Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 209

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the so-

lenoid. When de-energized, no vapors are purged.

The PCM de-energizes the solenoid during open loop

operation.

The engine enters closed loop operation after it

reaches a specified temperature and the time delay

ends. During closed loop operation, the PCM ener-

gizes and de-energizes the solenoid approximately 5

to 10 times per second, depending upon operating

conditions. The PCM varies the vapor flow rate by

changing solenoid pulse width. Pulse width is the

amount of time the solenoid energizes. The PCM ad-

justs solenoid pulse width based on engine air flow.

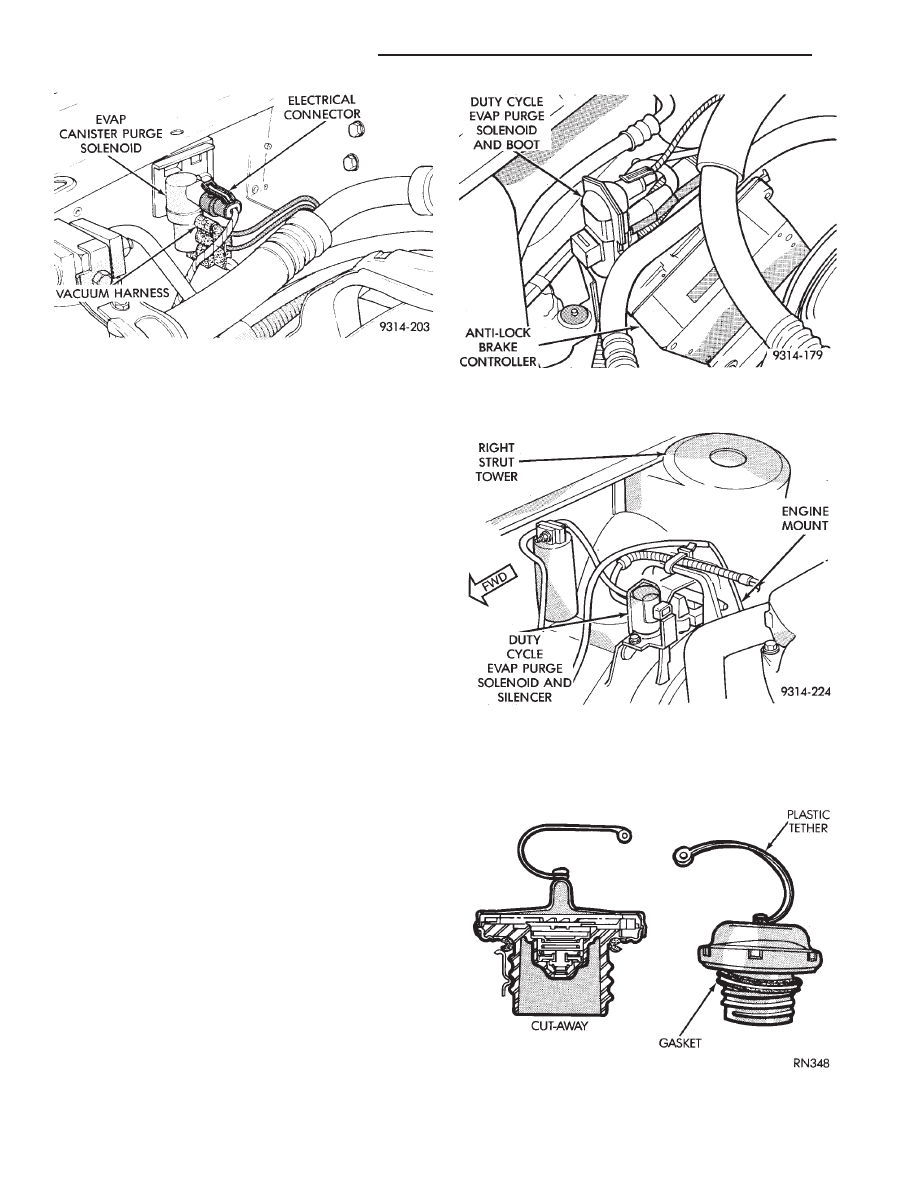

A rubber boot covers the duty cycle EVAP purge

solenoid. On 2.5L MPI flexible fuel AA-body vehicles,

the solenoid and bracket attach to the EVAP canister

mounting studs (Fig. 7). On vehicles with 3.0L en-

gines, the solenoid attaches to a bracket mounted to

the right engine mount (Fig. 8). The top of the sole-

noid has the word TOP on it. The solenoid will not

operate unless it is installed correctly.

PRESSURE-VACUUM FILLER CAP

CAUTION: Remove the fuel filler cap to relieve fuel

tank pressure. Remove the cap before disconnect-

ing fuel system components or servicing the fuel

tank.

A pressure-vacuum relief cap seals the fuel tank

(Fig. 9). Tightening the cap on the fuel filler tube

forms a seal between them. The relief valves in the

cap are a safety feature. They prevent possible exces-

sive pressure or vacuum in the tank. Excessive fuel

tank pressure could be caused by a malfunction in

the system or damage to the vent lines.

The seal between the cap and filler tube breaks

when the cap is removed. Removing the cap breaks

the seal and relieves fuel tank pressure.

If the filler cap needs replacement, only use a sim-

ilar unit.

Fig. 6 Canister Purge Solenoid—Except 3.0L and

2.5L MPI

Fig. 7 Duty Cycle EVAP Purge Solenoid—2.5L MPI

Flexible Fuel AA-Body

Fig. 8 Duty Cycle EVAP Purge Solenoid—3.0L

Engine

Fig. 9 Pressure Vacuum Filler Cap

25 - 14

EMISSION CONTROL SYSTEMS

Ä

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS

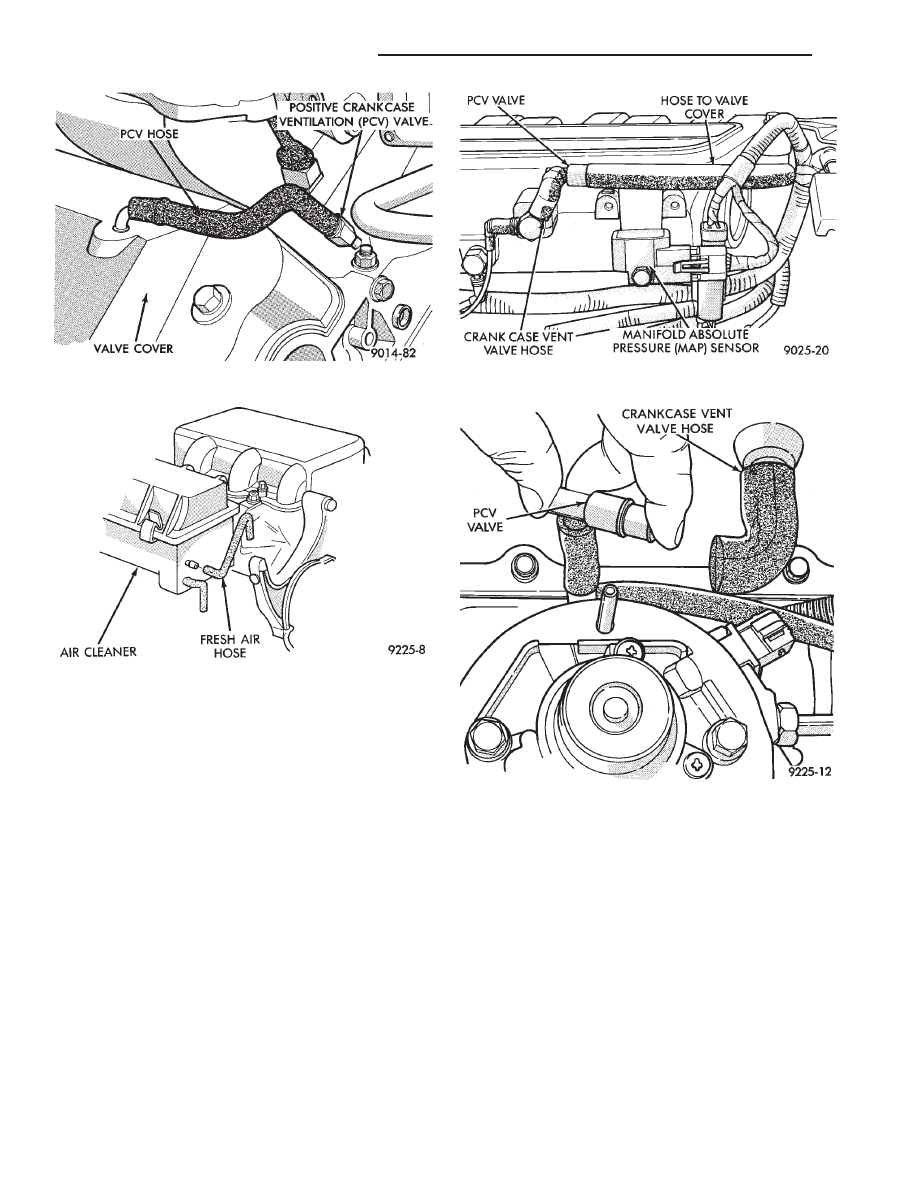

Intake manifold vacuum removes crankcase vapors

and piston blow-by from the engine. The emissions pass

through the PCV valve into the intake manifold where

they become part of the calibrated air-fuel mixture.

They are burned and expelled with the exhaust gases.

The air cleaner supplies make up air when the engine

does not have enough vapor or blow-by gases. In this

system, fresh air does not enter the crankcase (Figs. 10,

11, 12, 13, 14, 15, and 16).

PCV VALVE TEST

WARNING:

APPLY

PARKING

BRAKE

AND/OR

BLOCK WHEELS BEFORE PERFORMING ANY TEST

OR ADJUSTMENT WITH THE ENGINE OPERATING.

With the engine idling, remove the PCV valve

from its attaching point. If the valve is operating

properly, a hissing noise will be heard and a strong

vacuum felt when placing a finger over the valve in-

let (Fig. 17). With the engine off, the shake the

valve. The valve should rattle when shaken. Replace

the valve if it does not operate properly. Do not at-

tempt to clean the PCV valve.

Fig. 10 PCV Valve—2.5L TBI Engine

Fig. 11 PCV System—2.5L MPI (Flexible Fuel)

Fig. 12 PCV System—Turbo III Engine

Fig. 13 PCV System—3.0L Engine

Ä

EMISSION CONTROL SYSTEMS

25 - 15

CRANKCASE VENT FILTER

All engines have a crankcase vent filter. The filter

cleans outside air before it enters the PCV system.

On 2.5L engines, the filter mounts to the upper shell

assembly of the air cleaner. On 2.5L MPI (Flexible

Fuel AA-body) and Turbo III engines, the filter at-

taches to the inside of the filter element box, next to

the filter element. On 3.0L engines, it attaches to the

inside of the filter element box under the filter ele-

ment. On the 3.3L engines, the filter mounts to the

bottom of the filter element box. Refer to Group 0 for

mileage intervals and service procedures.

Fig. 14 PCV Valve—3.0L Engine

Fig. 15 PCV System Fresh Air Hose—3.0L Engine

Fig. 16 PCV System—3.3L/3.8L Engines

Fig. 17 Typical PCV Test

25 - 16

EMISSION CONTROL SYSTEMS

Ä

EXHAUST EMISSION CONTROLS

INDEX

page

page

Air Aspiration System

. . . . . . . . . . . . . . . . . . . . . 24

EGR Gas Flow Test

. . . . . . . . . . . . . . . . . . . . . . 21

EGR System On-Board Diagnostics

. . . . . . . . . . . 21

EGR Tube Service—2.2L and 2.5L TBI Engines

. 22

EGR Tube Service—3.0L Engines

. . . . . . . . . . . . 22

EGR Tube Service—3.3L and 3.8L Engines

. . . . 22

EGR Valve Service—2.2L and 2.5L TBI Engines

. 22

EGR Valve Service—3.0L Engines

. . . . . . . . . . . 22

EGR Valve Service—3.3L and 3.8L Engines

. . . . 22

Exhaust Gas Recirculation (EGR) System

. . . . . . 20

Exhaust Gas Recirculation (EGR) System Test

. . 21

Heated Inlet Air System

. . . . . . . . . . . . . . . . . . . 17

Heated Oxygen Sensor (O

2

Sensor)

. . . . . . . . . . 18

HEATED INLET AIR SYSTEM

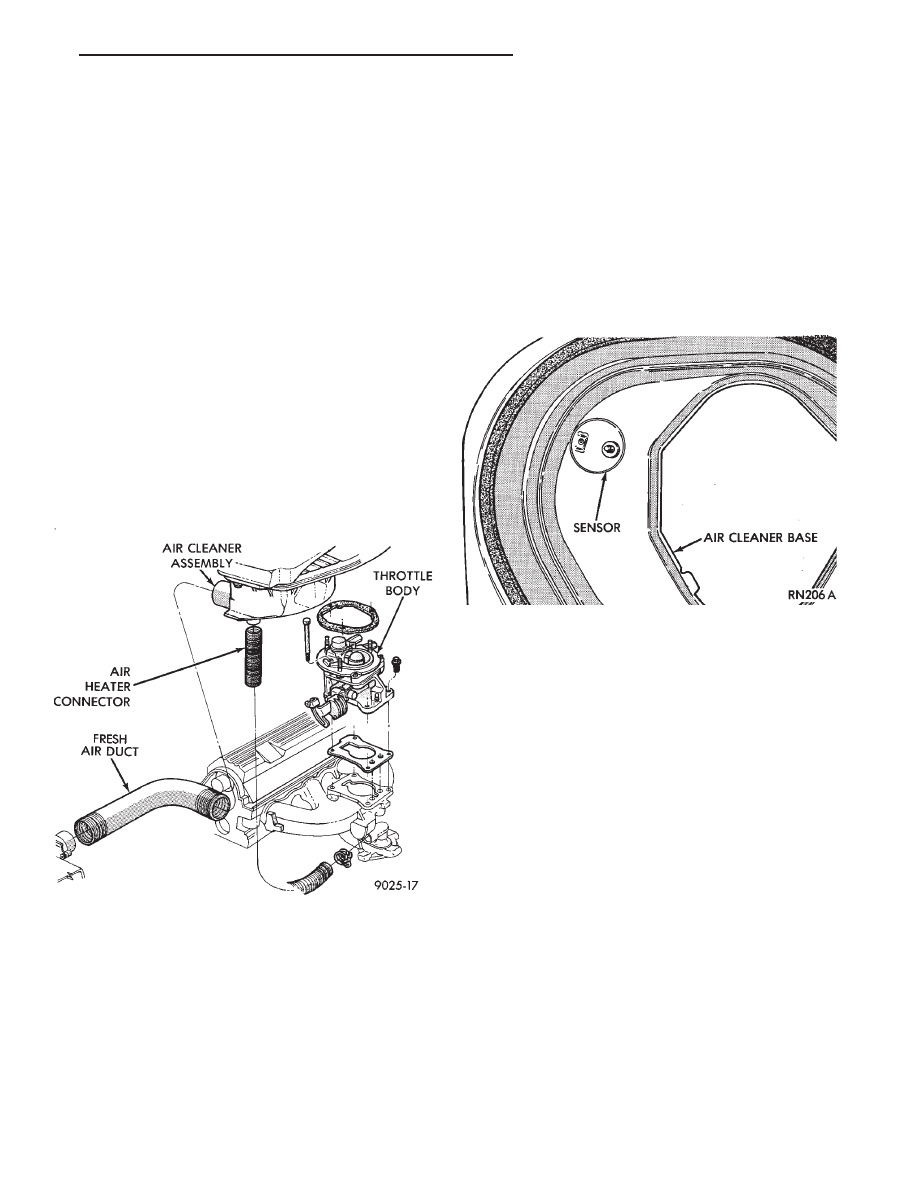

2.5L MPI (Flexible Fuel AA-body), Turbo III, 3.0L,

3.3L and 3.8L engines do not use a heated inlet air

system.

2.2L and 2.5L TBI air cleaners have a heated air

assembly (Fig. 1). When ambient temperatures are

low, the assembly warms the air before it enters the

throttle body. The heated air assembly reduces hy-

drocarbon emissions, improves engine warm-up char-

acteristics and minimizes icing.

The heated air assembly contains a vacuum oper-

ated blend door. The blend door opens to either

heated air from a stove on the exhaust manifold or

ambient air (outside air). A vacuum diaphragm oper-

ates the door. A spring opposes the vacuum dia-

phragm. A temperature sensor controls the vacuum

diaphragm (Fig. 2). Adjustment of inlet air tempera-

ture occurs only at road load throttle positions or

when the intake manifold vacuum exceeds the vac-

uum diaphragm spring rate.

Air flows through the outside air inlet when ambi-

ent air temperature is 8°C (15°F) or more above the

air temperature sensor control temperature.

When ambient air temperature falls below the con-

trol temperature, air flows through both the ambient

and heated circuits. This occurs after the engine has

been started and the exhaust manifold starts to give

off heat. Colder ambient air cause greater air flow

through the heat stove on the exhaust manifold.

Warmer ambient air results in greater ambient air

flow through the air cleaner snorkel.

HEATED INLET AIR SYSTEM SERVICE

Heated air inlet system malfunctions may affect

driveability and vehicle exhaust emissions.

Use the following procedure to determine if the

system functions properly.

(1) Inspect the condition of the heat stove to air

cleaner flexible connector and all vacuum hoses. In-

spect them for proper attachment. Replace as neces-

sary.

(2) With a cold engine and ambient temperature

less than 46°C (115°F.), the heat control door (valve

plate) should be in the up (heat on position).

(3) With the engine warmed up and running,

check the temperature of the air entering the snorkel

or passing the sensor. When the temperature of the

Fig. 1 Heated Air Inlet System

Fig. 2 Heated Air Temperature Sensor

Ä

EMISSION CONTROL SYSTEMS

25 - 17

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст