DAF 95XF. Manual — part 122

6

Description of components

DESCRIPTION OF BRAKE COMPONENTS

1-25

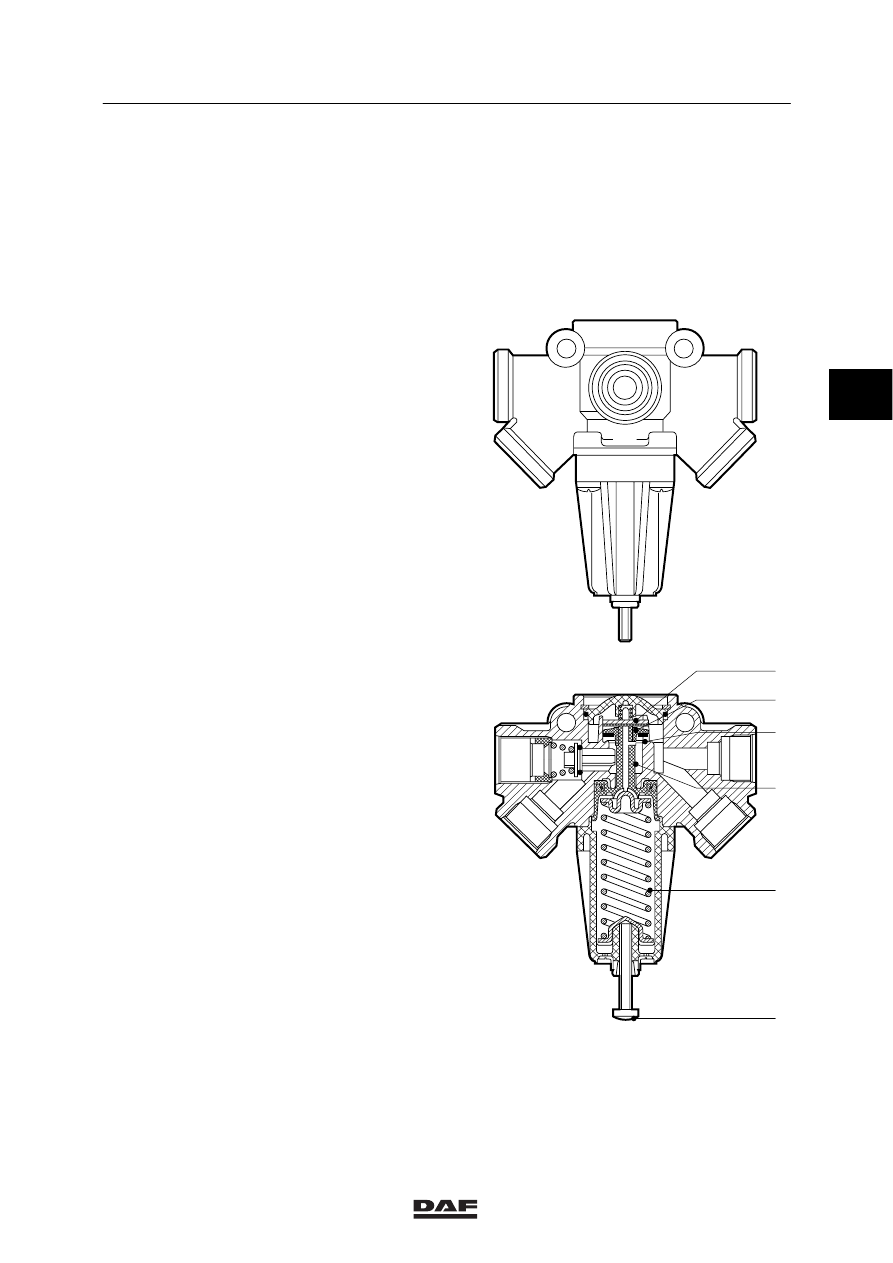

1.13 PRESSURE-RELIEF VALVE WITH NON-RETURN VALVE

Purpose

The purpose of the pressure-limiting valve with

non-return valve is to limit the output pressure to

a specified preset value (8 bar).

Lower pressures are passed unreduced. This

valve also includes a non-return valve for

circuit 3 of the brake system.

Operation

Compressed air is input at connection

number 12 (maximum system pressure).

The storage reservoir for circuit 3 is filled via

port 11.

At port numbers 21, 22 and 23, the

pressure-limited air is once again bled. If the

exhaust air has not yet reached the limit value,

piston-shaped valve (2) is open.

When the pressure at the piston-shaped

valve (2) reaches the limit set by the adjusting

screw (6), valve (2) will be forced downwards

against the pressure of spring (5), until it

contacts seat (3).

No air can now pass.

If pressure at ports (21), (22) and (23) exceeds

that at ports 11 and 12, via an opening in

piston (4), the pressure will raise spring-loaded

seal (1), from piston-shaped valve (2). As a

result the air can flow back to ports (11) and

(12).

R600226

11

2

3

6

5

12

23

21

22

1

4

3

ǹ 0006

6

DESCRIPTION OF BRAKE COMPONENTS

Description of components

1-26

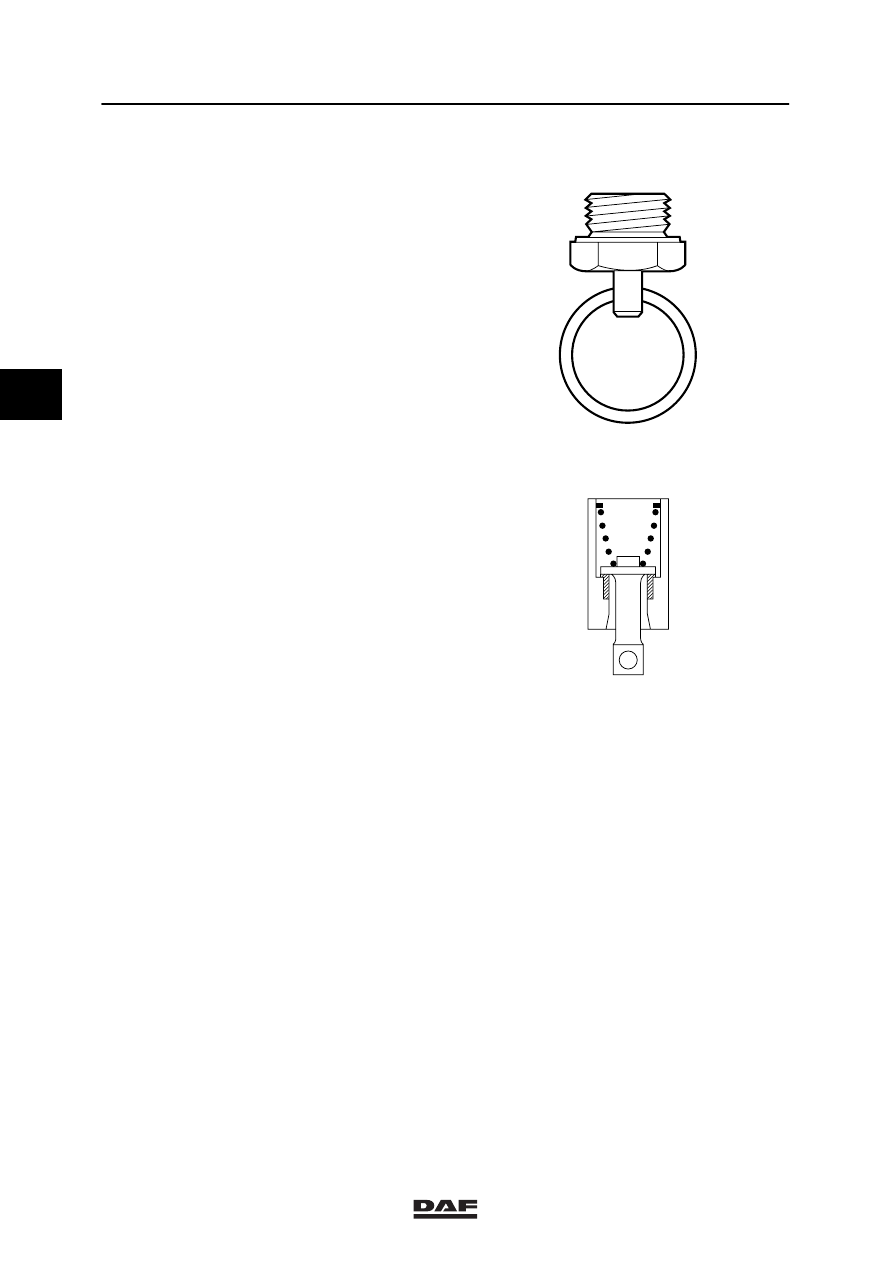

1.14 WATER BLOW-OFF VALVE

Purpose

The purpose of the water blow-off valve is to

enable any condensate in the air reservoir or air

lines to be drained and, if necessary, to vent the

system.

Operation

The valve is kept closed by the spring and the

reservoir pressure. By pushing the pin

sideways, the valve is lifted off the seat, allowing

condensate and compressed air to escape.

When the pin is released, the valve is closed.

Check that no other components are present

under the blow-off plug, as these could be

fouled during the blow-off process.

R600046

3

ǹ 0006

6

Description of components

DESCRIPTION OF BRAKE COMPONENTS

1-27

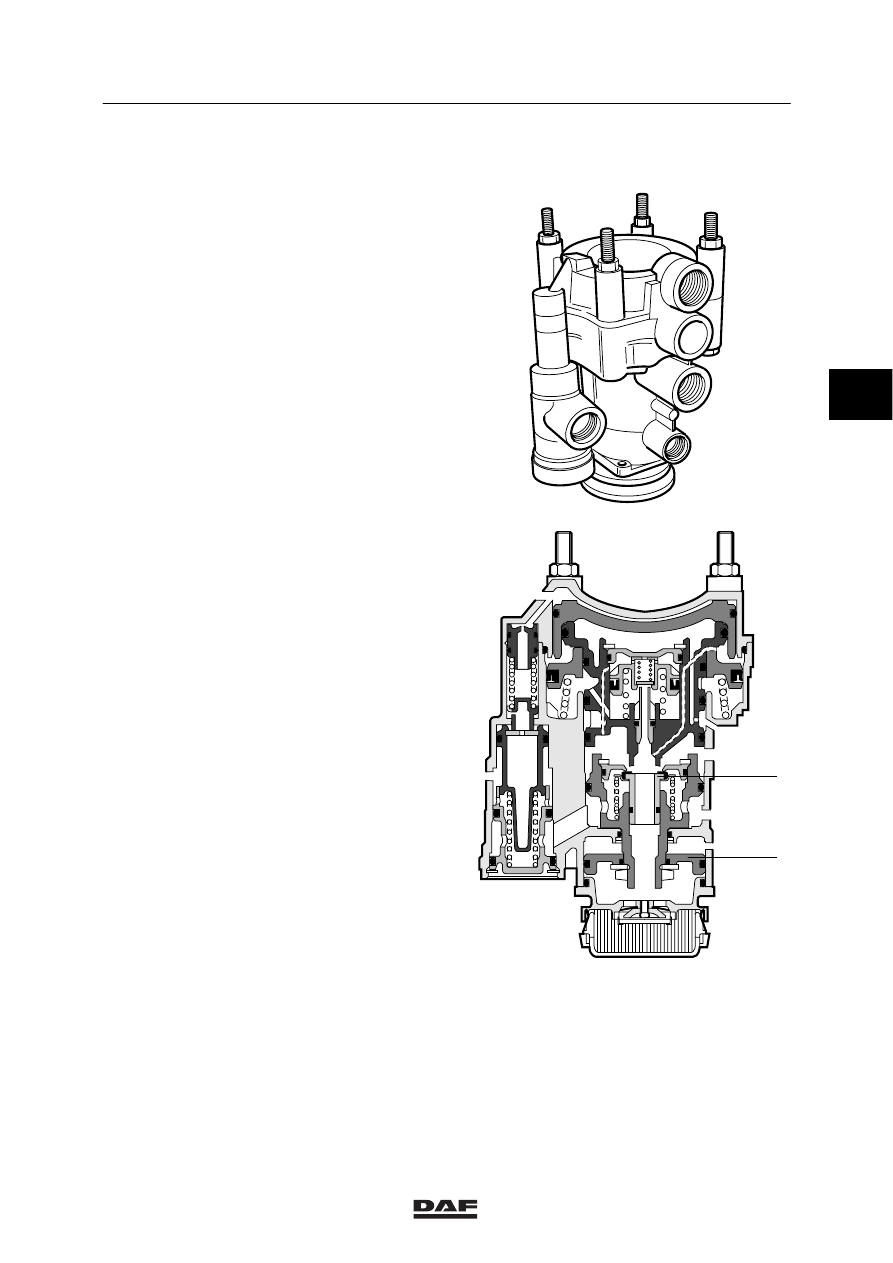

1.15 (SEMI-)TRAILER-REACTION VALVE

WABCO design

Purpose

The purpose of the trailer-reaction valve is to

pass on the brake commands from the tractor to

the (semi-)trailer.

Operation

Driving

Port (11) is connected with a reservoir, and

port (43) with the parking-brake valve. Both are

pressurised and in a state of balance. The

service -coupling head is connected via port (22)

and exhaust valve (2), and vent (3), to the

atmosphere.

R600157

R600122

2

1

42

22

12

43

3

11

41

3

ǹ 0006

6

DESCRIPTION OF BRAKE COMPONENTS

Description of components

1-28

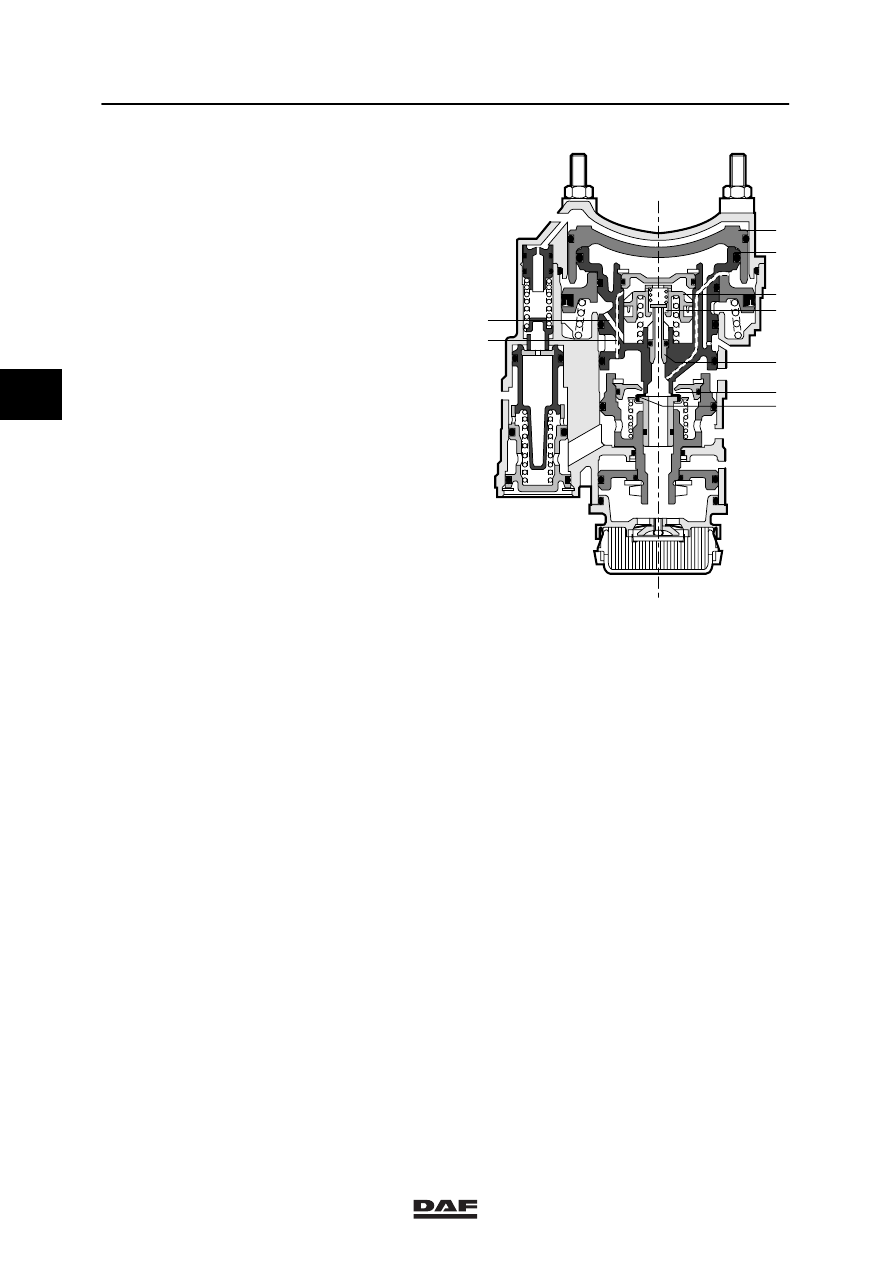

Braking with the service brake

Pressure build-up

With the service-brake valve, circuit 1, port (41),

and circuit 2, port (42), are pressurised.

This will force pistons (4) and (5) downwards,

closing exhaust valve (2) and opening inlet valve

(3). The reservoir pressure at port (11) can now

flow via inlet valve (3) to port (22), (yellow)

(semi-)trailer service-coupling head, and will

cause the (semi-)trailer to brake.

Regulating

When a preset value has been reached in the

output pressure at port (22), this pressure will

once again force pistons (4) and (5) upwards,

thus closing inlet valve (3).

There is now a state of balance between the

input pressure at port (41), and output pressure

at port (22).

Releasing

When the service-brake valve is released, the

input pressure at ports (41) and (42) falls away.

Pistons (4) and (5) are forced upwards, by the

output pressure at port 22.

As a result, inlet valve (3) is closed, and exhaust

valve (2) opened, thus linking port (22) with the

exhaust.

R600123

3

9

5b

5a

2

4

5

6

7

42

22

12

43

11

41

3

ǹ 0006

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст