Infiniti FX35, FX50 (S51). Manual — part 1146

COOLER PIPE AND HOSE

HA-97

< REMOVAL AND INSTALLATION >

[VK50VE]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

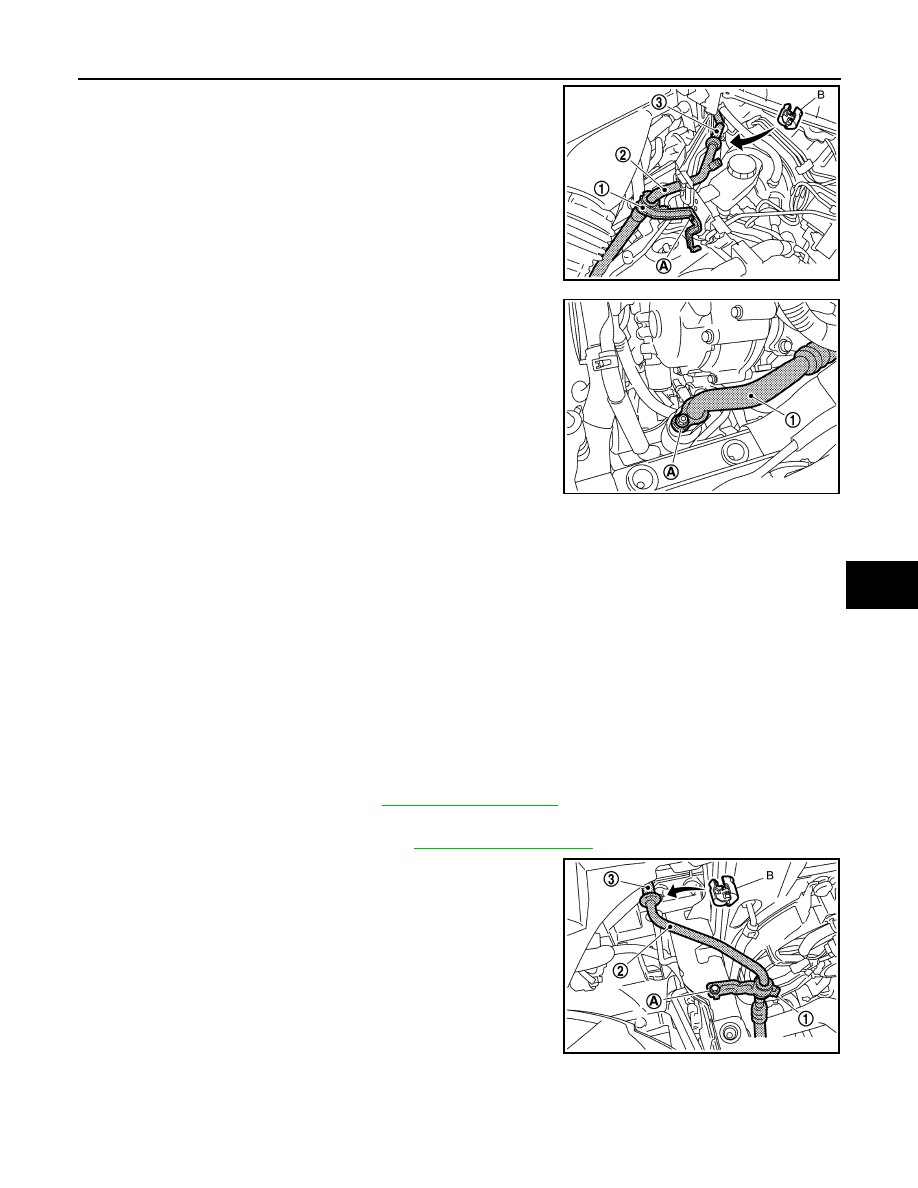

4.

Remove mounting bolt (A) from low-pressure flexible hose

bracket (1).

5.

Disconnect one-touch joint between low-pressure flexible hose

(2) and low-pressure pipe 2 (3) with disconnector (B) (SST:

9253089916).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

6.

Remove mounting nut (A), and then remove low-pressure flexi-

ble hose (1).

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• Check for leakages when recharging refrigerant.

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE : Removal and Installation

INFOID:0000000005249965

REMOVAL

1.

Remove hoodledge cover LH. Refer to

.

2.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

3.

Remove air cleaner case (bank 1). Refer to

4.

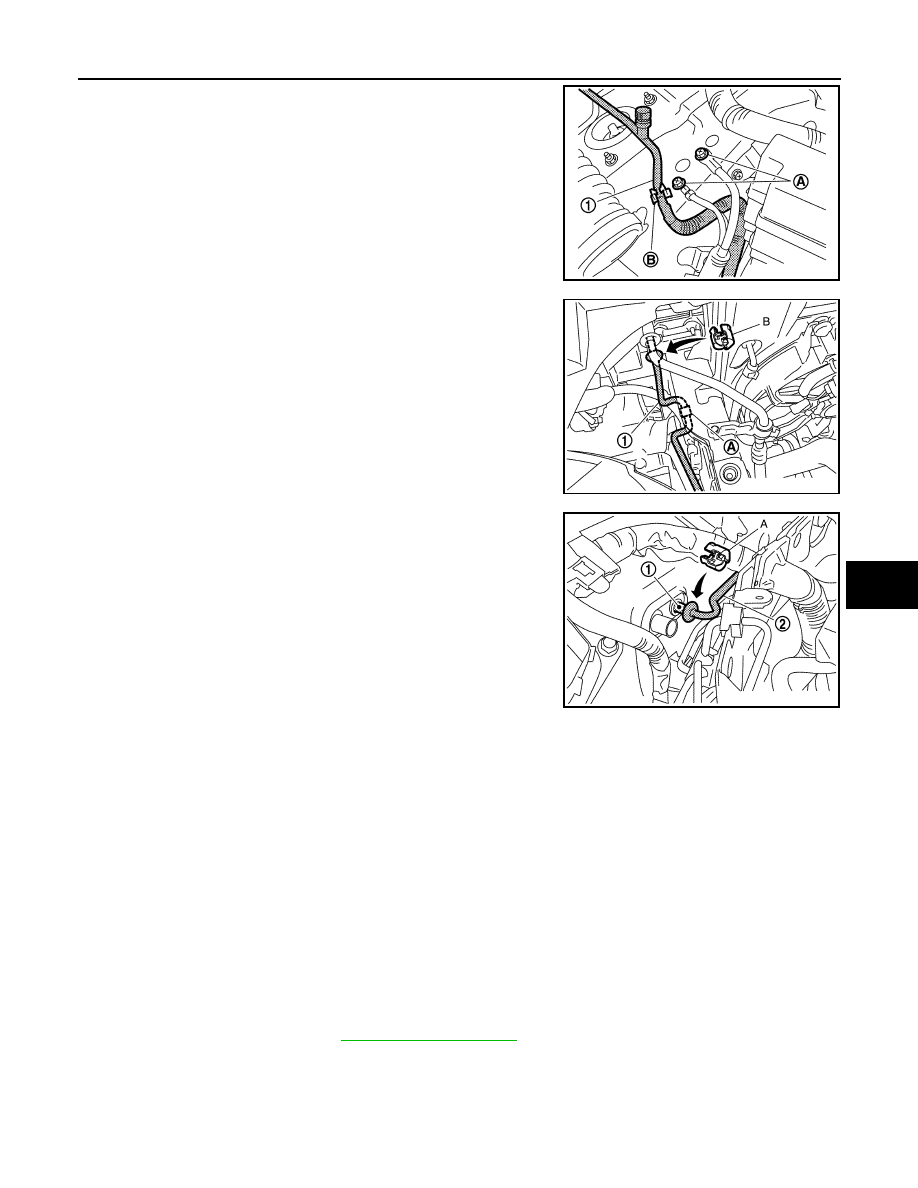

Remove mounting bolt (A) from high-pressure flexible hose

bracket (1).

5.

Disconnect one-touch joint between high-pressure flexible hose

(2) and condenser pipe assembly (3) with disconnector (B)

(SST: 9253089912).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

JSIIA1232ZZ

JSIIA1233ZZ

JSIIA1235ZZ

HA-98

< REMOVAL AND INSTALLATION >

[VK50VE]

COOLER PIPE AND HOSE

6.

Remove mounting nut (A), and remove low-pressure flexible

hose (1) a position without the hindrance for work.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

7.

Remove mounting nut (A), and then remove high-pressure flexi-

ble hose (1).

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• Check for leakages when recharging refrigerant.

HIGH-PRESSURE PIPE 1

HIGH-PRESSURE PIPE 1 : Removal and Installation

INFOID:0000000005249966

REMOVAL

1.

Remove low-pressure flexible hose and low-pressure pipe 2. Refer to

.

2.

Remove cramp (A), and then disconnect vacuum hose (1).

Refer to

.

JSIIA1233ZZ

JSIIA1239ZZ

JSIIA1257ZZ

COOLER PIPE AND HOSE

HA-99

< REMOVAL AND INSTALLATION >

[VK50VE]

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

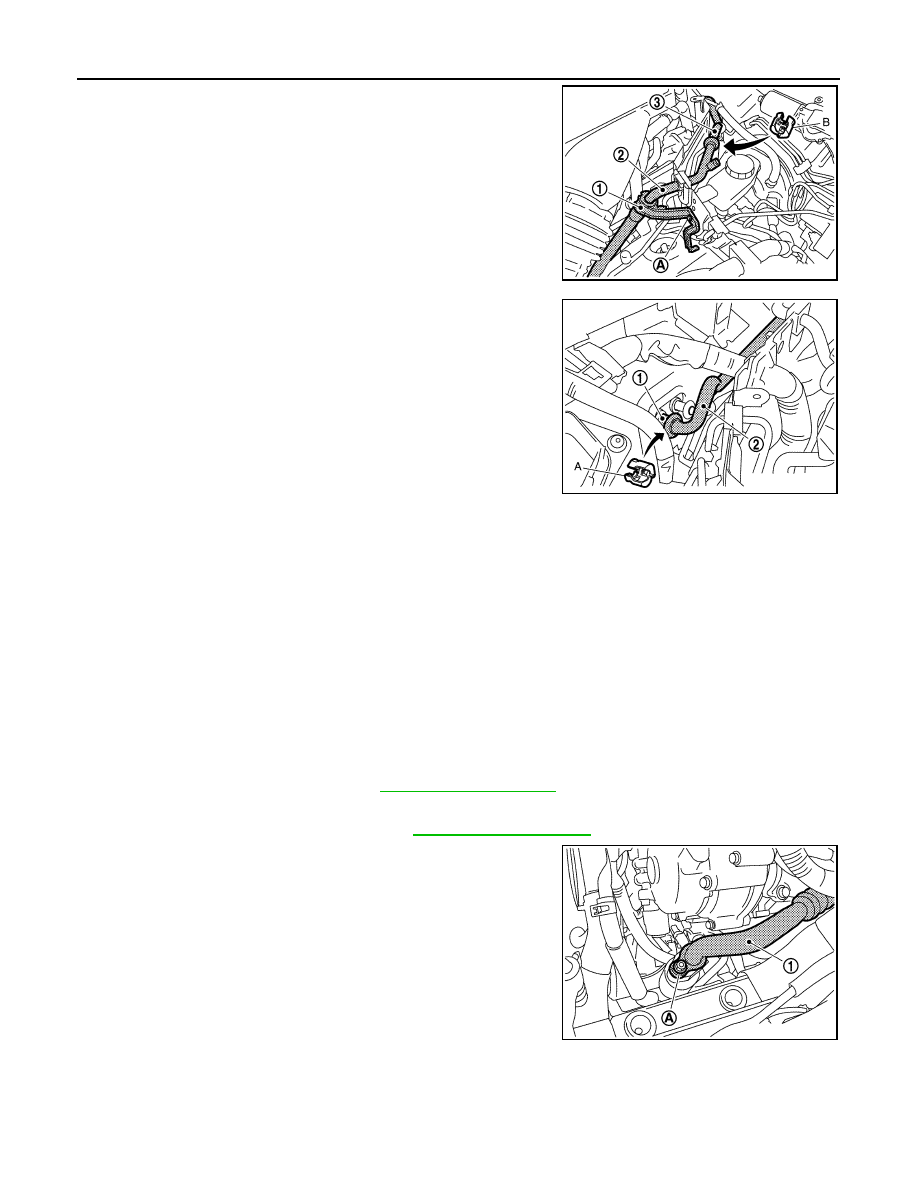

3.

Remove ground bolts (A).

4.

Remove high-pressure pipe 1 (1) from vehicle clip (B).

5.

Remove high-pressure pipe 1 (1) from vehicle clip (A).

6.

Disconnect one-touch joint between high-pressure pipe 1 and

condenser pipe assembly with disconnector (B) (SST:

9253089908).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

7.

Disconnect one-touch joint between high-pressure pipe 1 (2)

and high-pressure pipe 2 (1) with disconnector (A) (SST:

9253089908).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

8.

Remove high-pressure pipe 1.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• Check for leakages when recharging refrigerant.

LOW-PRESSURE PIPE 2

LOW-PRESSURE PIPE 2 : Removal and Installation

INFOID:0000000005249967

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2.

Remove cowl top cover. Refer to

JSIIA1258ZZ

JSIIA1259ZZ

JSIIA1260ZZ

HA-100

< REMOVAL AND INSTALLATION >

[VK50VE]

COOLER PIPE AND HOSE

3.

Remove mounting bolt (A) from low-pressure flexible hose

bracket (1).

4.

Disconnect one-touch joint between low-pressure flexible hose

(2) and low-pressure pipe 2 (3) with disconnector (B) (SST:

9253089916).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

5.

Disconnect one-touch joint between low-pressure pipe 1 (1) and

low-pressure pipe 2 (2) with disconnector (A) (SST:

9253089916).

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

6.

Remove low-pressure pipe 2.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

• Replace O-rings with new ones. Then apply compressor oil to them when installing.

• Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

• Insert piping securely until a click is heard.

• After piping connection is completed, pull male-side piping by hand to make sure that connection

does not come loose.

• Check for leakages when recharging refrigerant.

LOW-PRESSURE PIPE 3

LOW-PRESSURE PIPE 3 : Removal and Installation

INFOID:0000000005249968

REMOVAL

1.

Remove hoodledge cover LH. Refer to

.

2.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

3.

Remove air cleaner case (bank 1). Refer to

4.

Remove mounting nut (A), and remove low-pressure flexible

hose (1) a position without the hindrance for work.

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

JSIIA1238ZZ

JSIIA1264ZZ

JSIIA1233ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст