DAF LF45, LF55 Series. Manual — part 184

©

200505

2-3

General

BE ENGINE LUBRICATION SYSTEM

ΛΦ45/55 series

2

4

Cylinder head

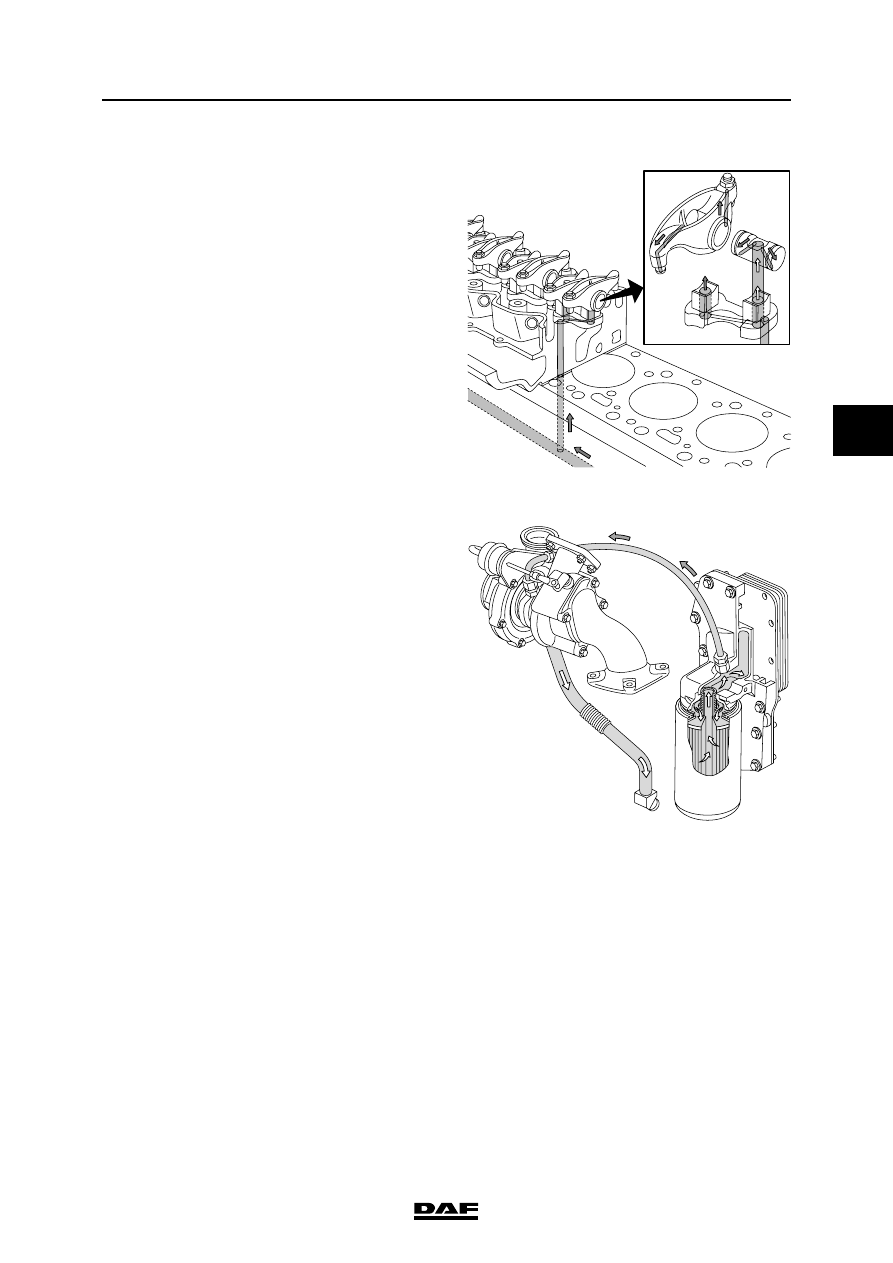

From the main oil channel, vertical oil channels

pass through the cylinder block to the cylinder

head. This bore is continued in the cylinder head

to supply lubricating oil to the rockers.

Piston and gudgeon pin

The pistons are lubricated by oil nozzles (B).

In addition to its lubricating function, the

lubricating oil has an important cooling function.

A hole has been drilled at the top of the

connecting rod, through which the oil that the oil

nozzles spray against the piston head may reach

the upper big-end bearing and the gudgeon pin.

Turbocharger

The turbocharger is lubricated via an oil pipe from

the oil cooler housing.

The oil discharge pipe from the turbocharger is

connected to the cylinder block, from where the

oil returns to the oil sump.

Air compressor

The air compressor is supplied with oil from an oil

channel in the timing gear case connected to the

main oil channel.

The oil returning from the air compressor flows

from the front of the air compressor to the timing

gear case, and from there to the oil sump.

M201123

M201122

BE ENGINE LUBRICATION SYSTEM

2-4

©

200505

General

4

ΛΦ45/55 series

2

©

200505

3-1

Checking and adjusting

BE ENGINE LUBRICATION SYSTEM

ΛΦ45/55 series

2

4

3. CHECKING AND ADJUSTING

3.1 CHECKING ENGINE OIL CONSUMPTION

Engine oil consumption relates to the engine oil

used during combustion in the engine. Since

engine oil consumption is affected by driving style

and the use to which the vehicle is put, it is also

related to average fuel consumption. See

"Technical data" for the maximum permissible

engine oil consumption.

Test conditions

1.

An engine oil consumption test is only

meaningful after the engine has been run in

(approx. 25,000 km).

2.

Check the engine carefully for engine oil

leakage before carrying out an engine oil

consumption test. First repair any leaks.

3.

Check the average fuel consumption and

engine oil consumption as accurately as

possible.

4.

Only check the engine oil level when the

engine is at operating temperature and only

when the engine has been turned off for five

minutes.

5.

Make sure the vehicle is horizontal before

checking the engine oil level.

BE ENGINE LUBRICATION SYSTEM

3-2

©

200505

Checking and adjusting

4

ΛΦ45/55 series

2

3.2 INSPECTION, LUBRICATING OIL PRESSURE

1.

Bring the engine up to operating

temperature.

2.

Remove the plug from the main oil channel.

It is located on the left, in the centre of the

engine block.

3.

Connect the special tool (DAF no. 0535551)

to the oil pressure gauge connection.

4.

Start the engine and measure the lubricating

oil pressure at idling speed and at full-load

engine speed.

Compare the pressure readings with the

technical data. See "Technical data".

5.

Stop the engine and remove the oil pressure

gauge. Fit a new sealing ring in the plug and

insert the plug.

M201150

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст