DAF 95XF. Manual — part 88

2

Disassembly and assembly

XE ENGINE

5-7

Note:

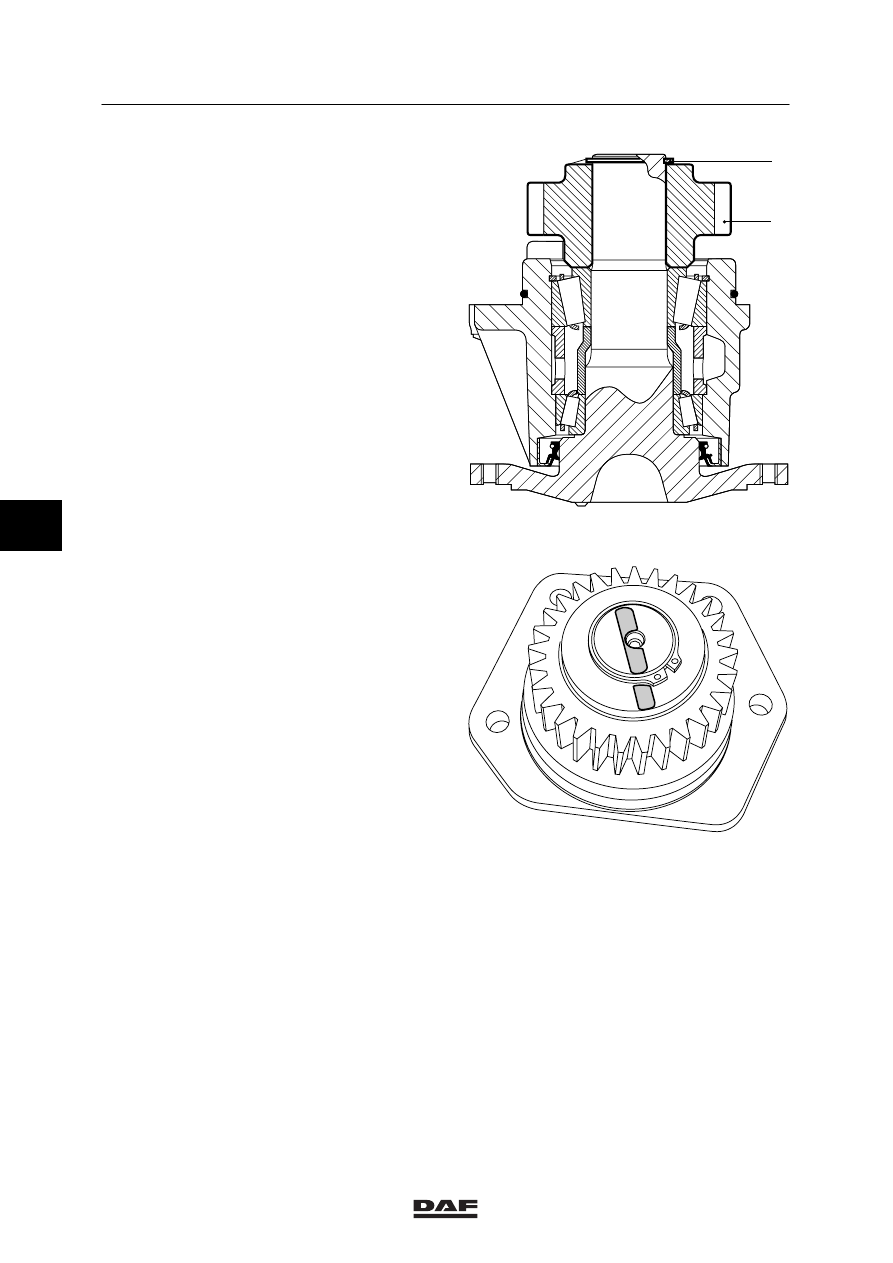

When forcing on the bearing (9), rotate the

bearing housing (11) at least 5 times, allowing

the bearings to settle.

8.

Using a low pressing force and the special

tool (DAF no. 1329382) press the bearing

(9) onto the shaft (1) until it abuts.

9.

Install the circlip (10) in the bearing housing

(11). Install a new O-ring (8).

11

9

1

M200685

8

10

M200686

5

ǹ 0008

2

XE ENGINE

Disassembly and assembly

5-8

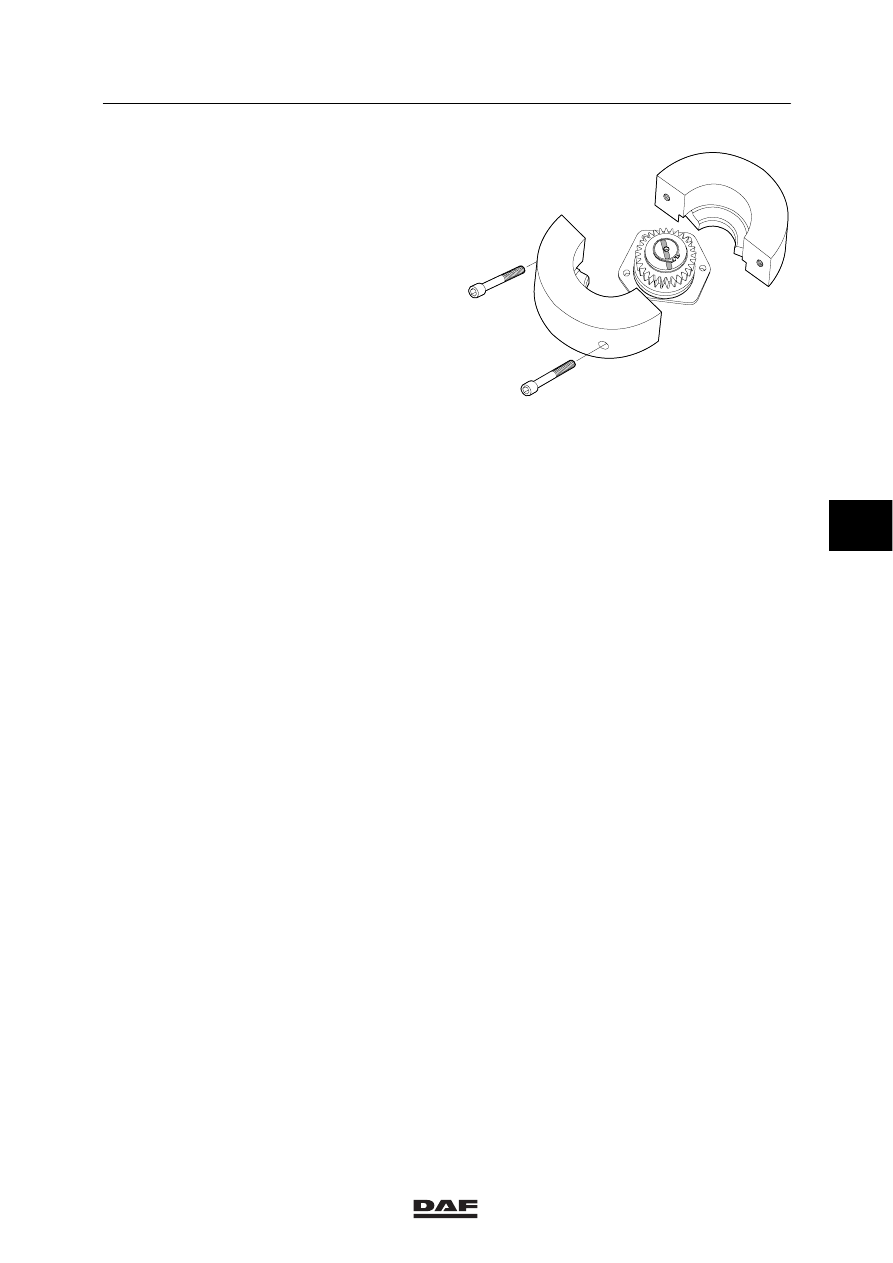

10. Remove any grease and oil from the shaft

(1) and gear wheel (12) local to the contact

areas.

Note:

The gear wheel (12) must not under any

circumstances be exposed to the specified

maximum temperature for more than

30 minutes. This may have a negative

impact on the mechanical properties of the

gear wheel (12).

11. Heat the gear wheel (12) evenly to the

specified temperature in the shortest

possible time (on a hot plate using thermal

pins), see main group “Technical data”.

12. Install the gear wheel (12) onto the shaft

(1). Do not use a press.

13. Fit the circlip (13).

14. Make a marking across shaft (1) and gear

wheel (12). This is necessary to check

during inspection or repair whether the gear

wheel (12) has turned relative to the

shaft (1).

12

13

M200687

M200688

5

ǹ 0008

2

Disassembly and assembly

XE ENGINE

5-9

Inspect

Fit the special tool (DAF no.1329445) under

the gear wheel (12) and press the shaft with

a force of 100 kN. If the shaft is pressed

from the gear wheel, the shaft and/or the

gear wheel is/are rejected.

15. Apply a little engine oil in the bearing

housing (11) and check the shaft (1) for

even rotation.

M200932

5

ǹ 0008

2

XE ENGINE

Disassembly and assembly

5-10

5

ǹ 0008

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст