Infiniti FX35, FX50 (S51). Manual — part 620

INSPECTION AND ADJUSTMENT

EC-21

< BASIC INSPECTION >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2.

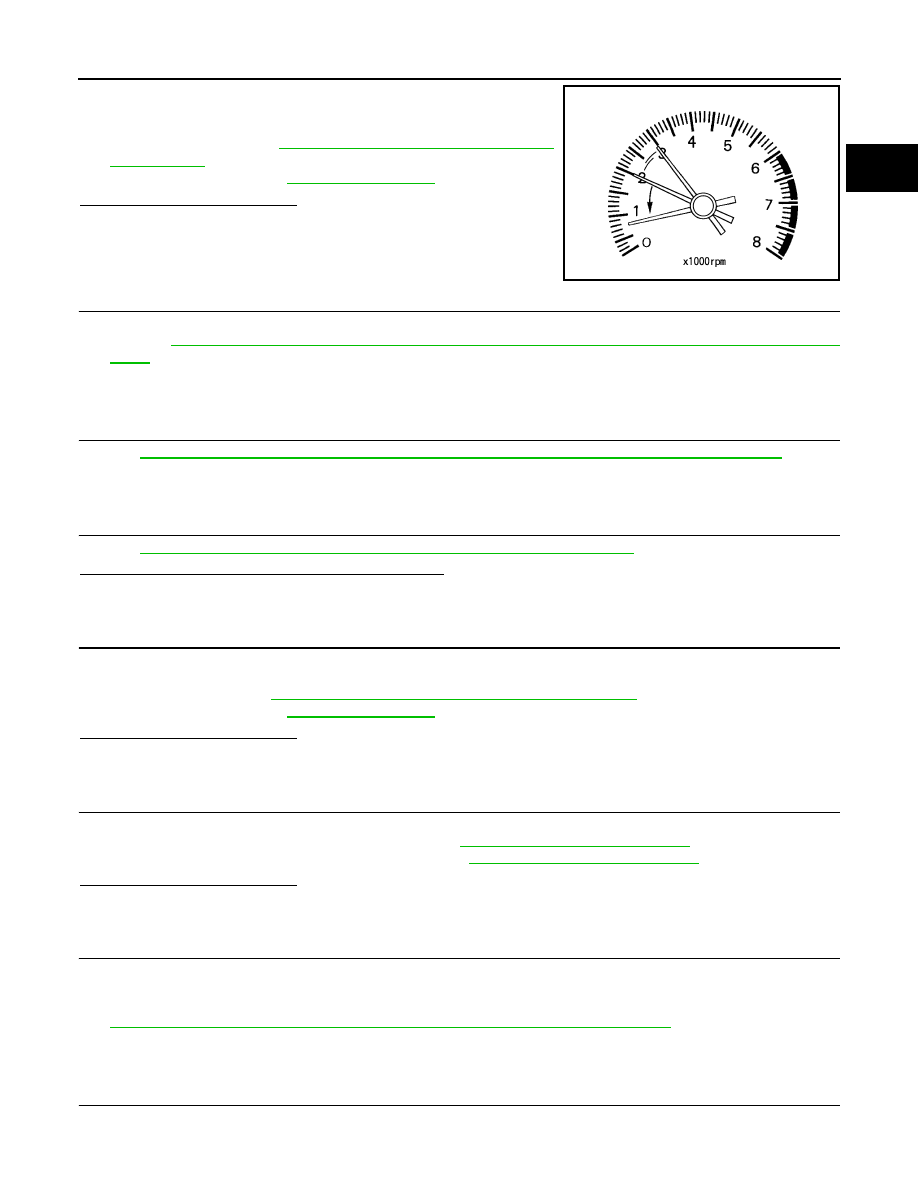

Rev engine (2,000 to 3,000 rpm) 2 or 3 times under no load,

then run engine at idle speed for approximately 1 minute.

3.

Check idle speed.

For procedure, refer to

EC-24, "IDLE SPEED : Special Repair

.

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 4.

4.

PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1.

Stop engine.

2.

Perform

EC-25, "ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

.

>> GO TO 5.

5.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform

EC-25, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 6.

6.

PERFORM IDLE AIR VOLUME LEARNING

Perform

EC-25, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

Is Idle Air Volume Learning carried out successfully?

YES

>> GO TO 7.

NO

>> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.

CHECK IDLE SPEED AGAIN

1.

Start engine and warm it up to normal operating temperature.

2.

Check idle speed.

For procedure, refer to

EC-24, "IDLE SPEED : Special Repair Requirement"

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 8.

8.

DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor and circuit. Refer to

EC-277, "Component Inspection"

.

• Check crankshaft position sensor and circuit. Refer to

EC-271, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace malfunctioning part. Then GO TO 4.

9.

CHECK ECM FUNCTION

1.

Substitute with a non-malfunctioning ECM to check ECM function. (ECM may be the cause of the incident,

although this is rare.)

2.

Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

SEC-8, "ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement"

.

>> GO TO 4.

10.

CHECK IGNITION TIMING

1.

Run engine at idle.

2.

Check ignition timing with a timing light.

PBIA8513J

EC-22

< BASIC INSPECTION >

[VQ35HR]

INSPECTION AND ADJUSTMENT

For procedure, refer to

EC-24, "IGNITION TIMING : Special Repair Requirement"

.

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 19.

NO

>> GO TO 11.

11.

PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1.

Stop engine.

2.

Perform

EC-25, "ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Require-

>> GO TO 12.

12.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform

EC-25, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 13.

13.

PERFORM IDLE AIR VOLUME LEARNING

Perform

EC-25, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

Is Idle Air Volume Learning carried out successfully?

YES

>> GO TO 14.

NO

>> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

14.

CHECK IDLE SPEED AGAIN

1.

Start engine and warm it up to normal operating temperature.

2.

Check idle speed.

For procedure, refer to

EC-24, "IDLE SPEED : Special Repair Requirement"

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 15.

NO

>> GO TO 17.

15.

CHECK IGNITION TIMING AGAIN

1.

Run engine at idle.

2.

Check ignition timing with a timing light.

For procedure, refer to

EC-24, "IGNITION TIMING : Special Repair Requirement"

.

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 19.

NO

>> GO TO 16.

16.

CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to

EM-54, "Removal and Installation"

Is the inspection result normal?

YES

>> GO TO 17.

NO

>> Repair the timing chain installation. Then GO TO 4.

17.

DETECT MALFUNCTIONING PART

Check the following.

• Check camshaft position sensor and circuit. Refer to

EC-277, "Component Inspection"

.

• Check crankshaft position sensor and circuit. Refer to

EC-271, "Component Inspection"

.

Is the inspection result normal?

YES

>> GO TO 18.

NO

>> Repair or replace malfunctioning part. Then GO TO 4.

18.

CHECK ECM FUNCTION

INSPECTION AND ADJUSTMENT

EC-23

< BASIC INSPECTION >

[VQ35HR]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

1.

Substitute with a non-malfunctioning ECM to check ECM function. (ECM may be the cause of the incident,

although this is rare.)

2.

Perform initialization of IVIS (NATS) system and registration of all IVIS (NATS) ignition key IDs. Refer to

SEC-8, "ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement"

.

>> GO TO 4.

19.

INSPECTION END

If ECM is replaced during this BASIC INSPECTION procedure, go to

EC-23, "ADDITIONAL SERVICE WHEN

REPLACING CONTROL UNIT : Special Repair Requirement"

.

>> INSPECTION END

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Description

INFOID:0000000005236676

When replacing ECM, the following procedure must be performed.

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Special Repair Re-

quirement

INFOID:0000000005236677

1.

PERFORM INITIALIZATION OF IVIS (NATS) SYSTEM AND REGISTRATION OF ALL IVIS (NATS) IGNI-

TION KEY IDS

SEC-8, "ECM RE-COMMUNICATING FUNCTION : Special Repair Requirement"

>> GO TO 2.

2.

PERFORM VIN REGISTRATION

EC-24, "VIN REGISTRATION : Special Repair Requirement"

.

>> GO TO 3.

3.

PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

Refer to

EC-25, "ACCELERATOR PEDAL RELEASED POSITION LEARNING : Special Repair Requirement"

.

>> GO TO 4.

4.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

EC-25, "THROTTLE VALVE CLOSED POSITION LEARNING : Special Repair Requirement"

>> GO TO 5.

5.

PERFORM IDLE AIR VOLUME LEARNING

EC-25, "IDLE AIR VOLUME LEARNING : Special Repair Requirement"

>> GO TO 6.

6.

PERFORM EXHAUST VALVE TIMING CONTROL LEARNING

EC-27, "EXHAUST VALVE TIMING CONTROL LEARNING : Special Repair Requirement"

.

>> END

IDLE SPEED

EC-24

< BASIC INSPECTION >

[VQ35HR]

INSPECTION AND ADJUSTMENT

IDLE SPEED : Description

INFOID:0000000005236678

This describes how to check the idle speed. For the actual procedure, follow the instructions in “BASIC

INSPECTION”.

IDLE SPEED : Special Repair Requirement

INFOID:0000000005236679

1.

CHECK IDLE SPEED

With CONSULT-III

Check idle speed in “DATA MONITOR” mode with CONSULT-III.

With GST

Check idle speed with Service $01 of GST.

>> INSPECTION END

IGNITION TIMING

IGNITION TIMING : Description

INFOID:0000000005236680

This describes how to check the ignition timing. For the actual procedure, follow the instructions in “BASIC

INSPECTION”.

IGNITION TIMING : Special Repair Requirement

INFOID:0000000005236681

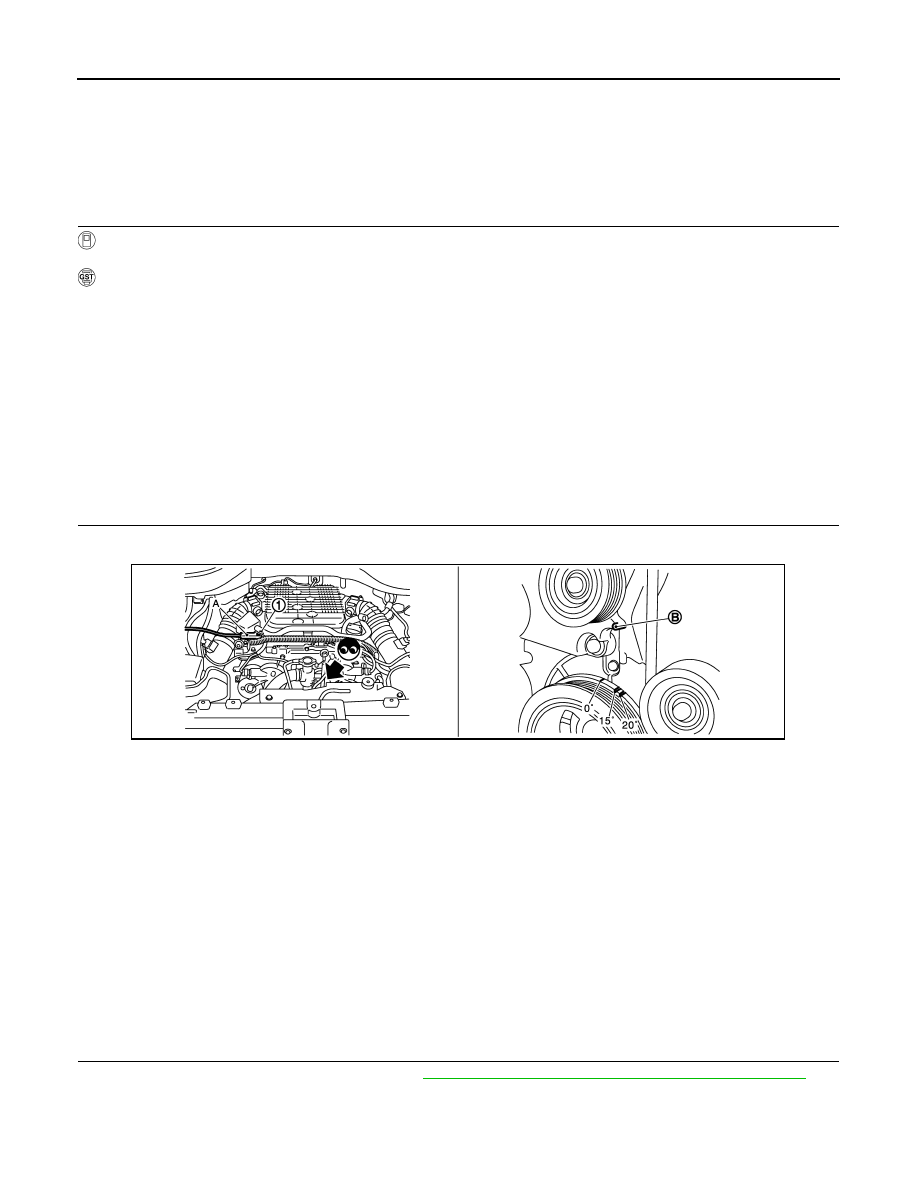

1.

CHECK IGNITION TIMING

1.

Attach timing light to loop wire as shown.

2.

Check ignition timing.

>> INSPECTION END

VIN REGISTRATION

VIN REGISTRATION : Description

INFOID:0000000005236682

VIN Registration is an operation to register VIN in ECM. It must be performed each time ECM is replaced.

NOTE:

Accurate VIN which is registered in ECM may be required for Inspection & Maintenance (I/M).

VIN REGISTRATION : Special Repair Requirement

INFOID:0000000005236683

1.

CHECK VIN

Check the VIN of the vehicle and note it. Refer to

GI-17, "Information About Identification or Model Code"

>> GO TO 2.

1.

Loop wire

A.

Timing light

B.

Timing indicator

JMBIA1517ZZ

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст