Infiniti FX35, FX50 (S51). Manual — part 1815

DIAGNOSIS SYSTEM (TCM)

TM-67

< SYSTEM DESCRIPTION >

[7AT: RE7R01A (VQ35HR)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

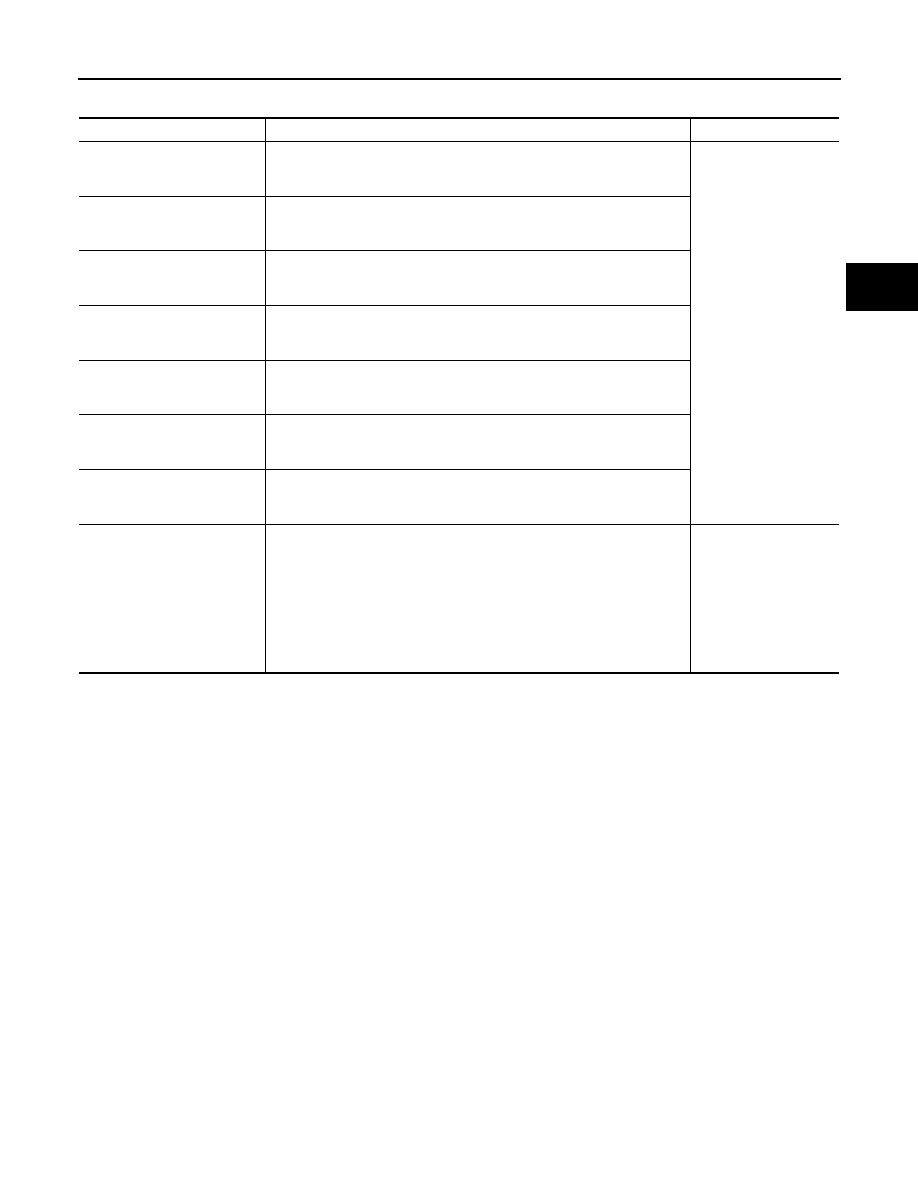

DTC Work Support

Item

Description

Check item

1ST GR FNCTN P0731

Following items for “1GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

• Input clutch solenoid

valve

• Front brake solenoid

valve

• Direct clutch solenoid

valve

• High and low reverse

clutch solenoid valve

• Low brake solenoid

valve

• 2346 brake solenoid

valve

• Anti-interlock sole-

noid valve

• Output speed sensor

• Input speed sensor 1,

2

• Each clutch and brake

• Hydraulic control cir-

cuit

2ND GR FNCTN P0732

Following items for “2GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

3RD GR FNCTN P0733

Following items for “3GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

4TH GR FNCTN P0734

Following items for “4GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

5TH GR FNCTN P0735

Following items for “5GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

6TH GR FNCTN P0729

Following items for “6GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

7TH GR FNCTN P1734

Following items for “7GR incorrect ratio” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

TCC SOL FNCTN CHECK

Following items for “TCC solenoid function” can be confirmed.

• Self-diagnosis status (whether the diagnosis is being performed or not)

• Self-diagnostic results (OK or NG)

• Harness or connec-

tors

• Torque converter

clutch solenoid valve

• Torque converter

• Input speed sensor 1,

2

• Hydraulic control cir-

cuit

TM-68

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A (VQ35HR)]

U1000 CAN COMM CIRCUIT

DTC/CIRCUIT DIAGNOSIS

U1000 CAN COMM CIRCUIT

Description

INFOID:0000000005250024

CAN (Controller Area Network) is a serial communication line for real-time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independently). In CAN communication, control units are con-

nected with 2 communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

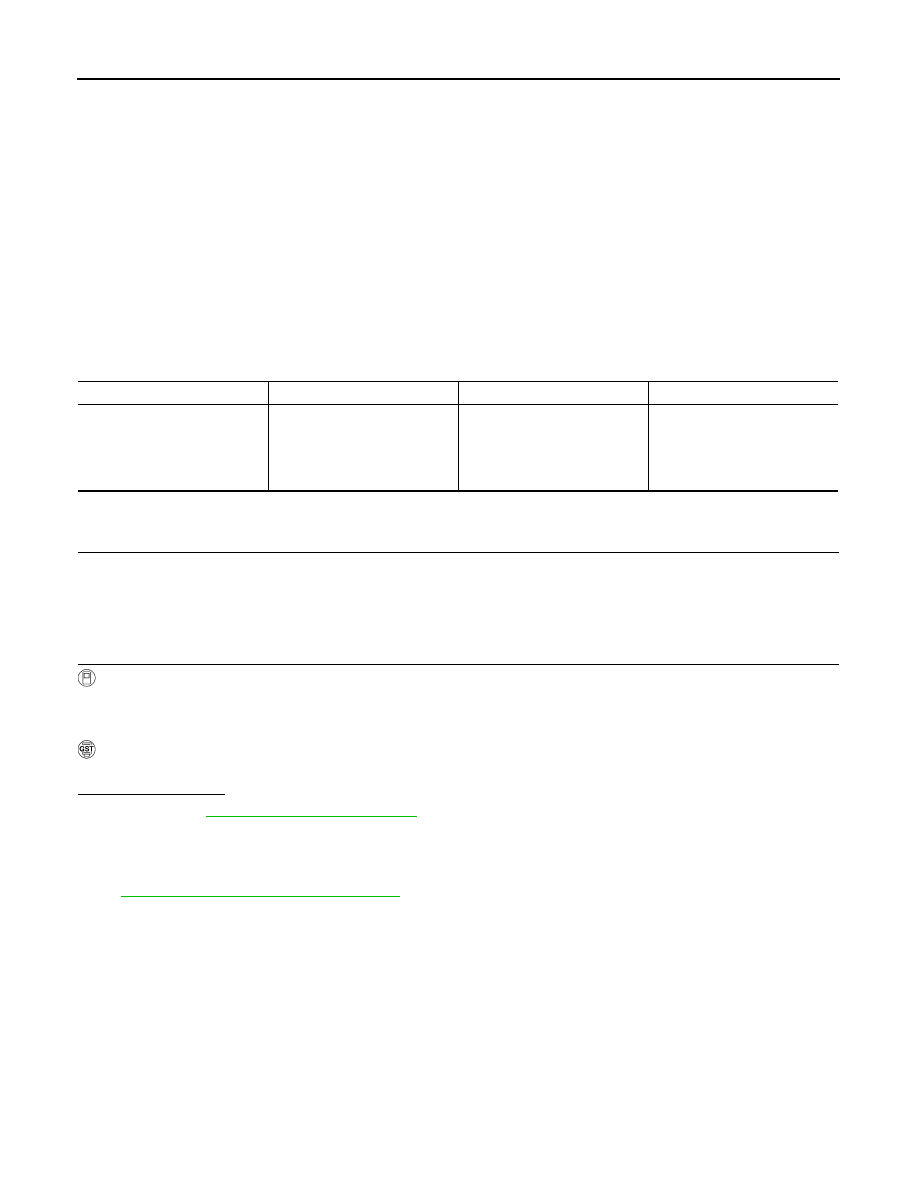

DTC Logic

INFOID:0000000005250025

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT-III

1.

Start the engine.

2.

Run engine for at least 2 consecutive seconds at idle speed.

3.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

With GST

Follow the procedure “With CONSULT-III”

Is “U1000” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000005250026

Go to

LAN-20, "Trouble Diagnosis Flow Chart"

.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

U1000

CAN Communication Line

TCM cannot transmit or receive

CAN communication signals

continuously for 2 seconds or

more when the ignition switch is

ON.

• Harness or connectors

(CAN communication line is

open or shorted.)

• TCM

P0615 STARTER RELAY

TM-69

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A (VQ35HR)]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

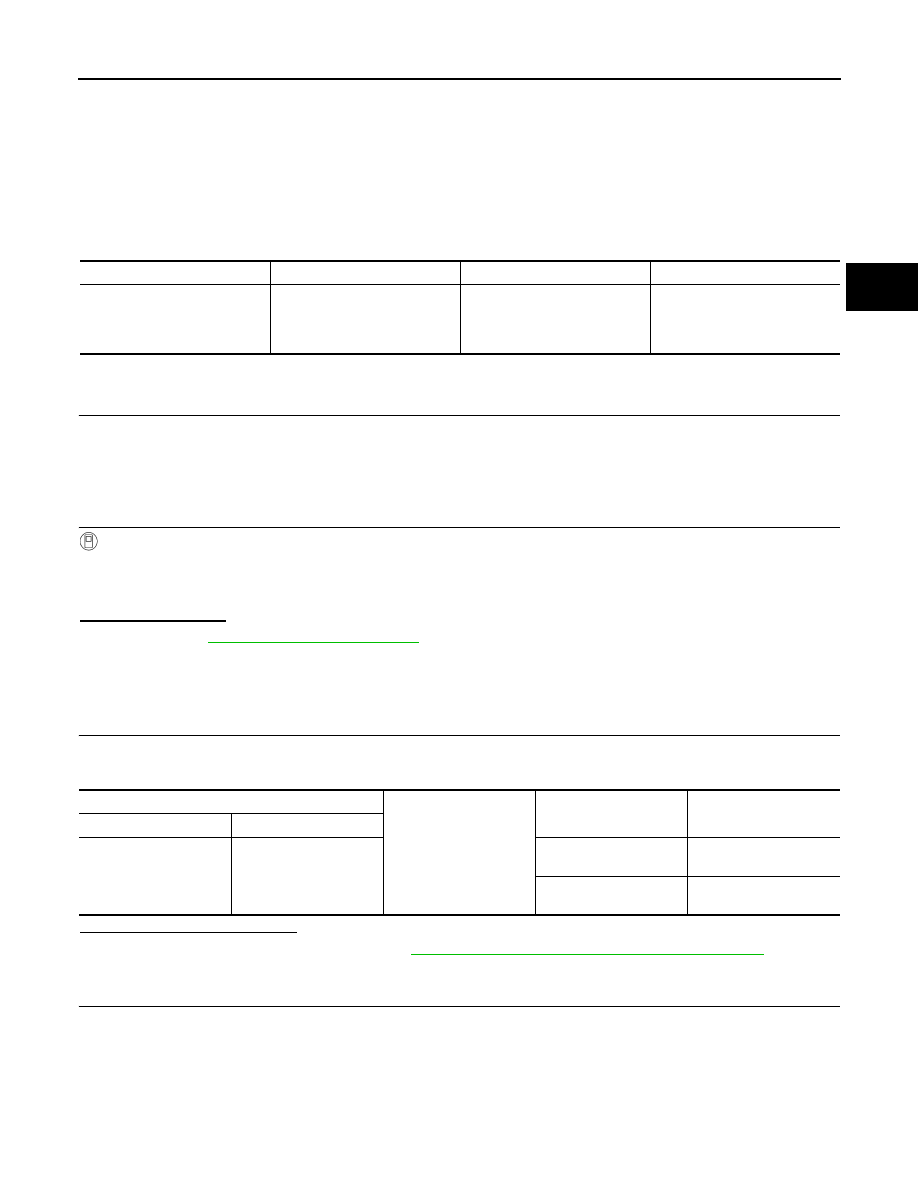

P0615 STARTER RELAY

Description

INFOID:0000000005250027

TCM prohibits cranking other than at “P” or “N” position.

DTC Logic

INFOID:0000000005250028

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

CHECK DTC DETECTION

With CONSULT-III

1.

Shift the selector lever to “P” and “N” positions.

2.

Turn ignition switch ON and wait 2 seconds or more.

3.

Perform “Self Diagnostic Results” in “TRANSMISSION”.

Is “P0615” detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000005250029

1.

CHECK STARTER RELAY SIGNAL

1.

Turn ignition switch ON.

2.

Check voltage between IPDM E/R connector terminal and ground.

Is the inspection result normal?

YES

>> Check starter relay circuit. Refer to

STR-10, "Wiring Diagram - STARTING SYSTEM -"

NO

>> GO TO 2.

2.

CHECK HARNESS BETWEEN A/T ASSEMBLY AND IPDM E/R (PART 1)

1.

Turn ignition switch OFF.

2.

Disconnect A/T assembly connector and IPDM E/R connector.

3.

Check the continuity between A/T assembly vehicle side harness connector terminal and IPDM E/R vehi-

cle side harness connector terminal.

DTC

Trouble diagnosis name

DTC is detected if...

Possible cause

P0615

Starter Relay Circuit

The starter monitor value is

OFF when the ignition switch is

ON at the“ P” and “N” positions.

• Harness or connectors

(Starter relay and TCM circuit

is open or shorted.)

• Starter relay circuit

IPDM E/R connector

Ground

Condition

Voltage (Approx.)

Connector

Terminal

E5

30

Selector lever in “P” and

“N” positions.

Battery voltage

Selector lever in other

positions.

0 V

TM-70

< DTC/CIRCUIT DIAGNOSIS >

[7AT: RE7R01A (VQ35HR)]

P0615 STARTER RELAY

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace damaged parts.

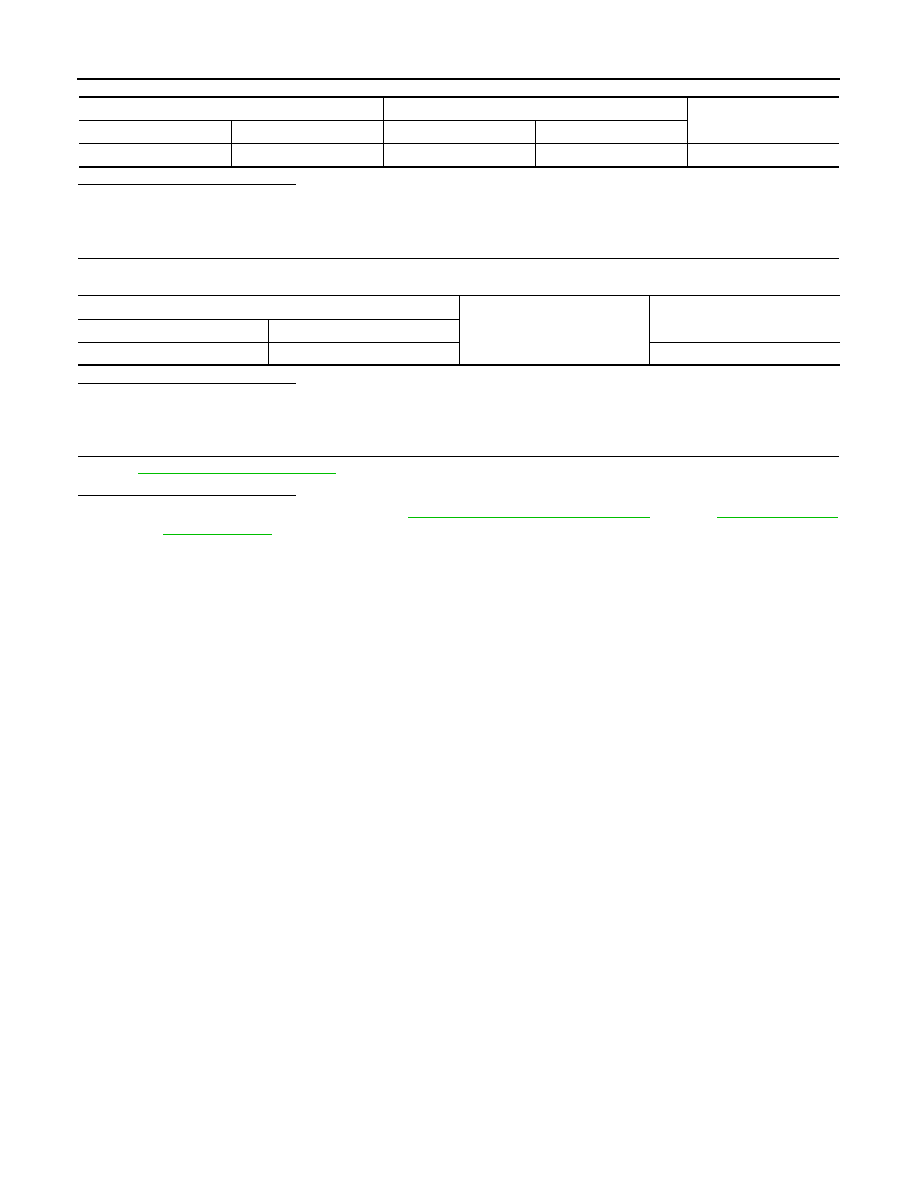

3.

CHECK HARNESS BETWEEN A/T ASSEMBLY AND IPDM E/R (PART 2)

Check the continuity between A/T assembly vehicle side harness connector terminal and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace damaged parts.

4.

CHECK INTERMITTENT INCIDENT

GI-36, "Intermittent Incident"

Is the inspection result normal?

YES

>> Replace A/T assembly. Refer to

(2WD),

(AWD).

NO

>> Repair or replace damaged parts.

A/T assembly vehicle side harness connector

IPDM E/R vehicle side harness connector

Continuity

Connector

Terminal

Connector

Terminal

F51

9

E5

30

Existed

A/T assembly vehicle side harness connector

Ground

Continuity

Connector

Terminal

F51

9

Not existed

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст