Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 68

(2) Using a lint free towel, wipe clean open power

steering hose ends, power steering pump and steer-

ing gear ports.

(3) Install new O-rings or sealing washers on the

ends of the power steering hoses. Lubricate O-rings

or sealing washers using clean power steering fluid.

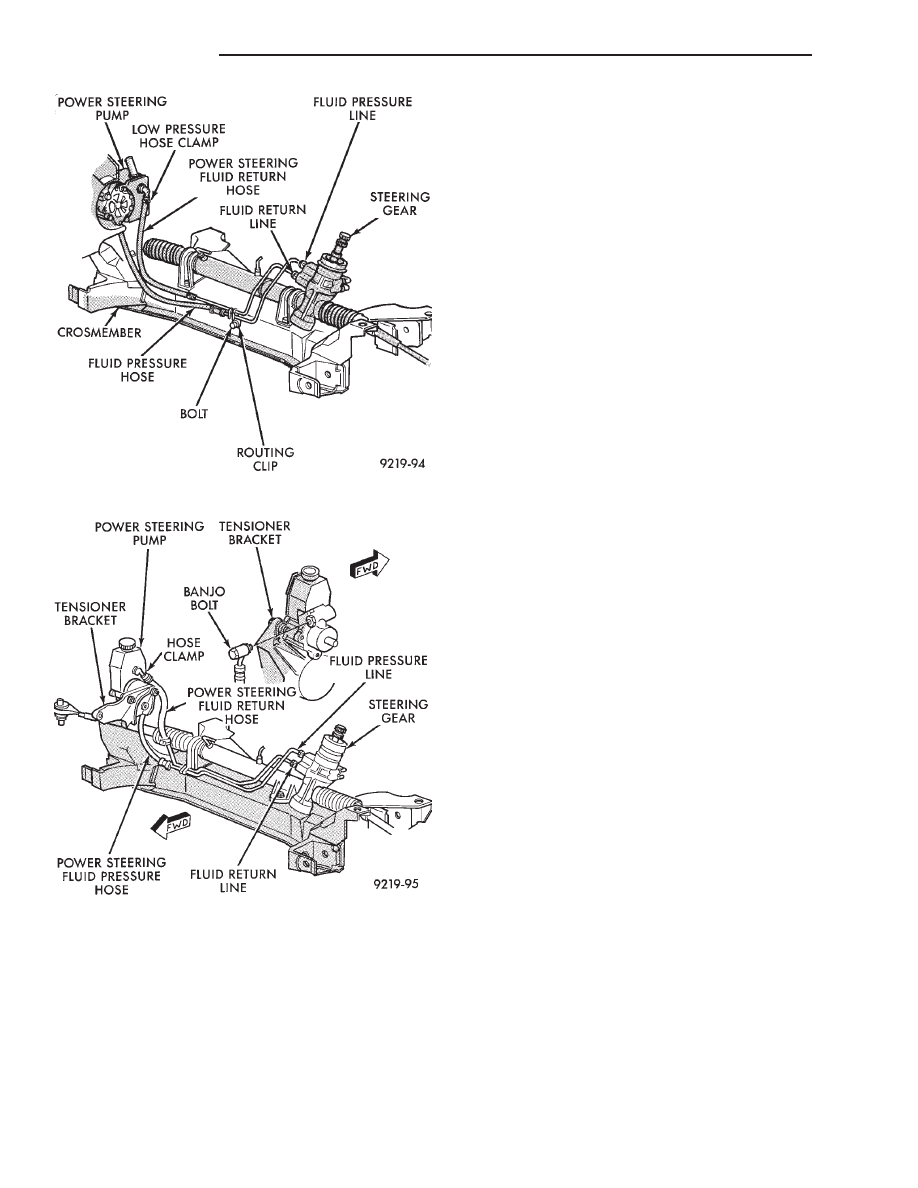

(4) Attach power steering hose to proper connec-

tions at power steering pump and steering gear. Cor-

rectly route power steering hoses avoiding tight

bends or kinking of the hose. Install power steering

hose to crossmember routing bracket. Hoses must

remain away from exhaust system, vehicle com-

ponents and unfriendly surfaces causing pos-

sible damage to power steering hoses.

(5) Tighten all fasteners shown for specific applica-

tions in (Fig. 1 to 4) to their correct torques listed

below:

• Pump End Banjo Bolt — 34 NIm (25 ft. lbs.)

• Pump End Tube Nut — 34 NIm (25 ft. lbs.)

• Gear End Tube Nuts (2) — 34 NIm (25 ft. lbs.)

• Crossmember Bracket Bolt — 23 NIm (17 ft. lbs.)

• Pump Bracket Nut — 40 NIm (30 ft. lbs.)

• Gear Bracket Bolt — 68 NIm (50 ft. lbs.)

(6) Install vehicle’s wiring harness connector (if ap-

plicable to vehicle being serviced) onto the power

steering pressure switch (Fig. 1 & 2).

(7) When used, protective sponge sleeves must be

properly positioned on power steering hoses. This is to

prevent hose contact with other components.

(8) After hose is installed, check for leaks. (See

Pump Installation).

POWER STEERING PUMP REMOVAL

WARNING: POWER STEERING OIL, ENGINE COMPO-

NENTS AND

EXHAUST

SYSTEM

MAY BE

EX-

TREMELY HOT IF ENGINE HAS BEEN RUNNING. DO

NOT START ENGINE WITH ANY LOOSE OR DISCON-

NECTED HOSES, OR ALLOW HOSES TO TOUCH HOT

EXHAUST MANIFOLD OR CATALYST.

2.2 & 2.5 LITER

REMOVE

(1) Remove battery cable from (-) negative post on

battery and isolate cable.

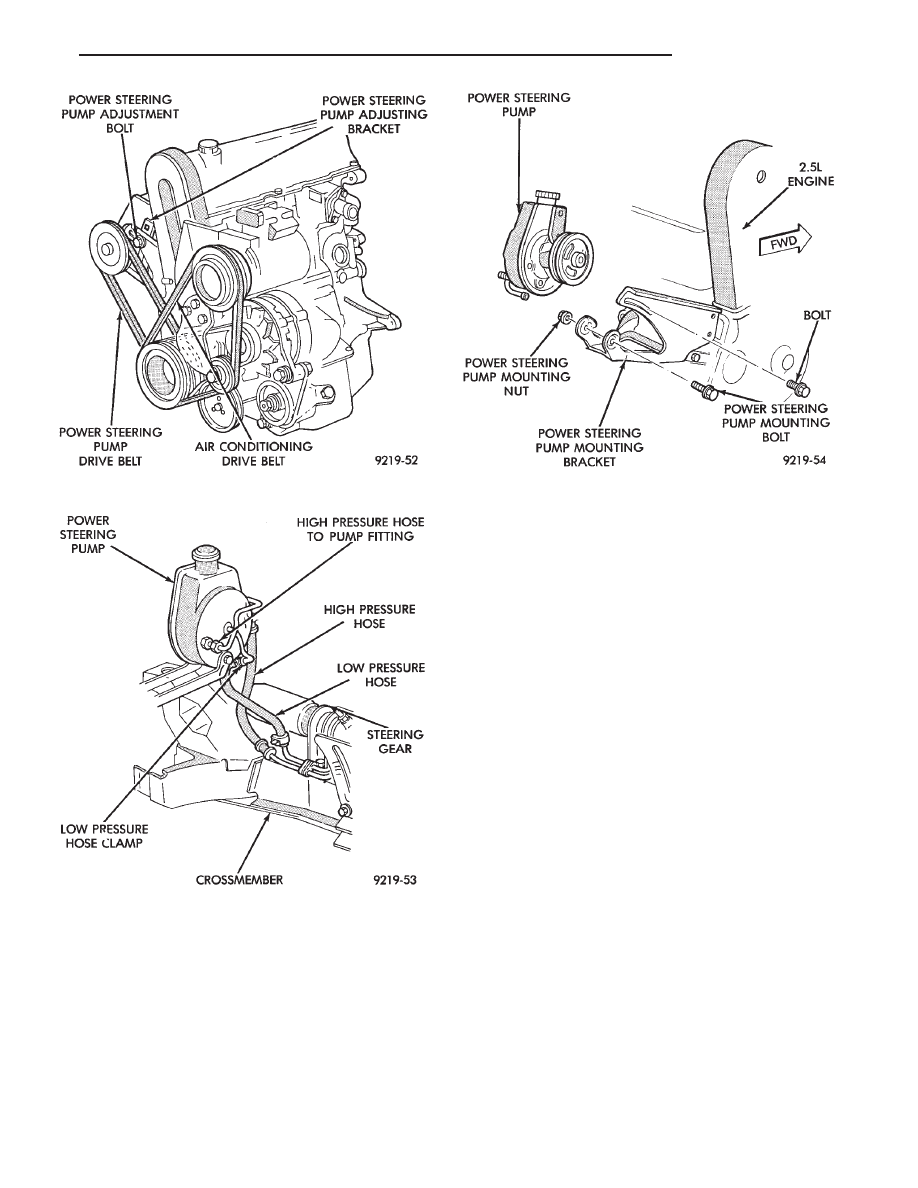

(2) Loosen power steering pump adjustment bolt

and rotate power steering pump forward in bracket.

Remove power steering pump drive belt from power

steering pump (Fig. 1). It is not necessary to remove

power steering pump drive belt from engine.

(3) Raise vehicle See Hoisting, Group 0. Remove

hose clamp and low pressure fluid hose from power

steering pump (Fig. 2).

(4) Remove power steering fluid pressure line (Fig.

2) from power steering pump. Drain excess power

steering fluid from line.

(5) Loosen but do not remove nut, holding back of

power steering pump to its mounting bracket (Fig. 3).

Then remove bolt attaching pulley side of power steer-

ing pump to the mounting bracket (Fig. 3).

(6) Lower Vehicle. Then remove bolt, retaining

power steering pump in adjusting slot of power steer-

ing pump mounting bracket (Fig. 3).

(7) Remove power steering pump from top of engine

compartment,

using

the

following

procedure.

Lifting

power

steering

pump

out

of

mounting

Fig. 5 Power Steering Hose Routing 3.3 & 3.8L

Fig. 6 Power Steering Hose Routing Turbo III

19 - 12

STEERING

Ä

bracket, rotating pump 90° and remove it out be-

tween engine and dash panel.

(8) Transfer required parts from removed power

steering pump, to replacement power steering pump.

INSTALL

(1) Install power steering pump back in vehicle in

the reverse order of removal.

(2) Install power steering pump back on mounting

bracket, being sure stud on back of power steering

pump is in slotted hole in mounting bracket. Install

bolt attaching power steering pump to adjusting slot

in bracket (Fig. 3), but do not tighten nut or bolt.

(3) Raise vehicle See Hoisting, Group 0.

(4) Install bolt attaching pulley side of power

steering pump to power steering pump mounting

bracket (Fig. 3). Do not fully tighten power steer-

ing pump mounting bolts at this time.

(5) Install power steering fluid pressure line into

output fitting on power steering pump (Fig. 2).

Torque power steering pressure line tube nut to 31

N

Im (275 in. lbs.). Before connecting pressure line

to power steering pump inspect O-ring on pres-

sure line for damage and replace if required.

(6) Install power steering fluid, low pressure re-

turn hose on power steering pump low pressure fit-

ting (Fig. 2). Install hose clamp on low pressure

return hose, being sure hose clamp is installed on

hose past upset bead on power steering pump tube.

(7) Lower vehicle.

(8) Install power steering pump drive belt on

power steering pump pulley. Using power steering

pump adjusting bracket (Fig. 1), rotate pump in

bracket to obtain correct belt tension. Tighten bolt at

power steering pump mounting bracket adjusting slot

(Fig. 1) to 54 N

Im (40 ft. lbs.). Torque the power

steering pump to mounting bracket pivot, nut and

bolt (Fig. 1) to 54 N

Im (40 ft. lbs.).

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar

T

, Power

Steering Fluid, or equivalent.

(9) Fill power steering pump reservoir to correct

fluid level.

Fig. 1 Power Steering Pump Drive Belt Removal

Fig. 2 Power Steering Fluid Hoses

Fig. 3 Power Steering Pump Remove And Install

Ä

STEERING

19 - 13

(10) Connect negative cable back on negative post

of battery.

(11) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks. See Checking Fluid Level.

3.0 LITER

REMOVE

(1) REMOVE THE (-) NEGATIVE BATTERY CA-

BLE FROM THE BATTERY AND ISOLATE CA-

BLE.

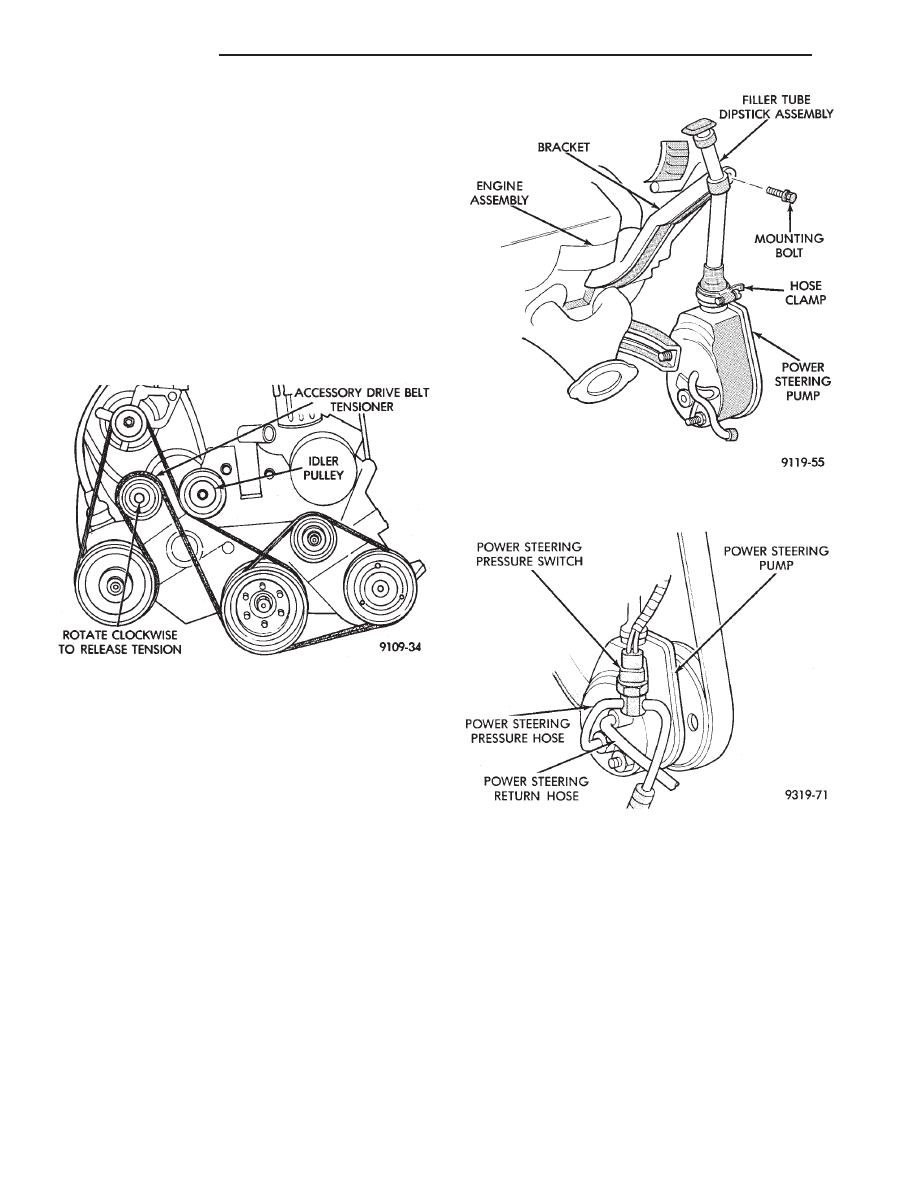

(2) Remove the serpentine accessory drive belt

from engine (Fig. 4). See Cooling, Group 7 for de-

tailed removal procedure.

(3) Remove the hose clamp and bolt mounting the

power steering pump filler tube and dipstick assem-

bly (Fig. 5) to power steering pump and generator

bracket. Remove filler tube and dipstick assembly

from power steering pump.

(4) Raise vehicle See Hoisting, Group 0.

(5) Remove the 2 nut, bolt and spring assemblies

attaching the exhaust pipe to exhaust manifold. Re-

move exhaust pipe from exhaust manifold and move

to left side of vehicle. This is required for clear-

ance to remove power steering pump from vehi-

cle.

(6) Remove vehicle’s wiring harness connector (if

applicable to vehicle being serviced) from the power

steering pressure switch (Fig. 6).

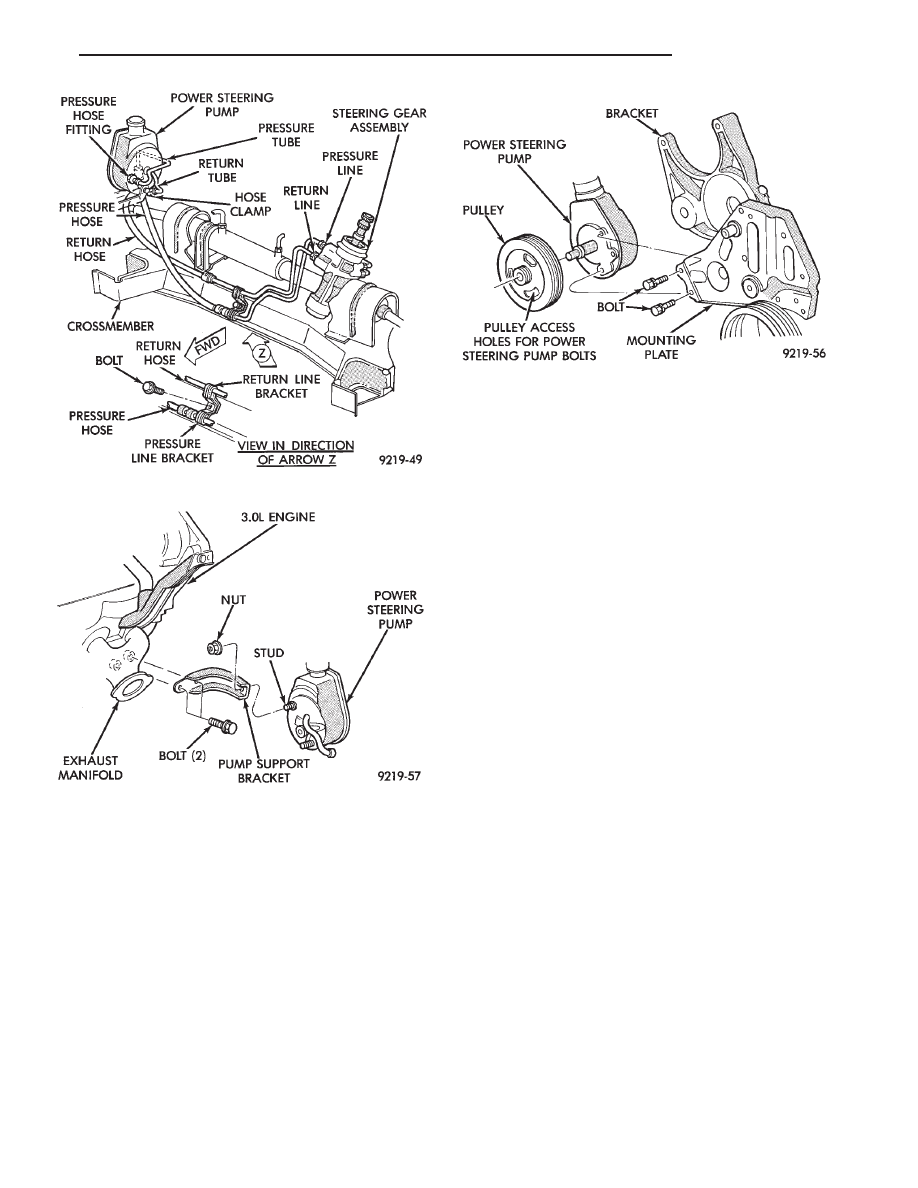

(7) Put oil drain pan under vehicle to catch power

steering fluid. Remove hose clamp and low pressure

fluid hose, from power steering gear fluid tube (Fig.

7). Allow excess power steering fluid to drain from

power steering pump and hose.

(8) Loosen the high pressure power steering fluid

line fitting at the power steering pump (Fig. 7). Then

remove high pressure power steering fluid line from

power steering pump.

(9) Remove nut holding the power steering pump

rear support bracket to pump (Fig. 8). Then remove

the 2 bolts (Fig. 7) mounting the power steering

pump support bracket to engine and remove bracket

from vehicle.

(10) Remove the 2 bolts that mount the front of

the power steering pump to the mounting plate (Fig.

9). Access to the mounting bolts is through the holes

in power steering pump pulley using a deep well

socket.

(11) Remove the power steering pump and pulley

assembly from vehicle. Remove pump assembly from

vehicle in area between floor pan and front suspen-

sion crossmember. Pump will fit through area of ex-

haust pipe tunnel in floor pan.

Fig. 4 3.0L Serpentine Drive Belt Routing

Fig. 5 Power Steering Pump Filler Tube/Dipstick

Assembly

Fig. 6 Power Steering Pressure Switch Location

3.0L

19 - 14

STEERING

Ä

(12) Transfer Required parts to the new power

steering pump assembly before installing in vehicle.

INSTALL

(1) Install the power steering pump assembly back

in vehicle in reverse order of removal.

(2) Hold power steering pump against mounting

plate. Align power steering pump mounting holes

with mounting holes in plate and install bolts (Fig.

9). Torque the 2 power steering pump to mounting

plate bolts to 54 N

Im (40 ft. lbs.).

(3) Install the rear power steering pump to engine

block support bracket, onto the stud on back of power

steering pump (Fig. 8). Then install the 2 bolts

mounting the support bracket to the engine block.

Torque the 2 support bracket to engine block mount-

ing bolts to 54 N

Im (40 ft. lbs.).

(4) Install the nut on stud of power steering pump

attaching pump to rear support bracket (Fig. 8).

Torque nut to 54 N

Im (40 ft. lbs.)

(5) Install the high pressure power steering fluid

line on the power steering pump outlet fitting (Fig.

7). Torque the high pressure fluid line to power

steering pump fitting to 31 N

Im (275 in. lbs.).

(6) Install the low pressure power steering fluid

hose onto the power steering gear fluid tube (Fig. 7).

Install hose clamp on hose. Be sure hose clamp is

installed beyond upset bead on tube.

(7) Install the exhaust pipe back on the exhaust

manifold. Install the nut, bolt and spring assemblies

and torque bolts to 28 N

Im (250 in. lbs.).

(8) Install vehicle’s wiring harness connector (if

applicable to vehicle being serviced) onto the power

steering pressure switch (Fig. 6).

(9) Lower vehicle.

(10) Install the power steering pump filler tube

and dip stick assembly on the neck of the power

steering pump (Fig. 5). Install the bolt (Fig. 5) at-

taching the filler tube/dip stick assembly to the gen-

erator bracket, then torque bolt to 11 N

Im (100 in.

lbs.).

(11) Position the hose clamp on the filler tube as-

sembly rubber boot and adequately tighten hose

clamp.

(12) Install the serpentine accessory drive belt on

engine (Fig. 4). See Cooling, Group 7 for detailed in-

stallation procedure.

CAUTION: Do not use automatic transmission fluid

in power steering system. Only use Mopar

T

, Power

Steering Fluid, or equivalent.

(13) Fill power steering pump reservoir to correct

fluid level.

(14) Connect the negative battery cable back on

the negative battery post.

Fig. 7 Power Steering Hose Remove/Replace

Fig. 8 Power Steering Support Bracket

Fig. 9 Power Steering Pump Mounting 3.0L

Ä

STEERING

19 - 15

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст