DAF LF45, LF55 Series. Manual — part 153

©

200505

4-5

CE engine

TECHNICAL DATA

ΛΦ45/55 series

2

0

Flywheel/starter ring gear

Flywheel housing

Vibration damper

M201199

A

B

Radial run-out,

measured on the

inside of the flywheel

outer edge (A).

max. 0.127 mm

Axial deviation,

measured on the

flywheel outer edge

(B).

max. 0.406 mm

Heat starter ring gear

(max. 20 min.)

max. 125

C

Fit flywheel housing using sealant

Loctite 5205

Difference in thickness at 4 places must not

exceed:

6.35 mm

TECHNICAL DATA

4-6

©

200505

CE engine

0

ΛΦ45/55 series

2

4.2 TIGHTENING TORQUES

The tightening torques stated in this section are

different from the standard tightening torques

stated in the overview of the standard tightening

torques. The other threaded connections not

specified must therefore be tightened to the

torque stated in the overview of standard

tightening torques.

When attachment bolts and nuts are replaced, it

is important that - unless stated otherwise - these

bolts and nuts are of exactly the same length and

property class as those removed.

Starter motor

Automatic poly-V-belt tensioner

Alternator

Air compressor

Steering pump

Air-conditioning compressor

Valve gear

Attachment bolts

43 Nm

Attachment bolts

43 Nm

Alternator bracket attachment bolts

30 Nm

Alternator attachment bolts

60 Nm

Pulley attachment nut

80 Nm

Compressor attachment nuts

80 Nm

Pipe attachments

39 Nm

Attachment bolts, steering pump

55 Nm

Line connection in the pump, delivery side

36 Nm

Attachment bolts, cover

20 Nm

Attachment bolts, reservoir

8 Nm

Compressor support attachment bolts

30 Nm

Compressor attachment bolts

60 Nm

Rocker setting bolt lock nut

24 Nm

Valve sleeve attachment bolts

24 Nm

Valve cover attachment bolts

10 Nm

Rocker seat attachment bolts

36 Nm

Injector wiring

1 Nm

©

200505

4-7

CE engine

TECHNICAL DATA

ΛΦ45/55 series

2

0

Intake manifold

Exhaust manifold

(1) Tighten crosswise from inside to outside.

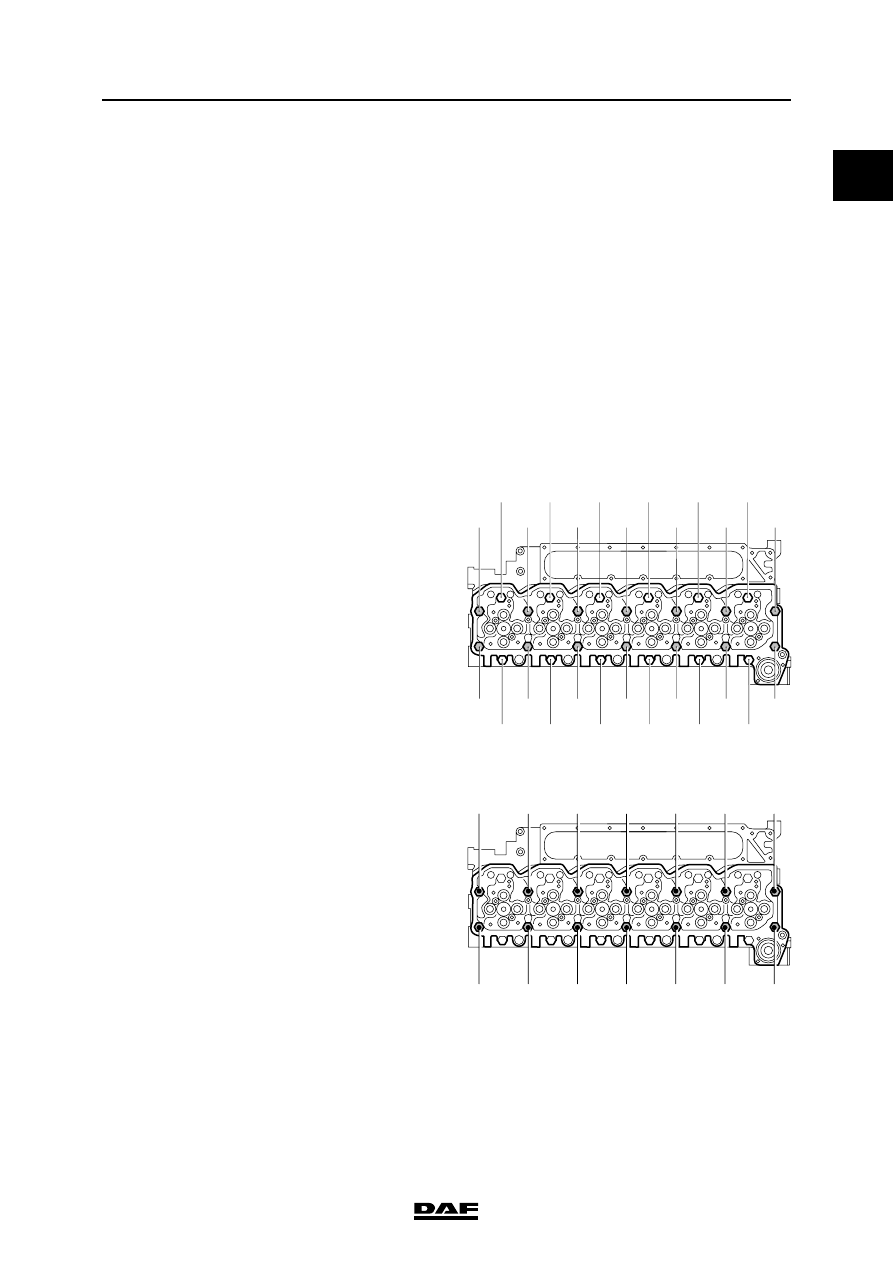

Cylinder head

Note:

Apply a drop of engine oil on the thread of the

attachment bolts and under the bearing surface

of the bolt heads.

Phase 1

(1) Tighten the bolts in the order indicated

Phase 2

(1) Tighten the bolts in the order indicated

Intake manifold attachment bolts

24 Nm

Fuel rail attachment bolts

24 Nm

Glow element attachment bolts

14 Nm

Air inlet hose clamps

7 Nm

Attachment bolts

43 Nm

Heat shields

56 - 64 Nm

M201143

4

5

13

21

9

17

8

7

3

6

14

22

2

10

18

26

1

25

20

12

24

23

19

11

15

16

All attachment bolts

35 Nm

M201202

12

11

8

7

4

3

1

2

5

6

9

10

13

14

Use only attachment

bolts that are

150 mm in length

55 Nm

TECHNICAL DATA

4-8

©

200505

CE engine

0

ΛΦ45/55 series

2

Phase 3

(1) Tighten the bolts in the order indicated

Vibration damper

Timing gear

Front engine panel

(1) Tighten the attachment bolts in the order indicated

Flywheel

M201143

4

5

13

21

9

17

8

7

3

6

14

22

2

10

18

26

1

25

20

12

24

23

19

11

15

16

All attachment bolts

2 steps of 90

angular

displacement

each

Attachment bolts

1

st

phase

50 Nm

2

nd

phase

90

angular displacement

Camshaft locking plate attachment bolts

24 Nm

M8 attachment bolts for timing gear case

24 Nm

M10 attachment bolts for timing gear case

47 Nm

M12 attachment bolts for timing gear case

50 Nm

Camshaft gear attachment bolts

36 Nm

M201144

1

12

9

6

3

8

5

2

4

7

11

10

13

Front engine panel

attachment bolts

24 Nm

Attachment bolts

30 Nm + 60

angular displacement

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст