Hummer H1 (2002+). Manual — part 104

______________

Wheels and Tires/Central Tire Inflation System (CTIS) 6-31

®

05745159

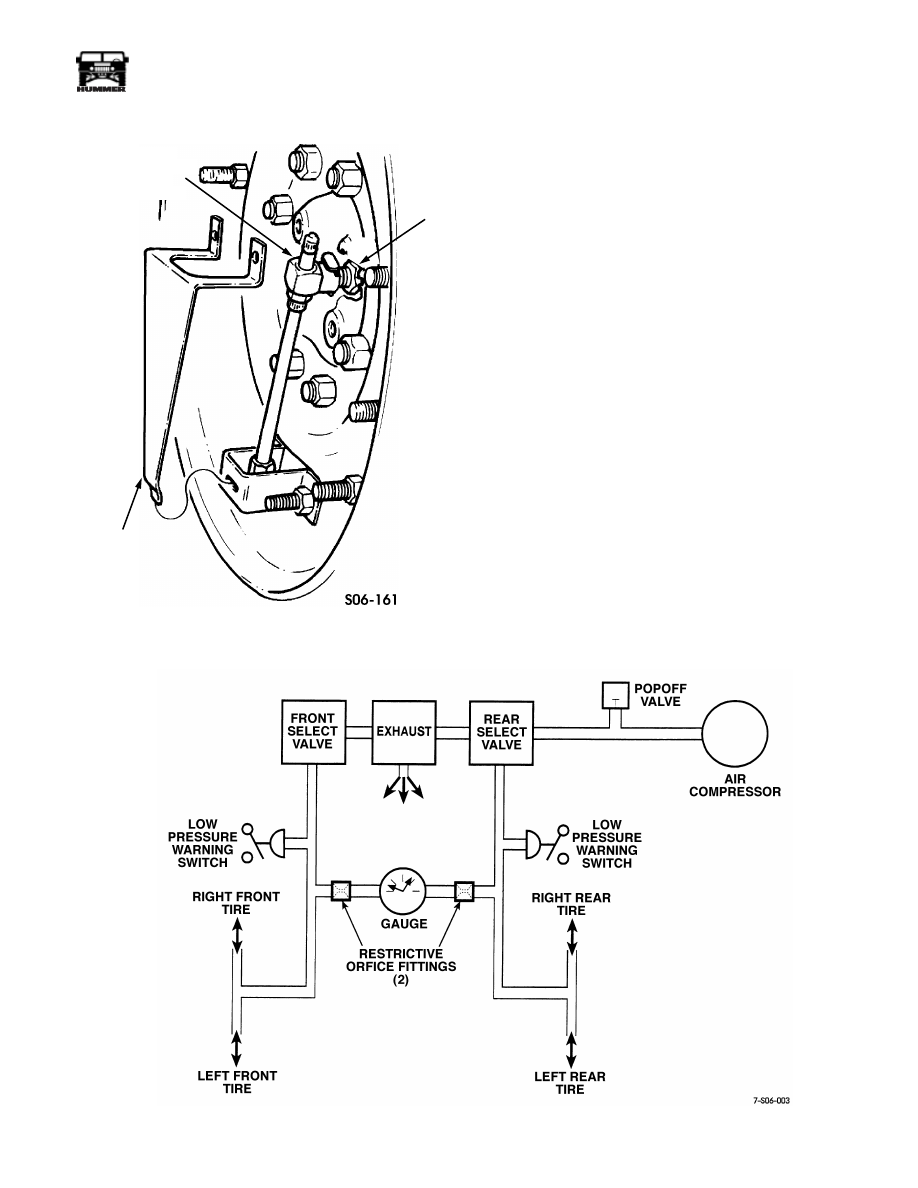

Figure 6-51: Quick-Disconnect Tab

CTIS TROUBLESHOOTING

The following pages contain troubleshooting information for

locating and correcting mechanical, pneumatic, and electrical

problems that may develop with the CTIS.

Electrical Troubleshooting

Symptoms are listed for system malfunctions, and procedures

and corrections are diagramed to assist service technicians.

Figure 6-52: Pneumatic Diagram for Central Tire Inflation System

TUBE SHIELD

QUICK-

VALVE

DISCONNECT

ASSEMBLY

VALVE

SPINDLE

NUT

6-32

Wheels and Tires/Central Tire Inflation System (CTIS)

_______________

®

CTIS AIR LEAK TROUBLESHOOTING

This section contains troubleshooting information for locating

and correcting air leaks within the Central Tire Inflation Sys-

tem.

WARNING: CTIS air system components are subject

to high pressure. Always relieve air pressure before

loosening or removing air system component(s) by dis-

connecting the quick-disconnect valve assemblies at

each wheel end. Failure to follow this warning may re-

sult in serious personal injury.

CTIS Troubleshooting Checklist

1.

Fill all tires to at least 40 psi (270 kPa) using the on-board

compressor or shop air source.

2.

Note the needle positions on the air gauge. If the needles

are not even, line them up by inflating the lower pressure

tires. Then return the inflate/deflate switch to OFF.

NOTE: The tires are isolated from the rest of the system so

that the areas between the compressor selector valve and

geared hubs and selector valve can be isolated and checked.

3.

Isolate each tire and wheel assembly by disconnecting

each quick-disconnect valve.

4.

After tires have been isolated, measure and record each

tire’s air pressure.

5.

After a minimum of 10 minutes, check to see if the air

gauge needles have moved.

NOTE: Leaks can be detected by using soapy water, but com-

mercially available leak detection liquids such as “Gaz-Tec”

work best. Most leaks can be corrected by tightening fittings.

Replace the fittings or air lines only when necessary.

6.

Determine if the front, rear, or both air systems have

leaked. If a leak is detected, concentrate on that area and

follow the appropriate troubleshooting chart.

• Geared Hubs, Seals, and Fittings - Chart 1

• Deflate Valve Area - Chart 2

• Under Vehicle Air Leak - Chart 3

7.

After checking and repairing leak points, place the selector

switch in the BOTH position.

8.

Note the gauge needle positions. Reposition or re-inflate

to align the needles.

9.

Wait at least two minutes and check to see if the needles

have moved. If movement is detected, concentrate on

detecting the leak point. Follow Refer to Troubleshooting

Chart 4 – Air Compressor Leak Test in this Section..

NOTE: If tires were hot, air loss may be a result of the tires

cooling down. If this is the case, all tires should lose about the

same amount of air.

10. Check the air pressure in each tire and compare it to the

information taken earlier. Note any air pressure loss and

concentrate on that tire position. Refer to Troubleshooting

Chart 5– Tire and Quick-Disconnect Valve in this

Section..

If no air loss is detected, there may be a small leak which will

require an overnight evaluation.

NOTE: Always complete the entire troubleshooting procedure

to ensure that all potential leak points have been corrected.

Verification

After completing the troubleshooting procedure, verify the sys-

tem by repeating the CTIS Troubleshooting checklist steps.

WARNING: CTIS air system components are subject

to high pressure. Always relieve air pressure before

loosening or removing air system components(s) by dis-

connecting quick-disconnect valve assemblies at each

wheel end. Failure to follow this procedure may result

in serious personal injury.

______________

Wheels and Tires/Central Tire Inflation System (CTIS) 6-33

®

05745159

Inspect the steering arm cover,

connector, and tube for damage.

Use a soap and water solution or a

commercial leak detection product

around the connector and steering

arm cover.

Damage is found

Replace the con-

nector or tube.

Air is leaking around the con-

nector or tube end.

Tighten the connec-

tor, hose clamp or

tube fitting.

Remove the connector from the

tube and steering arm cover. In-

spect connector and tube fitting

for damage (frays, stripped

threads, cracks, or breaks).

Leak continues

Damage is found

Apply new thread sealant

and install connector to

steering arm cover and

tube fitting or tube.

Air is leaking around steering arm

cover.

Steering arm cover seal or exten-

sion may need replacement. Re-

move steering arm cover and

inspect the seal for damage

(Figure 6-78).

Damage is found

If air is in hub, re-

place seal.

Remove the vent line and deter-

mine if air is escaping. If so, steer-

ing arm cover seal is damaged.

Loose Component

Replace seal

if damaged

Replace part

if damaged

Troubleshooting Chart 1 – Geared Hubs, Seals and Fittings

6-34

Wheels and Tires/Central Tire Inflation System (CTIS)

_______________

®

Inspect the deflate valve and con-

nections for damage (Figure 6-65).

Use a soap and water solution to

check for leaks.

Air is escaping from the

dust excluder or the seams

on the Deflate Valve

(Figure 6-66).

Replace the

deflate valve.

Air is escaping from the

sides of the check valve.

Replace the

check valve.

Tighten all suspect connections. If this fails to

seal the air leak, take the connections apart, clean,

apply new sealant, and tighten.

Leaks

Troubleshooting Chart 2 – Deflate Valve Area

Follow the CTI lines under the vehi-

cle. Inspect for damage. Use a soap

and water or commercial leak detec-

tion solution to detect air leaks.

Tighten all suspect connectors. If this fails to stop the air leak, re-

move the suspect part (elbow, fitting or connector) and inspect

the threads for stripping. Clean, apply new pipe sealant, and in-

stall into the CTI system.

Troubleshooting Chart 3 – Under Vehicle Air Leak

Check the relief valve to en-

sure air is not leaking from

the relief valve stem area.

Replace the

relief valve.

Air is

leaking

If air is leaking from a fitting, tee, elbow or

tube connection, tighten the part. If leak

persists, remove the CTI part, clean, apply

new sealant to the threads and install the

CTI part.

Air is

leaking

Troubleshooting Chart 4 – Air Compressor Leak Test

Inspect all fittings, tees, valves and

hoses connected to the compressor

(Figure 6-53). Use soap and water or

commercial leak detection product to

detect leaks.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст