Infiniti FX35 / FX45. Manual — part 453

IGNITION SIGNAL

EC-573

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

TER-

MI-

NAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

60

61

62

PU

L

Y

Ignition signal No. 5

Ignition signal No. 3

Ignition signal No. 1

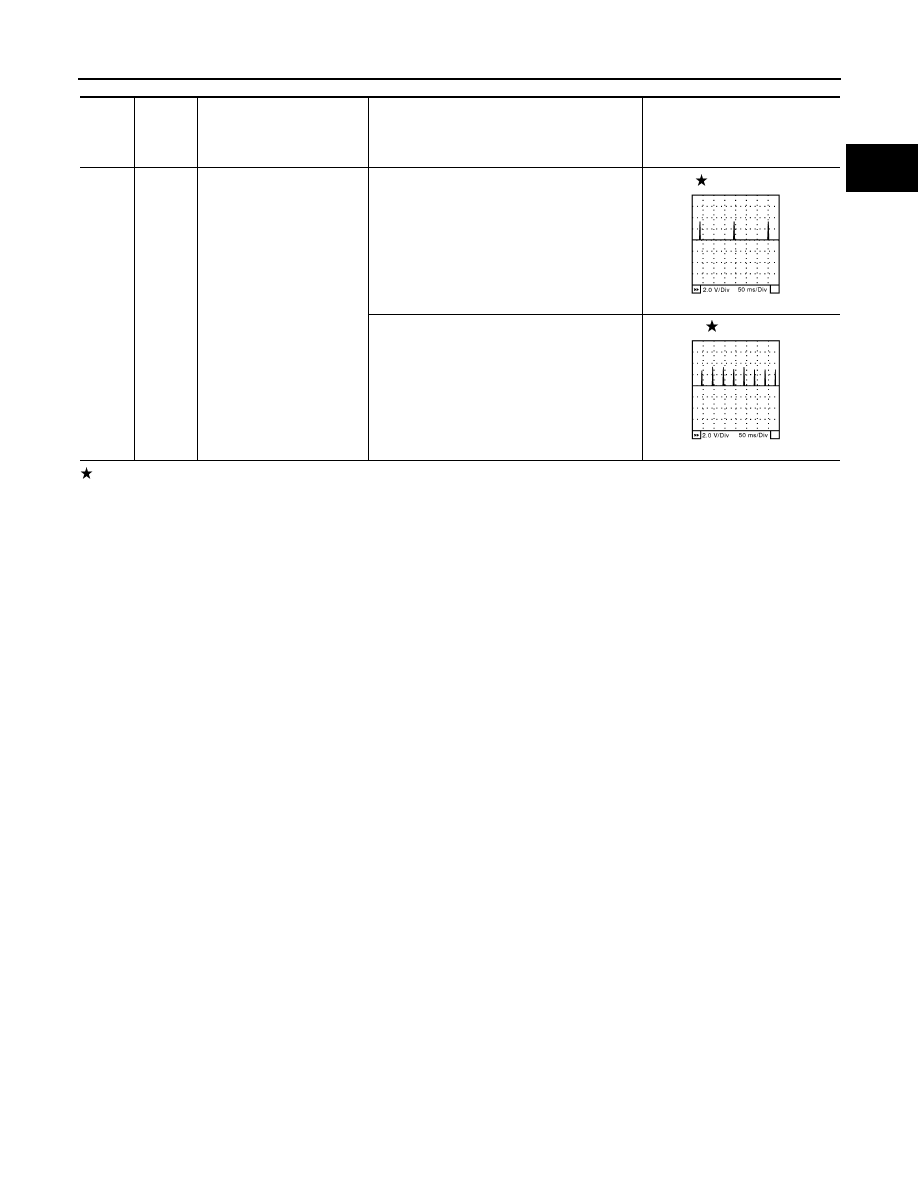

[Engine is running]

• Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

0 - 0.2V

[Engine is running]

• Warm-up condition

• Engine speed: 2,500 rpm

0.1 - 0.4V

SEC986C

SEC987C

EC-574

< SERVICE INFORMATION >

[VQ35DE]

IGNITION SIGNAL

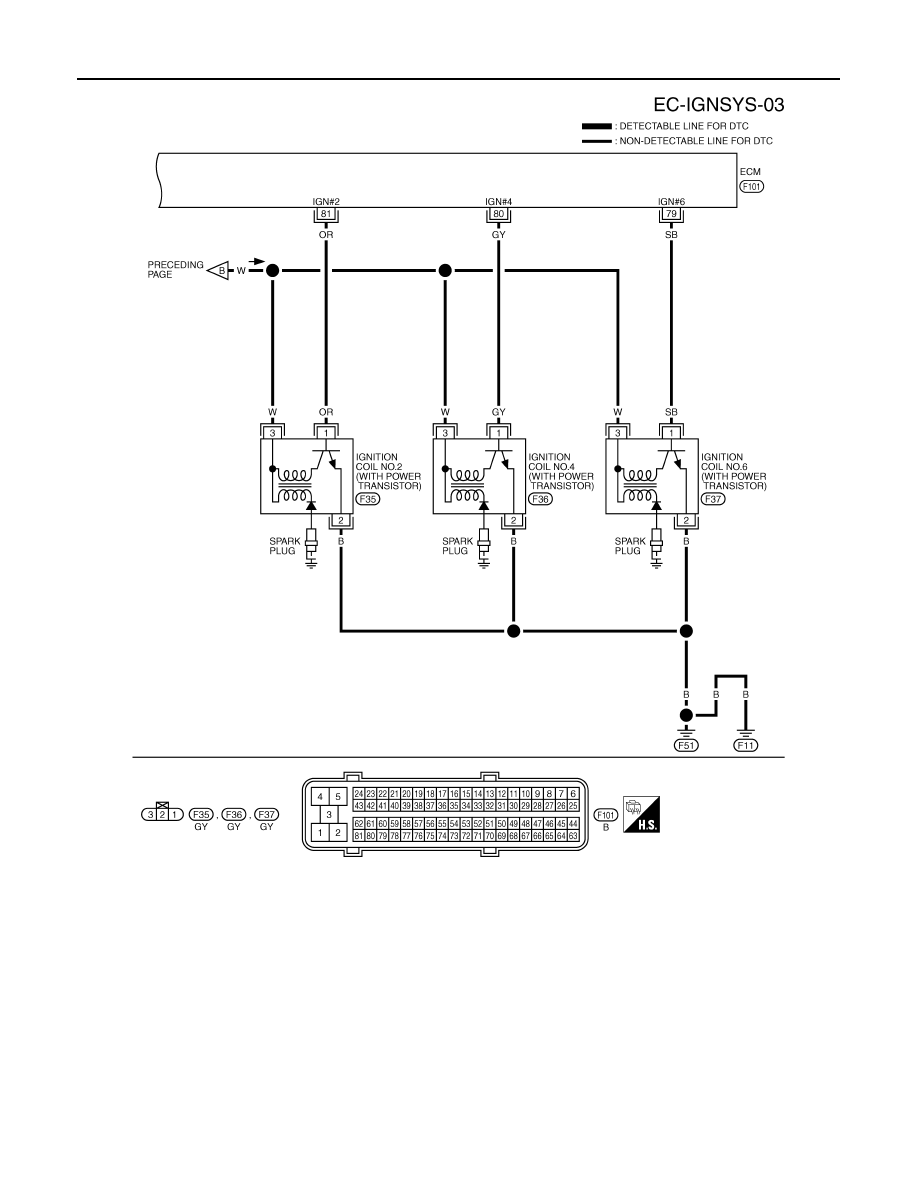

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-III.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TBWM0736E

IGNITION SIGNAL

EC-575

< SERVICE INFORMATION >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis Procedure

INFOID:0000000001326457

1.

CHECK ENGINE START

Turn ignition switch OFF, and restart engine.

Is engine running?

Yes or No

Yes (With CONSULT-III)>>GO TO 2.

Yes (Without CONSULT-III)>>GO TO 3.

No

>> GO TO 4.

2.

CHECK OVERALL FUNCTION

With CONSULT-III

1.

Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT-III.

2.

Make sure that each circuit produces a momentary engine speed drop.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 10.

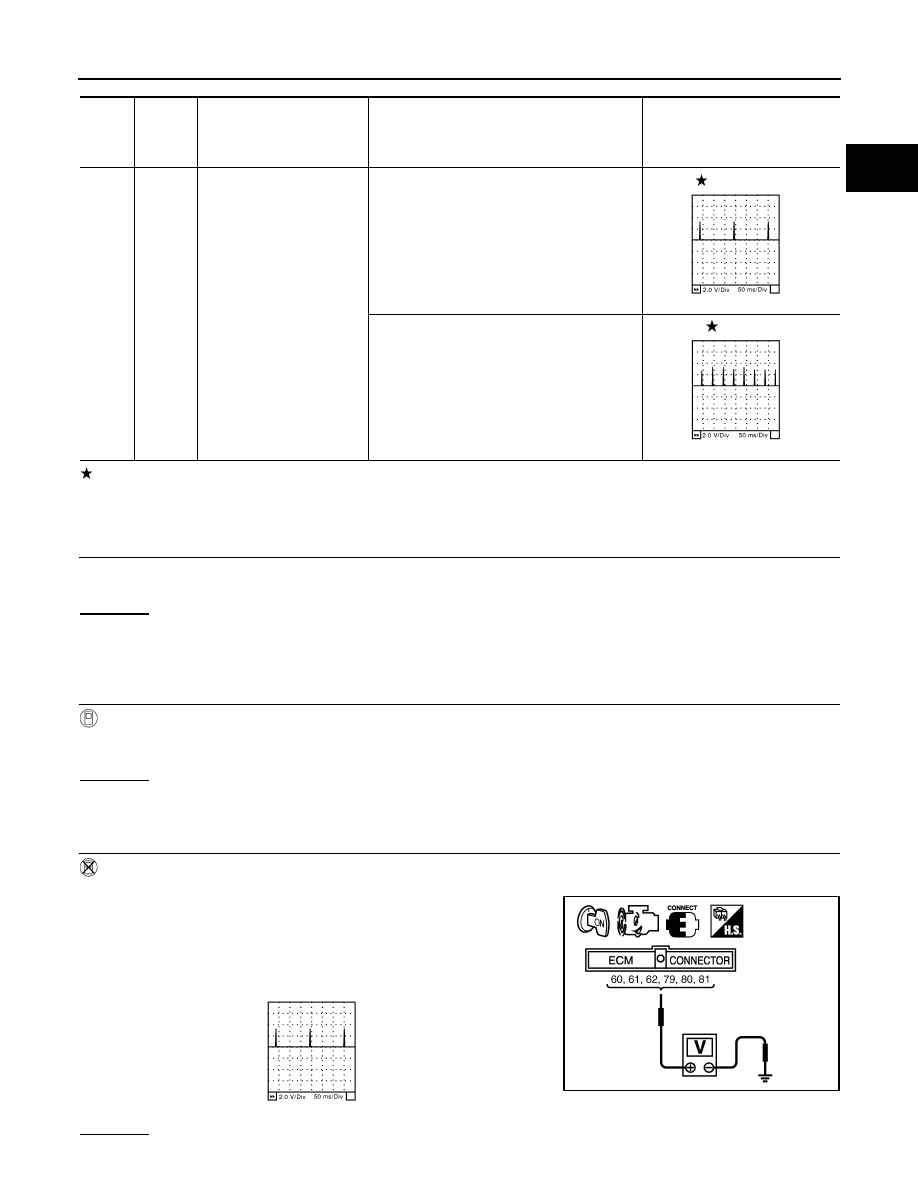

3.

CHECK OVERALL FUNCTION

Without CONSULT-III

1.

Let engine idle.

2.

Read the voltage signal between ECM terminals 60, 61, 62, 79,

80, 81 and ground with an oscilloscope.

3.

Verify that the oscilloscope screen shows the signal wave as

shown below.

NOTE:

The pulse cycle changes depending on rpm at idle.

OK or NG

TER-

MI-

NAL

NO.

WIRE

COLOR

ITEM

CONDITION

DATA (DC Voltage)

79

80

81

SB

GY

OR

Ignition signal No. 6

Ignition signal No. 4

Ignition signal No. 2

[Engine is running]

• Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle

0 - 0.2V

[Engine is running]

• Warm-up condition

• Engine speed: 2,500 rpm

0.1 - 0.4V

SEC986C

SEC987C

PBIB1186E

SEC986C

EC-576

< SERVICE INFORMATION >

[VQ35DE]

IGNITION SIGNAL

OK

>> INSPECTION END

NG

>> GO TO 10.

4.

CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1.

Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

2.

Check voltage between ECM terminals 119, 120 and ground

with CONSULT-III or tester.

OK or NG

OK

>> GO TO 5.

NG

>> Go to

.

5.

CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1.

Turn ignition switch OFF.

2.

Disconnect condenser harness connector.

3.

Turn ignition switch ON.

4.

Check voltage between condenser terminal 1 and ground with

CONSULT-III or tester.

OK or NG

OK

>> GO TO 8.

NG

>> GO TO 6.

6.

CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1.

Turn ignition switch OFF.

2.

Disconnect IPDM E/R harness connector E7.

3.

Check harness continuity between IPDM E/R terminal 17 and condenser terminal 1.

Refer to Wiring Diagram.

4.

Also check harness for short to ground and short to power.

OK or NG

OK

>> GO TO 17.

NG

>> GO TO 7.

7.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E64, F65

Voltage: Battery voltage

MBIB0034E

PBIB1606E

Voltage: Battery voltage

PBIB0624E

Continuity should exist.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст