DAF 95XF. Manual — part 542

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

Inspection and adjustment

3-44

3.37 CHECKING THE OPERATION OF THE DIFFERENTIAL LOCK

1.

Jack up the rear axle and support it on

stands.

2.

Bring the air system to operating pressure.

3.

Engage the differential lock. The warning

lamp should now come on.

4.

Check whether there is a “rigid” connection

between the driven wheels.

5.

Disengage the differential lock. The warning

lamp should not light up and the “rigid”

connection between the driven wheels

should be broken.

M8031

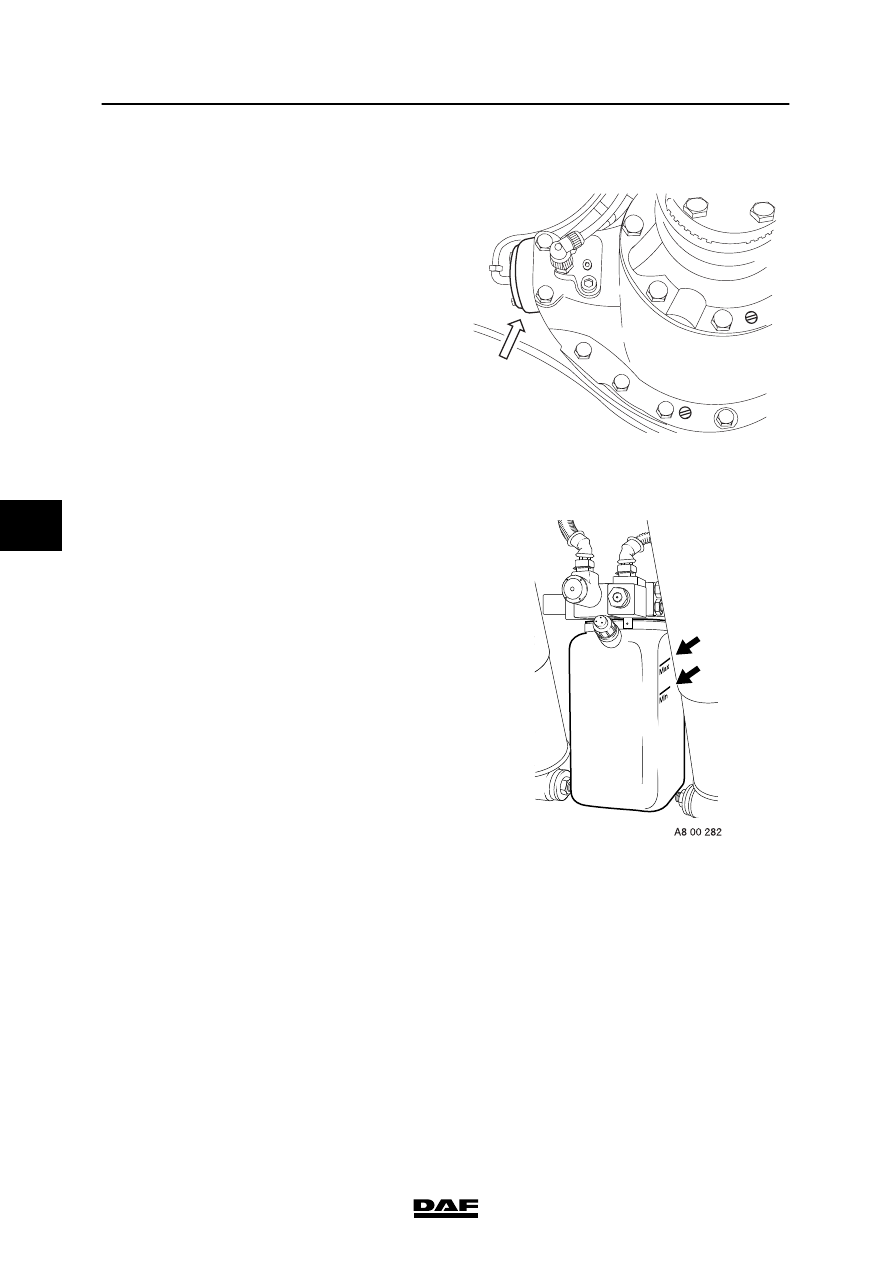

3.38 CHECKING THE FLUID LEVEL IN THE HYDRAULIC LIFTING GEAR

1.

Make sure that the trailing axle wheels are

fully lowered and on the ground.

2.

Check the fluid level.

The fluid level must be between the “min.”

and “max.” level marks. If necessary, top

up.

5

200424

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-45

3.39 CHECKING THE PIVOTS OF THE AXLE SUSPENSION, AIR SUSPENSION

Torque rod

1.

Check the attachment of the torque rod and

torque rod supports.

2.

Check the pivots of the torque rod for wear

and play.

Stabiliser bar

1.

Check the attachment of the stabiliser bar

and stabiliser bar support.

2.

Check the pivots of the stabiliser bar for

wear and play.

Ball joint of triangular link

1.

Check the attachment of the ball joints and

three--point fixation support.

2.

Check the ball joint housing for surface

cracks.

3.

Check the dust cover for damage.

5

200424

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

Inspection and adjustment

3-46

3.40 CHECKIGN THE DRIVE SHAFT PLAY

1.

Check the universal joints and centre

bearing for play and damage.

M3032

2.

Check the sliding clutch for axial and radial

play.

M3019

3.

There must be no clearly noticeable play on

universal joints, centre bearing or sliding

clutch.

M3020

5

200424

Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-47

3.41 CHECKING THE AIR SUSPENSION BELLOWS

1.

Raise the chassis to its highest position

using the remote control.

2.

Clean the air bellows using a cleaning rag

or a soap solution, if required.

3.

Check the air bellows for cracks and

damage. If cracks or damage are found

through which the webbing is visible, the air

bellows should be replaced.

4.

Check the air bellows, bellows seating and

air line connections for leaks.

Check that the air bellows, when in their

highest position and in driving position, do

not rub against air lines etc.

M9040

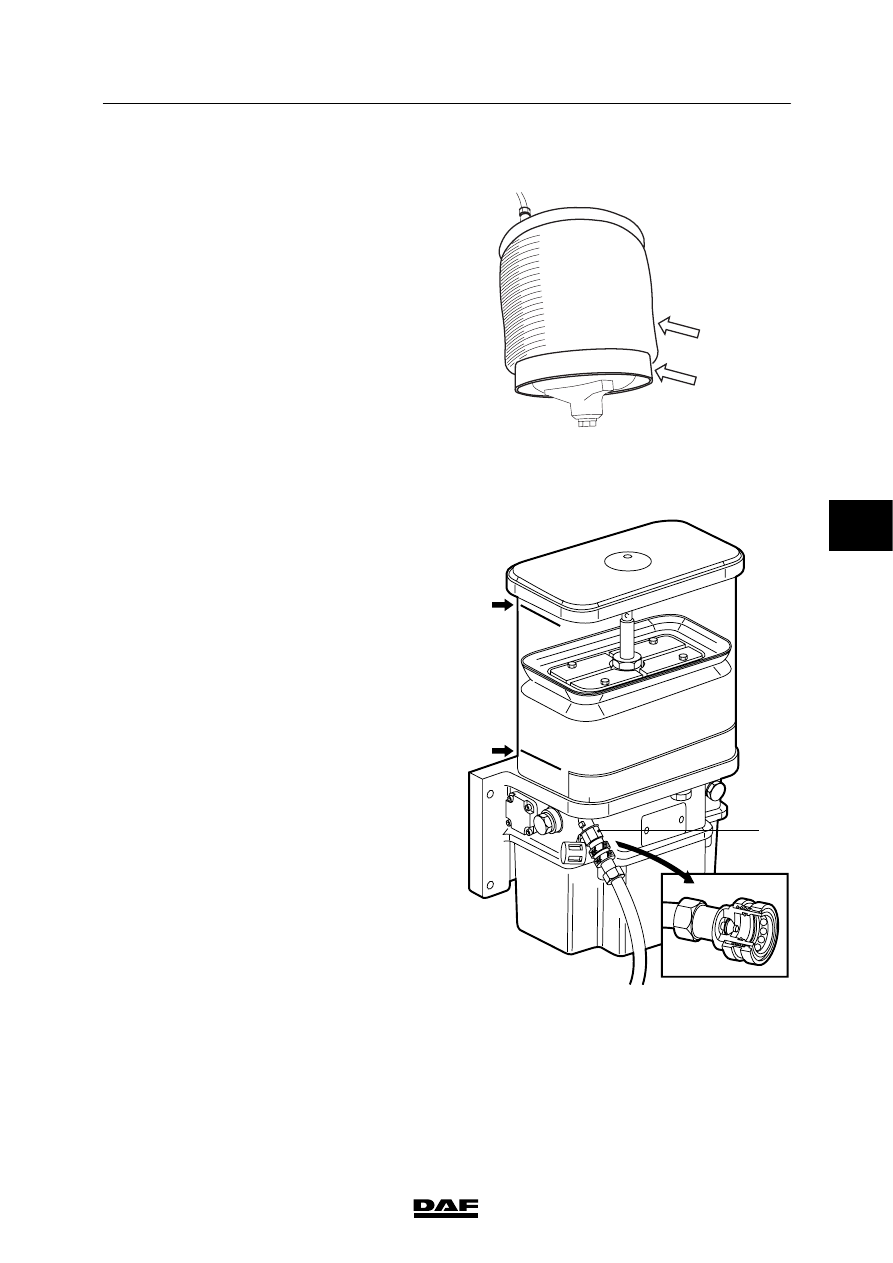

3.42 CHECKING THE OPERATION OF THE AUTOMATIC LUBRICATION SYSTEM

1.

Check the system for line fracture and

operation of the jets.

2.

Check whether all lubricating points are

lubricated.

3.

Check the lubricant level in the reservoir. If

required, top up the reservoir, see chapter

“Draining and filling”.

W 9 07 004

1

5

200424

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст