Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 37

2.5L FLEXIBLE FUEL MULTI-PORT FUEL INJECTION—GENERAL DIAGNOSIS

INDEX

page

page

Fuel System Diagram

. . . . . . . . . . . . . . . . . . . . . 66

Visual Inspection

. . . . . . . . . . . . . . . . . . . . . . . . . 66

FUEL SYSTEM DIAGRAM

Refer to the Component Identification portion of

this section for a more complete description of the

components shown in Figure 1.

VISUAL INSPECTION

Perform a visual inspection for loose, disconnected,

or misrouted wires and hoses before diagnosing or

servicing the fuel injection system. A visual check

helps save unnecessary test and diagnostic time. A

thorough visual inspection includes the following

checks:

(1) Check Ignition Coil Electrical Connections (Fig.

2).

(2) Verify the electrical connector is attached to

the Canister Purge Solenoid (Fig. 3). Check the vac-

uum connections at the solenoid and canister.

(3) Verify the electrical connector is attached to

the MAP sensor (Fig. 4). Inspect the MAP sensor

vacuum hose for damage and leaks.

(4) Verify generator wiring and belt are correctly

installed and tightened.

Fig. 1 Flexible Fuel MPI Components

Fig. 2 Ignition Coil Electrical Connection

14 - 66

FUEL SYSTEMS

Ä

(5) Check Ignition Cable Routing and Attachment

(Fig. 5).

(6) Check both electrical connectors at the distrib-

utor.

(7) Check radiator fan electrical connector.

(8) Check the engine coolant temperature sensor

electrical connection. Inspect battery ground cable

connection (Fig. 6).

(9) Inspect the engine temperature sensor electri-

cal connection (Fig. 7).

(10) Check power brake booster and speed control

vacuum connections (Fig. 8).

(11) Check engine harness to main harness electri-

cal connections.

(12) Check park/neutral switch wiring connection

(Fig. 9).

(13) Ensure battery connections are clean and

tight.

(14) Inspect relay connections (Fig. 10)

(15) Ensure the 60-way connector is fully inserted

into the socket on the PCM (Fig. 11). Make sure the

wires are not stretched or pulled out of the connector.

Fig. 3 EVAP Purge Solenoid

Fig. 4 MAP Sensor

Fig. 5 Ignition Cable Mounting and Attachment

Fig. 6 Engine Coolant Temperature Sensor

Fig. 7 Engine Temperature Sensor Electrical

Connection

Ä

FUEL SYSTEMS

14 - 67

(16) Verify the harness connector is attached to

idle air control motor (Fig. 12).

(17) Verify the harness connector is attached to

the throttle position sensor (Fig. 12).

Fig. 8 Power Brake Booster and Speed Control

Vacuum Hose Connections

Fig. 9 Automatic Transaxle Electrical Connections

Fig. 10 Relay Identification

Fig. 11 PCM Electrical Connector

Fig. 12 TPS and Idle Air Control Motor

14 - 68

FUEL SYSTEMS

Ä

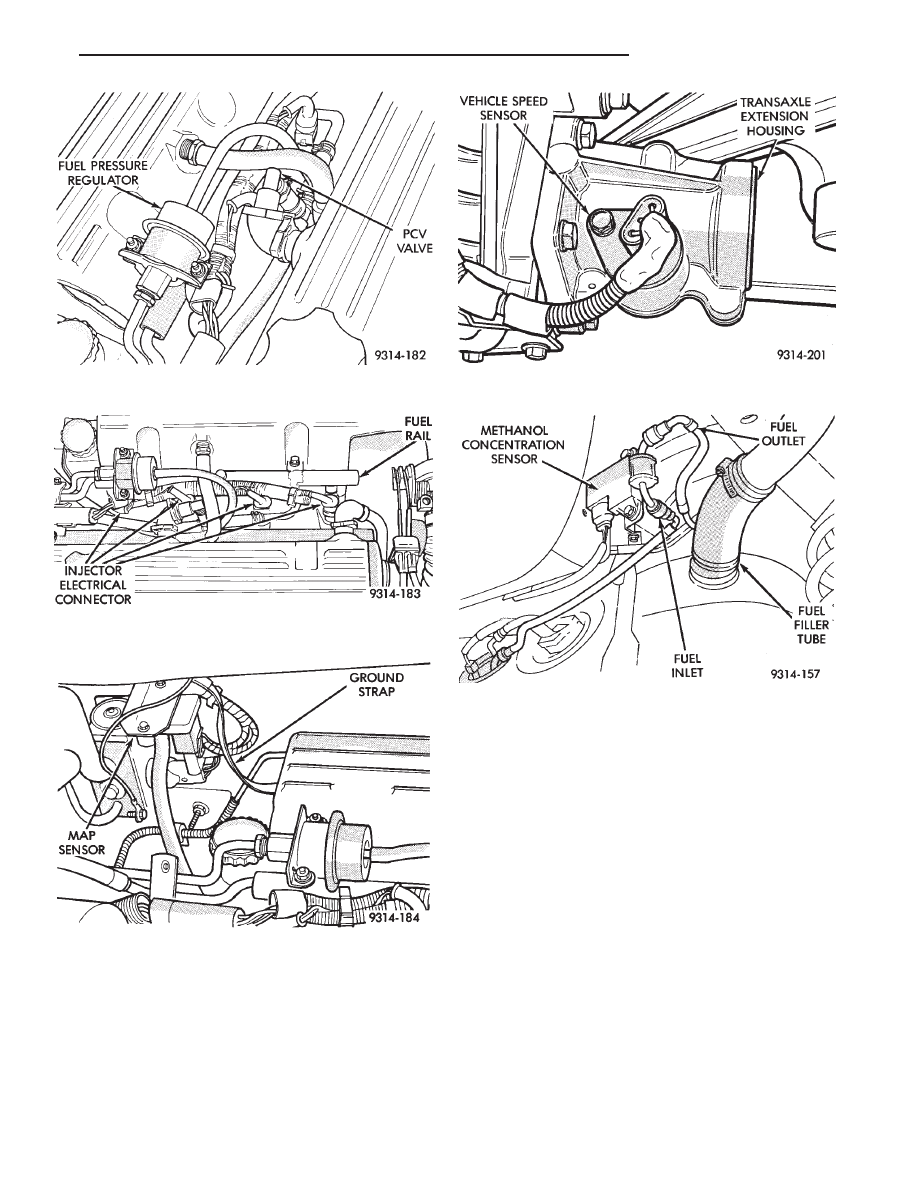

(18) Verify hose from PCV valve is securely at-

tached to the intake manifold vacuum port (Fig. 13).

(19) Check vacuum hose connection between vac-

uum source and fuel pressure regulator (Fig. 13).

(20) Inspect electrical connections at the fuel injec-

tors (Fig. 14).

(21) Inspect the heated oxygen sensor electrical

connector.

(22) Verify engine ground strap is attached to the

intake manifold and the dash panel (Fig. 15).

(23) Inspect all vacuum harness connections and

hoses for leaks.

(24) Verify the harness connector is attached to

the vehicle speed sensor (Fig. 16). Ensure the sensor

and connector are not damaged.

(25) Inspect hose and electrical connections at the

fuel pump. Ensure the electrical connector is fully

seated over the pump module terminals.

(26) Inspect electrical connections at the methanol

concentration sensor (Fig. 17).

Fig. 13 PCV Valve and Fuel Pressure Regulator

Fig. 14 Fuel Injector Electrical Connectors

Fig. 15 Ground Strap

Fig. 16 Vehicle Speed Sensor

Fig. 17 Methanol Concentration Sensor

Ä

FUEL SYSTEMS

14 - 69

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст