Jaguar S-Type. Manual — part 38

Wheel Changing

160

L

Wheel Changing

OVERVIEW

Be prepared for a flat tire. Know where

equipment is stowed and read the wheel

changing and jacking instructions

carefully.

If a wheel change is required, pull off the

road completely. Park on ground which is

as level and solid as possible. Make sure

that the vehicle is clear of any objects that

will obstruct the safe removal of the

wheel. Switch on the hazard warning

indicators, and where legally required,

display a warning triangle.

!

WARNING:

• It can be dangerous to change a

wheel when the vehicle is on a

slope or soft, uneven ground.

• Wheels are extremely heavy. Take

care when lifting and particularly

when removing and replacing a

wheel in its storage position in the

luggage compartment.

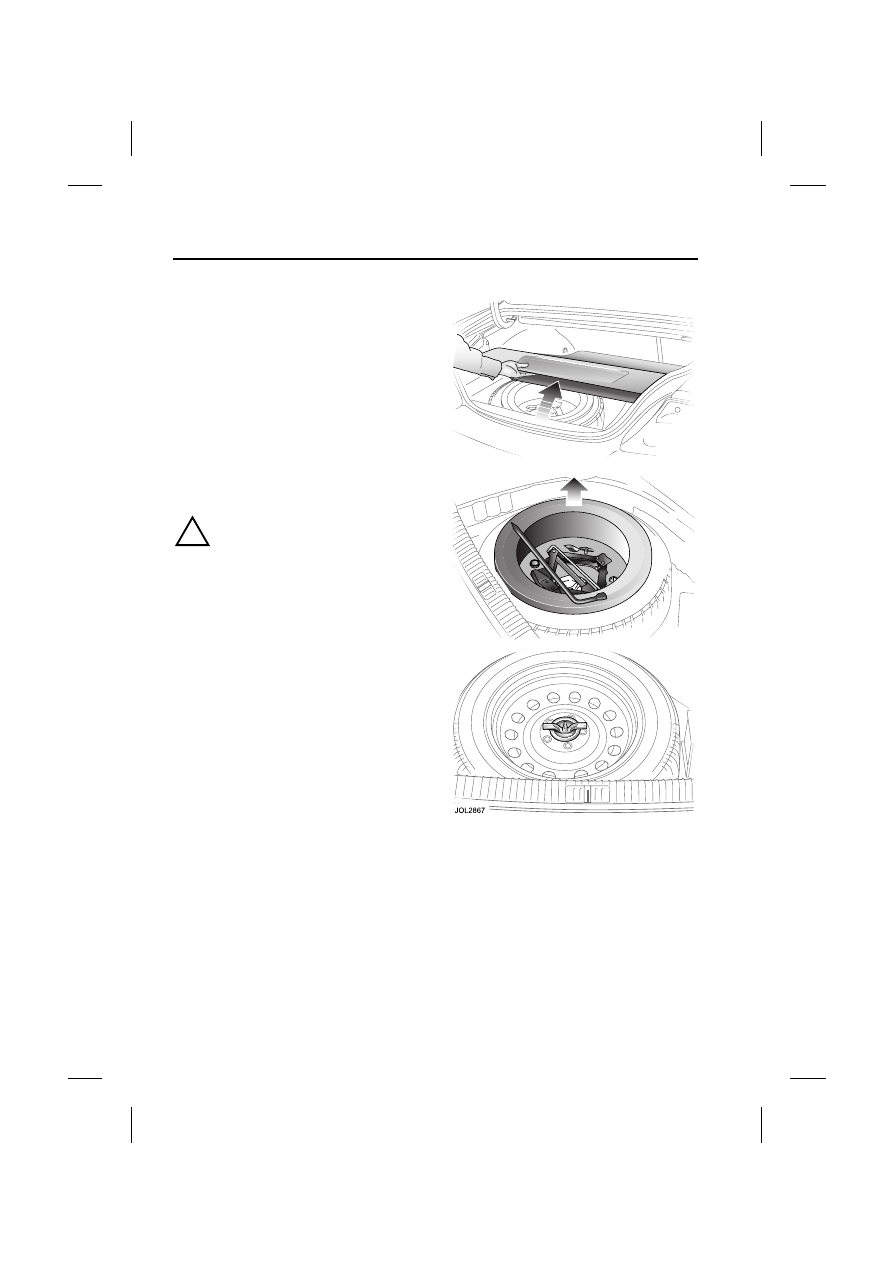

SPARE WHEEL LOCATION

The spare wheel and jacking equipment

are stored under the luggage

compartment floor panel.

To remove the spare wheel, fold the

luggage compartment floor panel towards

the rear seats. Remove the tray

containing the jacking equipment to gain

access to the wheel. Unscrew the

retaining nut and remove the spare wheel.

Remove the jack and wheel nut wrench.

161

Wheel Changing

R

TEMPORARY USE SPARE

WHEEL

Observe the following warnings before

using the wheel:

!

WARNING:

• Please note temporary use spare

wheel warning label. Follow the

instructions on the label. Failure to

comply can be dangerous.

• When a temporary use spare wheel

is fitted, drive with caution and

replace with the specified wheel

and tire as soon as possible.

• Do not fit more than one temporary

use spare wheel and tire assembly

at one time.

• The temporary use spare wheel

must be inflated to the correct

pressure.

• Temporary use spare wheel,

maximum speed is 80 km/h

(50 mph).

Note: Maintenance information for the

temporary use spare wheel is the same as

given for normal tires. See page 211.

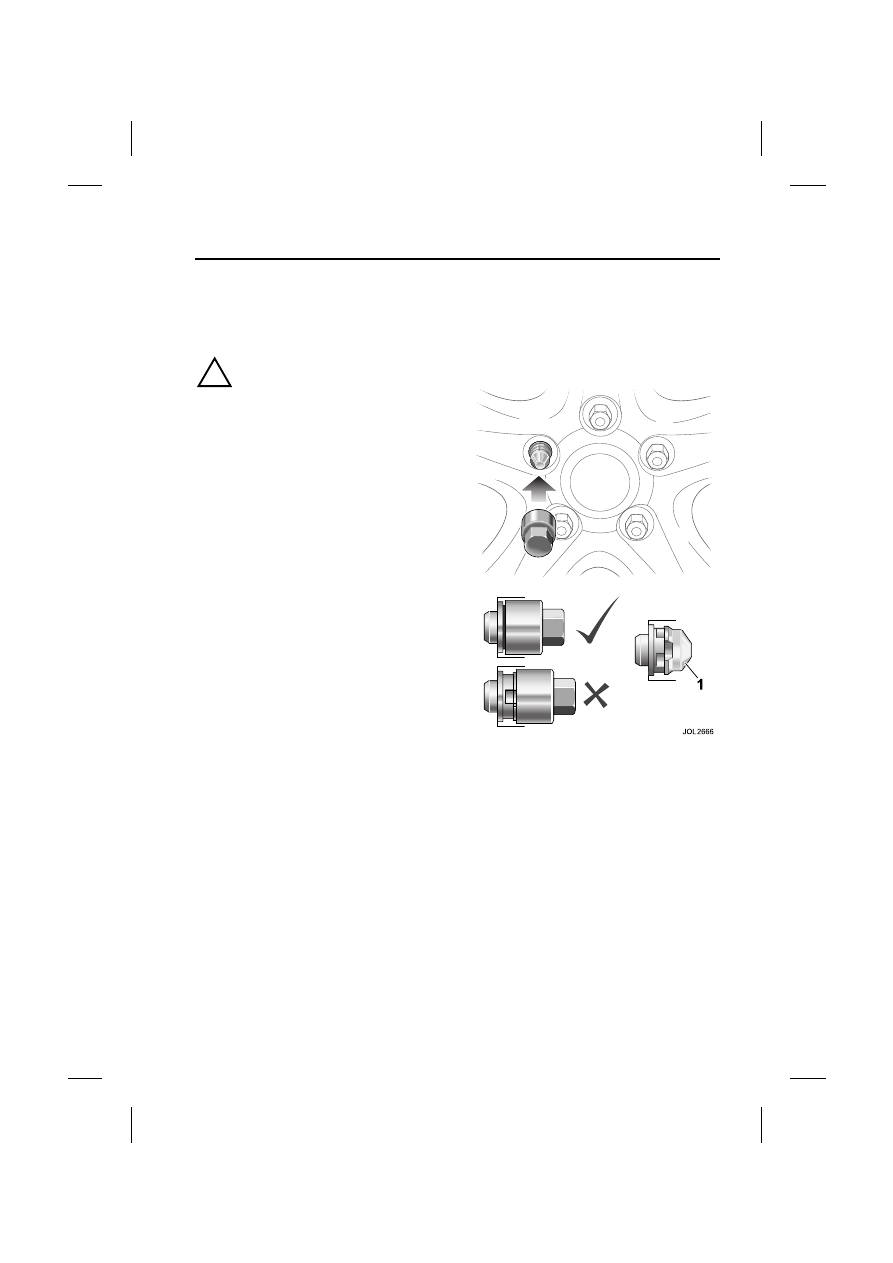

LOCKING WHEEL NUTS

Where Jaguar locking wheel nuts are

fitted (one on each wheel), they can only

be removed using the correct key socket.

The locking wheel nut comprises two

grooved parts, front and rear, which must

be turned together to allow the nut to be

fitted or removed.

To remove the nut, the front and rear

grooves must be aligned. Locate the key

socket in the grooves and push it fully

over both parts of the nut. Fit the wheel

nut wrench over the key socket and

loosen the locking wheel nut.

Attempting to remove the nut without the

correct key socket (such as attempted

theft) or with the socket not located over

the rear part of the nut, will cause the front

part (1) only to turn.

If this has happened, rotate the front part

with the key socket until the grooves are

re-aligned and then push the socket fully

over the nut.

Should a new key socket be required,

contact your Jaguar Dealer. Proof of

vehicle ownership will be required.

Wheel Changing

162

L

WHEEL CHANGING

1. Make sure that all passengers are in a

safe place, clear of the vehicle.

2. Apply the parkbrake and select gear

position P (Park) or select a low gear

on a manual transmission vehicle.

3. Make sure that the jack is placed on

firm and level ground.

Note: When one rear wheel is lifted off the

ground, the selection of a low gear on

manual vehicles or automatic

transmission P (Park) position will not

prevent the vehicle from moving and

possibly slipping off the jack.

!

WARNING:

• Before attempting to lift the vehicle

with the jack, chock the wheel

diagonally opposite to the wheel

being replaced to prevent the

vehicle from rolling when jacked

up. A wheel chock is supplied with

the jacking equipment for this

purpose.

• Never work under the vehicle using

only the jack as a support; always

use axle stands or suitable

supports under the jacking points.

Before raising the vehicle slacken, but do

not remove the wheel nuts.

Observe the instructions printed on the

jack.

Use the jack only for lifting the vehicle

during wheel changing, and only use the

jack which is stored in the vehicle.

Do not start or run the engine while the

vehicle is only supported by a jack.

There are four jacking points, two each

side of the vehicle on the underside of the

floor. These provide positive location for

the jack. The front jacking point is

approximately 18 cm (7 inches) from the

front wheel and the rear is approximately

28 cm (11 inches) forward of the rear

wheel.

The simplest way to correctly locate the

jacking point is to feel along the sill panel

to the cut-away portion and then fit the

jack to the body, not to the sill panel.

163

Wheel Changing

R

Caution: Make sure, before raising the

vehicle, that the jack is correctly

positioned to avoid any damage to the

vehicle sills or sill panels. Use only the

correct jacking points, never use

bumpers or any other part of the body

to lift the vehicle.

!

WARNING:

• Do not attempt to lift the vehicle

unless the jack head is fully

engaged in the jacking point.

• Make sure that the parkbrake is

applied.

Place the jack squarely beneath the

appropriate jacking point. Make sure that

the jack head is fully engaged. Carefully

raise the vehicle by turning the handle.

Stop jacking the vehicle when the tire just

clears the ground. Minimum tire lift gives

maximum vehicle stability.

Remove the wheel nuts and the wheel.

When changing the alloy road wheels,

transfer the center badge to the

replacement wheel (when a full size spare

wheel is used). Using the plastic tipped

end of the wheel nut wrench handle from

the inside of the wheel, push the center

badge from its housing. Push the center

badge into the replacement wheel. If the

temporary use spare wheel is to be fitted,

keep the center badge safely and fit it to

the repaired full size wheel when it has

been refitted.

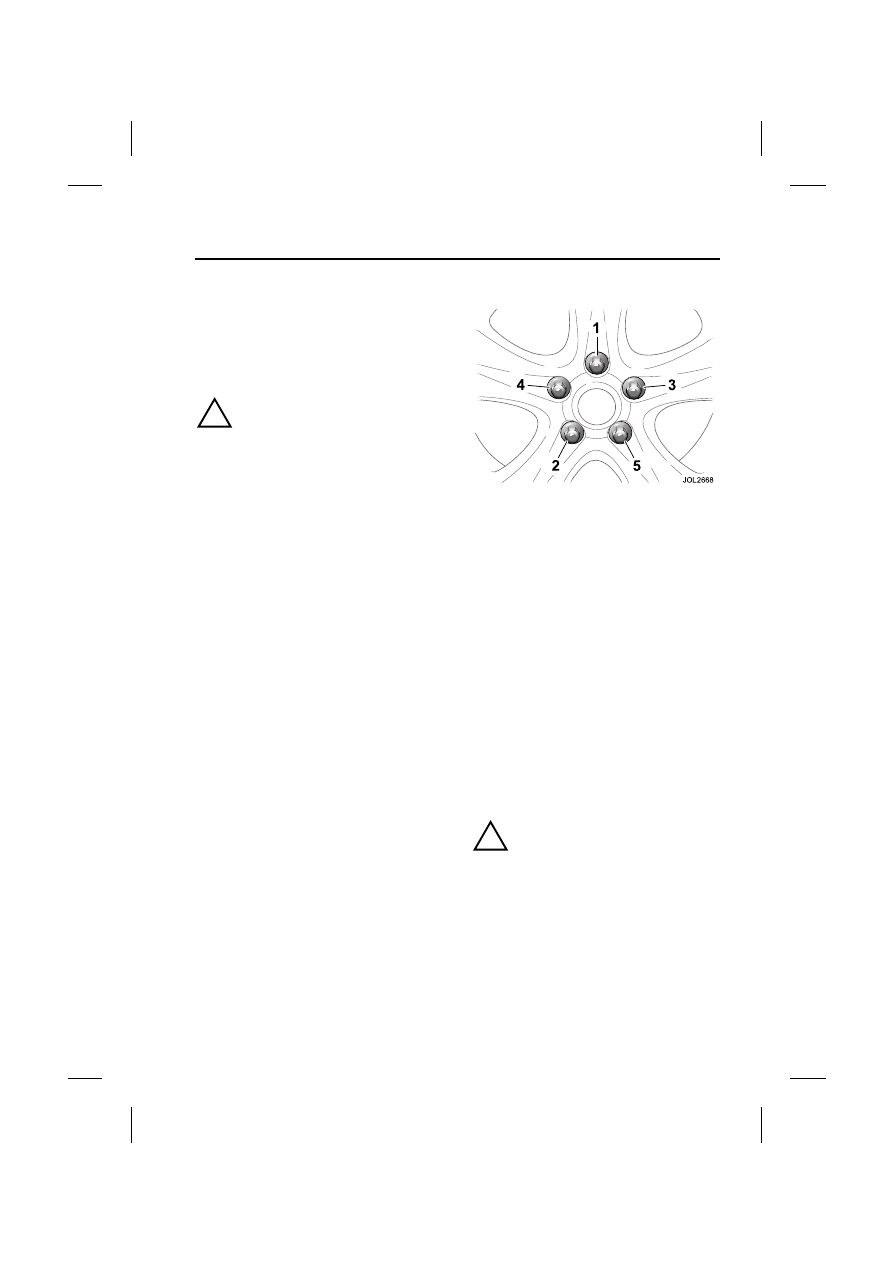

Fit the spare wheel and loosely secure

with the wheel nuts.

Using the wheel nut wrench, lightly

tighten the wheel nuts alternately using

the sequence shown in the illustration.

Tightening the wheel nuts

Lower the jack and tighten the wheel nuts

alternately, DO NOT OVER-TIGHTEN.

At the earliest opportunity have the wheel

nuts tightened with a torque wrench to

125 Nm (92 lbf.ft.).

This torque must not be exceeded.

Stowing the equipment

Stow the replaced road wheel in the

luggage compartment, position the wheel

and secure with the retaining nut.

Place the storage tray with the jack and

wrench over the wheel.

Reposition the luggage compartment

floor panel.

Note: Examine the jack occasionally and

clean and grease the threads to ensure it

is always ready for an emergency.

!

WARNING:

When the temporary use spare wheel

has been fitted, drive with caution and

replace with the specified wheel and

tire as soon as possible.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст