Jaguar XJ (X350). Manual — part 1106

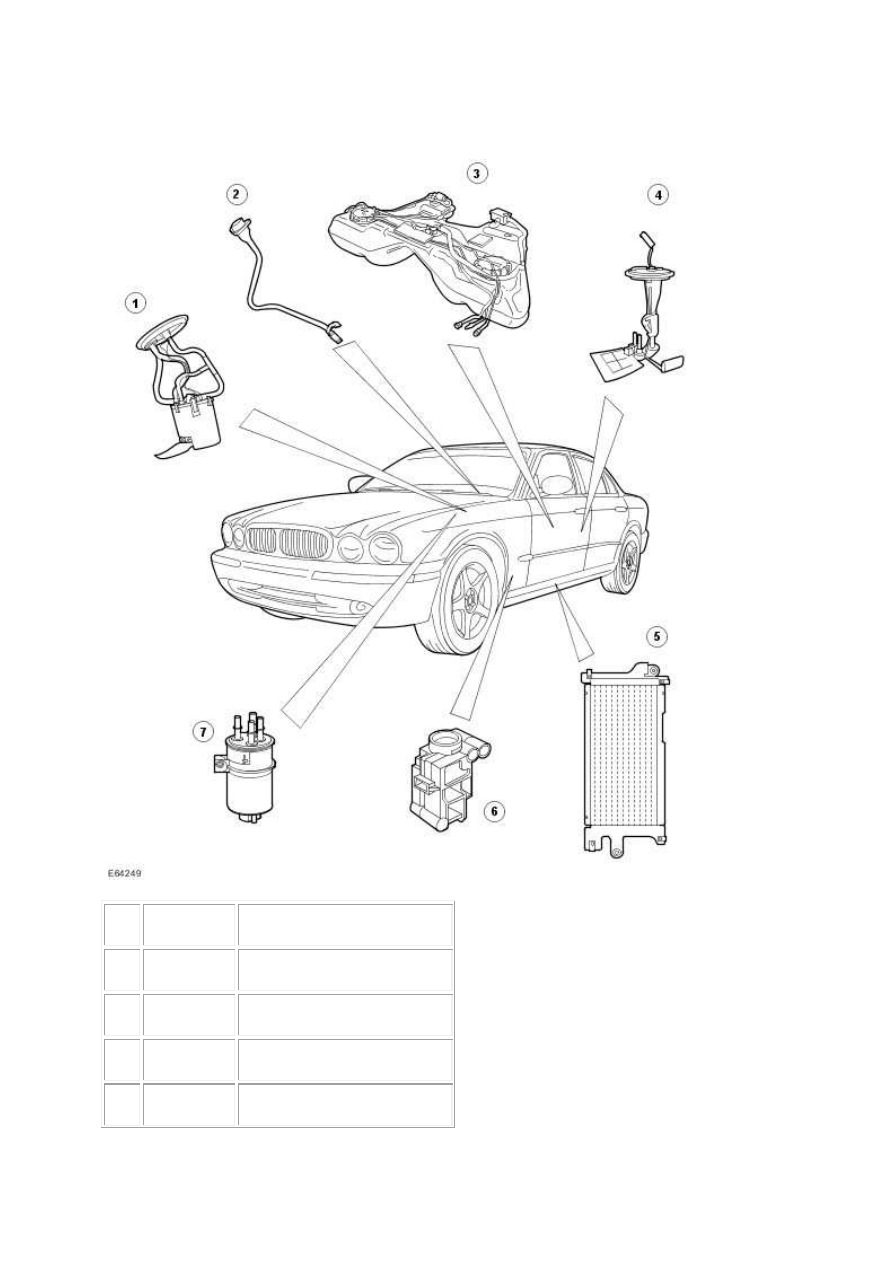

3

—

Fuel pump module

4

—

Fuel tank

5

—

Fuel tank filler pipe

6

—

Fuel transfer pump

The electronic returnless fuel system utilized has the following advantages:

reduced fuel tank vapor generation

requires less electrical power

does not require a fuel return line.

The intelligence of this system is contained within the engine control module (ECM).

The ECM determines the required fuel flow and communicates this information to the rear electronic

module (REM). The REM has the fuel pump driver functions fully integrated into the microprocessor.

The fuel pump relay is activated by the ECM power relay and provides a fused power supply to the

REM. The ECM and the REM calculate the frequency and determine the current required by the fuel

pump to maintain the correct fuel pressure at the fuel injectors.

The fuel tank is of a saddle design which incorporates a fuel pump module on the right-hand side and

a fuel transfer module on the left-hand side. The fuel pump crossover lines are internal to the fuel

tank to reduce potential leak paths.

Fuel is supplied at high pressure to the injectors through a fuel rail which incorporates a fuel pressure

and a fuel temperature sensor. The ECM increases the fuel pressure to minimize fuel vapor formation

to maintain fuel flow across the injectors. An inertia type fuel shut-off switch will cut power to the

fuel pump in the event of an accident.

Vehicles with Diesel Engine

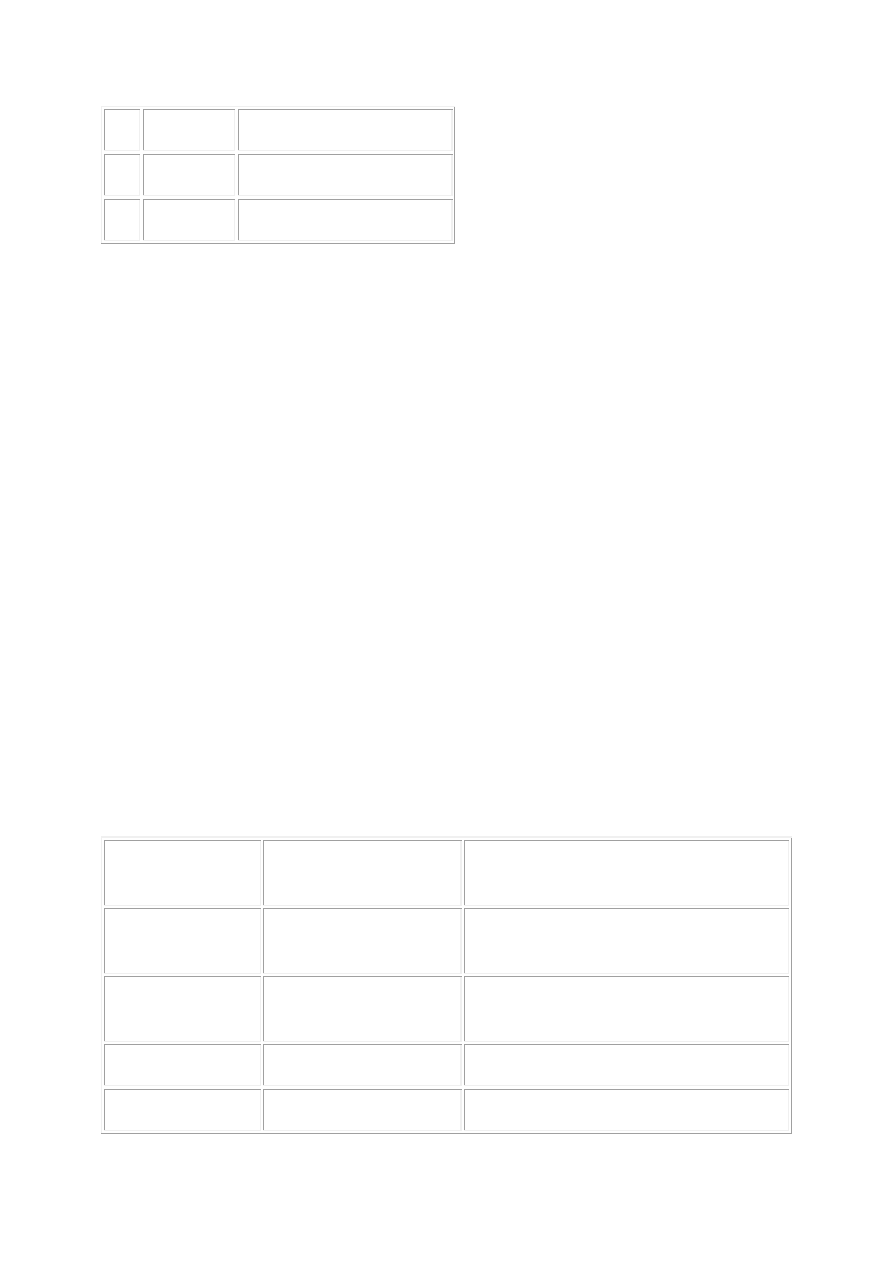

Item

Part Number

Description

1

—

Fuel pump module

2

—

Fuel tank filler pipe

3

—

Fuel level sensor

4

—

Fuel tank

www.

5

—

Fuel filter

6

—

Inertia fuel shut-off (IFS) switch

7

—

Fuel Cooler

Fuel System - Vehicles with Diesel Engine

The diesel fuel is drawn from the fuel tank by an internal electric lift pump which is supplied with

battery voltage from the fuel pump relay located in the rear power distribution box. The fuel pump

relay is controlled by the ECM. The fuel pump provides a low pressure diesel fuel supply to the

transfer pump incorporated in to the fuel injection pump. The fuel metering valve (FMV) governs the

amount of fuel supplied to the fuel injection pump. The fuel injection pump has a fuel return circuit

to the fuel filter, which is independent of the injector return pipes.

The fuel tank is of a saddle design which incorporates a fuel pump module and fuel level sensor in

the right-hand side and a fuel level sensor module in the left-hand side of the tank. The fuel pump

crossover lines are internal to the fuel tank to reduce potential leak paths. The signals from the fuel

level sensors are used both for the fuel gauge and the run dry prevention strategy within the ECM.

The driver will always be aware of the risk of running out of fuel as the fuel gauge will show empty

and the fuel warning lamp will be illuminated. In order to protect the fuel lift pump and fuel injection

pump and to prevent the need for fuel priming after the vehicle has run out of fuel, the ECM will

instigate the run dry prevention strategy prior to the fuel tank becoming completely empty. In order

to recognize the fuel tank becoming empty, a low level switch is incorporated in to the fuel tank swirl

pot. The signal from this switch, together with the signal from two fuel level sensors is relayed to the

ECM, through the controller area network (CAN) bus.

Before a run dry event occurs the ECM will take a series of actions to inform the driver of the low fuel

level in the fuel tank.

Fuel remaining in fuel

tank

Approximate distance

remaining*

Action

9·4 L

112 Km (70 Miles)

Low Fuel warning lamp illuminated in

instrument cluster

5·2 L

48 Km (30 Miles)

Fuel gauge reads Empty; RANGE display reads

0 Km (0 Miles)

3·9 L

28 Km (18 Miles)

ECM simulates engine misfire

3·7 L

25 Km (16 Miles)

Engine is stopped but restarts with misfire

2·0 L

0 Km (0 Miles)

Engine stops and will not restart

* Dependant on average fuel consumption

If, when the ignition key is turned to the ON position, the run dry event is still detected, this would

indicate that either no, or insufficient, fuel has been added to the fuel tank, or that the vehicle may

be parked on a slope. In this instance the fuel pump will run to fill the swirl pot and cover the low fuel

level switch. The ECM will not prevent the engine from cranking, but it will inhibit fuel injection. If,

after a delay, a run dry event is still detected, the fuel pump will be inhibited for the rest of the

ignition cycle. As soon as a run dry event is no longer detected normal starting can resume.

www.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст