Loader Bobcat 773. Manual — part 11

6. Tilt Cylinder Rod End. [A].

7. Bob–Tach Wedge (Both Sides) [B].

8. Bob–Tach Pivot Pin (Both Sides) [C].

9. Lift Arm Pivot Pin (Both Sides) [D].

10. Lift Arm Link Pivot Pin (Both Sides) [D].

LUBRICATION OF THE BOBCAT LOADER (Cont’d)

Revised Jan. 99

6

A

P–10625

8

C

P–10635

9

D

P–10621

10

–1–34–

773 BICS Loader

Service Manual

7

B

P–10626

LUBRICATION OF THE BOBCAT LOADER (Cont’d)

11. 250 Hours: Steering Lever Shaft (2) [A].

PIVOT PINS

All lift arm and cylinder pivots have a large pin held in

position with a retainer bolt and lock nut (Item 1) [B].

Check that the lock nuts are tightened to 18–20 ft.–lbs.

(24–27 Nm) torque.

Revised Jan. 99

A

P–01533

11

773 BICS Loader

–1–35–

Service Manual

B

P–10620

1

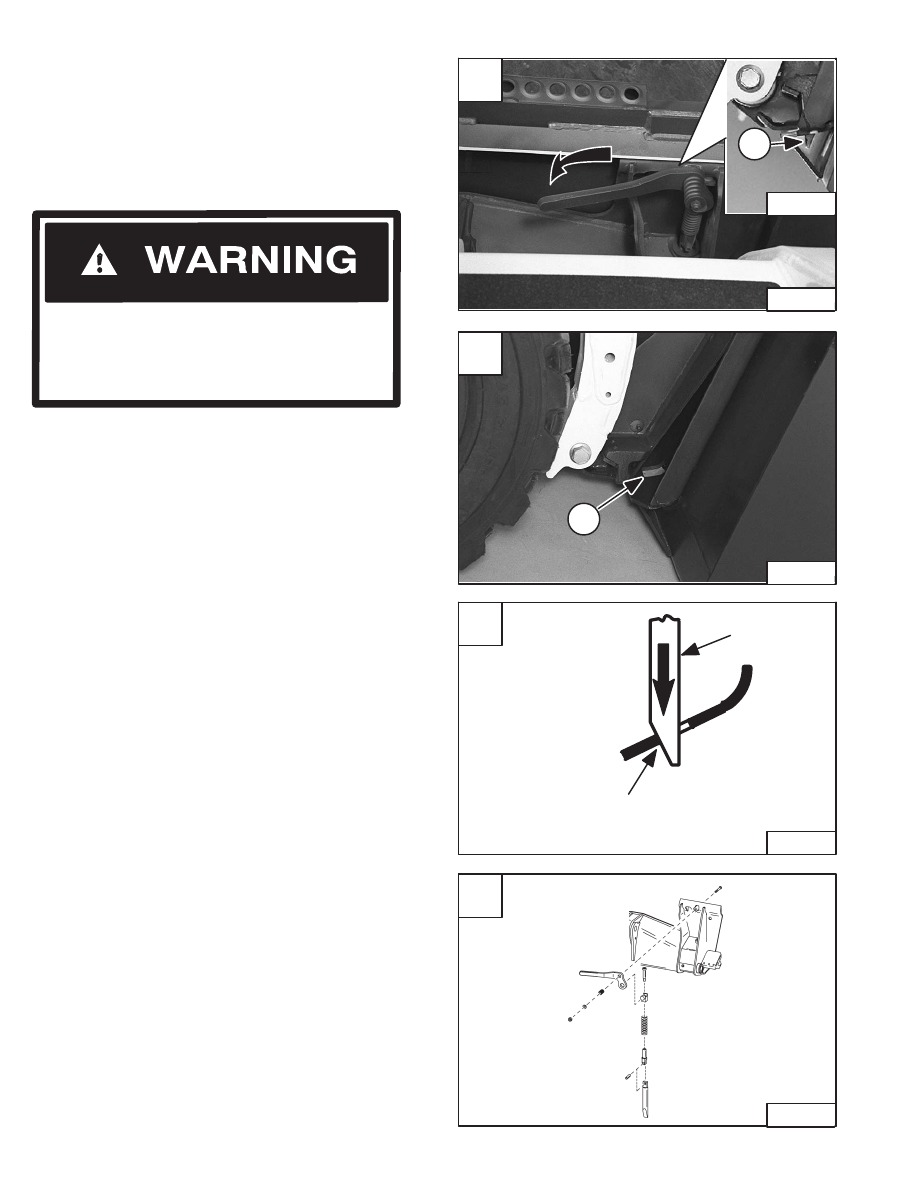

BOB–TACH

Inspection and Maintenance

Move the Bob–Tach levers to engage the wedges [A].

The levers and wedges must move freely.

The wedges must extend through the holes in the

attachment mounting frame (Item 1) [A].

The spring loaded wedge (Item 1) [A] must contact the

lower edge of the hole in the attachment (Item 1) [B] and

[C].

If the wedge does not contact the lower edge of the hole

[B] and [C], the attachment will be loose and can come

off the Bob–Tach.

Inspect the mounting frame on the attachment and the

Bob–Tach, linkages and wedges for excessive wear or

damage [D]. Replace any parts that are damaged, bent,

or missing. Keep all fasteners tight.

Look for cracked welds. Contact your Bobcat dealer for

repair or replacement parts.

Lubricate the wedges (See SERVICE SCHEDULE, Page

1–3 and LUBRICATION OF THE BOBCAT LOADER,

Page 1–33).

Revised June 01

Bob–Tach wedges must extend through the

holes in attachment. Levers must be fully

down and locked. Failure to secure wedges

can allow attachment to come off and cause

injury or death.

W–2102–0588

A

N–17027

N–17022

1

–1–36–

773 BICS Loader

Service Manual

D

TS–01062

C

Bob–Tach

Wedge

Wedge Must Contact

Lower Edge Of Hole

In The Attachment

B–15177

B

1

N–17023

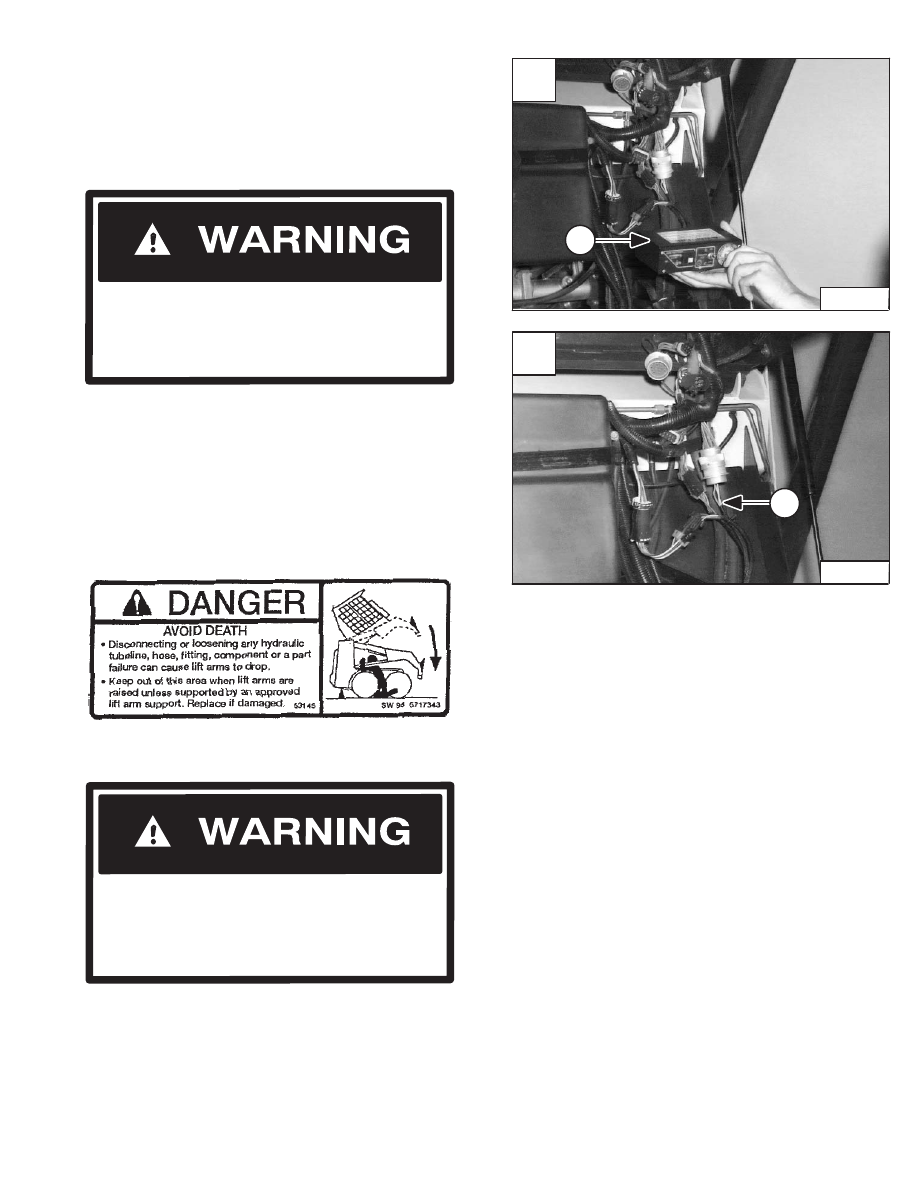

REMOTE START SWITCH

Procedure

The tool listed will be needed to do the following

procedure:

MEL1429 – Remote Start Switch

Put jackstands under the front axles and rear

corners of the frame before running the engine

for service. Failure to use jackstands can allow

the machine to fall or move and cause injury or

death.

W–2017–0286

The Remote Start Switch (Item 1) [A] is required when the

operator cab is in the raised position for service and the

service technician needs to start the engine. The operator

cab wire harness connectors must be separated from the

engine wiring harness connector under the cab.

The remote start switch is required when the service

technician is adjusting the steering linkage and checking

the hydraulic/hydrostatic system.

Lift and block the loader. (See Page 1–4.)

Raise the operator cab. (See Page 1–9.)

Connect the remote start switch to these connectors

(Item 1) [B].

Never work on a machine with the lift arms up

unless the lift arms are secured by an approved

lift arm support device. Failure to use an

approved lift arm support device can allow the

lift arms or attachment to fall and cause injury

or death.

W–2059–0598

Revised Jan. 99

Raise the lift arms and install an approved lift arm support

device. (See Page 1–7.)

A

P–10115

1

773 BICS Loader

–1–37–

Service Manual

B

P–10114

1

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст