Chrysler Le Baron, Dodge Dynasty, Plymouth Acclaim. Manual — part 363

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four thru six for each wire in the

connector. Check that all wires are inserted into the

proper cavities. For connector pin out identification

refer to the wiring diagrams.

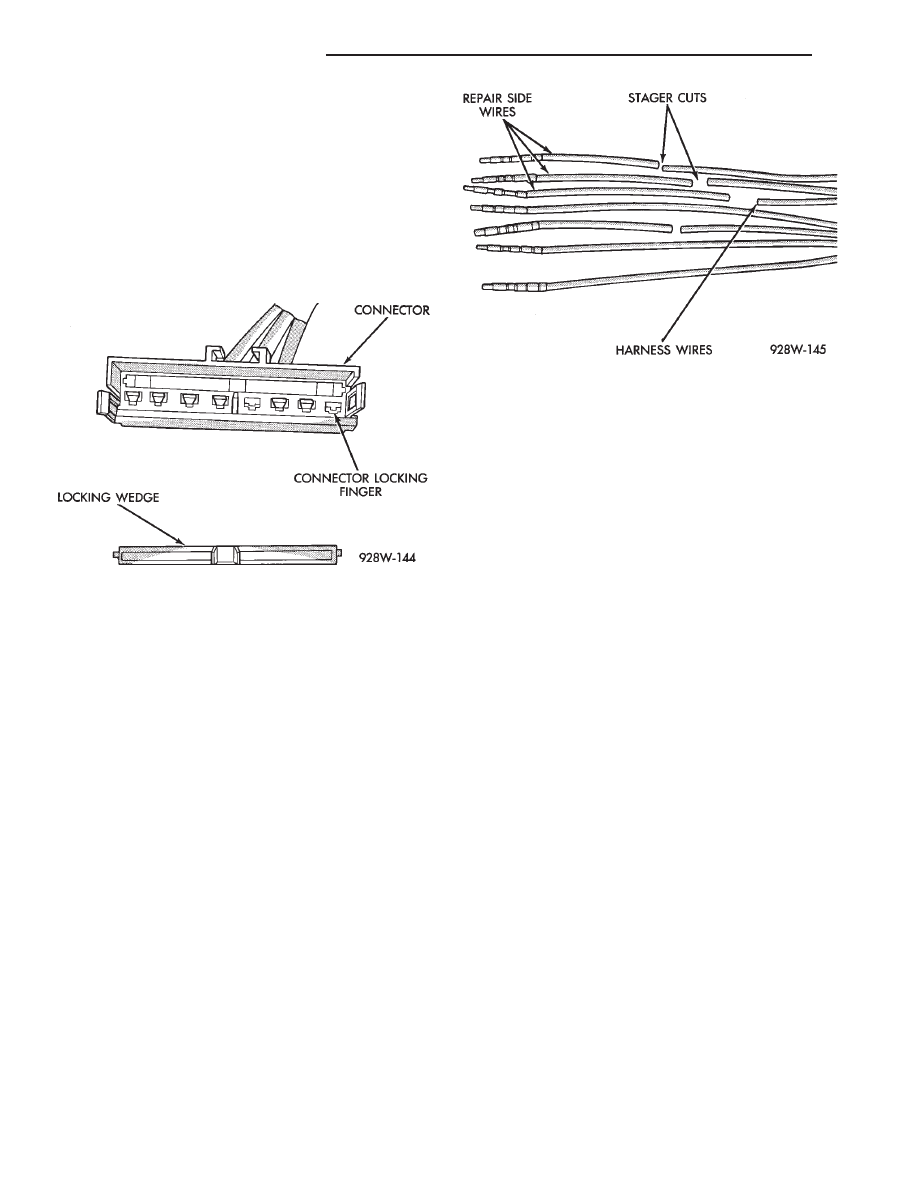

(8) Insert the connector locking wedge into the re-

paired connector.

(9) Connect connector to its mating half.

(10) Connect battery and test all affected systems.

CONNECTOR AND TERMINAL ASSEMBLY

REPLACEMENT

(1) Disconnect Battery.

(2) Disconnect the connector being repaired form

its mating half.

(3) Cut off the existing wire connector directly be-

hind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side about

1/2 inch apart (Fig. 14).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 14).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1).

(10) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2).

(11) Twist the wires together (Fig. 11 example 3).

(12) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(14) Repeat steps 8 thru 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Reconnect the repaired connector.

(17) Connect battery and test all affected systems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired form

its mating half.

(3) Remove connector locking wedge (Fig. 12).

(4) Position the connector locking finger away from

the terminal. Pull on the wire to remove the termi-

nal from the connector (Fig. 13).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and re-

move 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires (Fig. 11 example 1).

(11) Push the two ends of wire together until the

strands of wire are close to the insulation (Fig. 11 ex-

ample 2).

(12) Twist the wires together (Fig. 11 example 3).

(13) Solder the connection together using rosin

core type solder only. Do not use acid core solder.

Fig. 13 Connector Locking Finger and Locking

Wedge

Fig. 14 Stagger Cutting Wires

8W - 6

GENERAL INFORMATION

Ä

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge and recon-

nect the connector to its mating half.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect battery and test all affected systems.

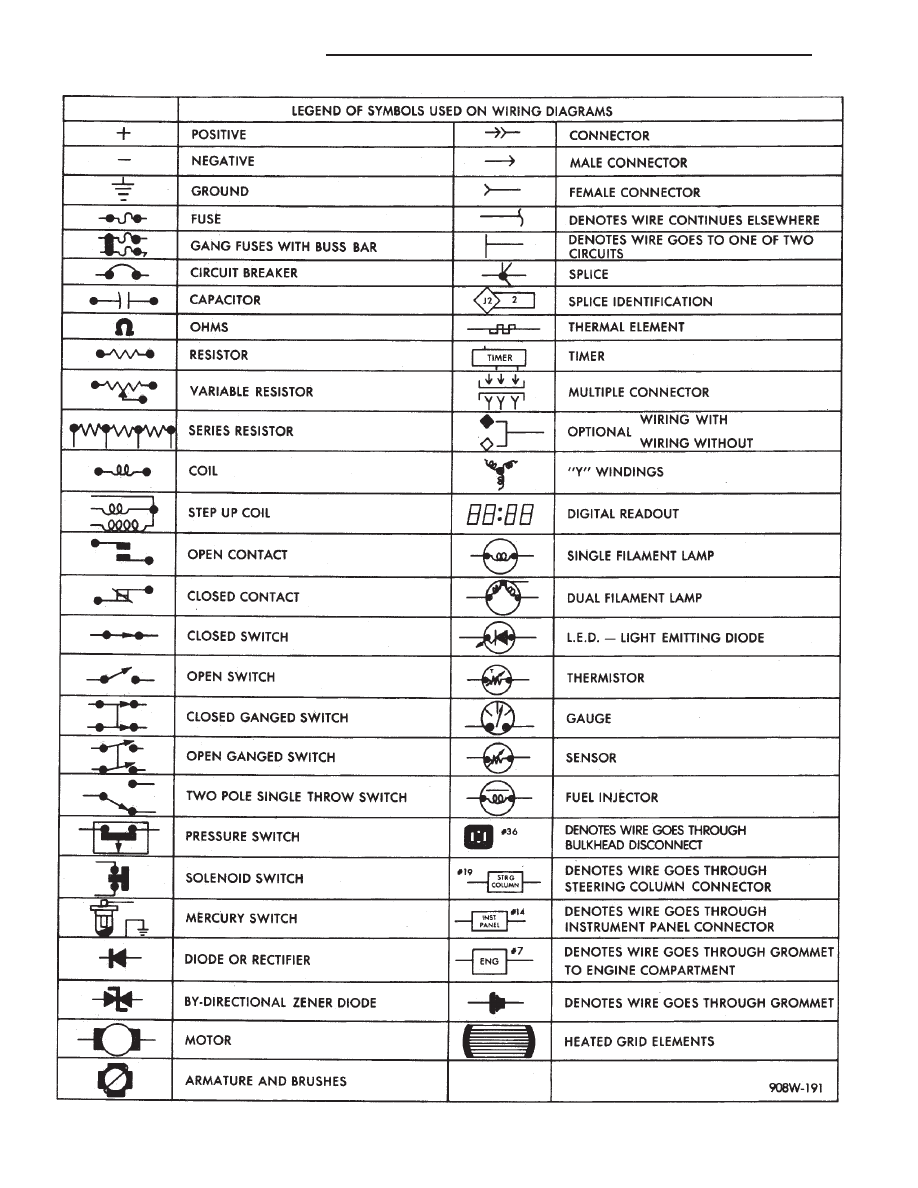

SYMBOLS, FUSES AND RELAYS

Various symbols are used throughout the wiring

diagrams. These symbols can be identified by refer-

ring to the symbol identification chart (Fig. 15).

For fuse block, relay bank, or power distribution

center information refer to the fuse charts and relay

bank section.

CAUTION: When replacing a blown fuse it is impor-

tant to replace it with a fuse having the correct am-

perage rating. The use of a fuse with a rating other

than indicated may result in an electrical overload.

If a proper rated fuse continues to blow, it indicates

a problem that should be corrected.

Ä

GENERAL INFORMATION

8W - 7

Fig. 15 Symbol Identification

8W - 8

GENERAL INFORMATION

Ä

FUSE CHARTS AND RELAY BANKS

INDEX

Caption

Fig.

Fuse Block and Relay Bank AA Body . . . . . . . . . . . . . . . . .1

Fuse Block AC, AY Body . . . . . . . . . . . . . . . . . . . . . . . . .2

Fuse Block AG, AJ Body . . . . . . . . . . . . . . . . . . . . . . . . .3

Fuse Block and Relay Bank AP Body . . . . . . . . . . . . . . . . .4

Caption

Fig.

Power Distribution Center AC, AY Body . . . . . . . . . . . . . . . .7

Power Distribution Center AG, AJ Body . . . . . . . . . . . . . . . .8

Relay Bank AC, AY Body . . . . . . . . . . . . . . . . . . . . . . . . .5

Relay Bank AG, AJ Body . . . . . . . . . . . . . . . . . . . . . . . . .6

Ä

FUSE CHARTS AND RELAY BANKS

8W - 9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст