DAF 95XF. Manual — part 616

8

HYDRAULIC LIFTING GEAR

Disassembly and assembly

5-6

5.3 DISASSEMBLY AND ASSEMBLY, CYLINDER

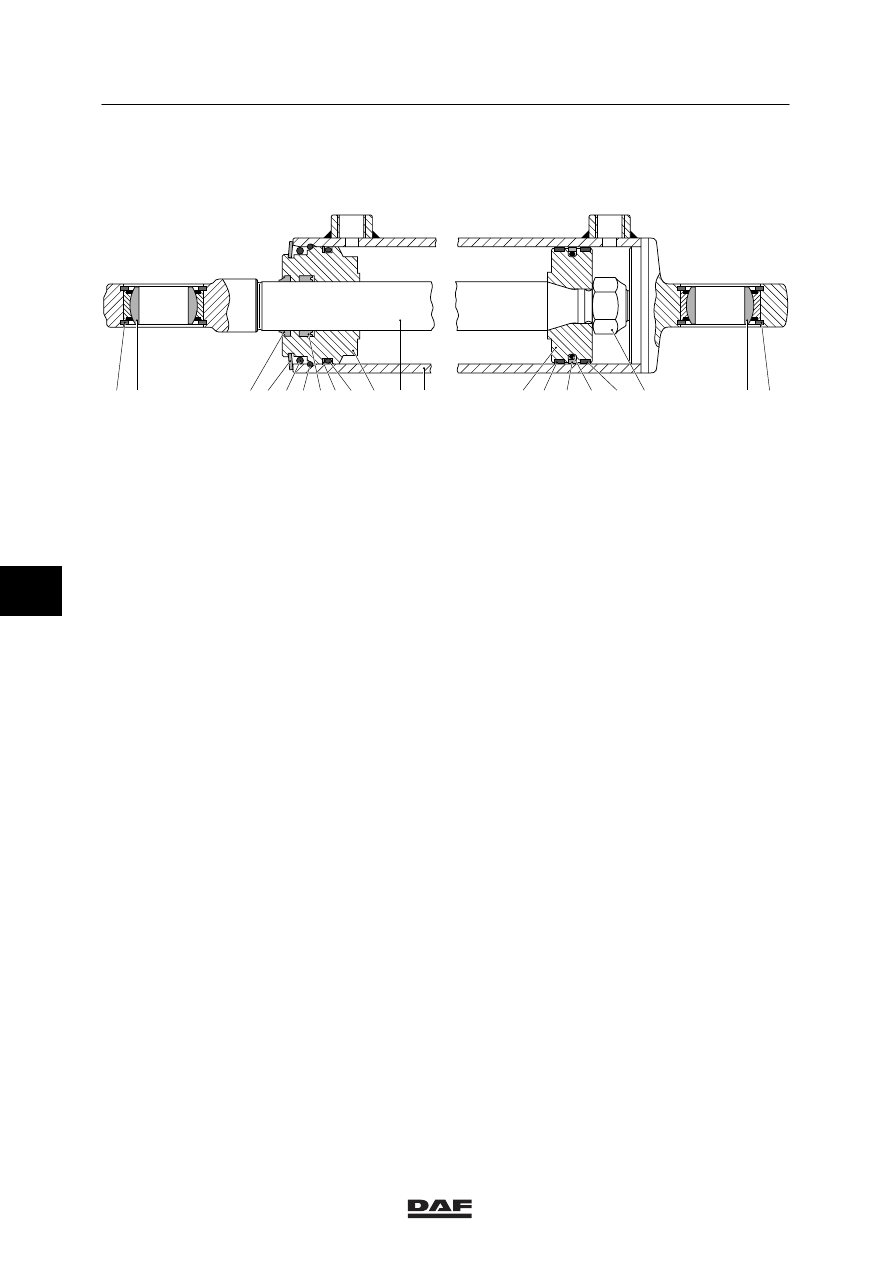

1 2

1

2

11 12

13 14 15 16 17 18

3 4 5 6

8 9

A

B

10

7

A8 00 248

Disassembly of the cylinder

1.

Remove the cylinder from the vehicle, see

the chapter “Removal and installation”.

2.

Check whether all the oil has been drained

from the cylinder.

3.

Clean the cylinder before disassembly.

Work in very clean conditions. Make sure

that the piston rod is not damaged during

the repair or maintenance activities.

4.

Remove the circlips (1) and push the

bearing (2) from the eye.

5.

Remove the circlip (4).

6.

Remove the dirt which has collected before

the O ring (5) and remove the O ring (5).

7.

Use a plastic mallet to tap the piston-rod

guide (10) deeper into the cylinder, until the

spring clip (6) can be removed. Make sure

that the piston rod is not damaged in the

process.

8.

Remove the spring clip (6) from the cylinder.

9.

Pull the entire length of the piston rod (11)

out of the cylinder. The piston-rod guide

(10) will come out of the cylinder together

with the piston rod.

10. Remove the plastic rings (14) and (16) from

the piston.

6

ǹ 0001

8

Disassembly and assembly

HYDRAULIC LIFTING GEAR

5-7

11. Remove the nut (18) and use a plastic

mallet to tap the piston (13) from the piston

rod.

12. Slide the piston-rod guide (10), the O ring

(5) and the circlip (4) from the piston rod.

Pay attention to the position of the circlip.

13. Remove the dirt scraper (3), sealing ring

(7), O ring (9) and plastic ring (8) from the

piston rod guide.

14. Remove the sealing ring (15) and the O ring

(16) below from the piston.

Assembly of the cylinder

1.

Check the sealing-ring chambers and

recesses, the dirt scraper and O rings for

impurities.

Check the surfaces of the piston rod and

the cylinder casing for signs of wear and/or

damage. Even the slightest damage can

cause a leak.

Check the condition of the spring clip (6)

and the circlip (4). Replace these, if

necessary.

Replace the sealing rings, dirt scraper and

O rings.

Apply a layer of grease to the O rings and

running surfaces of the sealing rings and

dirt scraper prior to assembly.

2.

Install the O ring (16) to the piston (13).

3.

Heat the new sealing ring (15) for 5 minutes

in water at a temperature of 90

_C.

4.

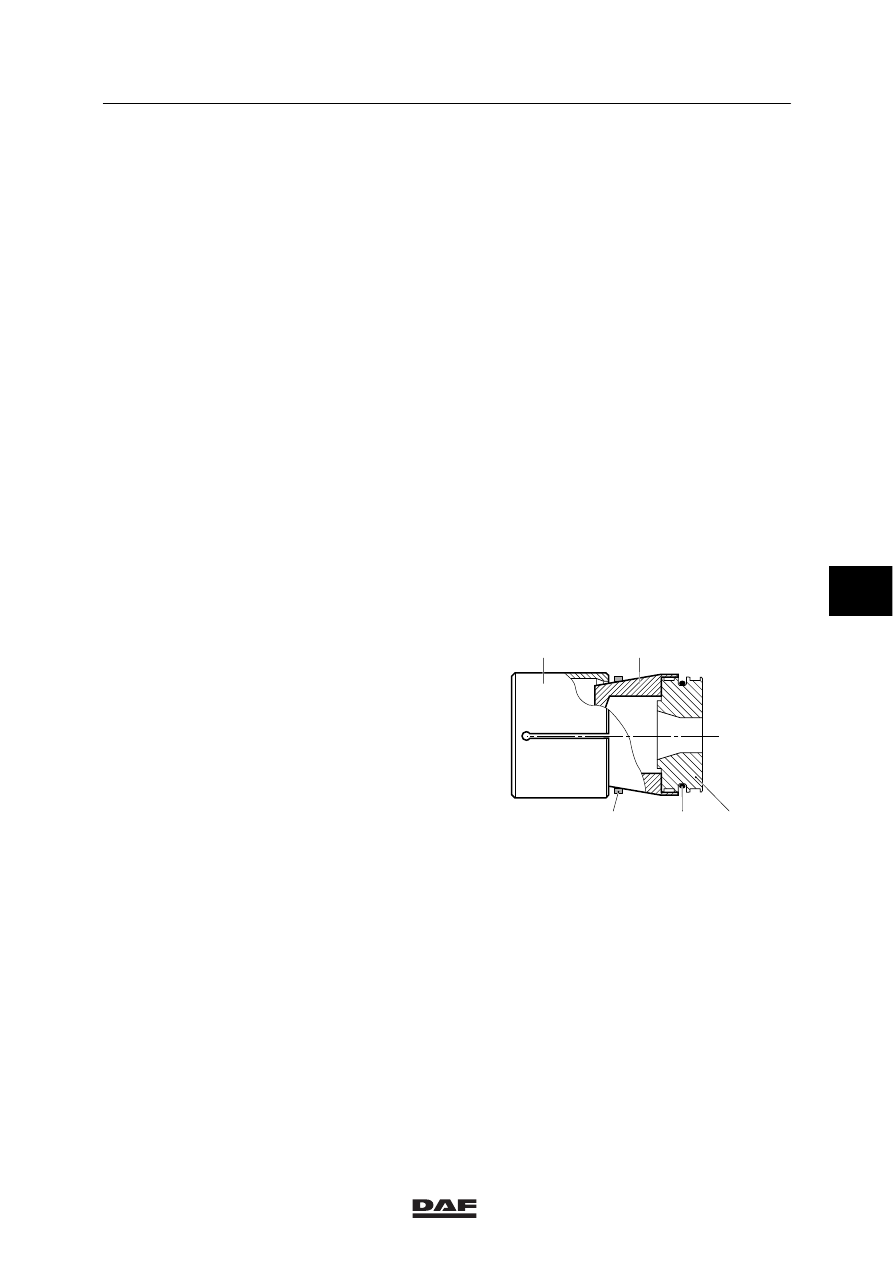

Fit the special tool (DAF no. 1310472), see

“b” in the illustration, on the piston (13).

5.

Slide the heated sealing ring (15) onto the

piston using special tool

(DAF no. 1310473), see “a” in the

illustration.

13

15

16

b

a

A8 00 260

6

ǹ 0001

8

HYDRAULIC LIFTING GEAR

Disassembly and assembly

5-8

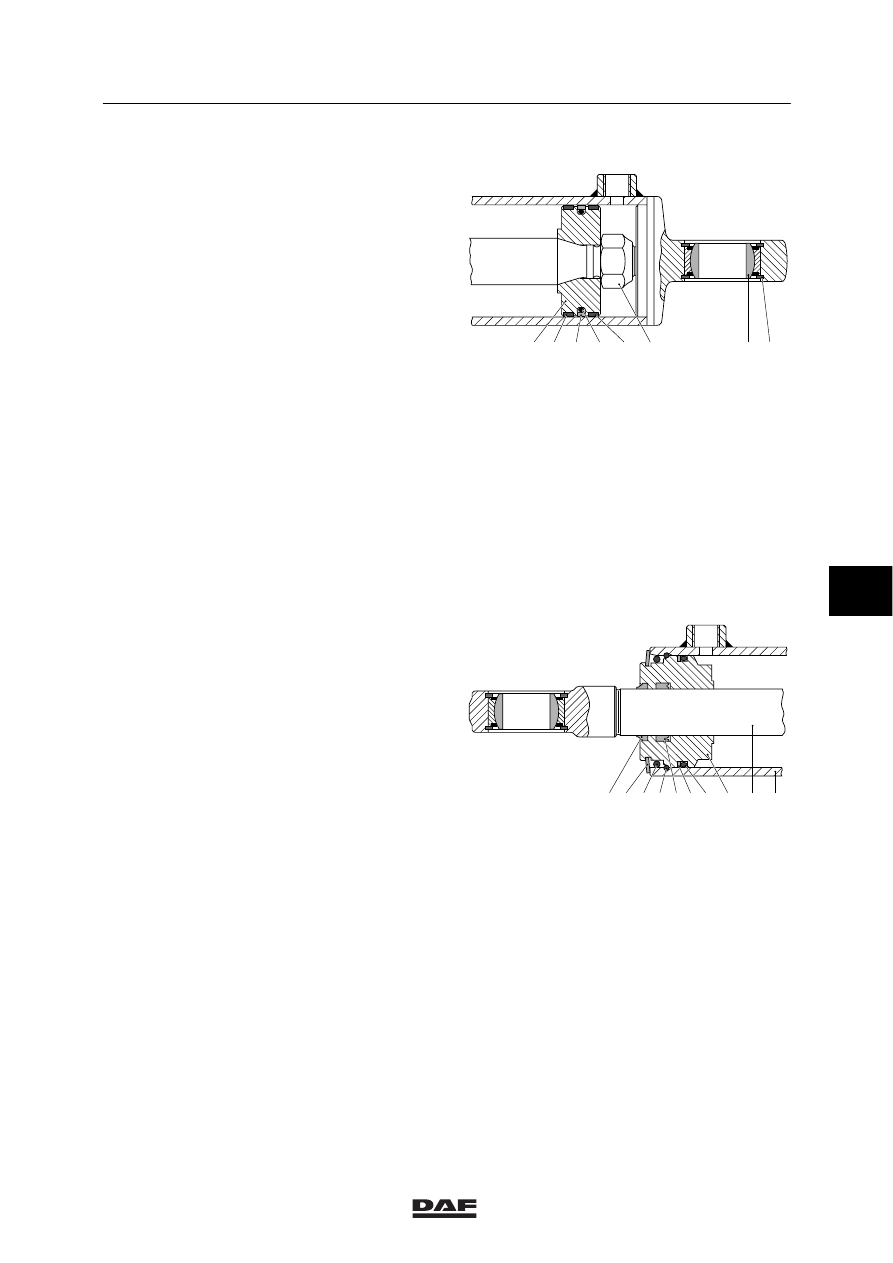

6.

Fit the special tool (DAF no. 1310474), see

“c” in the illustration, over the sealing ring

(15) and leave the special tool on the

sealing ring for 5 minutes.

7.

Install the sealing ring (7) with the recess

aimed towards the piston (13) into the

piston-rod guide (10). To do so, press the

sealing ring together as shown in the

illustration. Make sure that no sharp corners

are formed.

Subsequently, press the sealing ring into

the chamber of the piston-rod guide as

shown in the illustration.

8.

Install the dirt scraper (3) into the piston-rod

guide (10).

You should proceed in the same manner as

when installing the sealing ring (7).

9.

Install the plastic ring (8) onto the piston-rod

guide (10).

You should proceed in the same manner as

when installing the sealing ring (15) on the

piston.

10. Install the O ring (9) onto the piston-rod

guide (10). The O ring should fall into the

groove at the piston side. The plastic ring

(8) is positioned on the circlip side.

11. Slide the circlip (4) into the correct clamping

position over the piston rod.

12. Slide the O ring (5) over the piston rod.

13. Oil the piston rod (11) and slide the

piston-rod guide (10) onto the piston rod.

13

15

16

c

A8 00 261

A8 00 262

A8 00 263

6

ǹ 0001

8

Disassembly and assembly

HYDRAULIC LIFTING GEAR

5-9

14. Install the piston (13) on the piston rod,

replace the self-locking nut (18) and tighten

the nut to the prescribed tightening torque,

see main group “Technical data”.

15. Apply some oil to the cylinder casing.

16. Install the plastic rings (14) and (17) on the

piston. The gap openings of the rings

should be opposite each other. During the

installation of the piston in the cylinder, the

gap openings may not be positioned near

line connection A of the cylinder.

17. Apply some oil to the plastic rings (14) and

(17) and the sealing ring (15) and slide the

piston into the cylinder. When sliding the

piston into the cylinder, the plastic rings

should be pressed into the grooves.

18. Slide the piston-rod guide (10) into the

cylinder and tap the piston-rod guide

carefully into the cylinder using a plastic

mallet until the spring clip (6) can be fitted.

Make sure that the piston rod is not

damaged in the process.

19. Fit the spring clip (6) into the cylinder. Make

sure that the entire circlip is positioned

correctly in the groove.

20. Pull back the piston-rod guide (10) using the

piston rod, until the piston-rod guide is in

contact with the spring clip (6).

21. Fit the O ring (5).

22. Install the circlip (4). Make sure that the

entire circlip is positioned correctly in the

groove.

23. Install one of the circlips (1) and press a

new bearing (2) into the eye.

24. Install the second circlip (1).

25. Check the cylinder for internal and external

leakage, see chapter “Inspection and

adjusting”.

1

2

13 14 15 16 17 18

B

A8 00 286

11 12

3 4 5 6

8 9

A

10

7

A8 00 285

6

ǹ 0001

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст