 Go to Step 4

4

1. Turn the ignition “OFF”.

2. Using the J–39200, check the resistance across the ECT sensor harness

connector.

Is the resistance at the specified value?

Infinite

Go to Step 8 Go to Step 6

5

DCT is intermittent. If no additional DTCs are stored, refer to “Diagnostic

Aids.” If additional DTCs were stored, refer to those table(s) first.

Are any additional DTCs stored?

—

Go to the

applicable

DTC Table

Go to

Diagnostic

Aids

6

Repair the short to ground in the ECT signal circuit.

Is the action complete?

—

Go to Step 9

—

7

Replace the faulty ECT sensor.

Is the action complete?

—

Go to Step 9

—

8

Replace the faulty PCM.

NOTE:

If the PCM is faulty, the new PCM must be programmed.

Go to PCM replacement and programming procedures.

Is the action complete?

—

Go to Step 9

—

9

1. Using the Scan Tool, select “DTC,” “Clear Info.”

2. Start engine and idle at normal operating temperature.

3. Select “DTC,” “Specific,” then enter the DTC number which was set.

4. Operate vehicle within the conditions for setting this DTC as specified

in the supporting text.

Does the Scan Tool indicate that this diagnostic Ran and Passed?

—

Go to Step

10

Go to Step 2

10

Using the Scan Tool, select “Capture Info,” “Review Info.”

Are any DTC’s displayed that have not been diagnosed?

—

Go to the

applicable

DTC table

System OK

_____________________________________________________

PCM/Tech 1 Scan Tool 31

®

05745159

DTC P0118 Engine Coolant Temperature

(ECT) Sensor Circuit High Voltage

Circuit Description

The Engine Coolant Temperature (ECT) sensor is a thermistor

that controls signal voltage to the PCM. When the engine is

cold, the sensor resistance is high, therefore the PCM will see

high signal voltage. As the engine warms, the sensor resistance

becomes less and the voltage drops. The voltage measured

across the thermister is interpreted as a temperature. This is a

type B DTC.

Conditions for Setting the DTC

• Engine running for at least 8 minutes.

• ECT less than -30°C (-22°F).

• Conditions met for 2 seconds

Action Taken When the DTC Sets

Idle increase

Conditions for Clearing the MIL/DTC

• The PCM will turn the MIL off after three consecutive

trips without a fault condition.

• A History DTC will clear when forty consecutive

warm-up cycles that the diagnostic does not fail (coolant

temperature has risen 5°C (40°F) from start up coolant

temperature and engine coolant temperature exceeds

71°C (161°F) that same ignition cycle).

• Use of a scan tool.

Diagnostic Aids

• Check harness routing for a potential short to ground.

After engine is started, the ECT temperature should rise

steady to about 85°C (185°F). A mis-scaled sensor

could result in poor driveability complaints.

Test Description

Number(s) below refer to number(s) on the diagnostic tables.

2.

This test determines if PO 118 is an intermittent condition.

3. This test will determine if signal circuit is open, or a faulty

PCM.

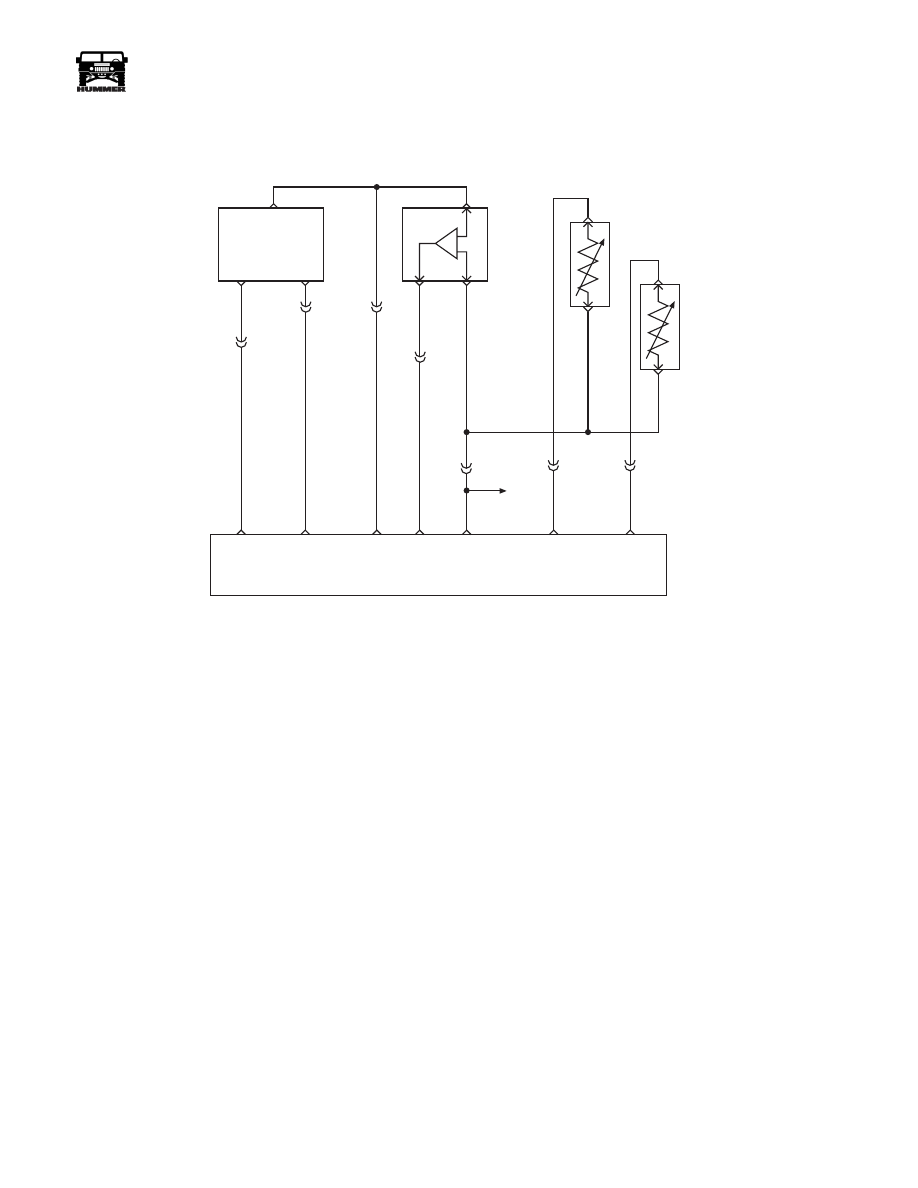

5 VOLT

REFERNCE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

CRANK

SHAFT

POSITION

SENSOR

(CKP)

A

B

B

A

B

B

A

A

C

C

C5-B12

C5-B5

C5-B9

BOOST/

BARO

PRESSURE

SENSOR

INTAKE AIR

TEMPERATURE

SENSOR (IAT)

ENGINE

COOLANT

TEMP

SENSOR

(ECT)

C5-B10

POWERTRAIN

CONTROL

MODULE

CKP

SENSOR

SIGNAL

SENSOR

GROUND

5 VOLT

REFERENCE

BOOST

SENSOR

SIGNAL

SENSOR

GROUND

ECT

SENSOR

SIGNAL

IAT

SENSOR

SIGNAL

C29-A5

359 BK

C5-C4

C5-C5

C27-C1

C27-D13

C27-C14

C29-B12

349 YL

651 PP

350 LG

394 LB

359 BK

C5-B11

TO

TFT

SENSOR

357 TN

354 YL

9-S12-066

32

PCM/Tech 1 Scan Tool

_____________________________________________________

®

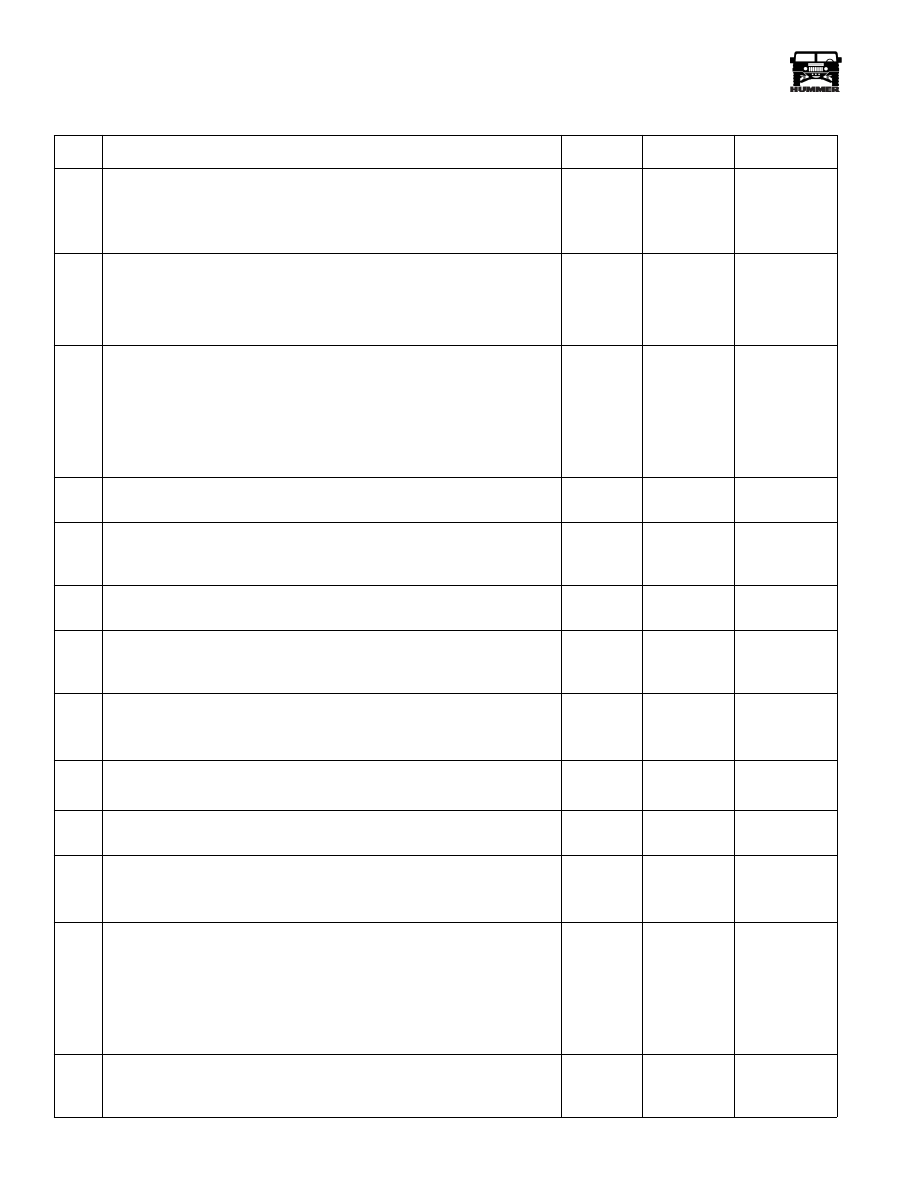

DTC P0118 - Engine Coolant Temperature (ECT) Sensor Circuit High Voltage

Step

Action

Value(s)

Yes

No

1

Important:

Before clearing DTC(s) use the scan tool “Capture Info” to

record Freeze Frame and Failure Record for reference, as data will be lost

when “Clear Info” function is used.

Was the “On-Board Diagnostic (OBD) System Check” performed?

—

Go to Step 2 Go to OBD

System Check

2

1. Scan tool connected.

2. Start the engine.

3. Monitor the ECT display on Scan Tool.

Is the ECT display less than or equal to the specified value?

-30°C

(-22°F)

Go to Step 3 Go to Step 5

3

1. Turn the engine “OFF.”

2. Turn the ignition “ON.”

3. Disconnect the ECT sensor connector.

4. Jumper the ECT harness terminals together.

Does the scan tool display ECT greater than or equal to the specified

value?

151°C

(303°F)

Go to Step 6 Go to Step 4

4

Jumper the ECT sensor signal circuit to a known good ground. Does the

scan tool display a ECT greater than the specified value?

151°C

(303°F)

Go to Step 7 Go to Step 8

5

DCT is intermittent. If no other DTC(s) are stored, go to “Diagnostic

Aids”.

Are there other DTCs stored?

—

Go to

applicable

DTC Table

Go to

Diagnostic

Aids

6

Inspect the sensor connector and PCM connector for a proper connection.

Was a problem found?

—

Go to Step 9

Go to Step 10

7

Check the ECT sensor ground circuit for an open between the ECT sensor

and the PCM.

Was a problem found?

—

Go to Step 9

Go to Step 11

8

Check the ECT sensor signal circuit for an open between the ECT sensor

and the PCM.

Was a problem found?

—

Go to Step 9

Go to Step 11

9

Repair the circuit as necessary.

Is the action complete?

—

Go to Step

12

—

10

Replace the faulty ECT sensor.

Is the action complete?

—

Go to Step

12

—

11

Replace the faulty PCM. NOTE: If the PCM is faulty, the new PCM must

be programmed. Go to PCM replacement and programming procedures.

Is the action complete?

—

Go to Step

12

—

12

1. Using the Scan Tool, select “DTC”, “Clear Info”.

2. Start engine and idle at normal operating temperature.

3. Select “DTC”, “Specific”, then enter the DTC which was set.

4. Operate vehicle within the conditions for setting this DTC as specified

in the supporting text.

Does the Scan Tool indicate that this diagnostic Ran and Passed?

—

Go to Step

13

—

13

Using the Scan Tool, select “Capture Info”, “Review Info”.

Are any DTC’s displayed that have not been diagnosed?

—

Go to

applicable

DTC table

System OK

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст