DAF 95XF. Manual — part 533

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

Inspection and adjustment

3-8

3.9 INSPECTION AND ADJUSTMENT, VALVE CLEARANCE AND UNIT

INJECTORS

VF engine

Note:

-

The valve clearances and unit injectors

must be adjusted when the engine is cold

(

≤ 60_C).

-

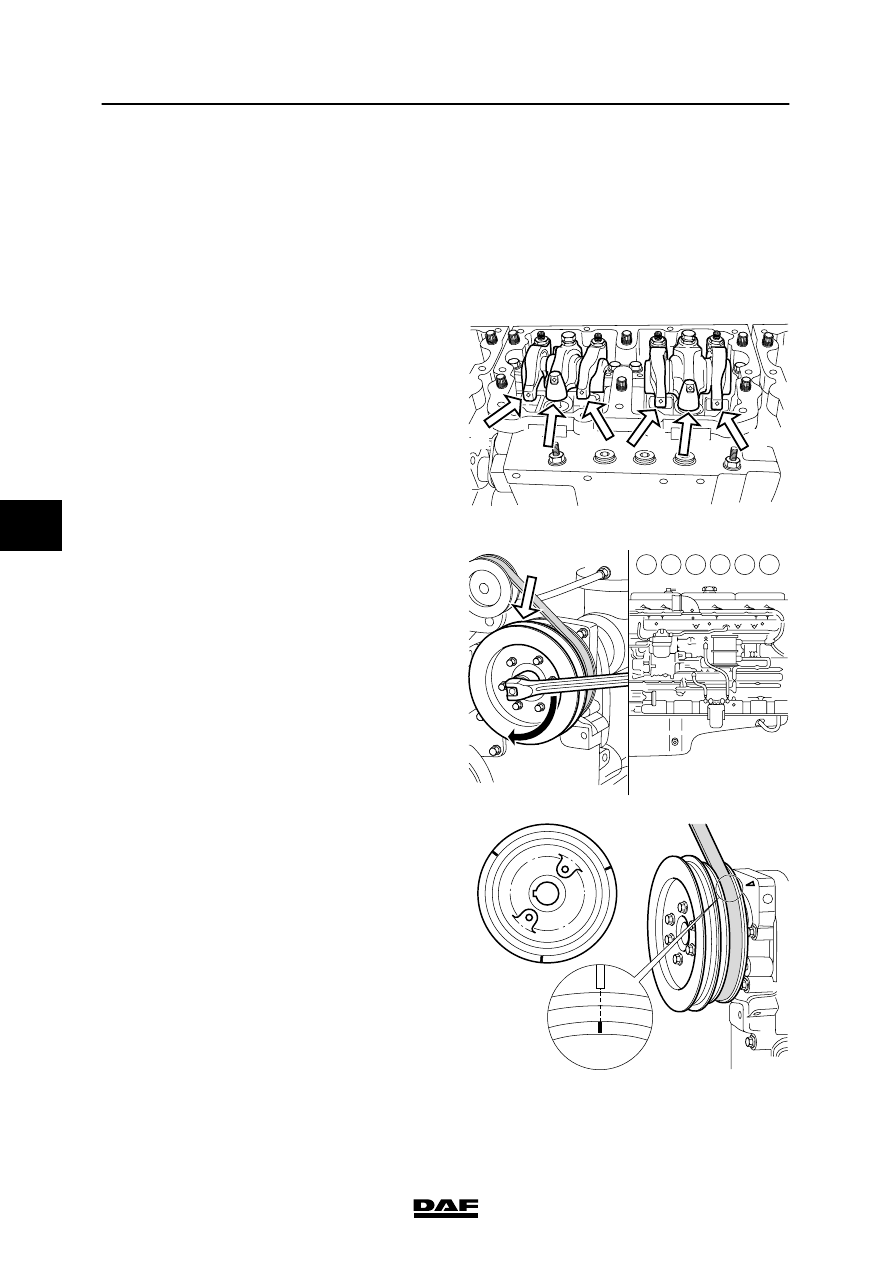

Each cylinder has three rockers:

1.

The rocker for the exhaust valves

2.

The rocker for the unit injector

3

.

The rocker for the inlet valves.

M2146

1

2

3

3

2

1

-

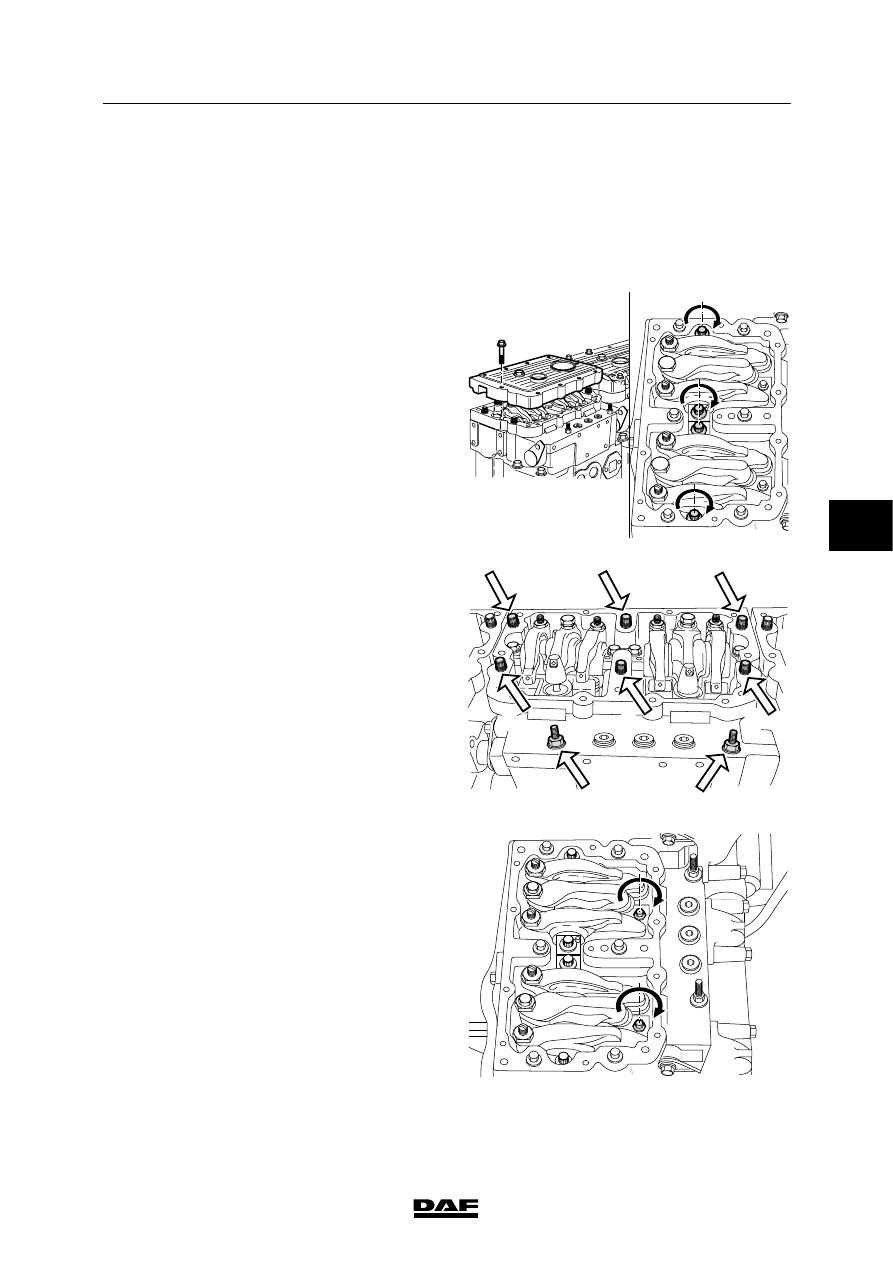

For the correct adjusting procedure for inlet

and exhaust valves and unit injectors, use

the marks made on the accessory drive

pulley (1) for the air-conditioning

compressor and water pump.

-

The direction of rotation of the crankshaft is

clockwise, as seen from the front of the

engine.

-

Cylinder 1 is on the timing-gear end, and

cylinder 6 on the flywheel end.

-

The injection sequence is 1-5-3-6-2-4.

-

Using the table below, and the marks on the

drive pulley and timing-gear cover, it is

possible to adjust the inlet and exhaust

valves and unit injectors of the cylinders

indicated.

Marks on drive pulley:

Adjustment of inlet and exhaust valves and

unit injectors of cylinder:

A

1 or 6

B

5 or 2

C

3 or 4

M2147

1

1 2 3 4 5 6

A

M2148

A

B

C

5

200424

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-9

1.

Disconnect the battery earth lead.

2.

Remove the valve covers. See “Removal

and installation”.

3.

If the vehicle is equipped with a C-brake,

the C-brake must be removed first, see

chapter “Removal and installation”.

4.

Tighten the rocker shaft attachment bolts to

the specified torque. See “Technical data”.

M2143

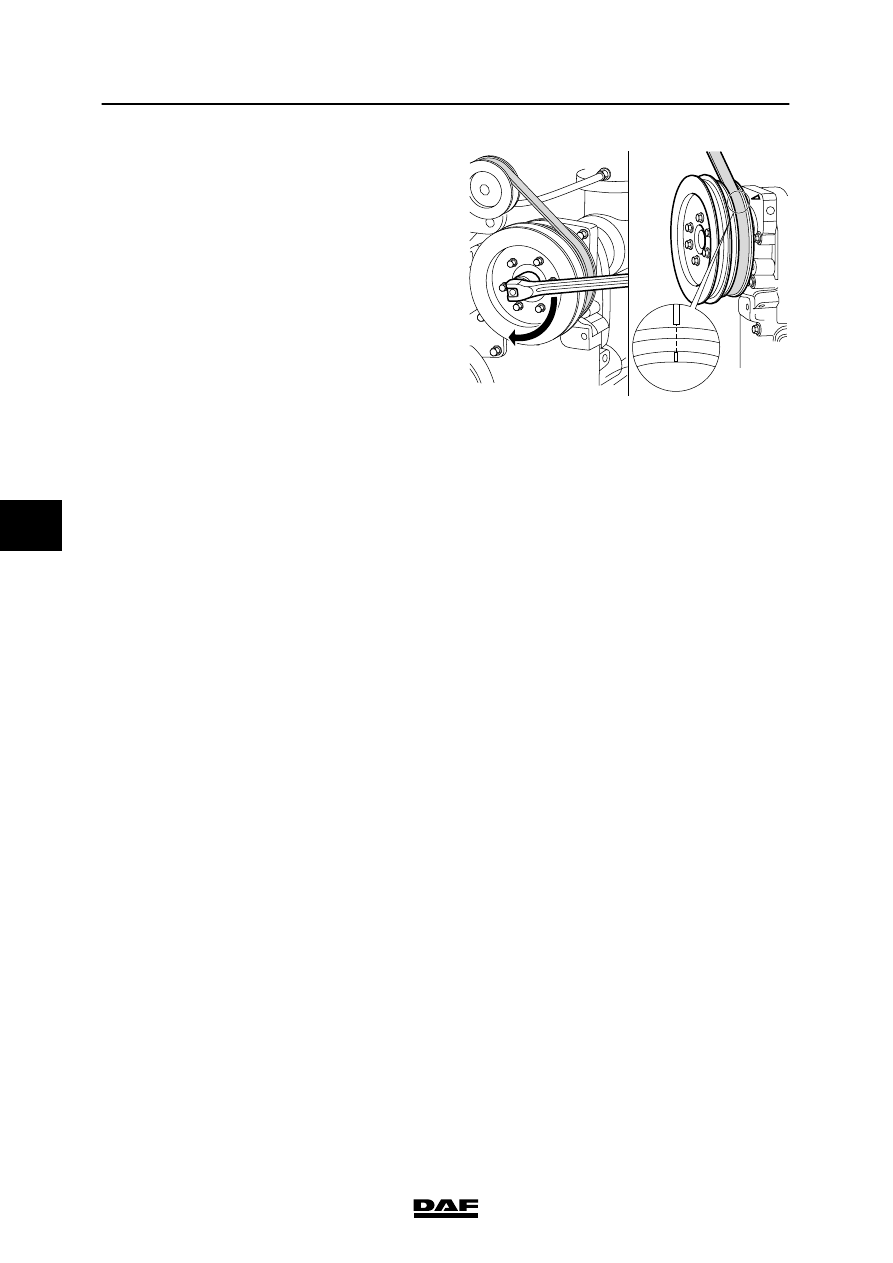

5.

Tighten the rocker-housing attachment

bolts, in the order shown in the diagram, to

the specified torque. See “Technical data”.

M2144

4

2

5

3

1

6

7

8

6.

Tighten the attachment bolts of the unit

injectors to the specified torque, see

“Technical data”.

M2145

5

200424

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

Inspection and adjustment

3-10

7.

Rotate the drive pulley (in the direction of

rotation of the crankshaft) using the

attachment nut on the pulley, until the “A”

marking is in line with the marking on the

timing cover.

8.

Check that the inlet and exhaust valves of

cylinder 1 are closed.

Note:

The valves are closed if both rockers can be

moved from side to side.

If necessary, rotate the drive pulley through

360

_ until the “A” marking is once again in

line with the marking on the cylinder block.

9.

Now adjust the valve clearance and the unit

injector of cylinder 1.

10. Repeat this adjustment procedure for the

remaining cylinders. Consult the following

table to this end.

Marks on drive pulley:

Adjustment of inlet and exhaust valves and

unit injectors of cylinder:

A

1 or 6

B

5 or 2

C

3 or 4

11. If required, fit the C-brake, see chapter

“Removal and Installation”.

12. Fit the valve covers. See “Removal and

installation”.

A

M2142

5

200424

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-11

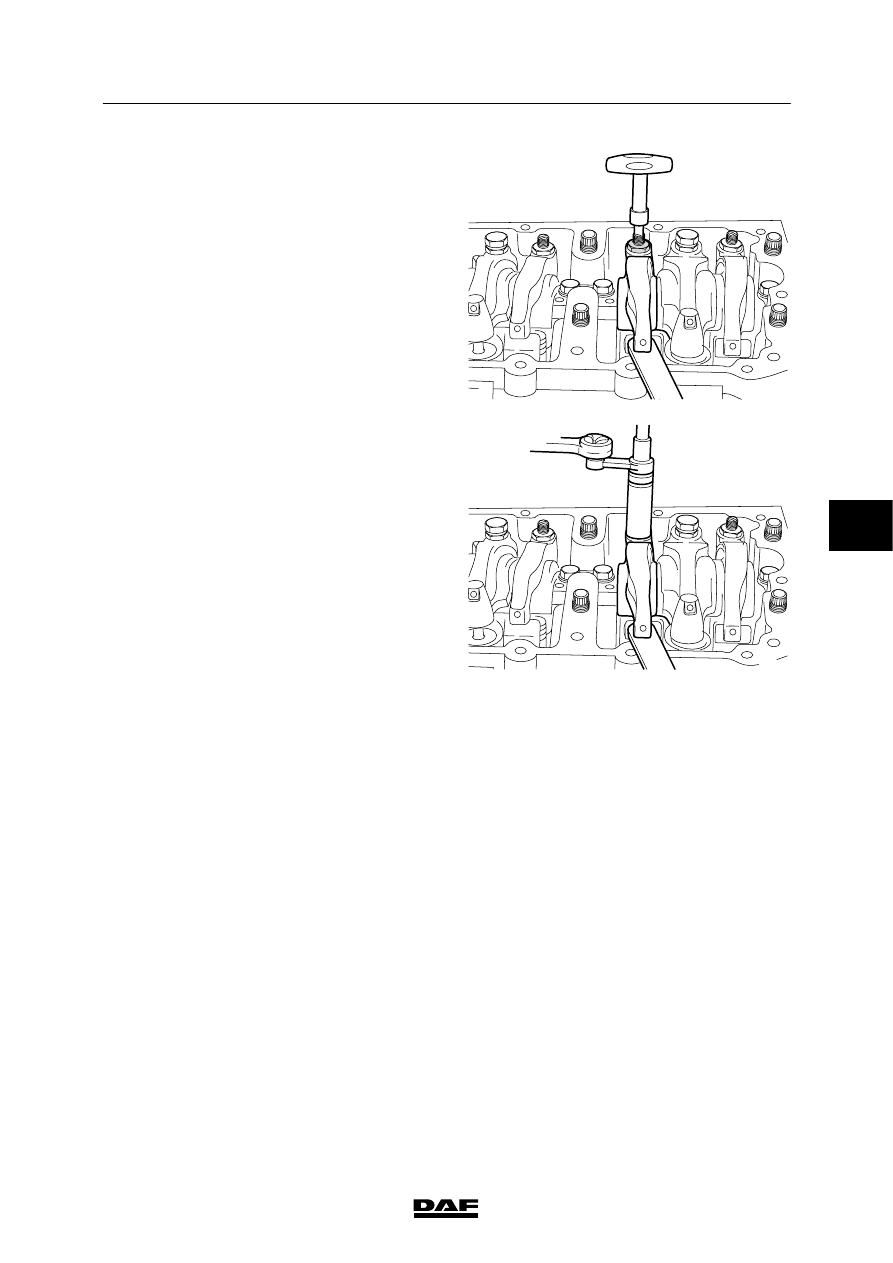

Adjusting the valve clearance

1.

Slacken the lock nut of the adjusting bolt.

2.

Using a feeler gauge and special tool (DAF

no. 1240043), adjust the specified valve

clearance, see “Technical data”.

3.

Tighten the adjusting bolt using special tool

(DAF no. 1240043) before removing the

feeler gauge.

The specified torque is 0.56 - 0.68 Nm.

M2140

4.

Hold the adjusting bolt in this position, and

tighten the lock nut using special tool (DAF

no. 1240042) to the specified tightening

torque, see “Technical data”.

M2141

5

200424

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст