DAF 95XF. Manual — part 783

9

REAR AXLE ALIGNMENT

Contents

2

6

ǹ 200316

9

General

REAR AXLE ALIGNMENT

1-1

1. GENERAL

1.1 DESCRIPTION OF POSSIBLE CAUSES OF REAR AXLE MISALIGNMENT

2

1

–

–

–

–

–

–

3

4

5

6

–

–

–

–

–

–

–

–

–

–

–

–

–

W9 08 001

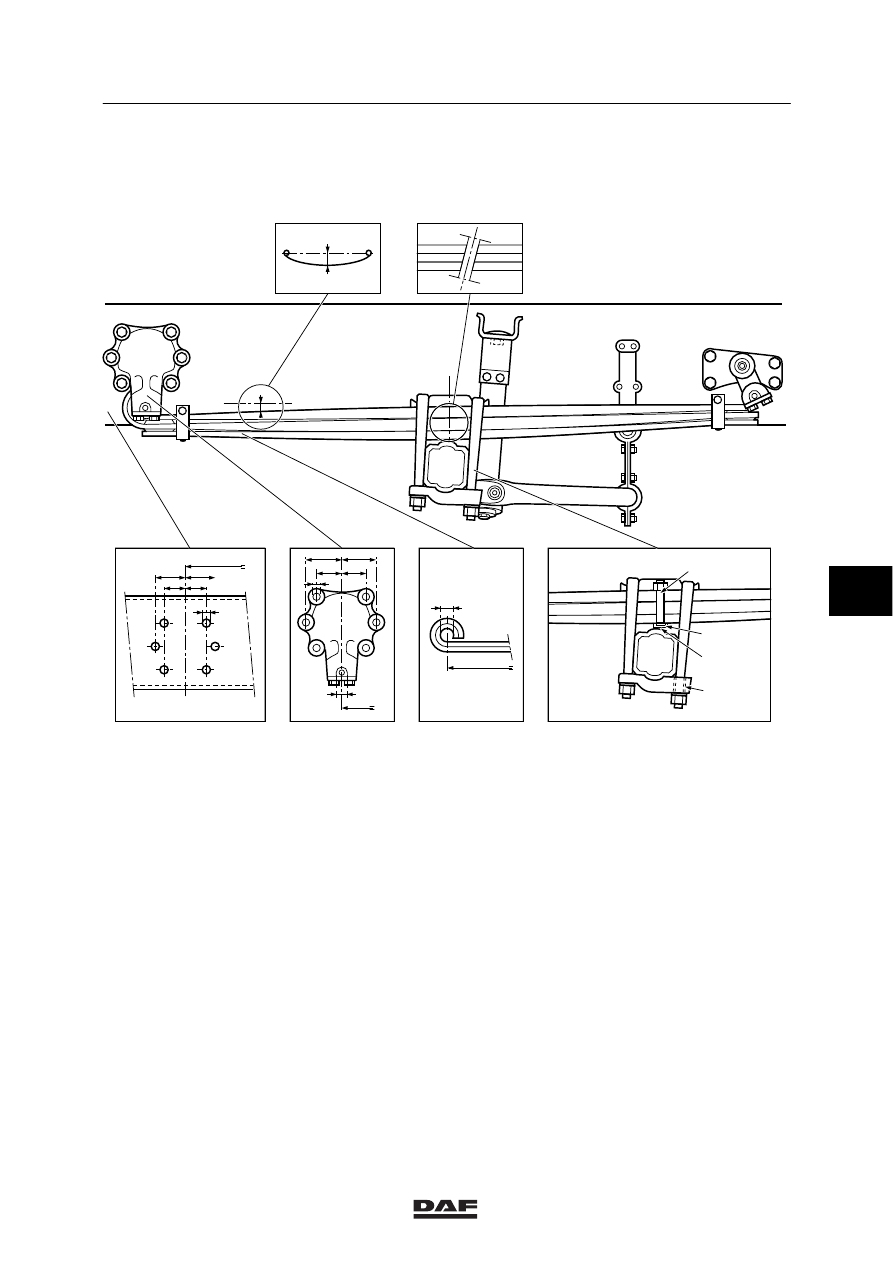

The drawing above shows several factors which

determine the position of the axle under the

vehicle:

1.

Difference in spring opening between the

spring assemblies on the left and right due

to the composition of the spring assemblies

or an unbalanced vehicle load.

2.

Play between the centre bolt and the spring

assembly.

3.

Location of the holes for attachment of the

spring bracket to the chassis.

4.

Dimensions of the spring bracket.

5.

Dimensions of the spring eye.

6.

Installation of spring assembly to the axle

housing.

6

ǹ 200316

9

REAR AXLE ALIGNMENT

General

1-2

Points 2 to 6 are factors determined by the

manufacturer. Generally, the manufacturer will

ensure that the axle is positioned (within tight

tolerances) at an angle of 90

° in relation to the

centreline of the chassis.

Point 1, however, cannot always be controlled

by the manufacturer.

The difference in spring opening, which is

minimal for new spring assemblies, may

increase as a result of the “settling” of the spring

assembly.

Furthermore, the superstructure and vehicle

load may be the cause of a difference in spring

opening and, consequently, misalignment of the

axle.

During spring movement the axle moves

backwards. If the springs on one side deflect

more than on the other side because of an

unbalanced vehicle or superstructure, this side

of the axle will move further backwards than the

other. This may cause misalignment of the axle.

The misalignment of the rear axle(s) may result

in increased tyre wear.

In case of a combination (truck and trailer or a

tractor and semi-trailer), a misaligned trailer or

semi-trailer may cause increased tyre wear on

the drawing vehicle.

6

ǹ 200316

9

Inspection and adjustment

REAR AXLE ALIGNMENT

2-1

2. INSPECTION AND ADJUSTMENT

2.1 INSPECTION AND ADJUSTMENT, AXLE POSITION

General

-

Only use high-quality testing tools for

measurements. They must be calibrated

regularly and preferably be checked before

every measurement.

-

Position the vehicle on a flat and level

surface during the measurement.

-

Work with great accuracy.

-

Check the position of each wheel in relation

to the centreline of the vehicle (twin wheels

are regarded as one wheel).

-

The misalignment of a rear axle is equal to

the average of the individual misalignments

of the left and right wheels.

-

In the case of a vehicle combination (truck

with trailer or tractor with semi-trailer) the

alignment of the combination as a whole

must be checked. A misaligned trailer or

semi-trailer may cause problems for the

tractor.

Inspection of axle position

1.

Make sure that the vehicle load is in

accordance with the vehicle’s normal load

conditions. The load must be at least 40%

of the permissible loading weight and be

evenly distributed over the vehicle.

2.

Drive the vehicle straight to the test location

to avoid stresses in the chassis or in the

axle suspension.

Note:

Avoid braking hard and do not put the

vehicle on the parking brake.

3.

Check the tyre pressure prior to the

measurement. Adjust if necessary.

4.

Check the spring opening of the spring

assembly and check the axle suspension

for play prior to the measurement. Any

defects should be repaired first.

6

ǹ 200316

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст