DAF 95XF. Manual — part 142

6

Removal and installation

BRAKE COMPONENTS

2-7

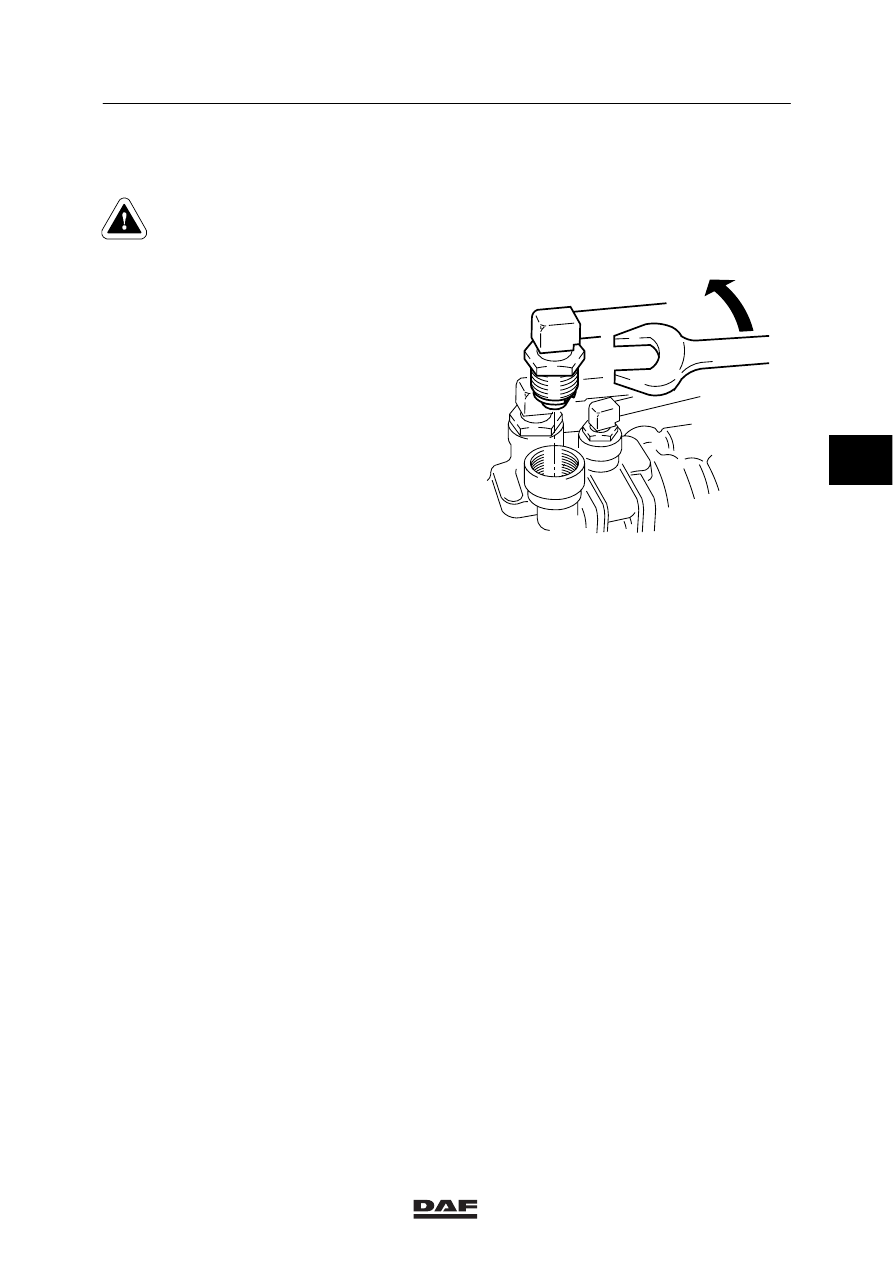

Removing a complete quick-release

coupling from a valve

Be sure to depressurise the

relevant port before removing any

lines and/or quick-release

couplings.

1.

Loosen the socket using an open-end

spanner.

2.

Remove the socket and the hose adapter

as a whole from the valve.

Installing a complete quick-release coupling

in a valve

1.

Check the bore hole for dirt and clean the

bore hole if necessary.

2.

Note:

If the plug is not removed from the socket,

the entire quick-release coupling (plug and

socket) can be reinstalled as a whole. The

socket does not have to be replaced.

Grease the O-ring with brake grease

(DAF no. 1250185).

3.

Tighten the socket to the specified

tightening torque, see main group

“Technical data”.

R600367

4

ǹ 0006

6

BRAKE COMPONENTS

Removal and installation

2-8

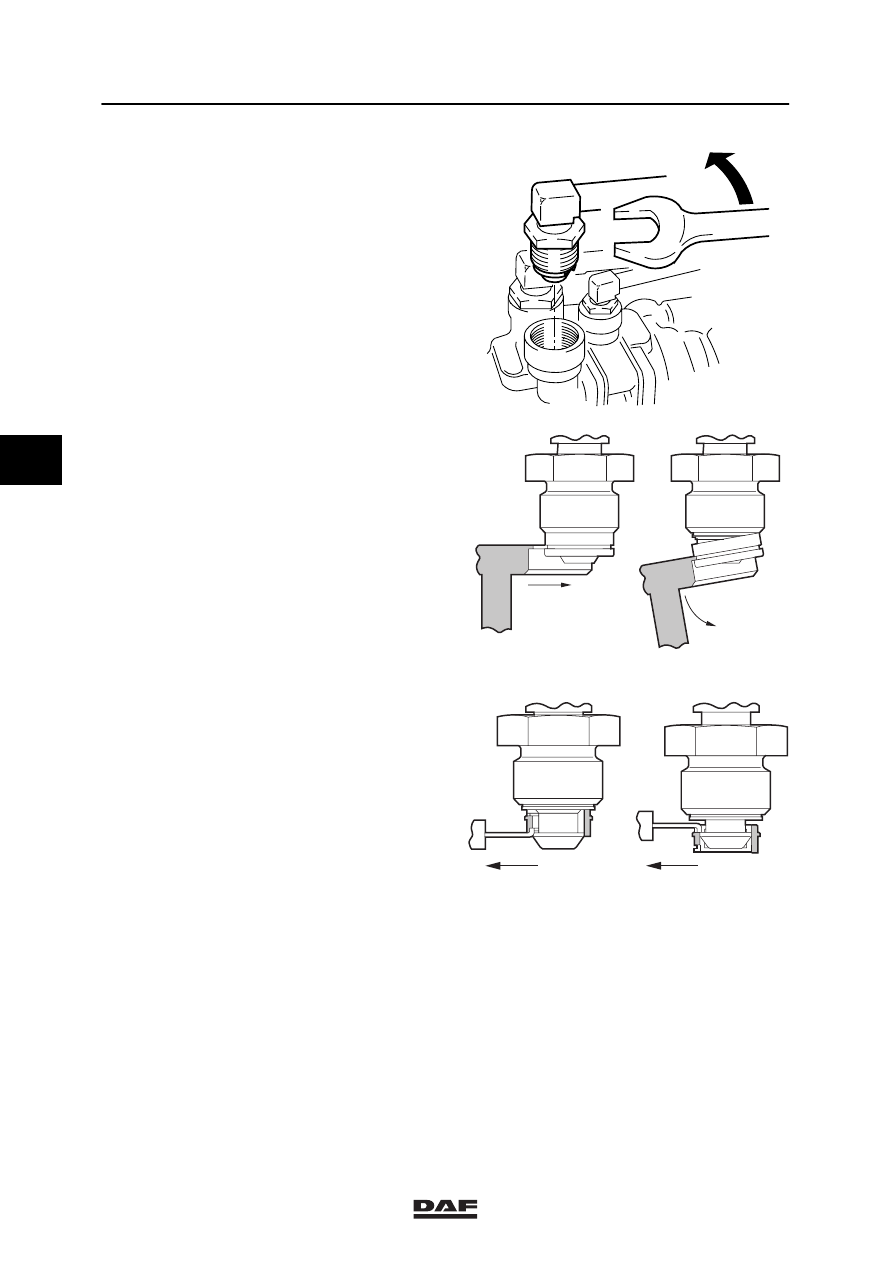

Removing the plug from the socket

1.

Remove the entire quick-release coupling

from the valve.

Note:

Make sure not to damage the plug while

removing sleeve, circlips and retaining ring.

2.

Remove the sleeve using the special tool

(DAF no. 1329459).

3.

Remove the retaining ring and the two

circlips using the special tool

(DAF no. 1329549).

4.

Remove the plug from the socket

R600367

R600368

R600369

4

ǹ 0006

6

Removal and installation

BRAKE COMPONENTS

2-9

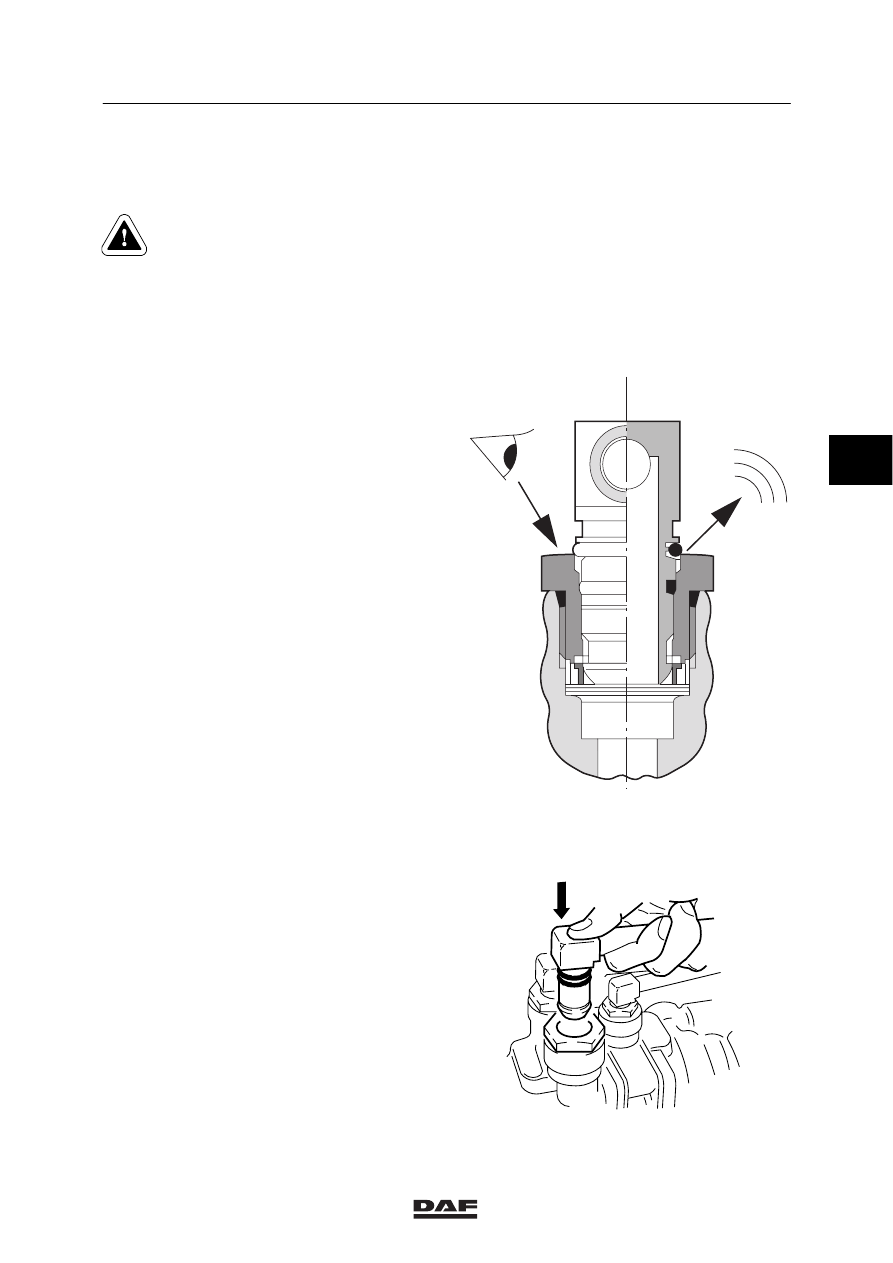

Installing the plug in the socket

1.

Check the bore hole for dirt and clean the

bore hole if necessary.

If the plug is removed from the

socket, the socket must always be

replaced. This is supplied complete

with retaining rings, circlips and

sleeve.

2.

Install the new socket in the valve and

tighten to the specified tightening torque,

see main group “Technical data”.

3.

Check the O-rings of the plug for damage

and replace if necessary.

Note:

If the upper O-ring is still visible, the

connection is not fully locked. Furthermore,

air will audibly escape if pressure is

present.

4.

Install the plug in the socket and check if

the connection is fully locked by pulling it

directly upwards.

R600366

W602006

4

ǹ 0006

6

BRAKE COMPONENTS

Removal and installation

2-10

STANDARD COUPLINGS

Removal of connection pieces with hose

adapter

Cut off the line close to the connection piece.

Remove the section of line attached to the

connection piece by heating, and not by cutting

along its length. The latter could cause damage

to the hose adapter and lead to leakage.

Connecting the connection pieces with the

hose adapter

1.

If a hose adapter has already been fitted on

the end of the line, first cut off this section

of line.

2.

Ensure that the line is long enough.

Replace as necessary.

3.

On no account heat the pipe.

4.

Use a special gripping device to clamp the

pipe (DAF no. 0694829, for line diameters

6, 8, 10 and 12 mm).

5.

Enter the line from the side with the

smallest bore into the gripping device. On

the other side of the grip, there is then

sufficient room to permit expansion of the

line.

6.

The banjo union or nipple can now be

tapped into the pipe with little difficulty using

a plastic mallet.

Leaky line connections

-

If a compression coupling is leaky, the

union nut may only be turned a half turn

tighter, and only once.

-

If the leak has not been corrected, the

connection must be removed and checked

for damage or fouling.

-

If necessary, replace the complete

connection.

-

Leaky banjo unions may not be made extra

tight. Check for damage or fouling. If

necessary, replace the connection.

4

ǹ 0006

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст