Jaguar XJ (X350). Manual — part 202

•

Harness fault

G295394p3

.

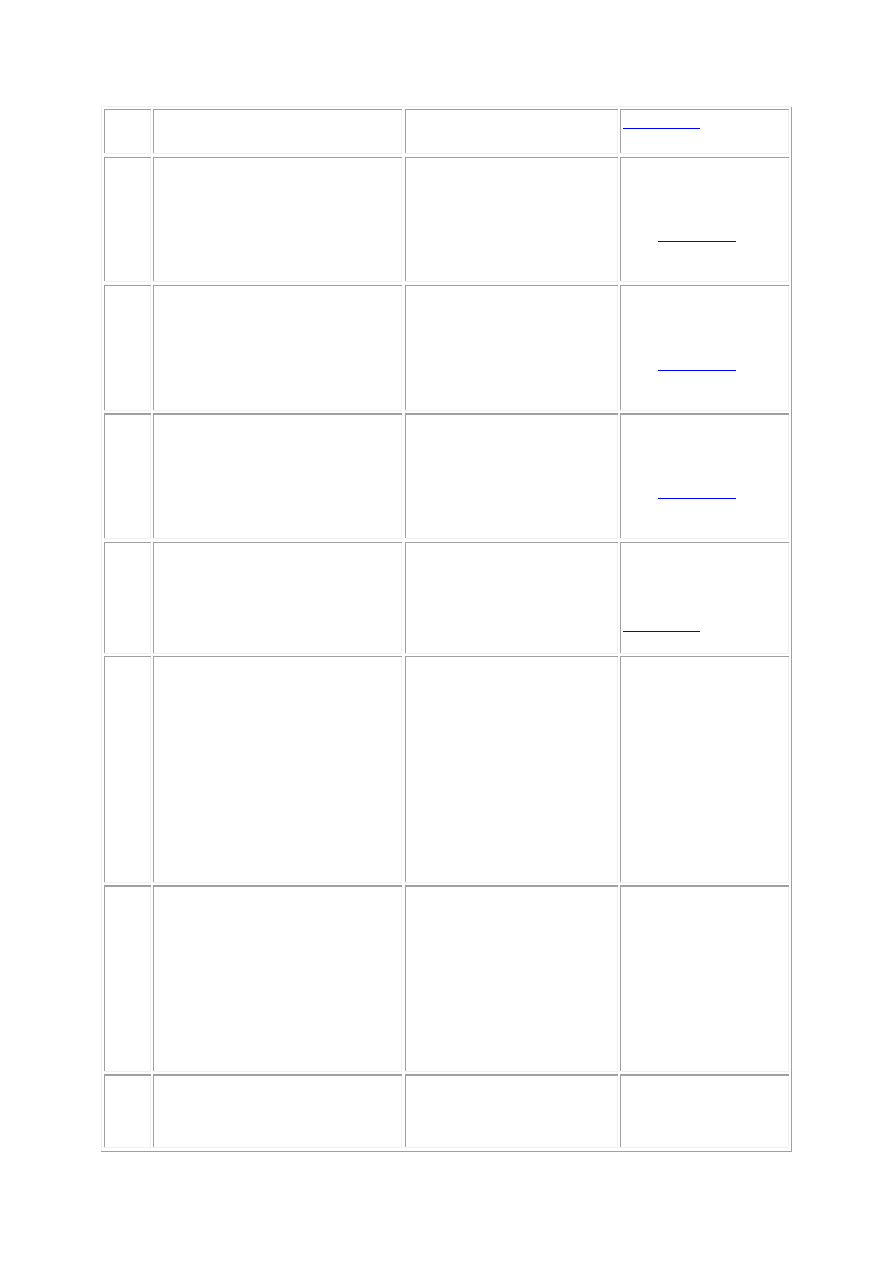

C1784

Parkbrake motor output short to

ground

•

Fuse failure

•

Connector pin(s) bent

•

Connector loose or

corroded

•

Harness fault

For EPB motor circuit

tests, GO to Pinpoint

Test

G295394p4

.

C1785

Parkbrake motor output open

circuit

•

Fuse failure

•

Connector pin(s) bent

•

Connector loose or

corroded

•

Harness fault

For EPB motor circuit

tests, GO to Pinpoint

Test

G295394p4

.

C1786

Parkbrake motor output battery

short to ground

•

Fuse failure

•

Connector pin(s) bent

•

Connector loose or

corroded

•

Harness fault

For EPB motor circuit

tests, GO to Pinpoint

Test

G295394p4

.

C1799 Hall effect sensor circuit failure

•

Hall effect circuit open

circuit

•

Hall effect circuit short

circuit to ground

For hall effect sensor

circuit tests, GO to

Pinpoint Test

G295394p5

.

C1801

Greater than expected motor

current draw reached before

expected travel (motor current

draw compared to expected

number of turns)

•

Cables fouled, trapped

or damaged

•

Cables incorrectly

routed or fixed

•

Rear lining wear

•

Service brake not

correctly adjusted

following lining change

•

Caliper malfunction

•

Actuator malfunction

Refer to the symptom

chart for actions

regarding mechanical

operation

C1802

Greater than expected travel for

measured current draw (motor

current draw compared to expected

number of turns)

•

Cables incorrectly

routed or fixed

•

Rear lining wear

•

Service brake not

correctly adjusted

following lining change

•

Caliper malfunction

•

Actuator malfunction

Refer to the symptom

chart for actions

regarding mechanical

operation

C1803

Less than expected travel for

parkbrake release

•

Cables fouled, trapped

or damaged

•

Cables incorrectly

Refer to the symptom

chart for actions

regarding mechanical

routed or fixed

•

Rear lining wear

•

Service brake not

correctly adjusted

following lining change

•

Caliper malfunction

•

Actuator malfunction

operation

Pinpoint Tests

CAUTION: When probing connectors to take measurements in the course of the pinpoint

tests, use the adaptor kit, part number 3548-1358-00.

NOTE:

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion.

NOTE:

When performing electrical voltage or resistance tests, always use a digital multimeter (DMM)

accurate to 3 decimal places, and with an up-to-date calibration certificate. When testing

resistance, always take the resistance of the DMM leads into account.

NOTE:

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

PINPOINT TEST G295394p1 : DTC

B1342; CONTROL MODULE FAILURE

G295394t1 : CHECK THE POWER SUPPLY TO THE EPB CONTROL MODULE

1. Disconnect the EPB control module electrical connector, CR50. 2. Measure the voltage between

CR50, pin 01 (NW) and GROUND.

•

Is the voltage less than 10 volts?

-> Yes

REPAIR the circuit between the EPB control module and battery. This circuit includes the battery

junction box (fuse 32). For additional information, refer to the wiring diagrams. CLEAR the DTC. TEST

www.

the system for normal operation.

-> No

GO to Pinpoint Test

G295394t2

.

G295394t2 : CHECK THE GROUND TO THE EPB CONTROL MODULE

1. Measure the resistance between CR50, pin 04 (B) and GROUND.

•

Is the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

-> No

Contact dealer technical support for advice on possible EPB control module failure.

PINPOINT TEST G295394p2 : DTC

C1094, C1769, C1782, C1783; PARK

BRAKE APPLY SWITCH CIRCUIT

FAILURE/SHORT TO GROUND, PARK

BRAKE RELEASE SWITCH CIRCUIT

FAILURE/SHORT TO GROUND

G295394t3 : CHECK THE SIGNAL GROUND TO THE EPB SWITCHPACK

1. Measure the resistance between TL82, pin 02 (BK) and GROUND.

•

Is the resistance greater than 5 ohms?

-> Yes

GO to Pinpoint Test

G295394t4

.

-> No

GO to Pinpoint Test

G295394t5

.

G295394t4 : CHECK THE SIGNAL GROUND CIRCUIT TO THE EPB

SWITCHPACK FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal. 2. Disconnect the EPB control module electrical

connector, CR32. 3. Measure the resistance between TL82, pin 06 (WU) and CR32, pin 12 (WU).

•

Is the resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

-> No

GO to Pinpoint Test

G295394t5

.

G295394t5 : CHECK THE VOLTAGE FROM THE EPB CONTROL MODULE TO

THE SWITCHPACK

1. Reconnect the battery negative terminal. 2. Reconnect the EPB control module electrical

connector, CR32. 3. Turn the ignition switch to the ON position. 4. Measure the voltage between

TL82, pin 08 (WU) and GROUND. 5. Measure the voltage between TL82, pin 04 (RW) and GROUND.

•

Is either voltage less than 3 volts?

-> Yes

GO to Pinpoint Test

G295394t6

.

-> No

Check the EPB switch function. CLEAR the DTC. TEST the system for normal operation.

G295394t6 : CHECK THE EPB CONTROL MODULE TO SWITCHPACK CIRCUITS

FOR HIGH RESISTANCE

1. Disconnect the battery negative terminal. 2. Disconnect the EPB control module electrical

connector, CR32. 3. Measure the resistance between TL82, pin 08 (WU) and CR32, pin 05 (WU). 4.

Measure the resistance between TL82, pin 04 (RW) and CR32, pin 06 (RW).

•

Is either resistance greater than 5 ohms?

-> Yes

REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

-> No

GO to Pinpoint Test

G295394t7

.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст