DAF LF45, LF55 Series. Manual — part 574

8

LF45/55 series

Removal and installation

SINGLE REAR AXLE 5.10

4-5

4.5 REMOVAL AND INSTALLATION, WHEEL-SPEED SENSOR

Removing the wheel-speed sensor

1.

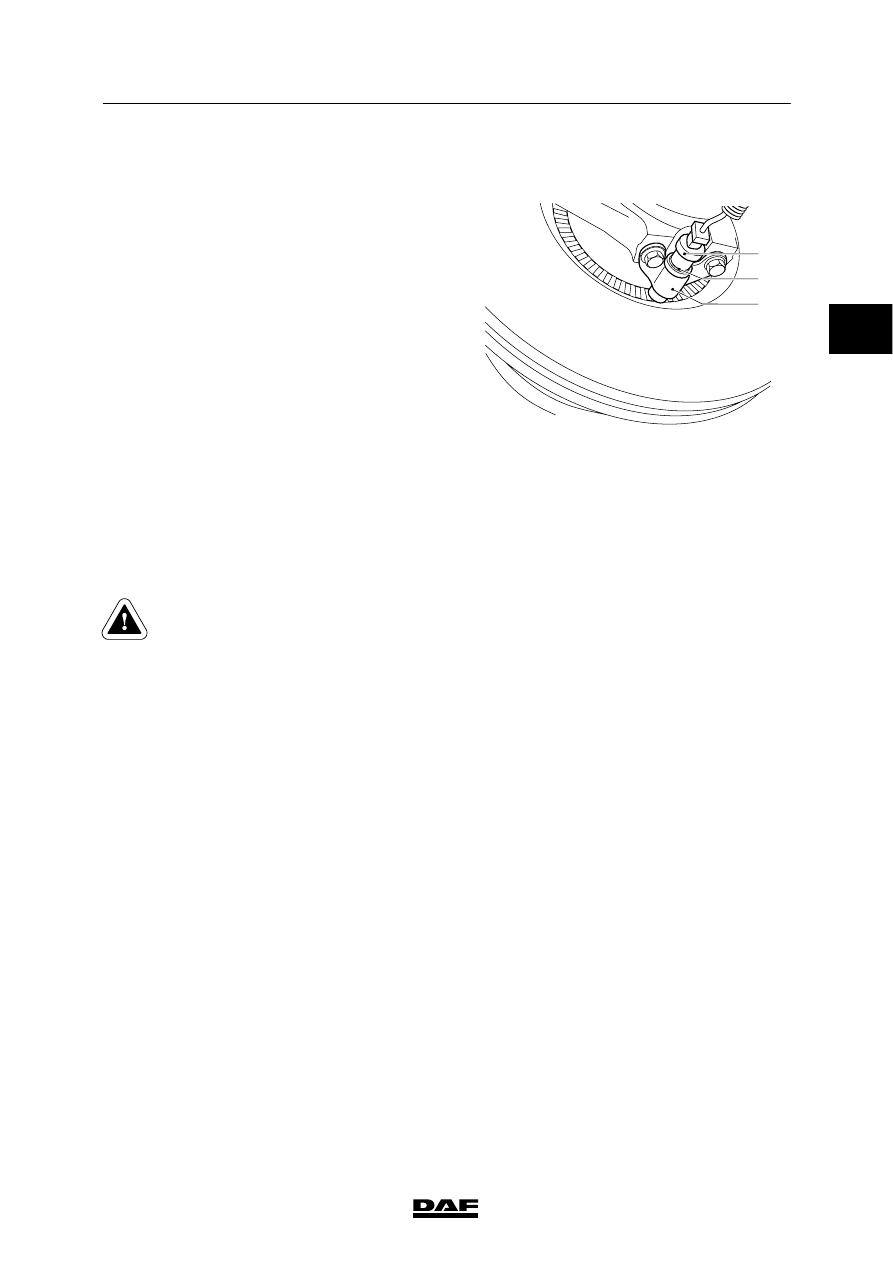

Remove the wheel-speed sensor (1) from

the holder (3).

2.

Cut the clamping strips attaching the cable.

3.

Unplug the connector and remove the

wheel-speed sensor.

Installing the wheel-speed sensor

1.

Clean the wheel-speed sensor (1) and the

clamping sleeve (2). If necessary, replace

the clamping sleeve (2).

2.

Apply the specified anti-corrosion agent to

the circumference of the wheel-speed

sensor (1). See main group “Technical

data”.

3.

Fit the wheel-speed sensor (1) in the holder

(3). Press it against the sensor ring

manually.

While the vehicle is being driven, the air gap

between the sensor and the sensor ring is

adjusted automatically.

Never tap the sensor with a

hammer. This may damage both the

sensor and the sensor ring.

4.

Fit the connector and secure the cable with

clamping strips.

5.

Check the ABS system for proper operation.

A8 00 435

2

3

1

2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

Removal and installation

LF45/55 series

4-6

4.6 REMOVAL AND INSTALLATION, DRIVE FLANGE

Removing drive flange

1.

Remove the prop shaft from the drive

flange.

2.

Jack up the rear axle and support it on

stands.

3.

Remove the stub axles.

4.

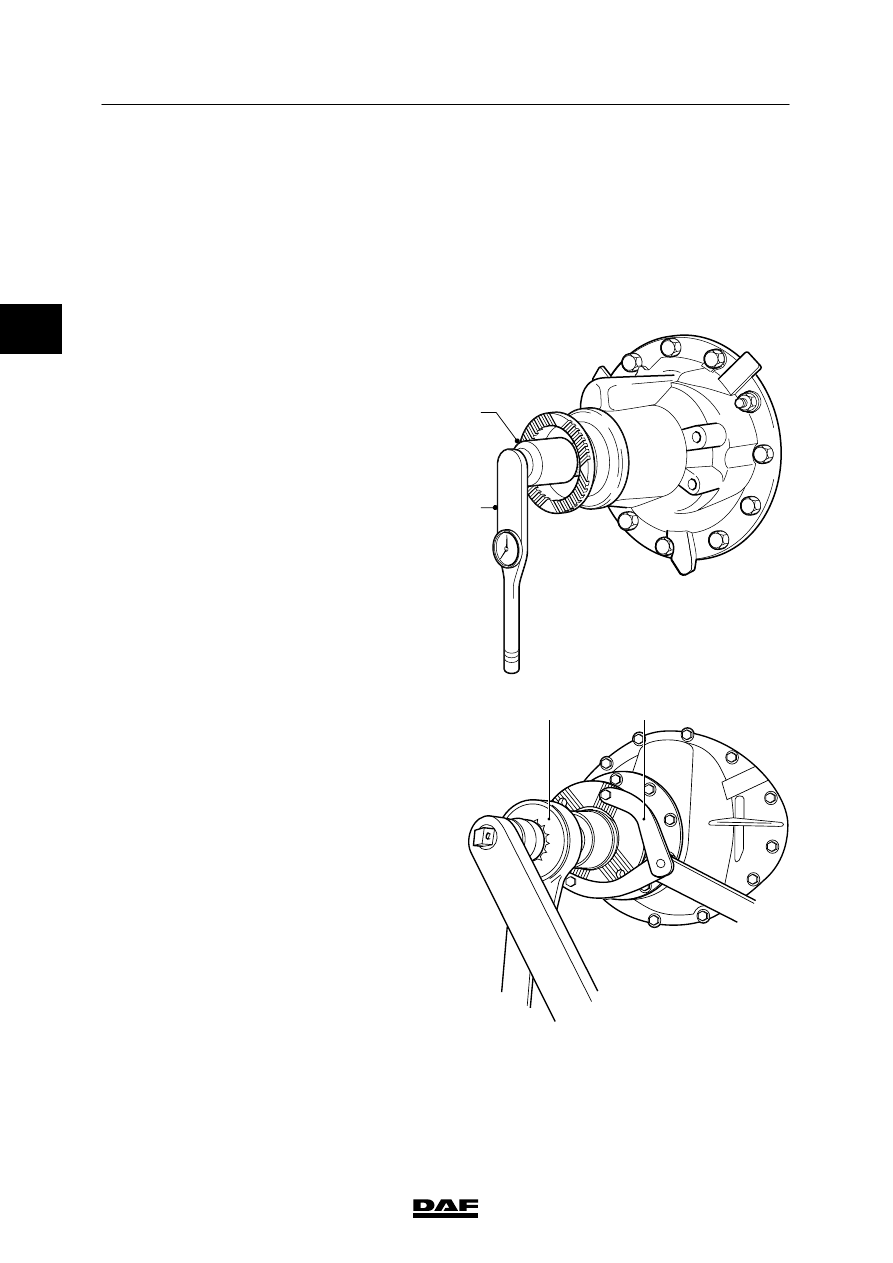

Determine the pre-load of the pinion

bearings by turning the drive flange nut

using a torque wrench with a dial (2) and a

12-sided socket (1). Write down the

measured slip torque.

A8 00 442

2

1

5.

Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Remove the drive flange nut using

a 12-sided socket and a torque

amplifier (A).

6.

Remove the drive flange. If necessary, use

a puller.

Installing drive flange

1.

Check the dust seal ring of the drive flange.

If required, replace the dust seal ring.

2.

Check the drive flange at the oil-seal

running surface for grooves and/or sharp

edges. If required, replace the drive flange.

3.

Clean the splines of the pinion and drive

flange.

A

B

A8 00 386

ᓻ 200313

2

8

LF45/55 series

Removal and installation

SINGLE REAR AXLE 5.10

4-7

4.

Apply the specified sealant to the splines of

the pinion. See main group “Technical data”.

5.

Fit the drive flange.

6.

Fit a new drive flange nut.

7.

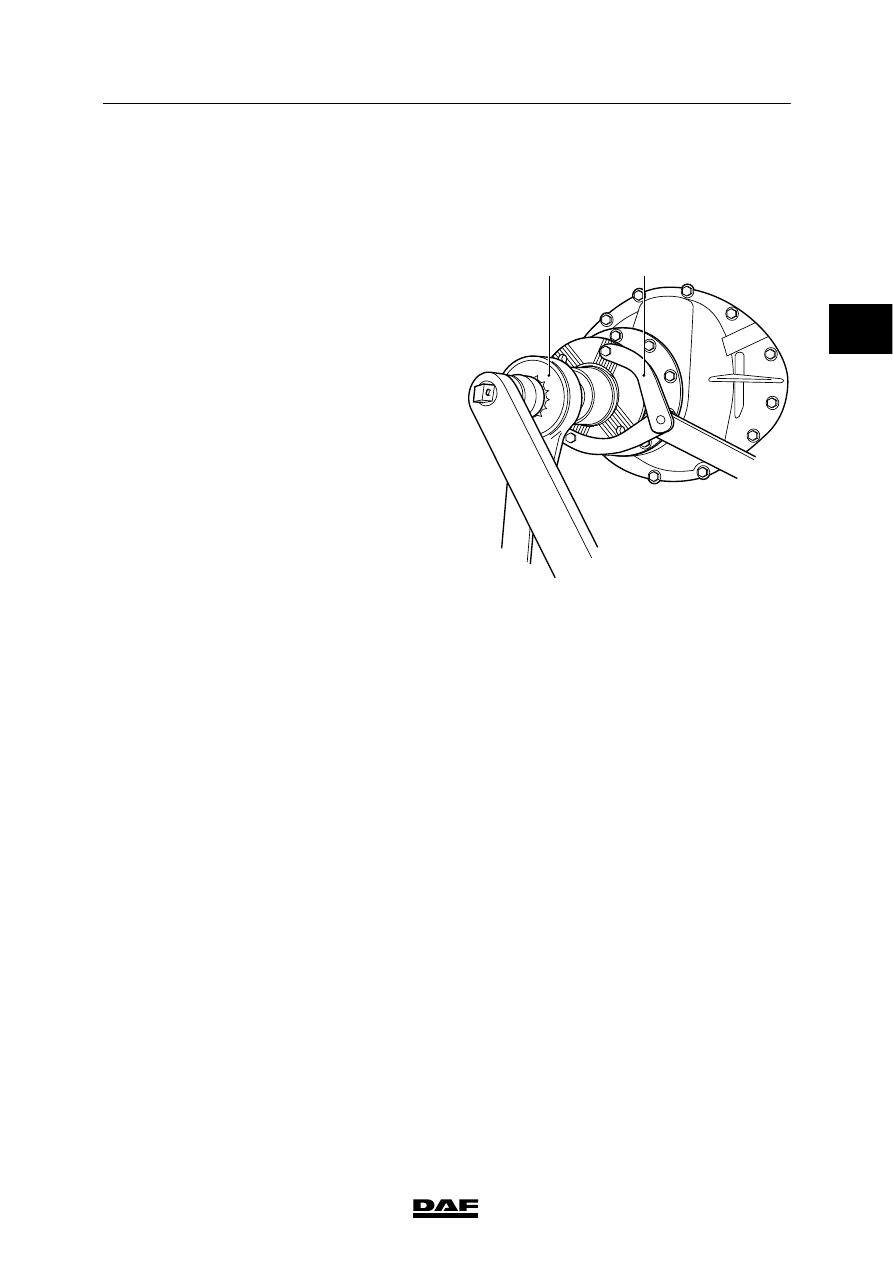

Fit the special tool (3) (DAF No. 0484977)

to the drive flange to prevent it from turning.

Tighten the drive flange nut using a

12-sided socket and a torque amplifier (A)

until no play is noticeable on the pinion.

8.

Turn the drive flange a number of times to

“seat” the pinion bearings.

9.

Tighten the drive flange until the slip torque

of the drive flange nut exceeds the noted

value by 0.4 - 0.6 Nm.

Note:

If the slip torque of the drive flange nut

exceeds the noted value increased by

0.4 - 0.6 Nm, loosen the drive flange nut a

few strokes and repeat the setting

procedure.

10. Fit the stub axles.

11. Fit the prop shaft to the drive flange.

A

B

A8 00 386

2

ᓻ 200313

8

SINGLE REAR AXLE 5.10

Removal and installation

LF45/55 series

4-8

4.7 REMOVAL AND INSTALLATION, PINION OIL SEAL

Removing pinion oil seal

1.

Remove the prop shaft from the drive

flange.

2.

Jack up the rear axle and support it on

stands.

3.

Remove the stub axles.

4.

Determine the pre-load of the pinion

bearings by turning the drive flange nut

using a torque wrench with a dial (2) and a

12-sided socket (1). Write down the

measured slip torque.

A8 00 442

2

1

5.

Fit the special tool (B) (DAF No. 0484977)

on the drive flange to prevent it from

turning. Remove the drive flange nut using

a 12-sided socket and a torque

amplifier (A).

6.

Remove the drive flange. If necessary, use

a puller.

A

B

A8 00 386

2

ᓻ 200313

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст