Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 236

card the old retainer clip, a new clip must be

used when hydraulic assembly is reinstalled

(Fig. 8).

(10) Remove the 4 hydraulic assembly to dash

panel mounting nuts from the hydraulic assembly

mounting studs, located under instrument panel (Fig.

8).

(11) Remove hydraulic assembly from vehicle.

INSTALL

(1) Position the hydraulic assembly into its mount-

ing holes on the dash panel of the vehicle.

(2) Install and tighten the 4 hydraulic assembly to

dash panel mounting stud nuts (Fig. 8) to 28 N

Im

(250 in. lbs.) torque.

(3) Using lubriplate or equivalent, coat the bearing

surface of the brake pedal pin.

(4) Connect push rod to pedal pin and install a

NEW retainer clip. HYDRAULIC ASSEMBLY

PUSH ROD MUST BE ASSEMBLED TO BRAKE

PEDAL PIN IN THE POSITION AS SHOWN IN

(FIG. 8).

(5) If proportioning valves were removed from the

hydraulic assembly, install and torque to 40 N

Im (30

ft. lbs.) torque. Then install all 4 brake tubes on the

hydraulic assembly (Fig. 7). Torque the brake tubes

to hydraulic assembly fittings to 16 N

Im (145 in.

lbs.).

(6) Install return hose on steel tube. Tighten the

return hose clamp to 1 N

Im (10 in.lbs.)

Fig. 7 Brake Tube and Hose Routing at Hydraulic

Unit

Fig. 8 Removing or Installing Hydraulic Assembly

5 - 98

ANTI-LOCK 10 BRAKE SYSTEM

Ä

(7) Install high pressure hose to hydraulic assem-

bly (Fig. 7). Tighten the hose, to hydraulic assembly

fitting to 16 N

Im (145 in. lbs)

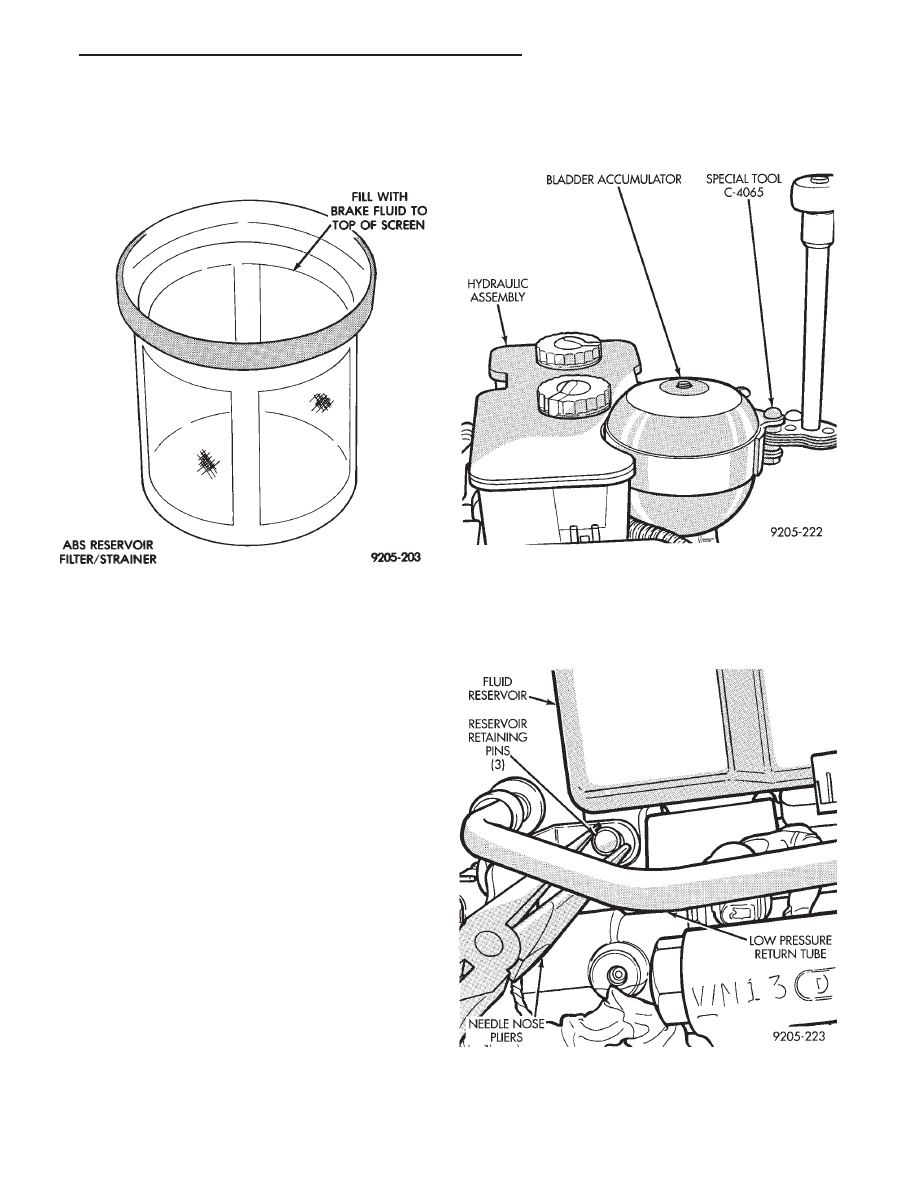

(8) Fill hydraulic assembly brake fluid reservoir to

top of screen on the reservoir filter/strainer Fig. 9.

(9) Connect all electrical connectors to the hydrau-

lic assembly.

(10) Bleed the entire brake system, see Bleeding

Brake System in this section of the Service Manual.

(11) Replace all fresh air intake ducts, air cleaner

and washer bottle.

(12) Check that the brake fluid in the hydraulic

assembly is at the correct level before moving vehicle

(Fig. 9). (See Checking Brake Fluid Level in this sec-

tion of the service manual).

BRAKE FLUID RESERVOIR

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove as much brake fluid as possible from

the fluid reservoir, using a syringe or equivalent

method.

(3) Using Oil Filter Band Wrench, Special Tool

C-4065 or equivalent loosen bladder accumulator.

Then remove the bladder accumulator and brake

fluid spray shield from the hydraulic assembly (Fig.

10). Remove high pressure banjo fitting from hydrau-

lic assembly.

(4) Using needle nose pliers, remove the three

fluid reservoir retaining pins from the hydraulic as-

sembly (Fig. 11). Compress the barb on the opposite

side of retaining pin to prevent pin from breaking.

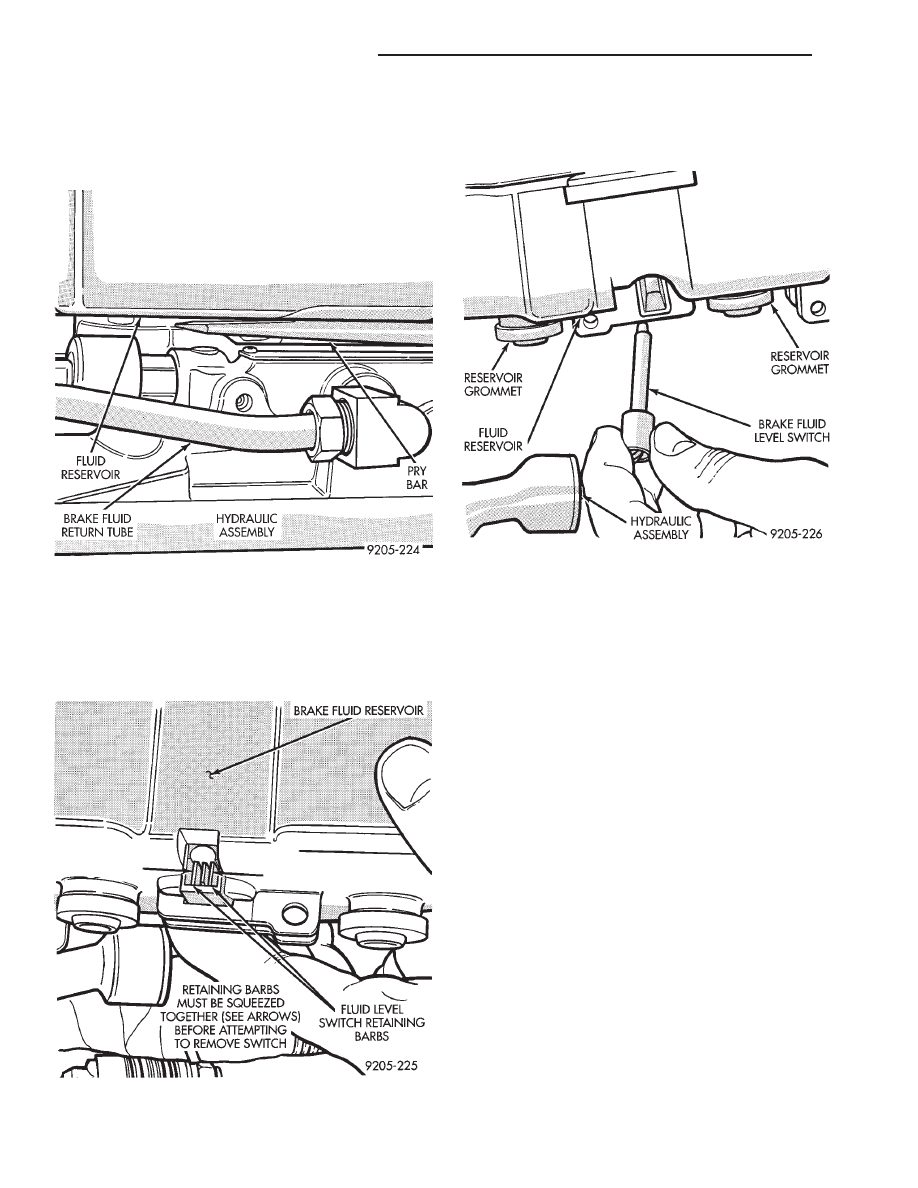

(5) Remove reservoir from hydraulic assembly by

CAREFULLY prying between reservoir and hydrau-

Fig. 9 ABS Fill Level On Filter/Strainer

Fig. 10 Removing Bladder Accumulator

Fig. 11 Remove Reservoir Retaining Pins

Ä

ANTI-LOCK 10 BRAKE SYSTEM

5 - 99

lic assembly with a blunt prying tool (Fig. 12). Use a

rocking motion to help disengage reservoir from

grommets while prying. BE EXTREMELY CARE-

FUL TO AVOID DAMAGING OR PUNCTURING

RESERVOIR DURING THIS PROCEDURE.

(6) Remove the brake fluid level sensor switch

from the reservoir. Remove switch by compressing

the retaining barbs (Fig. 13) on the end of the switch

and then slide switch out of the brake fluid reservoir

(Fig. 14)

(7) Using fingers, remove the 3 reservoir grommets

(Fig. 14) from the hydraulic assembly or reservoir, and

discard. Grommets must not to be reused when

reservoir is installed on hydraulic assembly.

INSTALL

(1) Thoroughly lubricate the new reservoir grom-

mets with clean brake fluid and install on reservoir

outlet ports (Fig. 14). The new reservoir grommets

supplied with reservoir, must ALWAYS be used.

(2) Install brake fluid level switch into brake fluid

reservoir (FIG. 14).

(3) Press reservoir into hydraulic assembly BY

HAND, using a rocking motion to help seat reservoir

into hydraulic assembly. Be sure that grommets are

fully seated in the hydraulic assembly. DO NOT AT-

TEMPT TO POUND RESERVOIR INTO HY-

DRAULIC ASSEMBLY, USING A HAMMER.

(4) Using needle nose pliers, install the 3 brake fluid

reservoir to hydraulic assembly retaining pins (Fig.

11). Make sure that pins are fully installed with barbs

extending past reservoir on opposite side.

(5) Reinstall the high pressure hose, banjo fitting

onto the hydraulic assembly and torque the fitting to

13 N

Im (10.0 ft.lbs).

(6) Install the brake fluid spray shield and bladder

accumulator onto the hydraulic assembly. Install the

bladder accumulator by hand to be sure it does not bet

cross threaded. Be sure that the O-Ring on the

bladder accumulator is fully seated into the hy-

draulic assembly.

(7) Using Oil Filter Band Wrench, Special Tool C-

4065 or equivalent, (Fig. 10) torque the bladder accu-

mulator to 48 N

Im (35 ft. lbs.)

Fig. 12 Remove Reservoir From Hydraulic Assembly

Fig. 13 Fluid Switch Retaining Barbs

Fig. 14 Remove Brake Fluid Level Switch

5 - 100

ANTI-LOCK 10 BRAKE SYSTEM

Ä

(8) Fill the hydraulic assembly reservoir to the top

of the screen on the filter/strainer (Fig. 15). Using

fresh clean brake fluid such as Mopar

t or equivalent,

conforming to DOT 3 requirements.

PUMP SUPPLY FILTER

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

WARNING: FAILURE TO DE-PRESSURIZE HYDRAU-

LIC ACCUMULATOR, BEFORE PERFORMING THIS

OPERATION, MAY RESULT IN PERSONAL INJURY

AND/OR DAMAGE TO PAINTED SURFACES.

(2) Remove and then reinstall one filler cap from

brake fluid reservoir on hydraulic assembly.

(3) Remove brake fluid supply hose from hydraulic

assembly master cylinder at the pump supply filter

(Fig. 16). After hose is removed from pump supply

filter, plug end of hose to stop brake fluid from drain-

ing out of fluid reservoir.

(4) Remove brake fluid supply hose (Fig. 16), from

pump supply filter going to the pump motor assem-

bly.

(5) Remove pump supply filter (Fig. 16) from at-

taching bracket on front of hydraulic assembly.

INSTALL

(1) Attach pump supply filter to attaching bracket

on front of hydraulic assembly (Fig. 16).

(2) Install replacement hose clamp, on brake fluid

supply hose to pump motor assembly.

(3) Install the brake fluid supply hose to pump mo-

tor assembly, onto the nipple of the pump supply fil-

ter. Position hose clamp on brake fluid supply hose

so that it is past upset bead on nipple, then torque

hose clamp to 1.5 N

Im (13.5 in. lbs.).

(4) Remove plug from brake fluid supply hose com-

ing from hydraulic assembly. Install the brake fluid

supply hose from hydraulic assembly, onto the nipple

of the pump supply filter. Position hose clamp on

brake fluid supply hose so that it is past upset bead

on nipple, then torque hose clamp to 1.5 N

Im (13.5

in. lbs.).

(5) Turn ignition switch to the run position to en-

ergize the pump/motor assembly and pressurize hy-

draulic system. Check for leakage at the hydraulic

assembly to hydraulic bladder accumulator fitting.

(6) Again de-pressurize accumulator by pumping

brake pedal a minimum of 40 times as described. Use

procedure in De-Pressurizing Hydraulic Accumulator

in this section of the manual.

(7) Then check the brake fluid level in the hydrau-

lic assembly reservoir. If brake fluid level is low, fill

reservoir to proper level (Fig. 15) with Mopar

t brake

fluid or equivalent conforming to DOT 3 require-

ments.

HYDRAULIC BLADDER ACCUMULATOR

REMOVE

(1) Fully de-pressurize the hydraulic accumulator

by pumping brake pedal a minimum of 40 times. Use

procedure described in De-Pressurizing Hydraulic Ac-

cumulator listed earlier in this section.

Fig. 15 ABS Reservoir Fill Level On Filter/Strainer

Fig. 16 Pump Supply Filter

Ä

ANTI-LOCK 10 BRAKE SYSTEM

5 - 101

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст