Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 231

pared by the (CAB) and used to detect brake system

faults that would require Anti -Lock Braking to be

disabled.

The Boost Pressure Transducer is mounted on the

bottom of the hydraulic assembly, (Fig. 1) and moni-

tors booster servo pressure. The Primary Pressure

Transducer is mounted on the left side of the hydrau-

lic assembly and monitors primary master cylinder

pressure.

DIFFERENTIAL PRESSURE SWITCH

A non-latching Differential Pressure Switch is used

to detect a pressure difference greater than 2,068

kPa (300 psi.) between the primary and secondary

master cylinder hydraulic circuits. If detected, the

Differential Pressure Switch grounds the output of

the primary pressure transducer (circuit B-218). This

results in a 0.0 volt signal from the Primary Pres-

sure Transducer that is sensed by the (CAB) as a dif-

ferential pressure fault. The (CAB) will then light

the Red Brake Warning Lamp and the Amber Anti-

Lock Warning Lamp and disable the Anti-Lock brak-

ing function. See Fig. 1 for location of the differential

pressure switch.

PROPORTIONING VALVES

The

ABS

system

uses

screw-in

Proportioning

Valves in place of the conventional Height Sensing

Proportioning Valve. Each rear brake circuit has its

own screw-in Proportioning Valve that is attached to

the rear brake outlet ports of the hydraulic assembly

(Fig. 1). These valves limit brake pressure to the

rear brakes after a certain brake pressure is reached.

This improves front to rear wheel brake balance dur-

ing normal braking.

FILTERS-SERVICEABILITY

There is a screen filter in each of the two master

cylinder fill ports. There is also a low pressure filter

for the pump/motor. The filter is integral to the

Pump/Motor low pressure hose.

FLUID LEVEL SWITCH

A Low Fluid Switch is located in the hydraulic as-

sembly fluid reservoir, (Fig. 1). The switch consists of

a float and magnetic reed switch that closes when

low fluid is detected. The Low Fluid Switch is used

as an input, to the Red Brake Warning Lamp, the

(CAB), and the EVIC (if so equipped). When a low

fluid condition exists the switch will close, grounding

the low fluid circuit and illuminating the Red Brake

Warning Lamp. The (CAB) will disable the Anti-

Lock Function and light the Amber Anti-Lock Warn-

ing Lamp if vehicle is in motion above 3 mph. If

vehicle is not in motion, the Amber Anti-Lock Warn-

ing Lamp will NOT be lit.

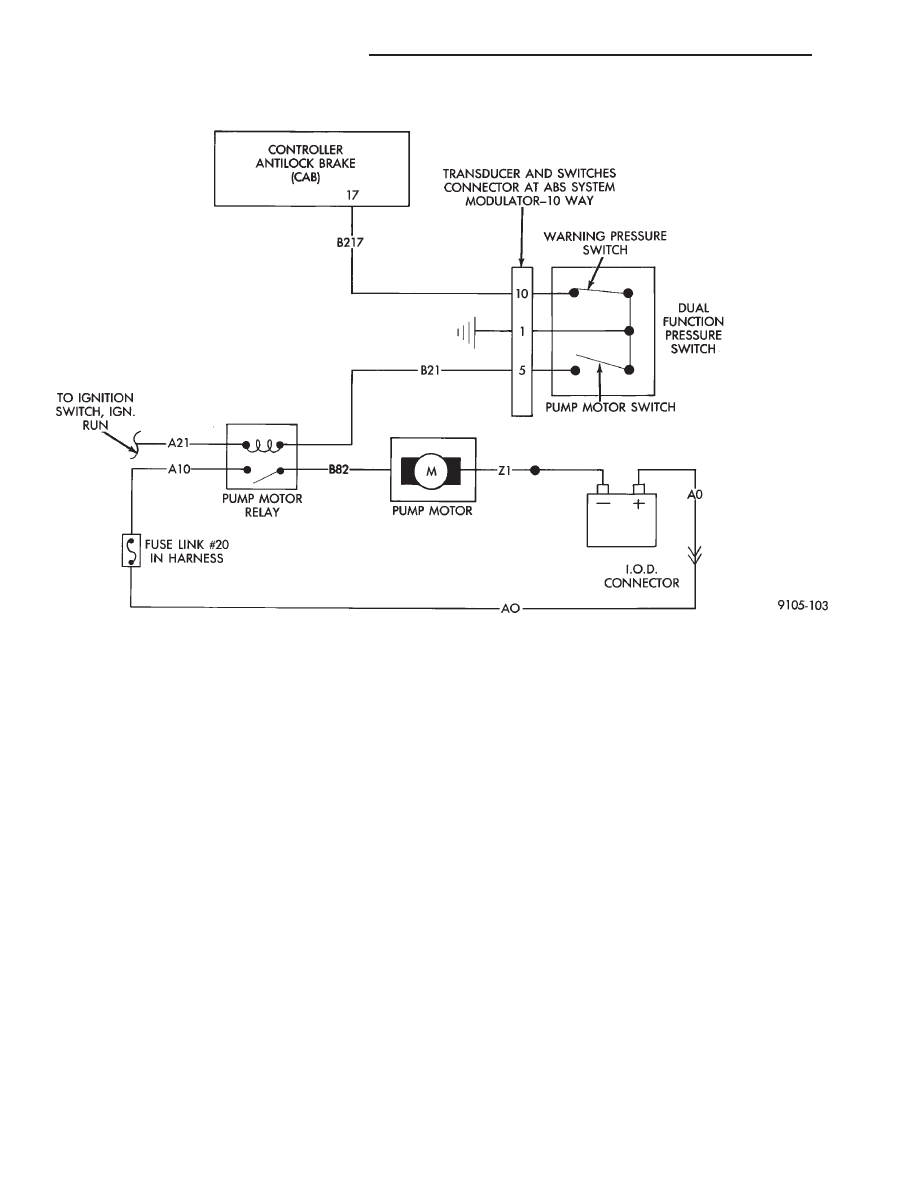

DUAL FUNCTION PRESSURE SWITCH WIRING DIAGRAM

5 - 78

ANTI-LOCK 10 BRAKE SYSTEM

Ä

PUMP/MOTOR ASSEMBLY

NOTE: The (CAB) does not control the opera-

tion of the pump/motor assembly.

The Pump/Motor Assembly is mounted to the tran-

saxle below the hydraulic assembly,(Fig. 3). Integral to

the Pump/Motor Assembly is an accumulator using a

sliding piston configuration with a nitrogen pre-charge

of 3,172 kPa (460 psi.) The Pump/Motor is an electri-

cally driven pump that takes low pressure brake fluid

from the hydraulic assembly fluid reservoir and pres-

surizes it. The pressurized fluid is then stored in the

piston accumulator and hydraulic bladder accumulator

for power assist and Anti-Lock Braking. Operation of

the Pump/Motor is controlled by the Dual Function

Pressure Switch through the Pump/Motor Relay. The

(CAB) does NOT control the Pump/Motor activa-

tion. Rubber isolators are used to mount the pump to

its bracket for noise isolation. The Pump/Motor Assem-

bly is connected to the Hydraulic Assembly with a low

pressure return hose and a high pressure hose. A filter

is located in the low pressure return line.

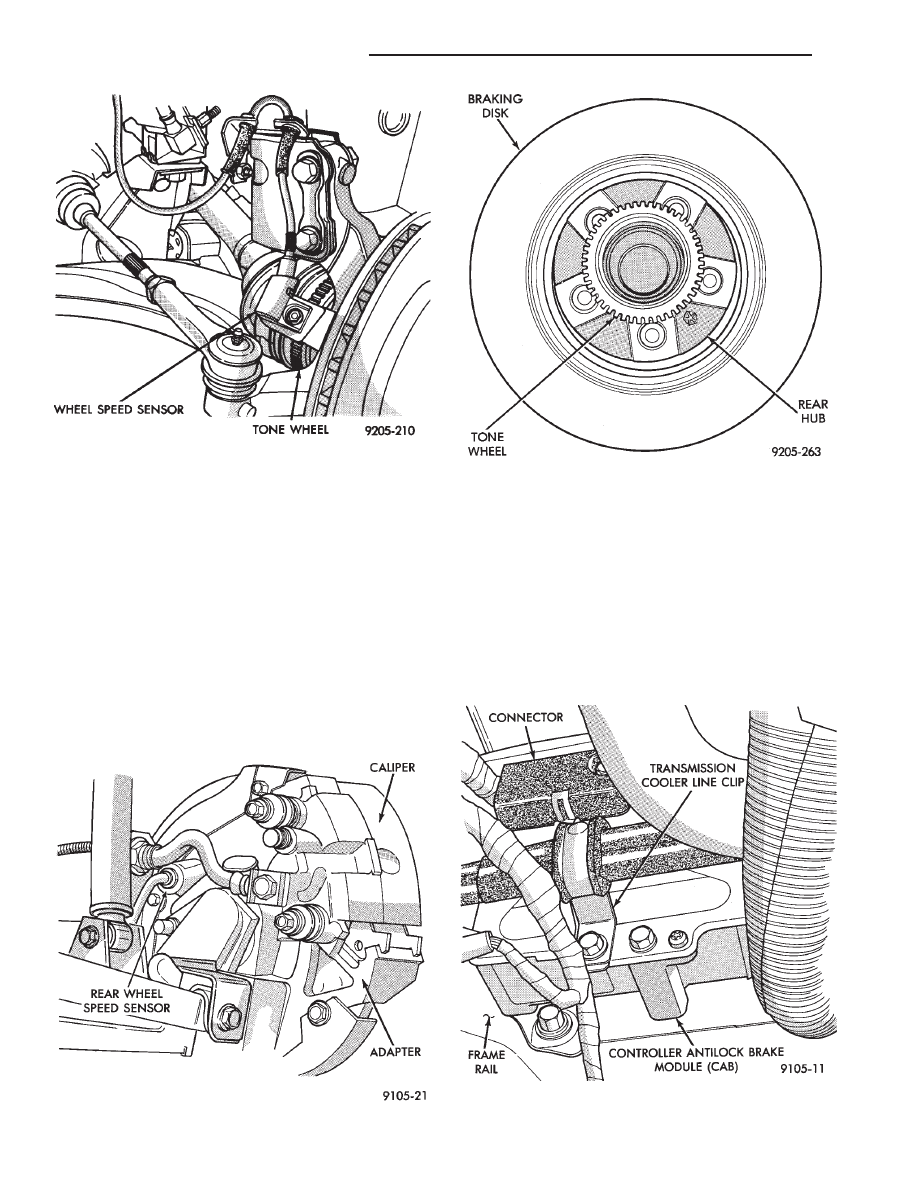

WHEEL SPEED SENSORS

One Wheel Speed Sensor (WSS), is located at each

wheel (Fig. 4, 5 and 6) and sends a small (AC) electrical

signal to the control module (CAB). This signal is

generated by magnetic induction. The magnetic induc-

tion is created when a toothed sensor ring (Tone Wheel)

passes by the stationary magnetic (Wheel Speed Sen-

sor). The (CAB) converts the (AC) electrical signal

generated at each wheel into a digital signal. If a wheel

locking tendency is detected, the (CAB) will then

modulate hydraulic pressure to prevent the wheel(s)

from locking.

The front Wheel Speed Sensor (Fig. 4) is mounted to

a boss on the steering knuckle, for both the Front

Wheel Drive and All Wheel Drive applications. The

Tone Wheel is part of the outboard constant velocity

joint housing.

The Rear Wheel Speed Sensor, is mounted to the

caliper mounting adapter (Fig. 5). The rear Tone

Wheel is an integral part of the rear disc brake rotor

hub (Fig. 6).

The speed sensor, to tone wheel air gap on all ap-

plications is NOT adjustable.

All 4 of the vehicles, Wheel Speed Sensors are ser-

viced individually as replaceable components.

The Front Wheel Drive front Tone Wheels are ser-

viced as an assembly with the front outboard con-

Fig. 3 Pump/Motor Assembly And Heat Shield

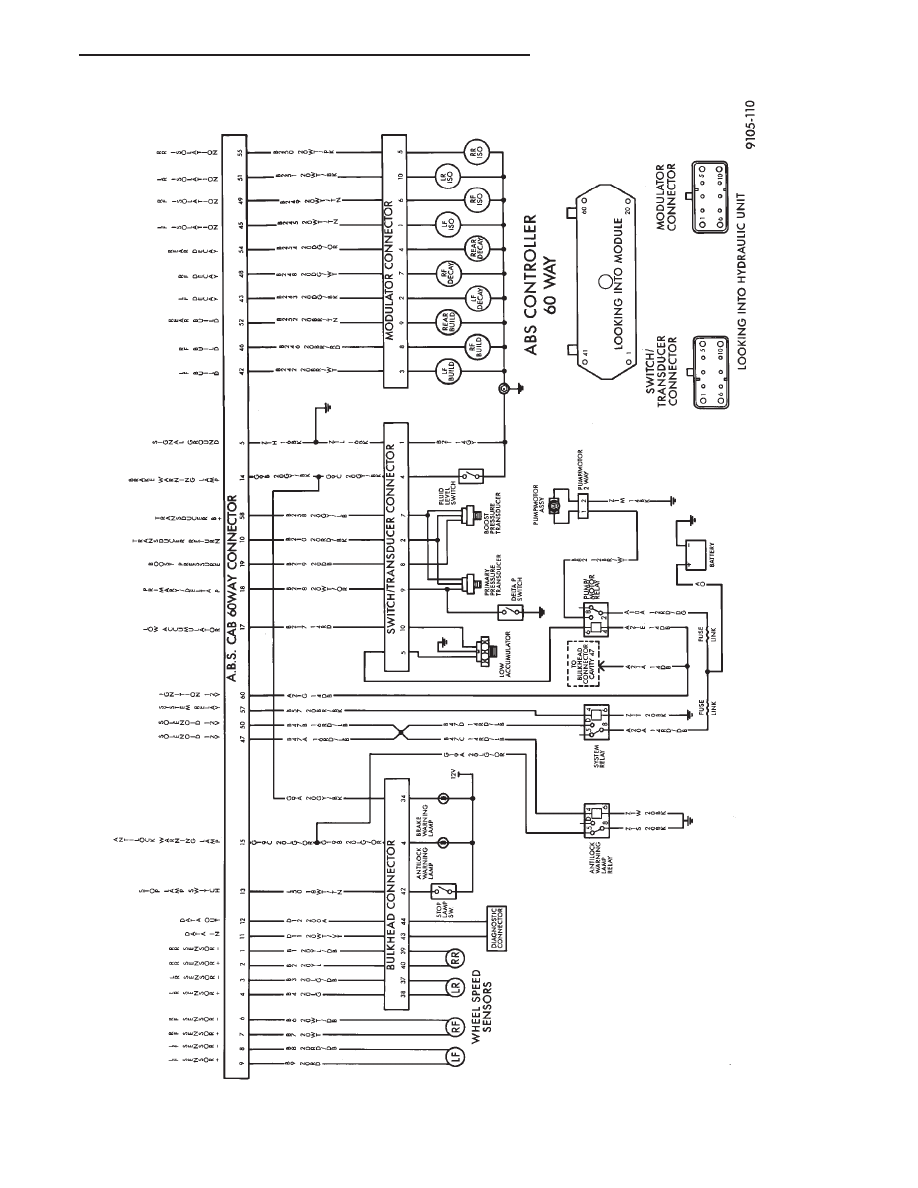

PRESSURE SWITCH AND PRESSURE TRANSDUCER WIRING

Ä

ANTI-LOCK 10 BRAKE SYSTEM

5 - 79

stant velocity joint housings. The rear Tone Wheels

are serviced as an assembly with the rear disc brake

rotor hub.

Correct Anti-Lock System operation is dependent

on wheel speed signals from the wheel speed sensors.

The vehicles’ wheels and tires must all be the same

size and type to generate accurate signals. In addi-

tion, the tires must be inflated to the recommended

pressures for optimum system operation. Variations

in wheel and tire size or significant variations in in-

flation pressure can produce inaccurate wheel speed

signals.

CONTROLLER ANTI-LOCK BRAKE (CAB)

The Anti-Lock Brake Controller is a small micro-

processor based device that monitors the brake sys-

tem and controls the system while it functions in

Anti-Lock Mode. The CAB is located under the bat-

tery tray and is mounted to the left frame rail (Fig.

7) and uses a 60-way system connector. The power

source for the CAB is through the ignition switch to

pin 60 of the controller. With the ignition in the

RUN or ON position. IF THE (ABS) CONTROL-

LER NEEDS TO BE REPLACED BE SURE THE

CORRECT CONTROLLER IS USED. THE CON-

TROLLER ANTI-LOCK BRAKE (CAB) IS NOT

ON THE CCD BUS

Fig. 5 Rear Wheel Speed Sensor

Fig. 4 Front Wheel Speed Sensor

Fig. 6 Rear Tone Wheel

Fig. 7 Location Controller Anti-Lock Brake (CAB)

5 - 80

ANTI-LOCK 10 BRAKE SYSTEM

Ä

ABS

SYSTEM

WIRING

SCHEMATIC

Ä

ANTI-LOCK 10 BRAKE SYSTEM

5 - 81

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст