Jaguar XJ (X350). Manual — part 157

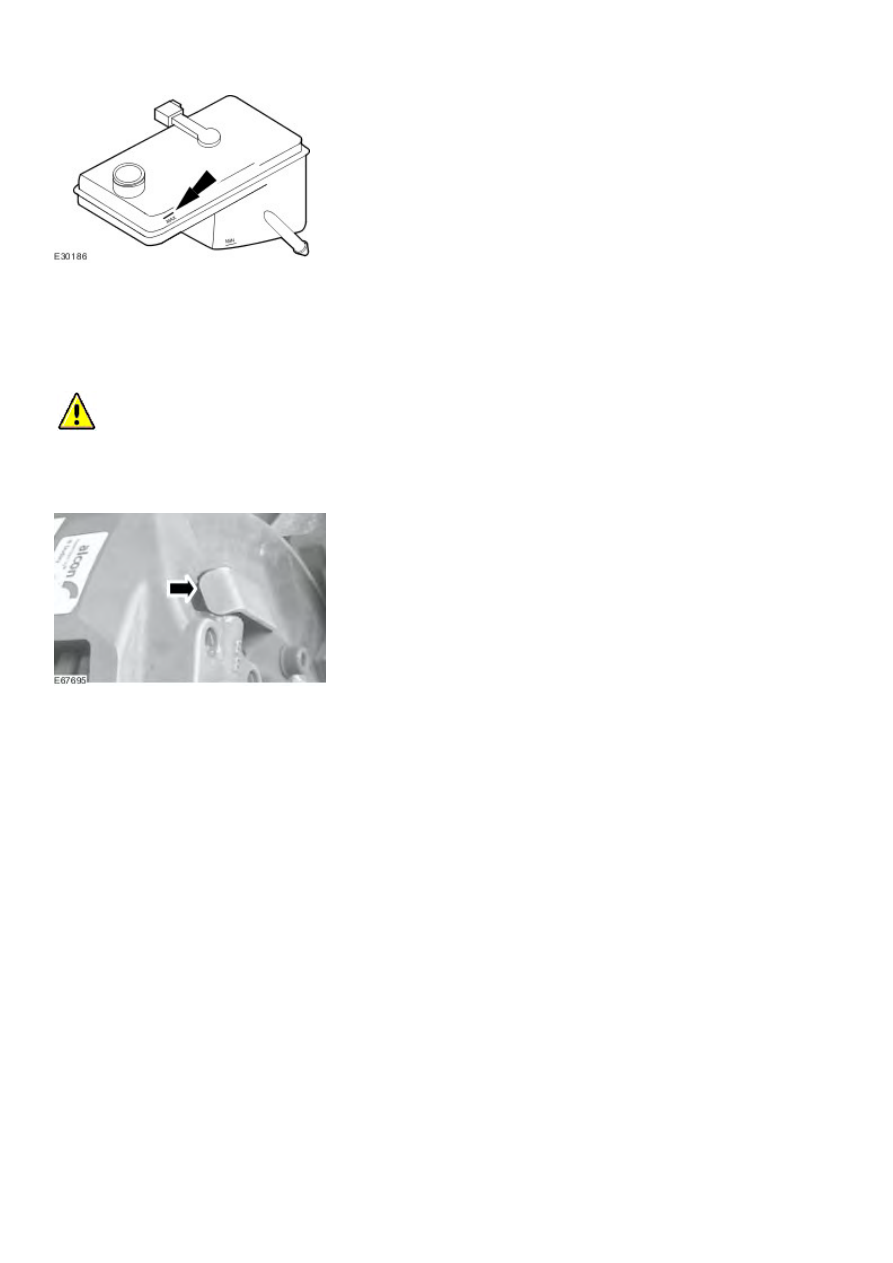

Fill the brake master cylinder reservoir to the MAX mark as necessary.

3. Remove the wheels and tires.

4.

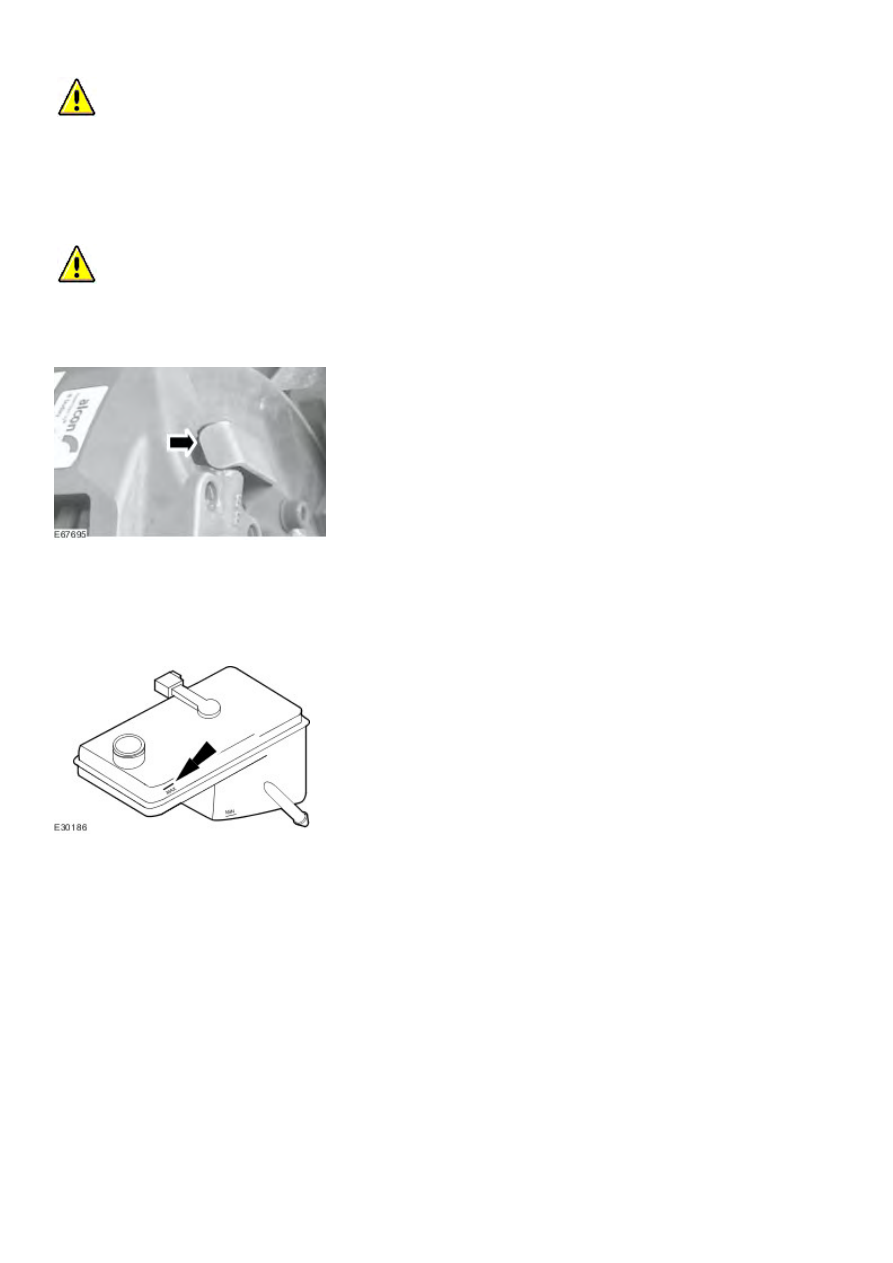

CAUTION: Make a note of the position of the brake caliper bleed nipple shields. Failure to follow this instruction

may result in damage to the vehicle.

Reposition the brake caliper bleed nipple shields.

5. Install a bleed tube to the rear right-hand brake caliper bleed nipple.

Remove the bleed nipple rubber cover (s).

6. Bleed the circuit.

Make sure the bleed tube is firmly attached to the bleed nipple.

Submerge the end of the bleed tube in a bleed jar containing a small quantity of approved brake fluid.

Position the bleed jar base at least 300 mm (12 in) above the bleed nipple to maintain fluid pressure and prevent air leaking

past the bleed nipple threads.

Open the bleed nipple half a turn.

Slowly apply the brake pedal to its maximum travel (this forces brake fluid into the bleed jar).

Close the bleed nipple.

Return the brake pedal to the rest position.

Wait 2 seconds to allow the brake fluid to replenish the system.

Fill up the brake master cylinder reservoir to the MAX mark as necessary.

Continue to bleed the circuit until air-free brake fluid is pumped into the jar.

Tighten the bleed nipple to 14 Nm.

Install the bleed nipple cover (s) and tighten to 5 Nm.

7.

CAUTION: Make sure that the fluid bleeding procedure is carried out on ALL of the brake caliper bleed nipples.

Failure to follow this instruction may result in damage to the vehicle.

Repeat the procedure for the rear left, front right and front left-hand brake circuits.

8.

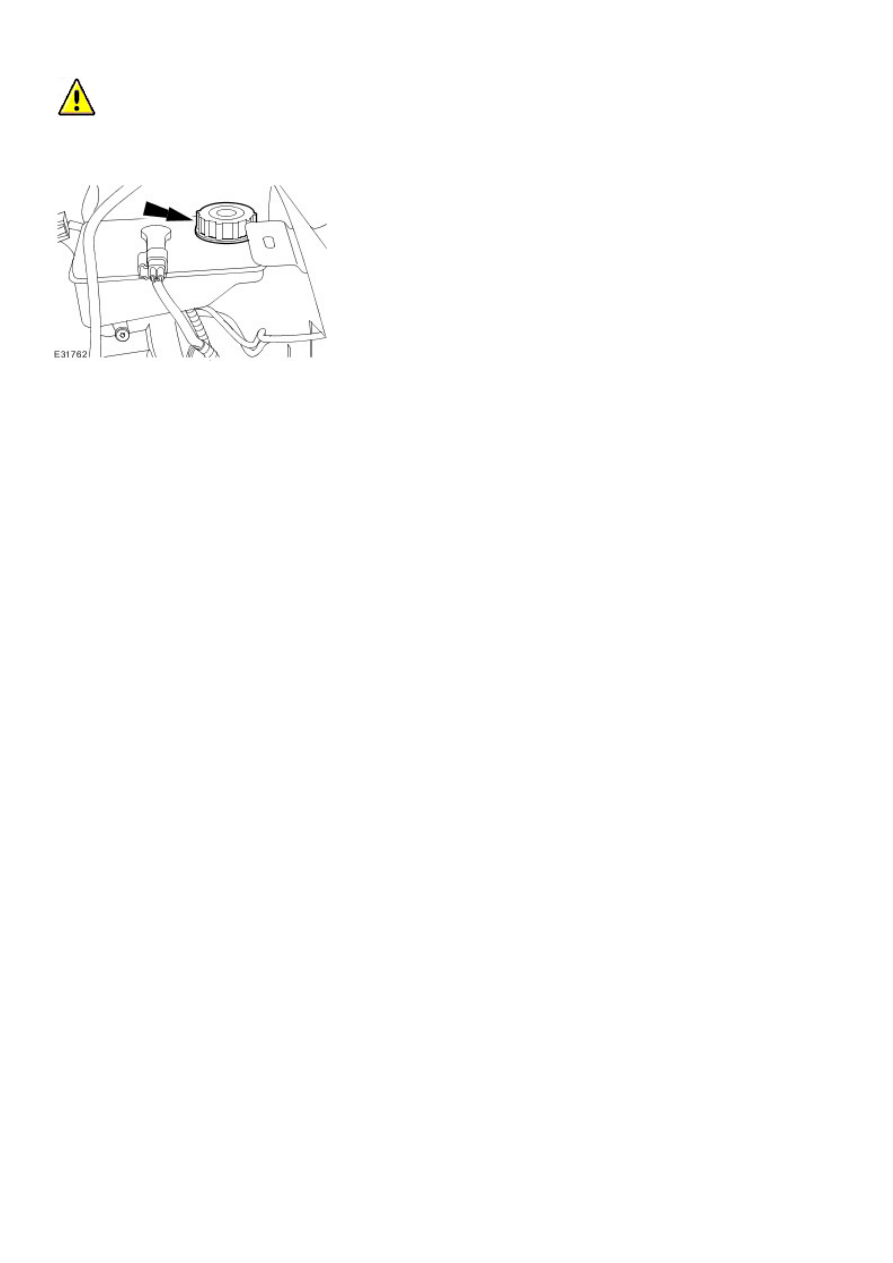

CAUTION: Make sure the brake caliper bleed nipple shields are correctly aligned. Failure to follow this instruction

may result in damage to the vehicle.

Reposition the brake caliper bleed nipple shields.

9. NOTE:

Always use fluid from a sealed container and dispose of used fluid safely.

Fill up the brake master cylinder reservoir to the MAX mark.

10. Install the wheels and tires.

www.

11.

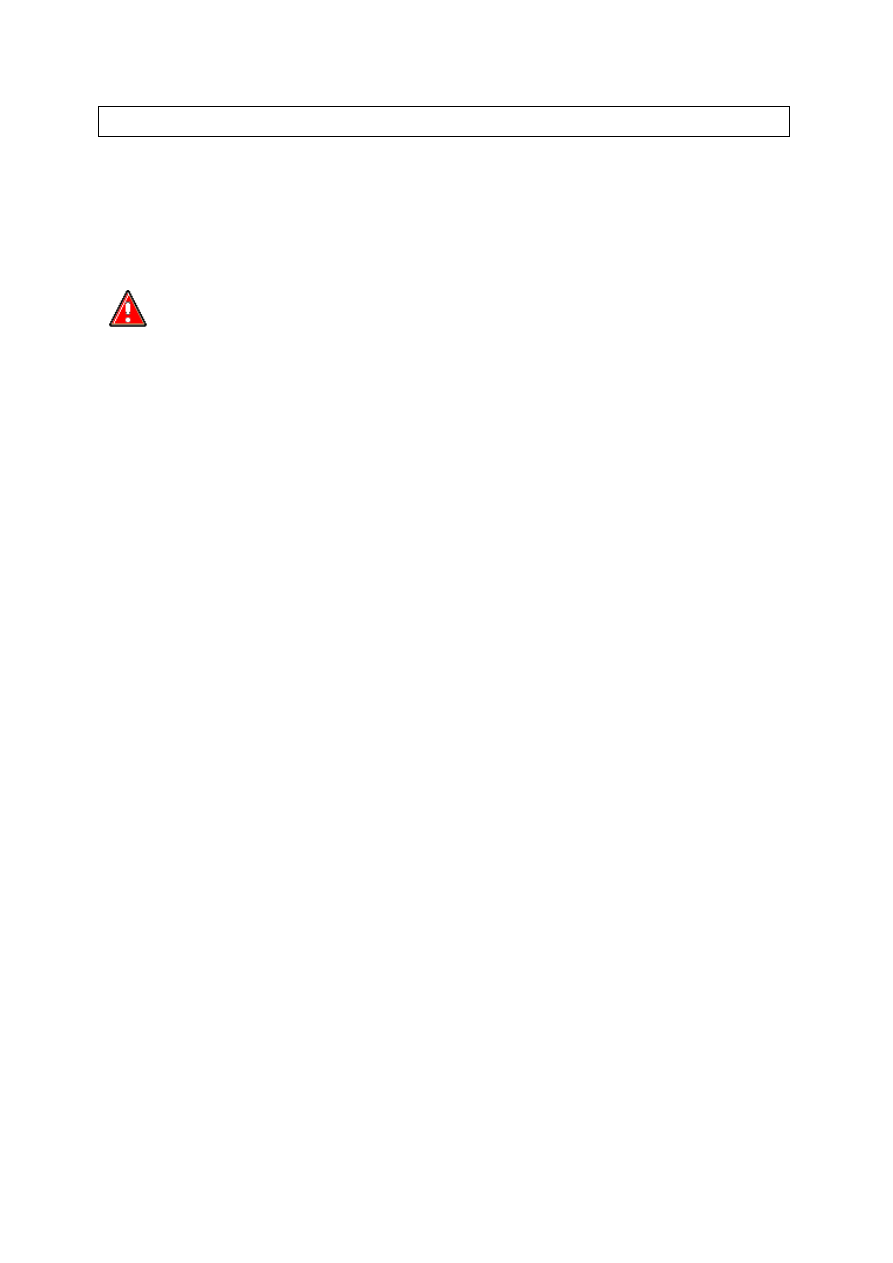

CAUTION: Make sure that the brake master cylinder reservoir filler cap does not become contaminated.

Install the brake master cylinder reservoir filler cap.

Description and operation

Brake System - VIN Range: G00442-

>G45703

WARNING: Brake fluid contains polyglycol ethers and polyglycols. Avoid contact

with the eyes. Wash hands thoroughly after handling, as prolonged contact may cause

irritation and dermatitis. If brake fluid contacts the eyes, flush the eyes with cold water

or eyewash solution and seek medical attention. If taken internally do not induce

vomiting, seek immediate medical attention. Failure to follow these instructions may

result in personal injury.

The braking system is a diagonally split, dual circuit design featuring front and rear disc

brakes.

The hydraulic system provides separate circuits for each pair of diagonally opposed wheels

(left front, right rear and right front, left rear).

The standard front brake caliper has two retaining bolts that attach the brake caliper to the

anchor plate. These are of double, sliding piston type which makes sure equal effort is applied

through both brake pads. The anchor plate is attached to the wheel knuckle with two bolts.

The standard rear brake calipers are single pistoned floating caliper type, which also

incorporates the park brake mechanism. The standard brake disc is manufactured from cast

iron and is of the vented type. It is retained on the hub by two retaining clips and the wheel

studs.

The Brembo front and rear brake calipers have two retaining bolts that attach the brake caliper

to the wheel knuckle. These are four piston fixed type which makes sure that equal effort is

applied through both brake pads.The Brembo rear brakes have separate brake calipers for the

parking brake. The Brembo brake disc is manufactured from cast iron and is of the vented

type. It is retained on the hub by two retaining clips and the wheel studs. The brake pads in all

cases are asbestos free.

Braided steel brake hoses are now fitted to reduce expansion under braking pressure and are

of a light weight design.

The brake master cylinder is of a tandem design and is linked to a brake booster to reduce the

brake pedal effort. The tandem design will make sure that in the event of one brake circuit

failure the other will remain fully operational. The brake booster operating rod is connected

directly to the brake pedal.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст