DAF LF45, LF55 Series. Manual — part 251

©

200508

1-1

General

EATON FS/6309A GEARBOX

ΛΦ45/55 series

3

6

1. GENERAL

1.1 GENERAL

Gearbox type

Each gearbox has a type plate attached to it,

indicating the type of gearbox. This data can also

be found on the vehicle identity card for the

vehicle concerned.

Eaton gearbox type plate

The Eaton specification number is unique to each

customer and gives detailed information on the

development level of the gearbox. The number

must be quoted whenever replacement parts are

ordered.

V300378

2

3

4

1

5

1.

Type of gearbox

2.

Specification no. Eaton

3.

DAF article Eaton code

4.

Serial no. Eaton

5.

Production date code

EATON FS/6309A GEARBOX

1-2

©

200508

General

6

ΛΦ45/55 series

3

1.2 SYSTEM DESCRIPTION

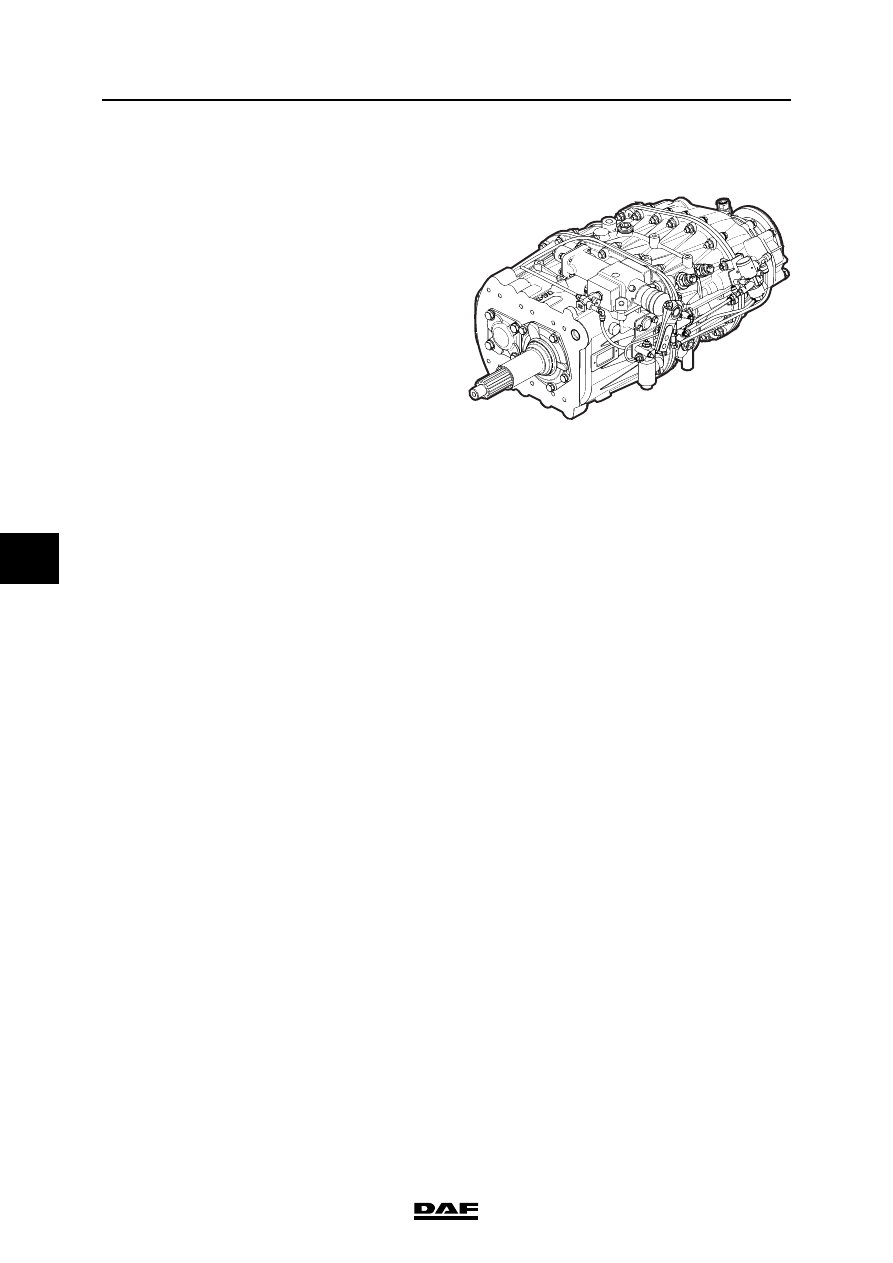

The gearbox consists of a main gearbox with four

synchromesh forward gears, a non-synchromesh

crawler gear, and one non-synchromesh reverse

gear. Between the main gearbox and the output

shaft there is a set of planetary range gears with

pneumatic synchronisation.

In the low range (planetary system engaged), the

crawler gear and gears 1, 2, 3 and 4 can be

engaged.

In the high range (planetary system disengaged),

gears 5, 6, 7 and 8 can be engaged.

The switching system is in a "single-H" pattern.

Use of the "single-H" system means that the low

or high range must be selected by means of a

button on the ball of the gear lever prior to

engaging gear. The group is changed as soon as

the selector shaft passes through the neutral

position.

V300438-2

©

200508

2-1

Inspection and adjustment

EATON FS/6309A GEARBOX

ΛΦ45/55 series

3

6

2. INSPECTION AND ADJUSTMENT

2.1 CHECKING GEARBOX OIL LEVEL

To prevent skin injury, avoid

unnecessary contact with the

drained oil.

1.

Position the vehicle on a level surface.

2.

Wait for some minutes to allow the oil to flow

back.

3.

Remove the level check/filler plug (1) and

check the oil level.

4.

The oil level must reach the rim of the level

check/filler opening (1).

5.

After checking the oil level, tighten the level

check plug to the specified torque. See

"Technical data".

}

1

2

3

4

V3 00 376

EATON FS/6309A GEARBOX

2-2

©

200508

Inspection and adjustment

6

ΛΦ45/55 series

3

2.2 INSPECTION AND ADJUSTMENT, INPUT SHAFT BEARING AXIAL PLAY

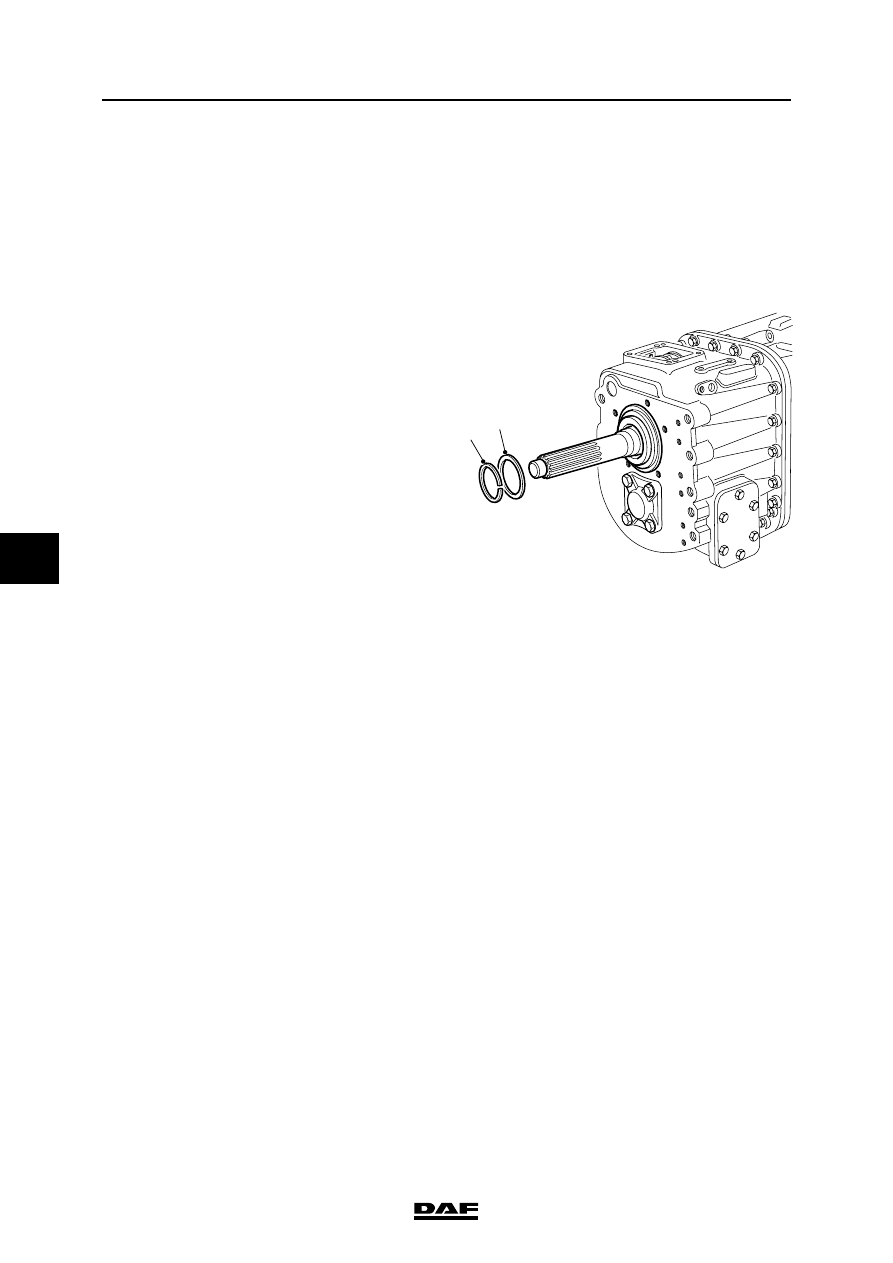

Inspection, input shaft bearing axial play

1.

Remove the gearbox. See "Removal and

installation".

2.

Remove the gearbox front cover from the

input shaft. See "Removal and installation".

3.

Check whether the circlip (1) is flush in the

groove. Check at various places around the

shaft.

4.

If necessary, adjust the axial play by means

of a thicker or thinner adjusting ring (2).

Adjustment, input shaft bearing axial play

1.

Remove the circlip (1) of the input shaft

bearing.

2.

Remove the adjusting ring (2).

3.

Place an adjusting ring (2) of the correct

thickness between the input shaft bearing

and the circlip. See "Technical data".

4.

Fit the circlip (1) without any play into the

groove. Check at various places around the

shaft.

5.

Fit a new gasket in the gearbox front cover

and install the gearbox front cover. See

"Removal and installation".

6.

Fit the gearbox. See "Removal and

installation".

1

2

V3 00 415

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст