Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 8

DRIVETRAIN

INDEX

page

page

Automatic Transaxle

. . . . . . . . . . . . . . . . . . . . . . 16

Automatic Transaxle Floor Shift

. . . . . . . . . . . . . . 16

Clutch and Gearshift Linkage

. . . . . . . . . . . . . . . 16

Drive Shaft Cv and Tripod Joint Boots

. . . . . . . . 17

Front Wheel Bearings

. . . . . . . . . . . . . . . . . . . . . 17

Manual Transaxle

. . . . . . . . . . . . . . . . . . . . . . . . 16

Tires

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CLUTCH AND GEARSHIFT LINKAGE

If the clutch or gearshift begins to operate with dif-

ficulty, squeak or grunt, the cables and linkage

should be lubricated before service replacement is

performed. For proper lubrication and service proce-

dures refer to Group 6, Clutch, or Group 21, Manual

Transaxle.

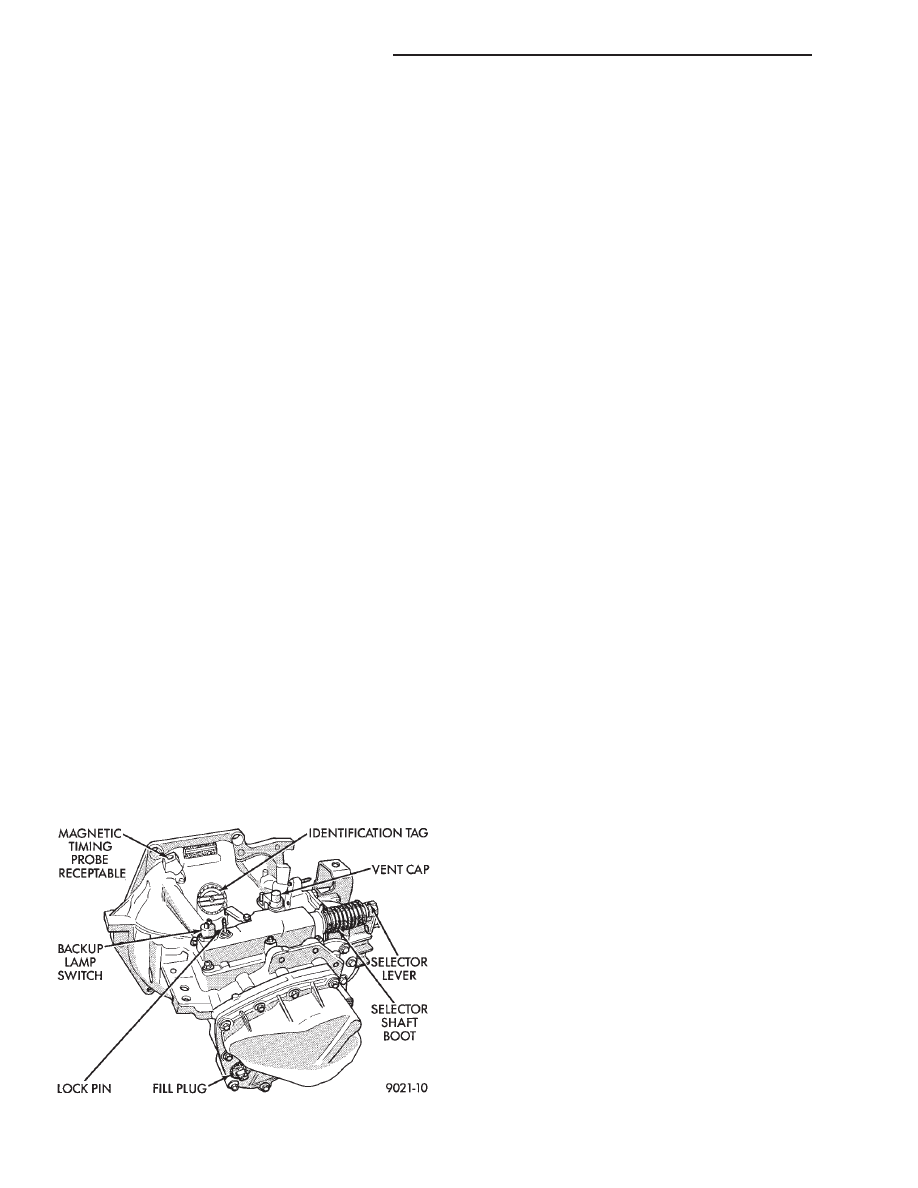

MANUAL TRANSAXLE

The manual transaxle should be inspected for oil

leaks and proper oil level when other under vehicle

service is performed. To inspect the transaxle oil

level, position the vehicle on a level surface. Remove

fill plug (Fig. 1) from the transaxle side cover. The

oil level should not be below 4 mm (3/16 in) from the

bottom of the oil fill opening.

The manual transaxle does not require periodic

maintenance. The oil should be changed only when

water contamination is suspected. If oil has a foamy

or milky appearance it probably is contaminated. A

circular magnet located behind the differential cover

collects metallic particles circulating in the oil. For

proper diagnostic and service procedures, refer to

Group 21, Manual Transaxle.

SELECTING MANUAL TRANSAXLE OIL

Chrysler Corporation recommends Mopar Engine

Oil, SG or SG/CD SAE 5W-30, or equivalent, be used

to fill a 5-speed transaxle.

AUTOMATIC TRANSAXLE FLOOR SHIFT

If the automatic transaxle floor shift mechanism

becomes difficult to operate or starts to make objec-

tionable noise, the mechanism should be lubricated

before service repair is performed. To lubricate the

shift mechanism, remove console as necessary. Refer

to Group 23, Body. Apply a film of Mopar Multipur-

pose Grease or equivalent, to slide surfaces and pawl

spring. For additional information, refer to Group 21,

Transaxle.

AUTOMATIC TRANSAXLE

The automatic transaxle should be inspected for

fluid leaks and proper fluid level when other under

hood service is performed.

CAUTION: To minimize fluid contamination, verify

that dipstick is seated in the fill hole or tube after

fluid level reading is taken.

TO INSPECT THE TRANSAXLE FLUID LEVEL:

(1) Position the vehicle on a level surface.

(2) Start engine and allow to idle in PARK for at

least 60 seconds. The warmer the transaxle fluid, the

more accurate the reading.

(3) While sitting in driver seat, apply brakes and

place gear selector in each position. Return gear se-

lector to park.

(4) Raise hood and remove transaxle fluid level in-

dicator (dipstick) and wipe clean with a suitable

cloth.

(5) Install dipstick and verify it is seated in fill

hole or tube (Fig. 2 or 3).

CAUTION: Do not overfill automatic transaxle, leak-

age or damage can result.

(6) Remove dipstick, with handle above tip, take

fluid level reading (Fig. 4). If the vehicle has been

driven for at least 15 minutes before inspecting fluid

level, transaxle can be considered hot and reading

should be above the WARM mark. If vehicle has run

for less than 15 minutes and more than 60 seconds

transaxle can be considered warm and reading

Fig. 1 Manual Transaxle Fill Plug

0 - 16

LUBRICATION AND MAINTENANCE

Ä

should be above ADD mark. Add fluid only if level is

below ADD mark on dipstick when transaxle is

warm.

The automatic transaxle does not require periodic

maintenance when used for general transportation. If

the vehicle is subjected to severe service conditions,

the automatic transaxle will require fluid/filter

change and band adjustments every 24 000 km

(15,000 miles). For additional information, refer to

Severe Service paragraph and Lubrication and Main-

tenance Schedules in General Information section of

this group. The fluid and filter should be changed

when water contamination is suspected. If fluid has

foamy or milky appearance, it is probably contami-

nated. If the fluid appears brown or dark and a foul

odor is apparent, the fluid is burned, transaxle re-

quires maintenance or service. A circular magnet lo-

cated in the transaxle pan, collects metallic particles

circulating in the oil. For proper diagnostic and ser-

vice procedures, refer to Group 21, Automatic Tran-

saxle.

SELECTING AUTOMATIC TRANSAXLE FLUID

Chrysler Corporation recommends Mopar ATF Plus

(automatic transmission fluid type 7176) be used to

add to or replace automatic transaxle fluid. If ATF

Plus is not available use Mopar Dexron II

t Auto-

matic Transmission Fluid or equivalent.

DRIVE SHAFT CV AND TRIPOD JOINT BOOTS

The front drive shaft constant velocity and tripod

joint boots (Fig. 5) should be inspected when other

under vehicle service is performed. Inspect boots for

cracking, tears, leaks or other defects. If service re-

pair is required, refer to Group 2, Suspension.

FRONT WHEEL BEARINGS

The front wheel bearings are permanently sealed,

requiring no lubrication. For proper diagnostic and

service procedures refer to Group 2, Suspension.

TIRES

The tires should be inspected at every engine oil

change for proper inflation and condition. The tires

should be rotated at the distance intervals described

in the Lubrication and Maintenance Schedules of the

General Information section in this group. For tire

inflation specifications refer to the Owner’s Manual.

A Tire Inflation sticker is located in the driver door

opening. For proper diagnostic procedures, see Group

22, Wheels and Tires.

Fig. 2 3-speed Automatic Transaxle Fill hole

Fig. 3 4-speed Automatic Transaxle Fill tube

Fig. 4 Automatic Transaxle Dipstick—Typical

Fig. 5 Drive Shaft Boots

Ä

LUBRICATION AND MAINTENANCE

0 - 17

TIRE ROTATION

The Forward Cross rotation method is recom-

mended for use on Chrysler Corporation vehicles

(Fig. 6). Other rotation methods can be used, but

may not have the benefits of the recommended

method. Only the four tire rotation method can be

used if the vehicle is equipped with a space saver

spare tire.

Fig. 6 Tire Rotation

0 - 18

LUBRICATION AND MAINTENANCE

Ä

CHASSIS AND BODY

INDEX

page

page

Body Lubrication

. . . . . . . . . . . . . . . . . . . . . . . . . 22

Brakes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Headlamps

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Lower Ball Joints

. . . . . . . . . . . . . . . . . . . . . . . . . 19

Power Steering

. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Rear Wheel Bearings

. . . . . . . . . . . . . . . . . . . . . 20

Steering Linkage

. . . . . . . . . . . . . . . . . . . . . . . . . 19

STEERING LINKAGE

INSPECTION

The steering linkage and steering gear should be in-

spected for wear, leaks or damage when other under ve-

hicle service is performed. The rack and pinion steering

gear end boots should not have excess oil or grease res-

idue on the outside surfaces or surrounding areas

(Fig.1). If boot is leaking, it should be repaired. For

proper service procedures, see Group 19, Steering.

The tie rod end seal should fit securely between the

steering knuckle and tie rod end (Fig.2). The steering

linkage should be lubricated at the time and distance

intervals described in the Lubrication and Mainte-

nance Schedules. Refer to General Information sec-

tion of this group.

TIE ROD END LUBRICATION

Lubricate the steering linkage with Mopar, Multi-

mileage Lube or equivalent. Using a wiping cloth,

clean grease and dirt from around grease fitting and

joint seal. Using a grease gun, fill tie rod end until

lubricant leaks from around the tie rod end side of

the seal (Fig.2). When lube operation is complete,

wipe off excess grease.

LOWER BALL JOINTS

INSPECTION

The front suspension lower ball joints should be in-

spected for wear, leaks or damage when other under ve-

hicle service is performed. The ball joint seal should fit

securely between the steering knuckle and lower control

arm (Fig. 3). The ball joints should be lubricated at the

time and distance intervals described in the Lubrication

and Maintenance Schedules. Refer to the General Infor-

mation section of this group.

BALL JOINT LUBRICATION

CAUTION: Do not over fill ball joint with grease,

damage to seal can result.

Lubricate the ball joints with Mopar, Multi-mile-

age Lube or equivalent. Using a wiping cloth, clean

grease and dirt from around grease fitting and joint

seal. Using a grease gun, fill ball joint until seal

starts to swell (Fig. 3). When lube operation is com-

plete, wipe off excess grease.

POWER STEERING

The power steering fluid level should be inspected

when other under hood service is performed. If the

fluid level is low and system is not leaking, use Mo-

par, Power Steering Fluid or equivalent. The power

steering system should be inspected for leaks when

other under vehicle service is performed. For proper

service procedures, refer to Group 19, Steering.

Fig. 1 Inspect Steering Linkage

Fig. 2 Tie Rod End Lubrication

Ä

LUBRICATION AND MAINTENANCE

0 - 19

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст