Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 264

RADIATOR PRESSURE CAP

Radiators are equipped with a pressure cap which

releases pressure at some point within a range of

97-124 kPa (14-18 psi) (Fig. 7).

The system will operate at higher than atmospheric

pressure which raises the coolant boiling point allow-

ing increased radiator cooling capacity.

There is also a vent valve in the center of the cap that

allows a small coolant flow to the CRS tank. If valve is

stuck shut, the radiator hoses will be collapsed

on cool down. Clean the vent valve (Fig. 7) to

ensure proper sealing when boiling point is

reached.

There is also a gasket in the cap to seal to the top of

the filler neck so that vacuum can be maintained for

drawing coolant back into the radiator from the coolant

reserve system tank.

RADIATOR CAP TO FILLER NECK SEAL PRES-

SURE RELIEF CHECK

The pressure cap upper gasket (seal) pressure relief

can be checked by removing the overflow hose at the

radiator filler neck nipple (Fig. 7). Attach the Radiator

Pressure Tool to the filler neck nipple and pump air

into the radiator. Pressure cap upper gasket should

relieve at 69-124 kPa (10-18 psi) and hold pressure at

55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS DO NOT OPEN

HOT ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING

OR

INJURY,

THE

RADIATOR

CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM IS

HOT AND/OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

time except for the following purposes:

(1) Check and adjust antifreeze freeze point.

(2) Refill system with new antifreeze.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT

PUSHING

DOWN

ROTATE

IT

COUNTER-

CLOCKWISE TO THE FIRST STOP. ALLOW FLUIDS

TO ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE) BE-

FORE AND AFTER TURNING TO THE FIRST STOP IS

RECOMMENDED.

PRESSURE TESTING RADIATOR CAPS

Dip the pressure cap in water, clean any deposits off

the vent valve or its seat and apply cap to end of

Radiator Pressure Tool. Working the plunger, bring the

pressure to 104 kPa (15 psi) on the gauge. If the

pressure cap fails to hold pressure of at least 97 kPa

(14 psi) replace cap. See CAUTION

If the pressure cap tests properly while positioned on

Radiator Pressure Tool, but will not hold pressure or

vacuum when positioned on the radiator. Inspect the

radiator filler neck and cap top gasket for irregularities

that may prevent the cap from sealing properly.

CAUTION: Radiator Pressure Tool is very sensitive to

small air leaks which will not cause cooling system

problems. A pressure cap that does not have a

history of coolant loss should not be replaced just

because it leaks slowly when tested with this tool.

Add water to the tool. Turn tool upside down and

recheck pressure cap to confirm that cap is bad.

INSPECTION

Hold the cap in hand, right side up (Fig. 7). The

vent valve at the bottom of the cap should open. If the

rubber gasket has swollen and prevents the valve from

opening, replace the cap.

Hold the cleaned cap in hand upside down. If any

light can be seen between vent valve and rubber

gasket, replace cap. Do not use a replacement cap

that has a spring to hold the vent shut.

Replacement cap must be of the type designed for

coolant reserve systems. This design assures coolant

return to radiator.

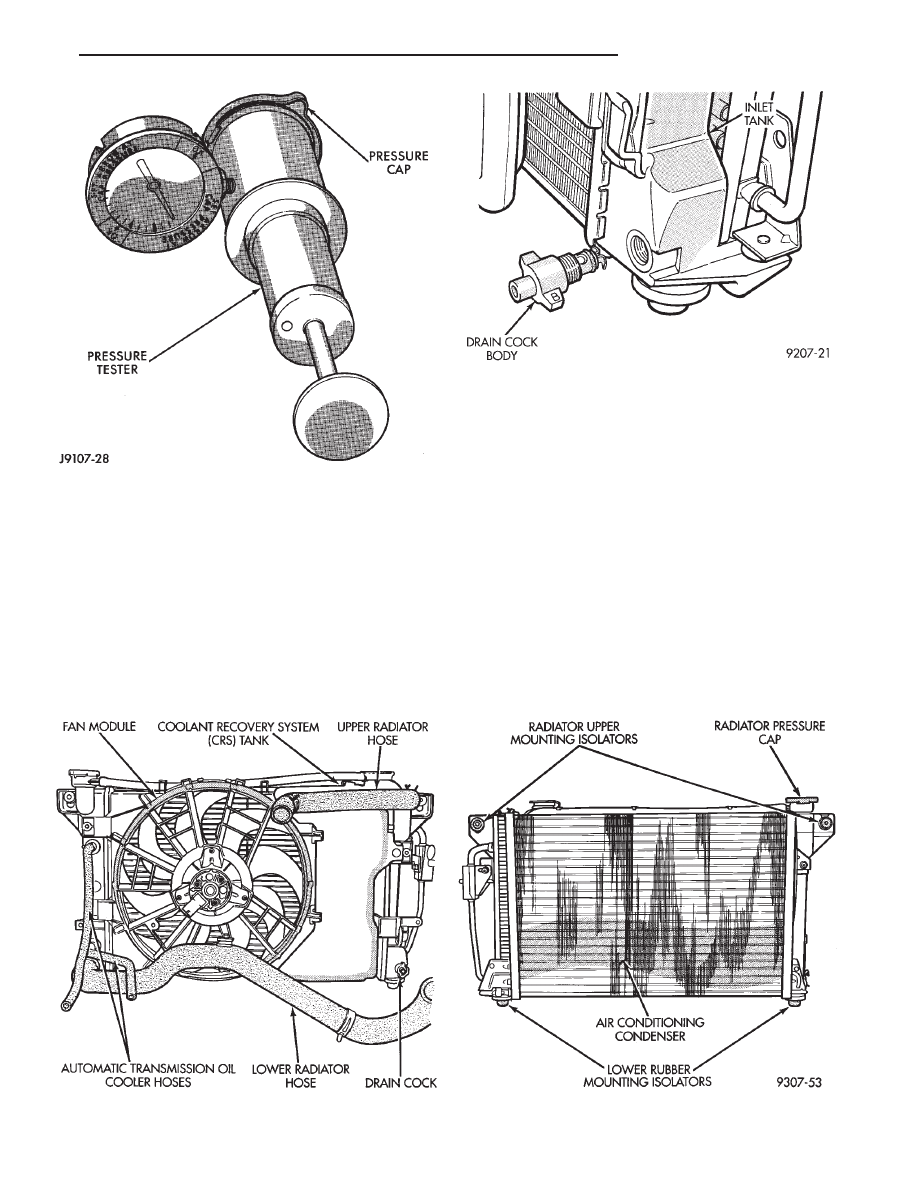

RADIATORS

The radiators are crossflow types (horizontal tubes)

with design features that provide greater strength as

well as sufficient heat transfer capabilities to keep the

engine satisfactorily cooled.

CAUTION: Plastic tanks, while stronger then brass

are subject to damage by impact, such as wrenches.

Fig. 7 Radiator Pressure Cap Filler Neck

7 - 18

COOLING SYSTEM

Ä

RADIATOR DRAINCOCK SERVICE

REMOVAL

(1) Turn the drain cock stem counterclockwise to

unscrew the stem. When the stem is unscrewed to

the end of the threads, pull the stem (Fig. 10) from

the radiator tank.

INSTALLATION

(1) Push the draincock assembly body into the

tank opening until it snaps into place.

(2) Tighten the draincock stem by turning clock-

wise to 2.0-2.7 N

Im (18-25 in. lbs.) torque.

RADIATOR COOLANT FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedure:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper ra-

diator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE RADIATOR PRES-

SURE CAP WITH THE SYSTEM HOT AND UNDER

PRESSURE

BECAUSE

SERIOUS

BURNS

FROM

COOLANT CAN OCCUR.

Fig. 9 Cooling Module—Typical

Fig. 8 Pressure Testing Radiator Cap

Fig. 10 Draincock Assembly—Typical

Ä

COOLING SYSTEM

7 - 19

(2) Remove radiator pressure cap when engine is

cold, Idle engine until thermostat opens, you should

observe coolant flow while looking down the filler

neck. Once flow is detected install radiator pressure

cap.

RADIATOR

REMOVAL

(1) Disconnect negative battery cable from battery.

WARNING:

DO

NOT

REMOVE

THE

CYLINDER

BLOCK PLUG OR THE RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

(2) Drain cooling system. Refer to Draining Cool-

ing System of this section.

(3) Remove hose clamps and hoses from the radia-

tor (Fig. 11). Remove coolant reserve system tank to

filler neck tube.

(4) Remove

automatic

transmission

hoses,

if

equipped.

(5) Remove fan and fan support assembly by dis-

connecting fan motor electrical connector. Remove

fan shroud retaining clips, located on the top and

bottom of the shroud for AA, AG, AJ and AP vehi-

cles. AC/AY vehicle retainer clips are located on the

top only. Lift shroud up and out of bottom shroud at-

tachment clips separating shroud from radiator. Fan

damage should always be avoided.

(6) Remove upper radiator mounting screws. Dis-

connect the engine block heater wire if equipped.

(7) Remove the air conditioning condenser attaching

screws located at the top front of the radiator,if

equipped.

Radiator can now be lifted free from engine compart-

ment. Care should be taken not to damage radia-

tor cooling fins or water tubes during removal.

INSTALLATION

(1) Slide radiator down into position behind radiator

support (yoke).

(2) Attach air conditioning condenser to radiator, if

equipped, with a force of approximately 10 lbs. to seat

the radiator assembly lower rubber isolators in the

mount holes provided.

(3) Tighten radiator mounting screws to 11.9N

Im

(105 in. lbs.).

(4) Connect

automatic

transmission

hoses,

if

equipped. Tighten hose clamps to 4 N

Im (35 in. lbs.).

(5) Slide fan shroud, fan and motor down into clips

on lower radiator flange. Replace shroud retaining

clips.

(6) Install upper and lower radiator hoses (including

coolant reserve hose).

(7) Connect fan motor electrical connection and con-

nect negative battery cable.

(8) Fill cooling system with coolant. Refer to Refill-

ing Cooling Systems. in this group.

(9) Operate engine until it reaches normal operating

temperature. Check cooling system and automatic

transmission for correct fluid levels.

Fig. 11 Cooling Modules—All Models

7 - 20

COOLING SYSTEM

Ä

RADIATOR HOSES

The hoses are removed using Constant Tension

Clamp pliers to compress hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original style spring type clamp.

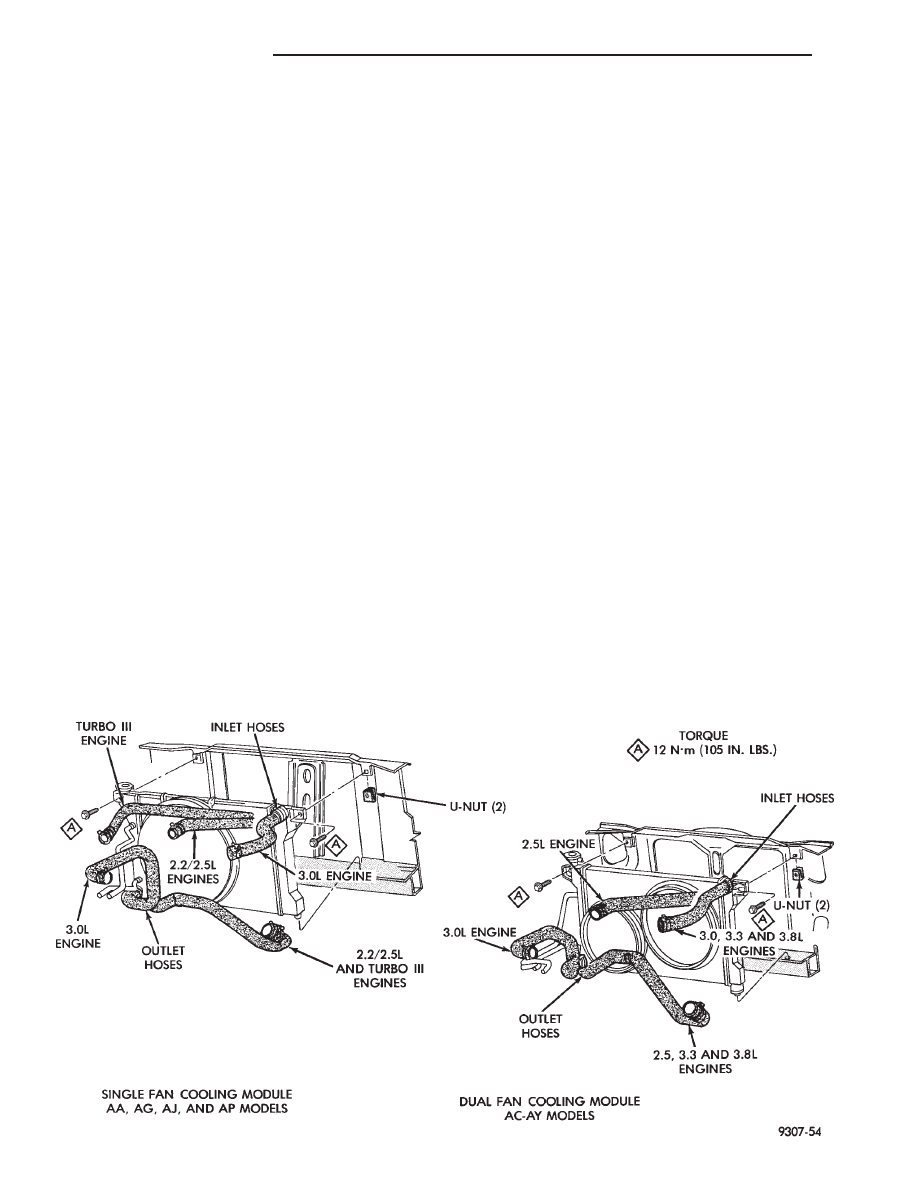

FANS

All models use electric motor driven cooling system

fans. The fan modules include a motor support which

may (depending on model) include a shroud. The

module is fastened to the radiator by screws with

U-nuts and retaining clips (Fig. 12).

All fan motors are one speed. Attempts to reduce

high temperature gauge reading by increasing en-

gine speed, at the same vehicle speed, can increase

high temperature.

SINGLE FAN

There are no repairs to be made to the fan. If the

fan is warped, cracked, or otherwise damaged, it

must be replaced with only the recommended part for

adequate strength, performance and safety (Fig. 13).

DUAL FAN MODULE—AC/AY BODY

The dual fan module (Fig. 11) is a combination of 2

fans mounted in a one piece shroud which are simul-

taneously activated. The dual fan system improves

engine cooling and air conditioning performance in hot

weather and severe driving conditions, while reducing

fan noise and power consumption.

REMOVAL

Disconnect electric motor lead. Remove fan module

to radiator fasteners and retaining clips. Remove as-

sembly from radiator support.

To remove fan from motor shaft, bench support the

motor and motor shaft, while removing the fan retain-

ing clip, so that the shaft and motor will not be

damaged by excessive force. Surface or burr re-

moval may be required to remove fan from motor

shaft. (Fig. 13). Do not permit the fan blades to touch

the bench.

INSTALLATION

Slide the fan on motor shaft. Support motor and

shaft as above while installing fan retaining clip.

Install assembly into pocket on lower radiator tank.

Attach retaining clips and fasteners to radiator tank.

Right side fastener is longer on A/C equipped

vehicles. Connect fan motor lead. For wiring dia-

grams of fan motor systems see Wiring Diagrams

Manual

RADIATOR FAN CONTROL—ALL EXCEPT V-6

ENGINE

Fan control is accomplished two ways. The fan al-

ways runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan is

turned on by the temperature of the coolant which is

sensed by the coolant temperature sensor which

Fig. 12 Servicing Fan Module

Fig. 13 Radiator Fan Retaining Clip—Typical

Ä

COOLING SYSTEM

7 - 21

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст