Dodge Dakota (ND). Manual — part 627

P0058-O2 SENSOR 2/2 HEATER CIRCUIT HIGH (CONTINUED)

5.

(K399) O2 2/2 HEATER CONTROL CIRCUIT SHORTED TO BATTERY VOLTAGE

Turn the ignition off.

Disconnect the C3 PCM harness connector.

Ignition on, engine not running.

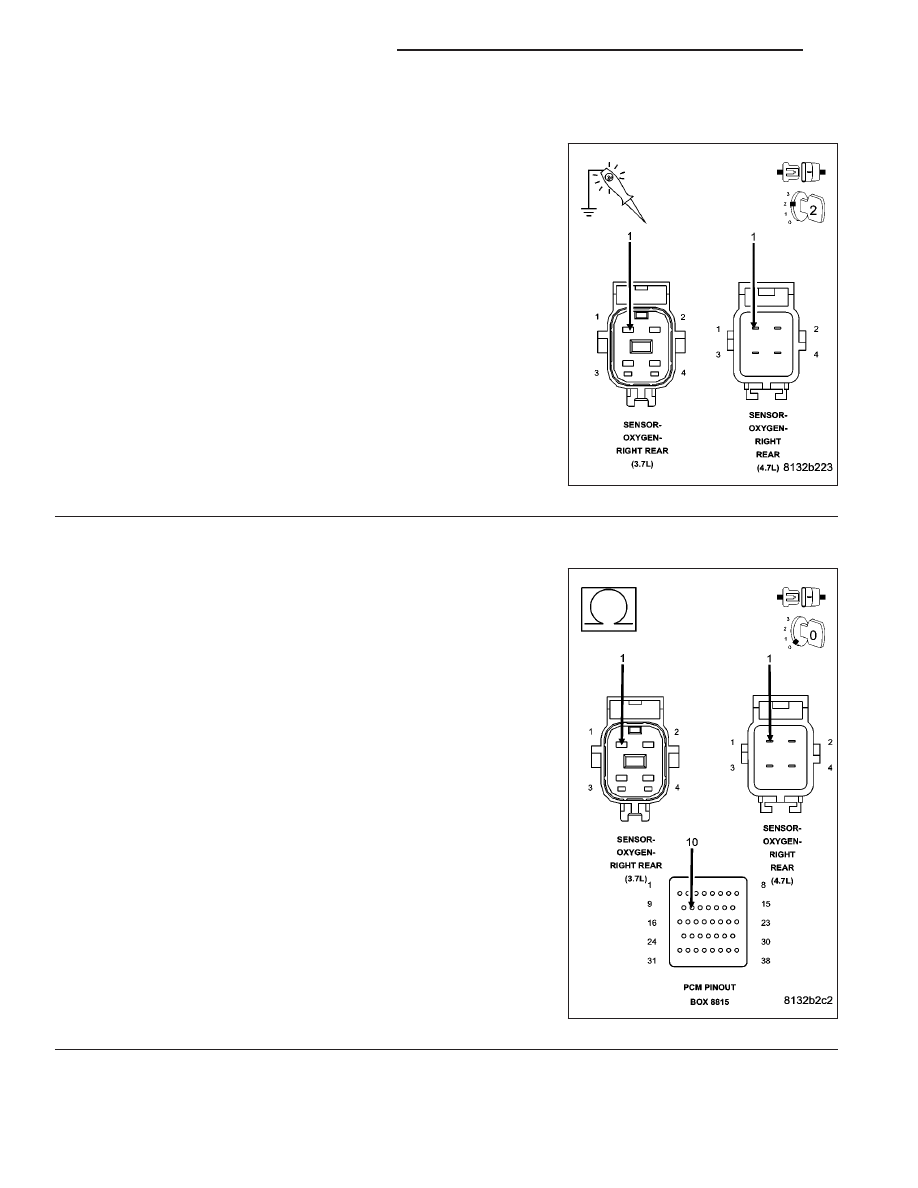

Using a 12-volt test light connected to ground, probe the (K399) O2

Heater 2/2 Control circuit in the O2 Sensor harness connector.

Does the test light illuminate?

Yes

>> Repair the short to battery voltage in the (K399) O2 2/2

Heater Control circuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9

- ENGINE - STANDARD PROCEDURE)

No

>> Go To 6

6.

(K399) O2 2/2 HEATER CONTROL CIRCUIT OPEN

Turn the ignition off.

CAUTION: Do not probe the PCM harness connectors. Probing

the PCM hanrness connectors will damage the PCM terminals

resulting in poor terminal to pin connection. Install Miller Special

Tool #8815 to perform diagnosis.

Measure the resistance of the (K399) O2 2/2 Heater Control circuit

from the O2 Sensor harness connector to the appropriate terminal of

special tool #8815.

Is the resistance below 5.0 ohms?

Yes

>> Go To 7

No

>> Repair the open in the (K399) O2 2/2 Heater Control cir-

cuit.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9

- ENGINE - STANDARD PROCEDURE)

9 - 46

ENGINE ELECTRICAL DIAGNOSTICS

ND

P0058-O2 SENSOR 2/2 HEATER CIRCUIT HIGH (CONTINUED)

7.

PCM

NOTE: Before continuing, check the PCM harness connector terminals for corrosion, damage, or terminal

push out. Repair as necessary.

Using the schematics as a guide, inspect the wire harness and connectors. Pay particular attention to all Power and

Ground circuits.

Were there any problems found?

Yes

>> Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

No

>> Replace and program the Powertrain Control Module per Service Information.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

ND

ENGINE ELECTRICAL DIAGNOSTICS

9 - 47

P0068-MANIFOLD PRESSURE/THROTTLE POSITION CORRELATION

9 - 48

ENGINE ELECTRICAL DIAGNOSTICS

ND

P0068-MANIFOLD PRESSURE/THROTTLE POSITION CORRELATION (CONTINUED)

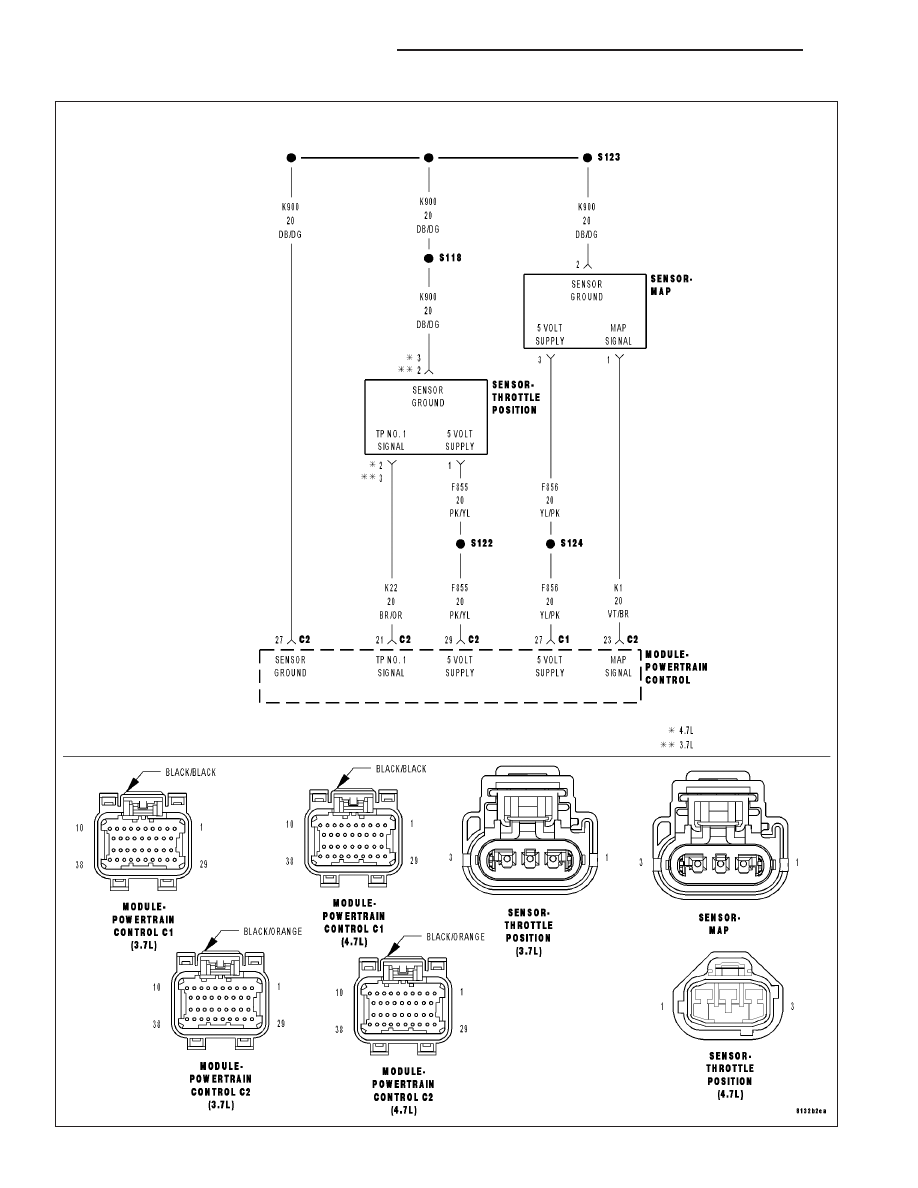

For the Engine circuit diagram (Refer to 9 - ENGINE - SCHEMATICS AND DIAGRAMS).

For a complete wiring diagram Refer to Section 8W.

Theory of Operation

This DTC sets when an unexpected high intake manifold air flow condition exists that can lead to increased engine

speed and puts the NGC into a High Air flow Protection limiting mode. The High Air flow Protection feature includes

RPM limits for when a Throttle and/or MAP sensor limp-in fault is present.

•

When Monitored:

During all drive modes.

•

Set Condition:

If vacuum drops below 1.5

9

Hg with engine RPM greater than 2000 RPM and closed throttle. One Trip Fault.

Three good trips to turn off the MIL.

Possible Causes

VACUUM LEAK

RESISTANCE IN THE (F856) 5-VOLT SUPPLY CIRCUIT

(F856) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K1) MAP SIGNAL CIRCUIT

(K1) MAP SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (F855) 5-VOLT SUPPLY CIRCUIT

(F855) 5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K22) TP SENSOR NO.1 SIGNAL CIRCUIT

(K22) TP SENSOR NO.1 SIGNAL CIRCUIT SHORTED TO GROUND

RESISTANCE IN THE (K900) SENSOR GROUND CIRCUIT

MAP SENSOR

THROTTLE POSITION SENSOR

PCM

Always perform the Pre-Diagnostic Troubleshooting procedure before proceeding. (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING).

Diagnostic Test

1.

ACTIVE DTC

NOTE: Diagnose any TP Sensor or MAP Sensor component DTCs before continuing.

NOTE: If the P0501 - No Vehicle Speed Signal is set long with this DTC, refer to the P0501 diagnostics

before continuing.

NOTE: The throttle plate and linkage should be free from binding and carbon build up.

NOTE: Make sure the throttle plate is at the idle position.

Ignition on, engine not running.

With a scan tool, read DTCs.

Is the DTC active at this time?

Yes

>> Go To 2

No

>> Refer to the INTERMITTENT CONDITION Diagnostic Procedure.

Perform POWERTRAIN VERIFICATION TEST. (Refer to 9 - ENGINE - STANDARD PROCEDURE)

ND

ENGINE ELECTRICAL DIAGNOSTICS

9 - 49

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст