Jaguar XJ (X350). Manual — part 22

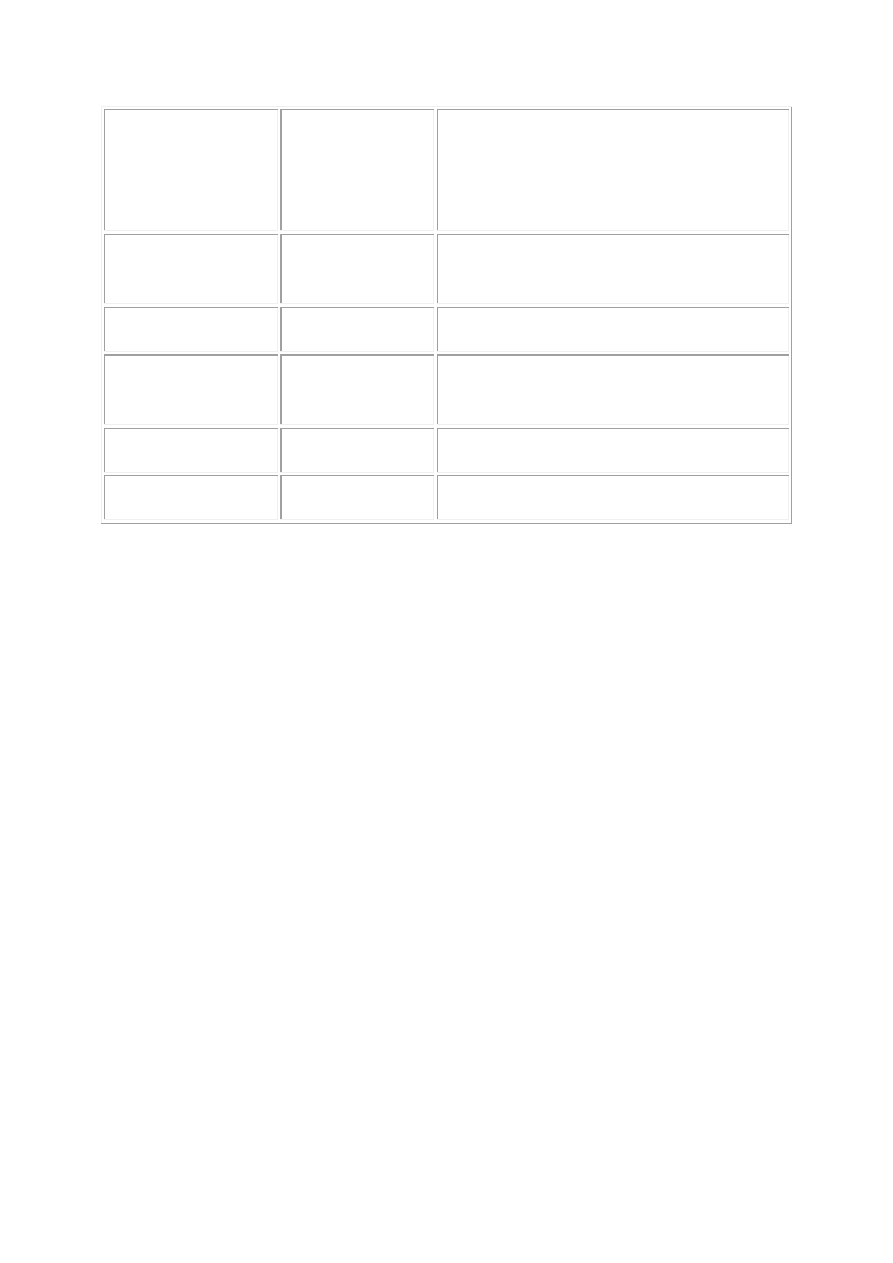

Transmission Oil

Temperature

TOT

Indicates temperature of transmission

fluid

Transmission

Range

TR

The range in which the transmission is

operating

Turbine Shaft

Speed

TSS

Indicates rotational speed of

transmission output shaft or turbine

shaft

Vacuum Solenoid

Valve

VSV

Vacuum operated valve used in the

speed control system

Vacuum Solenoid

Valve (atm)

VSV(VA)

Vacuum atmospheric valve used in the

speed control system

Vacuum Solenoid

Valve (rel)

VSV(VR)

Vacuum release valve used in the

speed control system

Vacuum Solenoid

Valve (vac)

VSV(VV)

Vacuum valve used in the speed control

system

Variable Valve

Timing

VVT

A system by which the relationship of

the crankshaft and camshaft may be

altered during engine running

Vehicle Battery

Adapter

VBA

Provides electrical power to the Jaguar

approved diagnostic system and

supplies a battery reference level

Vehicle Control

Monitor

VCM

Instrument panel display which warns of

faults

Vehicle Emission

Control Information

Label

VECI Label

Vehicle

Identification

Number

VIN

Number assigned to the vehicle by the

manufacturer, primarily for licensing and

identification purposes

Vehicle Interface

Adapter

VIA

Extends the Jaguar approved

diagnostic system capability and

provides a parallel interface to vehicle

harnesses and ECMs

Vehicle Speed

Sensor

VSS

Sensor which provides vehicle speed

information

Viscosity Index

VI

Voltage Regulator

VR

Device which regulates the variable

output voltage of a generator

Watt

W

SI unit of power (1 hp = 745.7 watts)

Wide Open Throttle

WOT

Full throttle position

www.

Health and Safety Precautions

Prolonged and repeated contact with mineral oil will result in the removal of natural oils from

the skin, leading to dryness, irritation and dermatitis. In addition, used engine oil contains

potentially harmful contaminants which may cause skin cancer. Washing facilities and

adequate means of skin protection should be provided.

Observe these recommendations:

•

Wear protective clothing, including impervious gloves where practicable.

•

Do not put oily rags in pockets. Avoid contaminating clothes, particularly underwear,

with oil.

•

Overalls must be cleaned regularly. Discard oil impregnated clothing and footwear

which cannot be washed or cleaned.

•

First Aid treatment should be obtained immediately for open cuts or wounds.

•

Use barrier creams, applying before each work period, to enable easier removal of

dirty oil and grease from the skin.

•

Wash with soap and water to make sure that all oil is removed (skin cleaner and a nail

brush will help). The use of preparations containing lanolin will help to replace the

natural skin oils which have been removed.

•

Do not use petrol, kerosene, gas oil, thinners or solvents for washing skin.

•

If skin disorders develop, obtain medical advice immediately.

•

Where practical, degrease components prior to handling.

•

Where there is a risk of fluids coming into contact with the eyes, eye protection should

be worn, for example, goggles or a face shield. An eye wash facility should be

provided.

The Health and Safety Precautions subsection refers to some commonly used chemicals and

materials, hazards associated with their use, and safety measures to be taken. Some of these

chemicals may be included in the following list either in their own right or as an ingredient in

a sealer or adhesive.

Acids and Alkalis

See also Battery Acids.

e.g. caustic soda, sulphuric acid.

Used in batteries and cleaning materials.

Irritant and corrosive to the skin, eyes, nose and throat. Cause burns. Can destroy ordinary

protective clothing.

Avoid splashes to the skin, eyes and clothing. Wear suitable protective impervious apron,

gloves and goggles. Do not breath mists.

Ensure access to eye wash bottles, shower and soap are readily available for splashing

accidents.

Display Eye Hazard sign.

Air Bags

See also Fire, Chemical Materials - General

Highly flammable, explosive – observe No Smoking policy.

Used as a safety restraint system mounted in the steering wheel.

The inflator contains a high - energetic propellant which, when ignited, produces a VERY

HOT GAS (2500º C).

The gas generant used in air bags is Sodium Azide. This material is hermetically sealed in the

module and is completely consumed during deployment. No attempt should be made to open

an air bag inflator as this will lead to the risk of exposure to Sodium Azide. If a gas generator

is ruptured, full protective clothing should be worn when dealing with the spillage.

After normal deployment, gloves and safety goggles should be worn during the handling

process.

Deployed air bags should be disposed of in a plastic bag in accordance with local regulations

at an approved chemical waste site.

Following any direct contact with gas generant.

•

Wash affected areas thoroughly with water.

•

Seek medical assistance if necessary.

Air Bags - Do's

•

Do store in an airbag safe when not fitted to the vehicle.

•

Do store modules in an upright position.

•

Do keep modules dry.

•

Do carry modules with the cover side pointing away from the body.

•

Do place modules with their cover side upwards.

•

Do carefully inspect modules for damage.

•

Do stand to one side when connecting modules.

•

Do make sure all test equipment is properly calibrated and maintained.

•

Do wash you hands after handling deployed air bags.

Air Bags - Do Nots

•

Do not store highly flammable material together with modules or gas generators.

•

Do not store gas generators at temperatures exceeding 80º C.

•

Do not store modules upside down.

•

Do not attempt to open a gas generator housing.

•

Do not expose gas generators to open flame or sources of heat.

•

Do not place anything on top of a module cover.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст