Infiniti FX35 / FX45. Manual — part 702

FFD-18

< SERVICE INFORMATION >

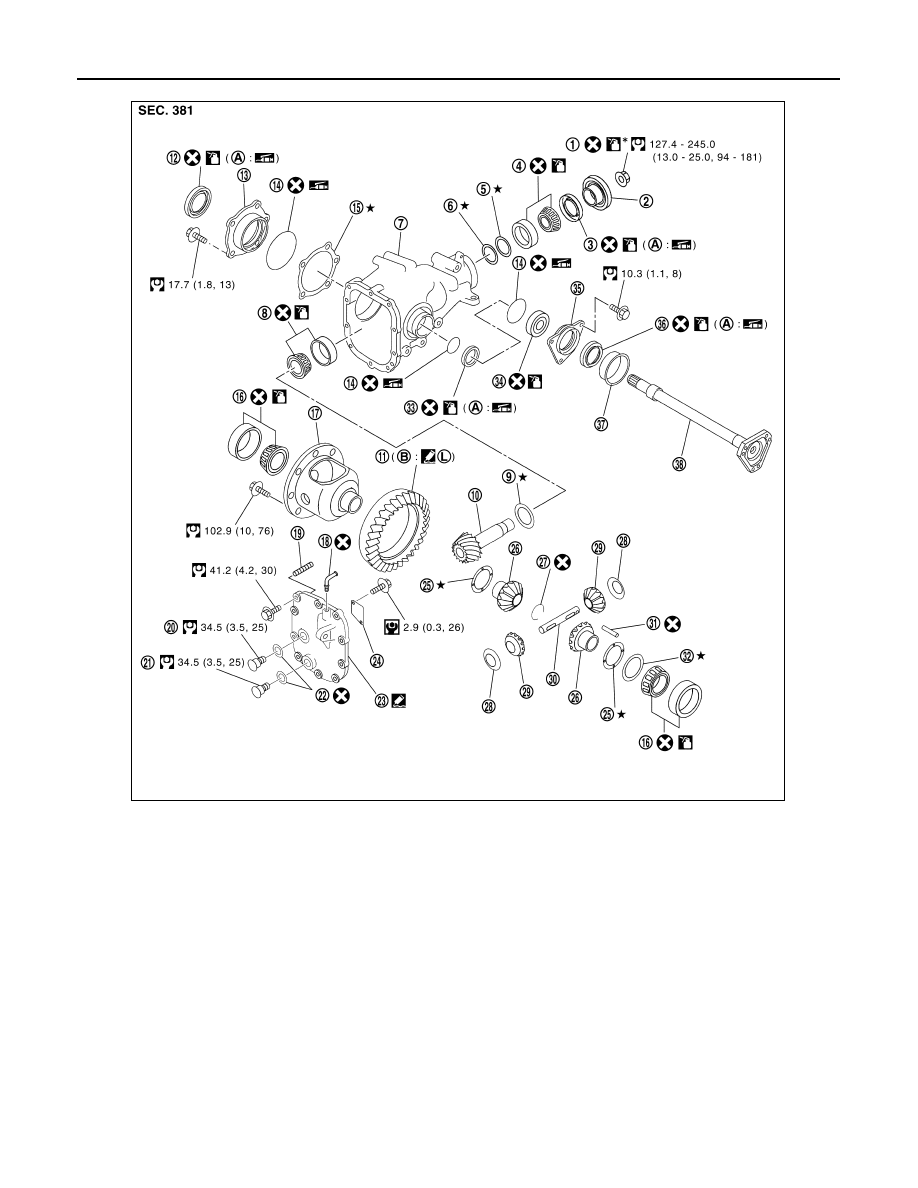

FRONT FINAL DRIVE ASSEMBLY

1.

Drive pinion lock nut

2.

Companion flange

3.

Front oil seal

4.

Pinion front bearing

5.

Drive pinion bearing adjusting wash-

er

6.

Drive pinion adjusting washer

7.

Gear carrier

8.

Pinion rear bearing

9.

Pinion height adjusting washer

10. Drive pinion

11.

Drive gear

12. Side oil seal (right side)

13. Side retainer

14. O-ring

15. Side bearing adjusting shim

16. Side bearing

17. Differential case

18. Breather connector

19. Dowel pin

20. Filler plug

21. Drain plug

22. Gasket

23. Carrier cover

24. Gear oil defence

25. Side gear thrust washer

26. Side gear

27. Circular clip

28. Pinion mate thrust washer

29. Pinion mate gear

30. Pinion mate shaft

31. Lock pin

32. Side bearing adjusting washer

33. Side oil seal (left side)

34. Side shaft bearing

35. Extension tube retainer

36. Side shaft oil seal

37. Dust sealed

38. Side shaft

A: Oil seal lip

B: Screw hole

PDIA0791J

FRONT FINAL DRIVE ASSEMBLY

FFD-19

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

FFD

N

O

P

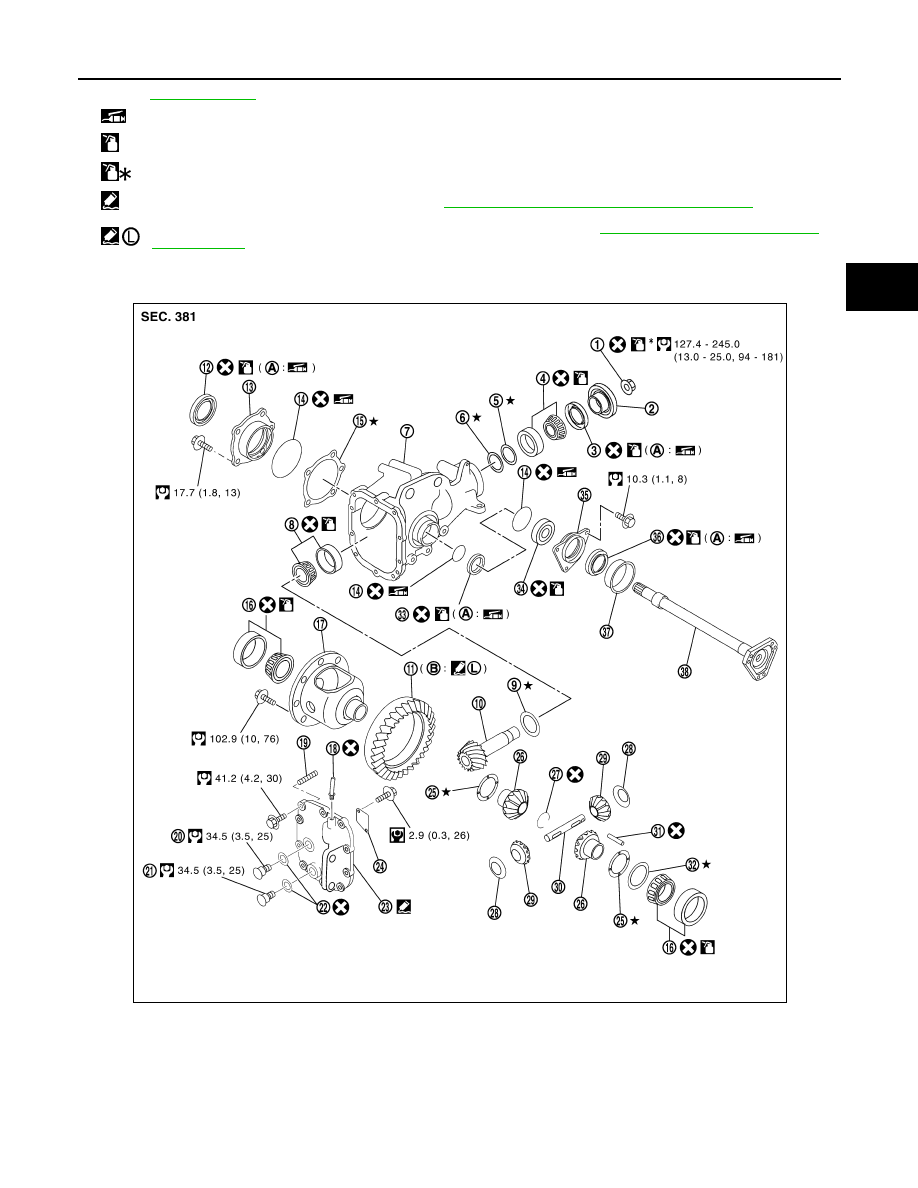

COMPONENTS (VK45DE MODELS)

Refer to

and the followings for the symbols in the figure.

:

Apply multi-purpose grease.

:

Apply gear oil.

:

Apply anti-corrosion oil.

:

Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "Recommended Chemical Product and Sealant"

.

:

Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "Recommended Chemical Prod-

1.

Drive pinion lock nut

2.

Companion flange

3.

Front oil seal

4.

Pinion front bearing

5.

Drive pinion bearing adjusting wash-

er

6.

Drive pinion adjusting washer

7.

Gear carrier

8.

Pinion rear bearing

9.

Pinion height adjusting washer

10. Drive pinion

11.

Drive gear

12. Side oil seal (right side)

13. Side retainer

14. O-ring

15. Side bearing adjusting shim

PDIA1206E

FFD-20

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

• Before inspection and adjustment, drain gear oil.

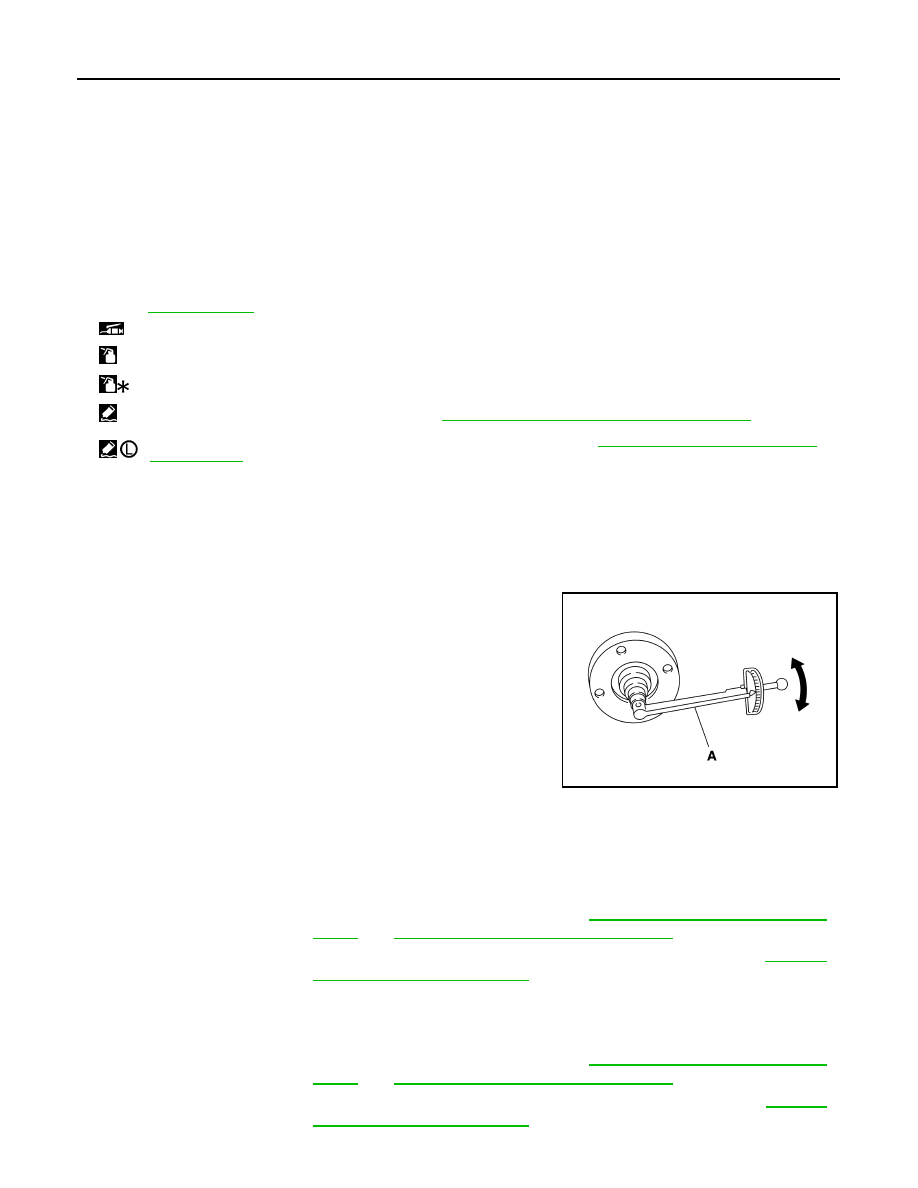

Total Preload Torque

1.

Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

2.

Rotate drive pinion at least 20 times to check for smooth operation of the bearing.

3.

Measure total preload with preload gauge.

NOTE:

Total preload torque = Pinion bearing preload torque + Side

bearing preload torque

• If measured value is out of the specification, disassemble it to

check and adjust each part. Adjust the pinion bearing preload and

side bearing preload.

Adjust the pinion bearing preload first, then adjust the side bearing preload.

16. Side bearing

17. Differential case

18. Breather connector

19. Dowel pin

20. Filler plug

21. Drain plug

22. Gasket

23. Carrier cover

24. Gear oil defence

25. Side gear thrust washer

26. Side gear

27. Circular clip

28. Pinion mate thrust washer

29. Pinion mate gear

30. Pinion mate shaft

31. Lock pin

32. Side bearing adjusting washer

33. Side oil seal (left side)

34. Side shaft bearing

35. Extension tube retainer

36. Side shaft oil seal

37. Dust sealed

38. Side shaft

A: Oil seal lip

B: Screw hole

Refer to

and the followings for the symbols in the figure.

:

Apply multi-purpose grease.

:

Apply gear oil.

:

Apply anti-corrosion oil.

:

Apply Genuine Silicone RTV or equivalent. Refer to

GI-44, "Recommended Chemical Product and Sealant"

.

:

Apply Genuine Medium Strength Thread Locking Sealant or equivalent. Refer to

GI-44, "Recommended Chemical Prod-

.

Tool number

A: ST3127S000 (J-25765-A)

Total preload torque:

1.56 - 2.65 N·m (0.16 - 0.27 kg-m, 14 - 23 in-lb)

PDIA0792J

When the preload torque is large

On pinion bearings:

Decrease the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to

FFD-39, "Inspection and Adjust-

FFD-39, "Inspection and Adjustment"

On side bearings:

Increase the side bearing adjusting shim thickness. Refer to

.

When the preload torque is small

On pinion bearings:

Increase the drive pinion bearing adjusting washer and drive pinion

adjusting washer thickness. Refer to

FFD-39, "Inspection and Adjust-

FFD-39, "Inspection and Adjustment"

On side bearings:

Decrease the side bearing adjusting shim thickness. Refer to

.

FRONT FINAL DRIVE ASSEMBLY

FFD-21

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

M

A

B

FFD

N

O

P

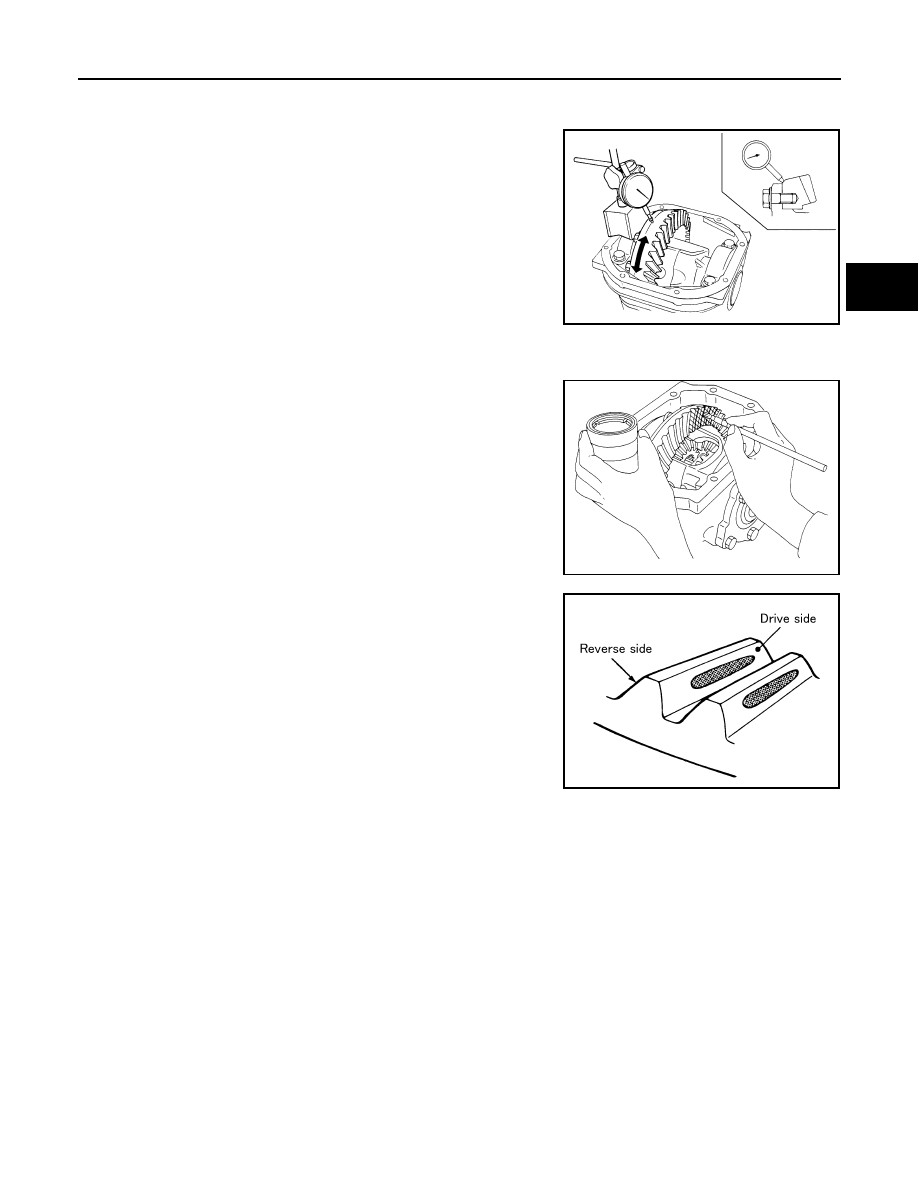

Drive Gear Runout

1.

Remove carrier cover. Refer to "Differential Assembly".

2.

Fit a dial indicator to the drive gear back face.

3.

Rotate the drive gear to measure runout.

• If the runout is outside of the repair limit, check drive gear assem-

bly condition; foreign material may be caught between drive gear

and differential case, or differential case or drive gear may be

deformed, etc.

CAUTION:

Replace drive gear and drive pinion gear as a set.

Tooth Contact

1.

Remove carrier cover. Refer to "Differential Assembly".

2.

Apply red lead to drive gear.

CAUTION:

Apply red lead to both the faces of 3 to 4 gears at 4 loca-

tions evenly spaced on drive gear.

3.

Rotate drive gear back and forth several times, check drive pin-

ion gear to drive gear tooth contact.

CAUTION:

Check tooth contact on drive side and reverse side.

Runout limit:

0.05 mm (0.0020 in)

SPD886

SPD357

SDIA0570E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст