Infiniti FX35 / FX45. Manual — part 421

DTC P1217 ENGINE OVER TEMPERATURE

EC-445

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Check the following.

• Harness connectors E29, E121

• Harness for open or short between cooling fan motor-2 and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.

CHECK COOLING FAN MOTORS

EC-446, "Component Inspection"

OK or NG

OK

>> GO TO 13.

NG

>> Replace malfunctioning cooling fan motors.

13.

CHECK INTERMITTENT INCIDENT

Perform

OK or NG

OK

>> Replace IPDM E/R. Refer to

.

NG

>> Repair or replace harness or connector.

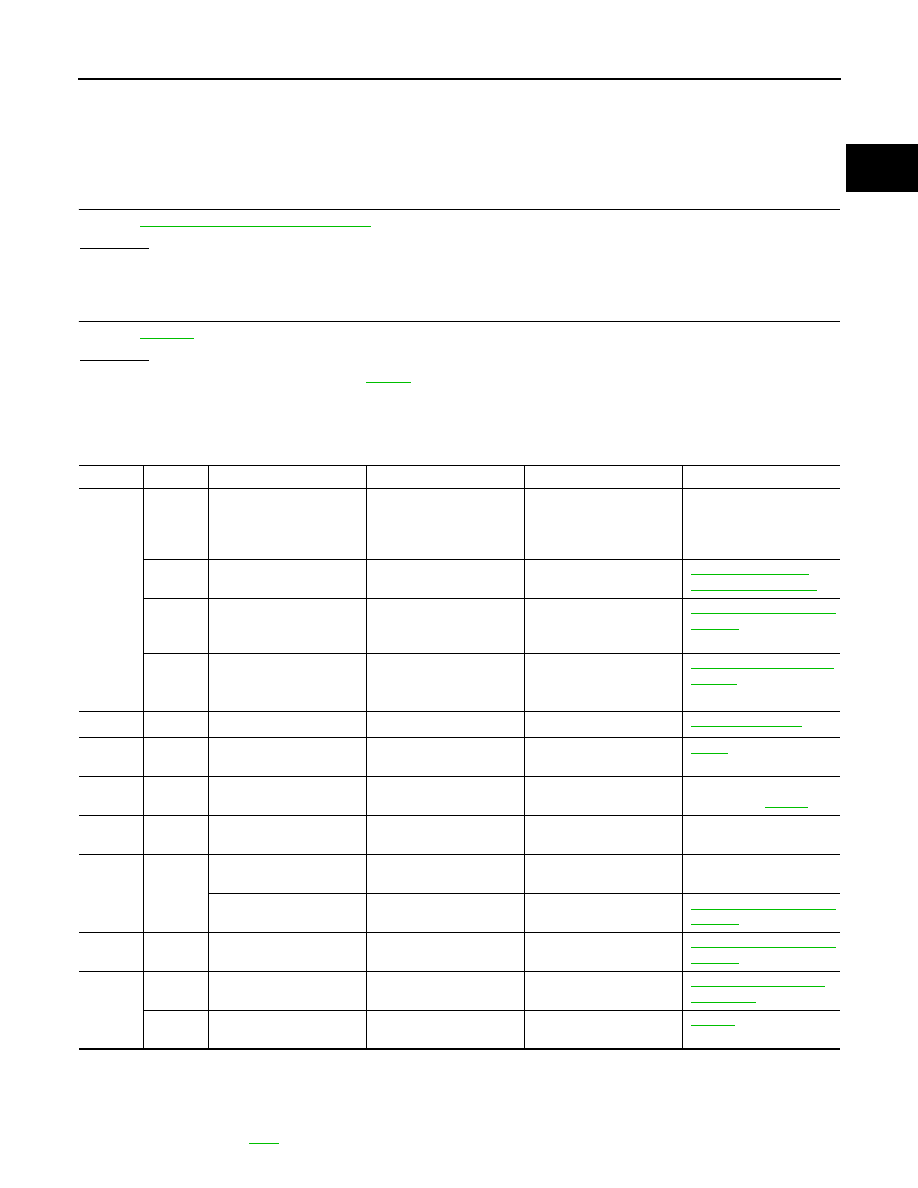

Main 12 Causes of Overheating

INFOID:0000000001326297

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to

.

Engine

Step

Inspection item

Equipment

Standard

Reference page

OFF

1

• Blocked radiator

• Blocked condenser

• Blocked radiator grille

• Blocked bumper

• Visual

No blocking

—

2

• Coolant mixture

• Coolant tester

50 - 50% coolant mixture

MA-10, "Anti-Freeze

Coolant Mixture Ratio"

3

• Coolant level

• Visual

Coolant up to MAX level in

reservoir tank and radiator

filler neck

CO-10, "Changing Engine

Coolant"

4

• Radiator cap

• Pressure tester

59 - 98 kPa

(0.6 - 1.0 kg/cm

2

, 9 - 14

psi) (Limit)

CO-14, "Checking Radia-

tor Cap"

ON*

2

5

• Coolant leaks

• Visual

No leaks

ON*

2

6

• Thermostat

• Touch the upper and

lower radiator hoses

Both hoses should be hot

ON*

1

7

• Cooling fan

• CONSULT-III

Operating

See trouble diagnosis for

DTC P1217 (

).

OFF

8

• Combustion gas leak

• Color checker chemical

tester 4 Gas analyzer

Negative

—

ON*

3

9

• Coolant temperature

gauge

• Visual

Gauge less than 3/4 when

driving

—

• Coolant overflow to res-

ervoir tank

• Visual

No overflow during driving

and idling

CO-10, "Changing Engine

Coolant"

OFF*

4

10

• Coolant return from res-

ervoir tank to radiator

• Visual

Should be initial level in

reservoir tank

CO-10, "Changing Engine

Coolant"

OFF

11

• Cylinder head

• Straight gauge feeler

gauge

0.1 mm (0.004 in) Maxi-

mum distortion (warping)

EM-101, "Removal and

Installation"

12

• Cylinder block and pis-

tons

• Visual

No scuffing on cylinder

walls or piston

EC-446

< SERVICE INFORMATION >

[VQ35DE]

DTC P1217 ENGINE OVER TEMPERATURE

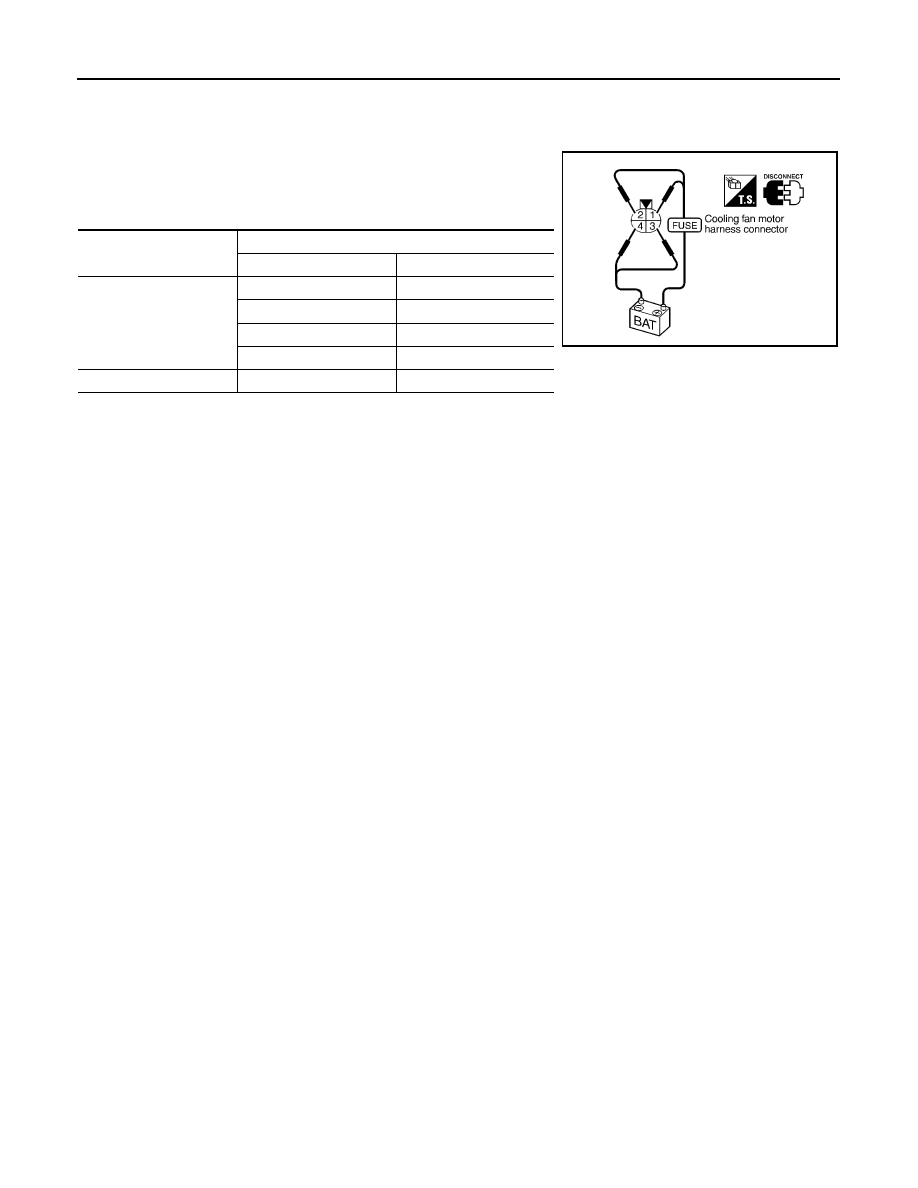

Component Inspection

INFOID:0000000001326298

COOLING FAN MOTORS-1 AND -2

1.

Disconnect cooling fan motor harness connectors.

2.

Supply cooling fan motor terminals with battery voltage and

check operation.

Cooling fan motor should operate.

If NG, replace cooling fan motor.

Cooling fan speed

Cooling fan motor terminals

(+)

(

−

)

Middle (MID)

1

3 and 4

2

3 and 4

1 and 2

3

1 and 2

4

High (HI)

1 and 2

3 and 4

SEF734W

DTC P1225 TP SENSOR

EC-447

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

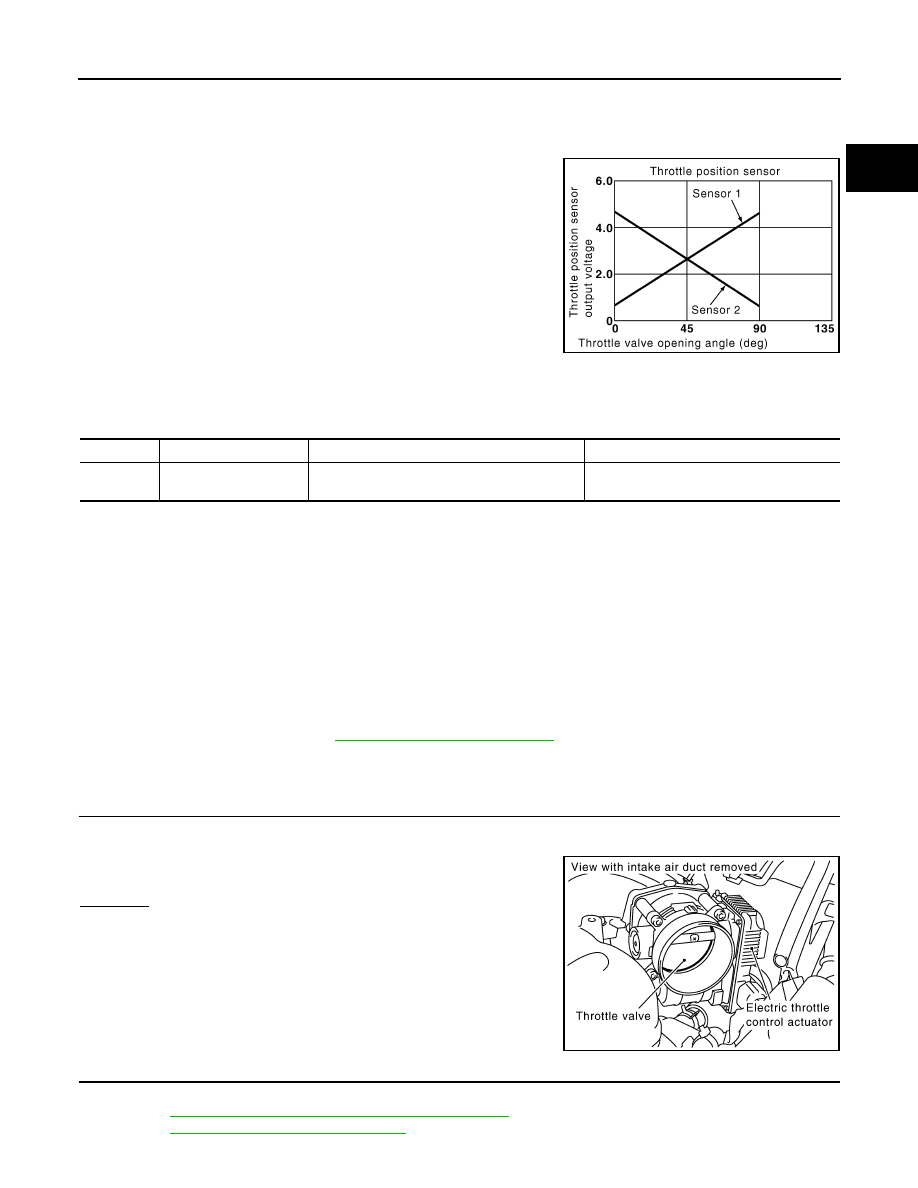

DTC P1225 TP SENSOR

Component Description

INFOID:0000000001326299

Electric throttle control actuator consists of throttle control motor,

throttle position (TP) sensor, etc. The throttle position sensor

responds to the throttle valve movement.

The throttle position sensor has two sensors. These sensors are a

kind of potentiometers which transform the throttle valve position into

output voltage, and emit the voltage signal to the ECM. In addition,

these sensors detect the opening and closing speed of the throttle

valve and feed the voltage signals to the ECM. The ECM judges the

current opening angle of the throttle valve from these signals and the

ECM controls the throttle control motor to make the throttle valve

opening angle properly in response to driving condition.

On Board Diagnosis Logic

INFOID:0000000001326300

The MIL will not light up for this self-diagnosis.

DTC Confirmation Procedure

INFOID:0000000001326301

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

1.

Turn ignition switch ON.

2.

Turn ignition switch OFF and wait at least 10 seconds.

3.

Turn ignition switch ON.

4.

Check 1st trip DTC.

5.

If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000001326302

1.

CHECK ELECTRIC THROTTLE CONTROL ACTUATOR VISUALLY

1.

Turn ignition switch OFF.

2.

Remove the intake air duct.

3.

Check if foreign matter is caught between the throttle valve and

the housing.

OK or NG

OK

>> GO TO 2.

NG

>> Remove the foreign matter and clean the electric throttle

control actuator inside.

2.

REPLACE ELECTRIC THROTTLE CONTROL ACTUATOR

1.

Replace the electric throttle control actuator.

2.

EC-85, "Throttle Valve Closed Position Learning"

.

3.

EC-85, "Idle Air Volume Learning"

PBIB0145E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P1225

1225

Closed throttle position

learning performance

Closed throttle position learning value is exces-

sively low.

• Electric throttle control actuator

(TP sensor 1 and 2)

PBIB1556E

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст