SAAB 9000. Manual — part 55

12•12 Body electrical systems

Removal

4 Disconnect the battery negative cable, and

position it away from the terminal.

5 Refer to the relevant paragraphs of Chap-

ter 11, Section 27, and remove the panel from

the top of the facia.

6 With reference to Chapter 3, remove the air

ducting from above the instrument panel.

7 Apply light hand pressure at the rear of the

module, to release it from the facia.

8 At the rear of the module, disconnect the

multi-plug cable connectors, labelling the,m to

aid refitting later.

Refitting

9 Refit the clock/trip computer module by

reversing the removal procedure. Ensure that

the multi-plug cable connectors are refitted

according to the notes made during removal,

and that they are firmly plugged in.

Removal

1 Disconnect the battery negative cable, and

position it away from the terminal.

2 Refer to the relevant paragraphs of Chap-

ter 11, Section 27, and remove the ashtray

assembly from the facia front panel.

3 Unplug the cable connectors from the rear

of the cigarette lighter body, labelling them to

aid refitting later.

4 Using a small, flat-bladed screwdriver, prise

off the metal retaining clip, then withdraw the

cigarette lighter from the ashtray.

Refitting

5 Refit the cigarette lighter by reversing the

removal procedure.

General

1 Two types of speedometer drive

mechanism have been fitted. Vehicles built

before 1987 have a conventional speedometer

cable, which drives the speedometer remotely,

by means of a cable with a rotating, flexible

inner shaft.

2 An erratic or inconsistent speedometer

display, such as needle flickering or jumping,

may be attributable to wear in the

speedometer drive cable.

3 Vehicles built after 1987 are fitted with an

electronic transducer in place of the drivegear.

This device measures the rotational speed of

the transmission final drive, and converts the

information into an electronic signal, which is

then sent to the speedometer module in the

instrument panel. The signal is also used as an

input by the engine management system ECU

(and where fitted, the cruise control ECU, the

trip computer, and the traction control system

ECU).

Removal

4 Refer to the relevant paragraphs of Chap-

ter 11, Section 27, and remove the panel from

the top of the facia.

5 With reference to Chapter 3, remove the air

ducting from above the instrument panel.

6 Disconnect the drive cable from the rear of

the speedometer module.

7 Release the cable from the clips securing it

to the inside of the facia, then pull the free end

of cable through the bulkhead into the engine

bay, noting the cable routing. Do not use

excessive force, as this may damage the

rubber grommet at the bulkhead.

8 At the gearbox, unscrew the knurled nut at

the point where the speedometer cable enters

the differential casing. Withdraw the cable

inner from the drivegear.

9 Remove the speedometer cable from the

vehicle.

Refitting

10 Refit the speedometer drive cable by

reversing the removal process. Follow the

same routing behind the facia as the original

drive cable, ensuring that all moving

components are avoided. Do not force the

cable to follow tight curves, as this may

adversely affect the rotation of the cable inner.

Horn push buttons

1 Disconnect the battery negative cable, and

position it away from the terminal.

2 Using a thin plastic spatula, prise the horn

button from the steering wheel spoke, and lift

off the upper electrical contact (see

illustration).

3 Remove the retaining screw, and lift off the

lower electrical contact (see illustration).

4 Examine both the lower and upper contacts

for signs of wear or corrosion; renew them if

necessary.

5 Refitting is a reversal of removal.

Horns

Note: On early models, the second horn is

mounted in the engine bay, inside the left-

hand wheelarch.

6 Disconnect the battery negative cable, and

position it away from the terminal.

7 Refer to Chapter 11, Section 8 and remove

the front grille.

8 Unplug the wiring harness connector from

the horn.

9 Slacken and withdraw the retaining nut at

the bottom of the horn bracket, and lift off the

horns (see illustration).

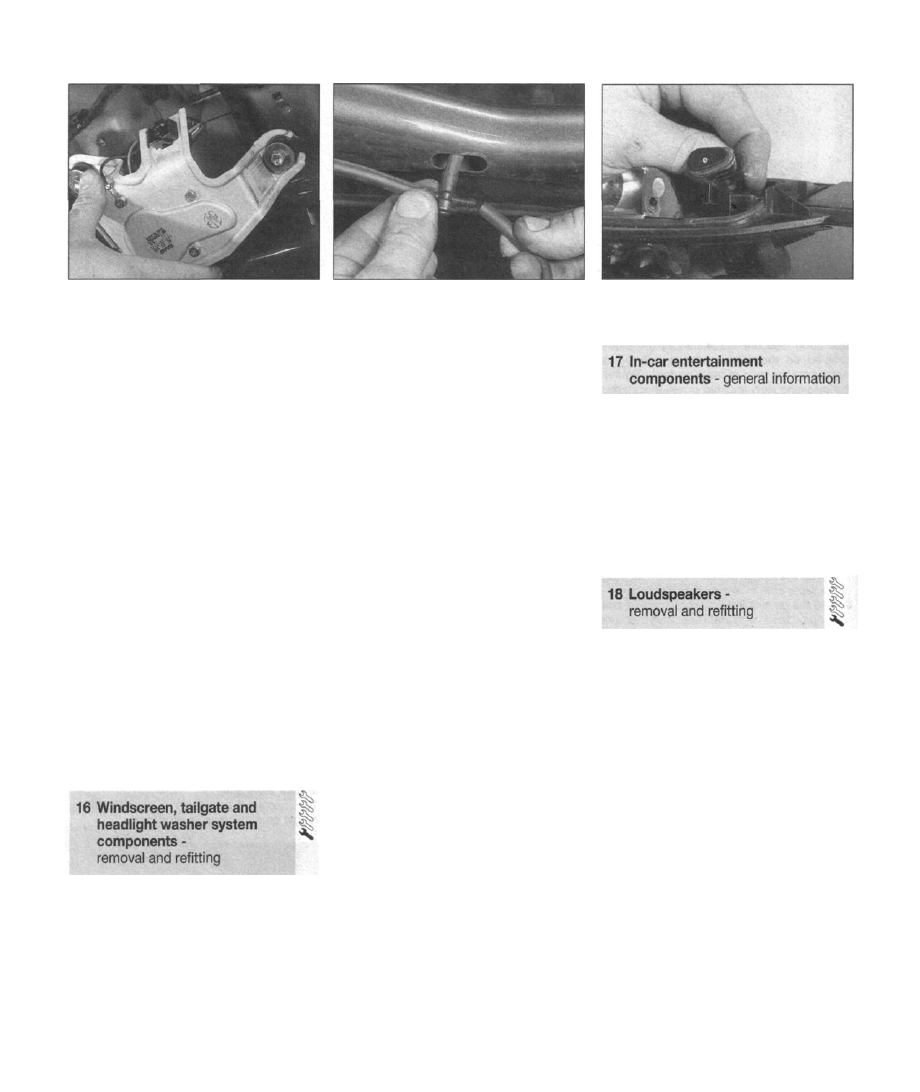

Windscreen wiper arms

1 Note the position on the windscreen at

which wiper blades settle, when in the parked

position. Mark this position on the screen with

a strip of masking tape.

2 Flip up the hinged plastic cover at the base

of the wiper arm, to expose the retaining nut.

3 Slacken and remove the nut, then lift off the

wiper arm.

4 When refitting, ensure that the splined drive

spindle engages with the wiper arm mounting

13.2 Prise the horn button from the

steering wheel spoke (airbag removed for

clarity)

13.3 Remove the retaining screw, and lift

off the lower electrical contact (airbag

removed for clarity)

13.9 Slacken and withdraw the retaining

nut (arrowed) at the bottom of the horn

bracket

Body electrical systems 12•13

14.5 Flip up the hinged plastic cover at the

base of the tailgate wiper arm, to expose

the retaining nut

hole such that the blade falls in the same

position on the windscreen as before, as

marked by the strip of masking tape. Tighten

the retaining nut, and flip down the plastic

cover.

Tailgate wiper arm

5 The procedure is identical to that given for

the windscreen wiper arms above (see

illustration).

Headlight wiper arms

6 Note the position on the headlight lens at

which wiper blade settles, when in the parked

position. Mark this position on the lens with a

strip of masking tape.

7 Flip up the hinged plastic cover at the base

of the wiper arm, to expose the retaining nut.

8 Hold the drive spindle stationary with a pair

of grips, then slacken and remove the

retaining nut, and lift off the wiper arm.

9 When refitting, ensure that the drive spindle

engages with the wiper arm mounting hole

such that the blade falls in the same position

on the headlight lens as before, as marked by

the strip of masking tape. Tighten the retaining

nut securely, and flip down the plastic cover.

Warning: To eliminate the risk of

causing accidental short-circuits,

disconnect the battery negative

cable, and position it away from

the terminal, before attempting any of the

following operations

Windscreen wiper motor and

linkage

Removal

1 With reference to Section 14, remove both

wiper arms.

2 Lift off the rubber grommets and plastic

weather caps, as applicable, from the spindle

shaft.

3 On later models, remove the plastic trim panel

from the lower edge of the windscreen, by

15.6 Using a ring spanner, slacken and

remove the drive spindle extension shaft

nuts

releasing the press-stud fixings and then lifting

off the bonnet hinge end caps at either side.

Carefully lift the lower edge of the windscreen

sealing strip, and slide out the trim panel.

4 Access to the wiper motor and linkage can

be improved if the false bulkhead panel and

cover are removed from the engine bay;

remove the two retaining screws at either side

and lift the panel out; refer to Chapter 2B,

Section 4.

5 Unplug the wiper motor cables at the

connectors - label them to aid refitting later.

6 Using a ring spanner, slacken and remove

the wiper drive spindle nuts. Note that on later

models, the wiper drive spindles are fitted with

extension shafts, which are secured to the

bodywork by separate retaining bolts (see

illustration).

7 Remove the four wiper motor assembly

mounting bolts.

8 Using a screwdriver as a lever, separate the

link rod from the left-hand wiper extension

shaft at the balljoint. Separate the other end of

the link rod from the wiper motor assembly at

the drive arm balljoint (see illustrations).

9 Lift out the wiper motor assembly and left-

hand wiper link rod. Note the position of the

drive arm in the "parked" position, to aid

refitting later.

10 The right-hand wiper link rod can be

removed in the same way. Note that on later

models, where drive spindle extension shafts

are fitted, a bracing bar is fitted between the

two extension shafts. This must be detached

15.8a Separate the link rod from the left-

hand wiper extension shaft at the balljoint

15.8b Separate the other end of the link rod

from the wiper motor assembly at the

balljoint

by unscrewing the through-bolt, before the

extension shafts can be unbolted.

Refitting

11 Refit the wiper motor and linkage by

reversing the removal process; ensure that the

wiper motor drive arm is still in the "parked"

position before attempting to reconnect the

link rods.

Tailgate wiper motor

Removal

12 With reference to Section 14, remove the

tailgate wiper arm.

13 Unscrew the spindle nut, then lift off the

rubber grommet (see illustrations).

15.13a Unscrew the tailgate wiper spindle

nut..

15.13b . . . then lift off the rubber grommet

12•14 Body electrical systems

15.16 Slacken the retaining bolts, and

lower the wiper motor assembly away from

the tailgate

14 Open the tailgate and remove the trim

panel from the inside of the tailgate, referring

to Chapter 11 for details.

15 Unplug the wiper motor cable at the

connector.

16 Slacken the retaining bolts and lower the

wiper motor assembly away from the tailgate,

guiding the drive spindle through the tailgate

aperture (see illustration).

Refitting

17 Refit the wiper motor assembly by

reversing the removal procedure. Ensure that

the three anti-vibration rubber bushes are

correctly seated, before tightening the

retaining bolts.

Headlight wiper motor

General

18 On earlier models fitted with single-

reflector headlight units, the wiper motor

assembly is bolted to the underside of the

headlight unit.

19 On later models, where dual-reflector

headlight units are fitted, the wiper motor

assembly is bolted to the bodywork, directly

underneath the headlight unit.

20 Removal of the wiper motor assembly is

described in Section 6, as part of the headlight

unit dismantling procedure.

General

1 The windscreen, tailgate and headlight

washer jets are all supplied by one electric

pump, which is mounted on the washer fluid

reservoir.

2 The mounting position of the fluid reservoir

depends on the age of the vehicle. On earlier

vehicles, the reservoir is screwed to the left-

hand inner wing, in front of the battery tray. On

later models, the fluid reservoir is mounted

inside the right-hand wing cavity, in front of

the wheelarch.

16.9 Disconnect the hose from the

underside of the washer jet

Washer pump

Removal

3 Disconnect the battery negative cable, and

position it away from the terminal.

4 On later models, refer to Chapter 11,

Section 22 and remove the right-hand

wheelarch liner.

5 Disconnect the fluid delivery hose from the

port on the pump housing. Be prepared for

fluid spillage as the hose is removed.

6 Unplug the motor cabling at the connector.

7 Remove the pump by easing it away from

the reservoir slightly, and then pulling it up out

of the rubber sealing grommet. If the level of

fluid in the reservoir is above the level of the

sealing grommet, be ready to catch the

spillage by positioning a container under the

reservoir.

Refitting

8 Refit the washer pump by reversing the

removal procedure.

Windscreen washer jets

9 Open the bonnet, and disconnect the hose

from the underside of the washer jet (see

illustration).

10 Using a plastic spatula, or a flat-bladed

screwdriver wrapped in PVC to protect the

paintwork, prise the washer jet from the

bonnet aperture.

11 Refitting is a reversal of removal.

Tailgate washer jet

12 Refer to Section 7, and separate the high-

level brake light lens and cover moulding from

the bulbholder assembly.

13 Slide the washer jet moulding out of the

housing in the bulbholder assembly (see

illustration).

14 Refitting is a reversal of removal.

Headlight washer jet

15 The headlight washer jets are integrated

into the headlight lens wiper arms; refer to

Section 14 for guidance in removing the wiper

arm.

16.13 Slide the washer jet moulding out of

the housing in the bulbholder assembly

The make and type of radio/cassette/

compact disc player fitted depends on the age

and specification of the vehicle, as does the

method of removal. For specific instructions

regarding the removal of the unit, refer to the

manufacturer's documentation supplied with

the vehicle, or seek advice from your Saab

dealer.

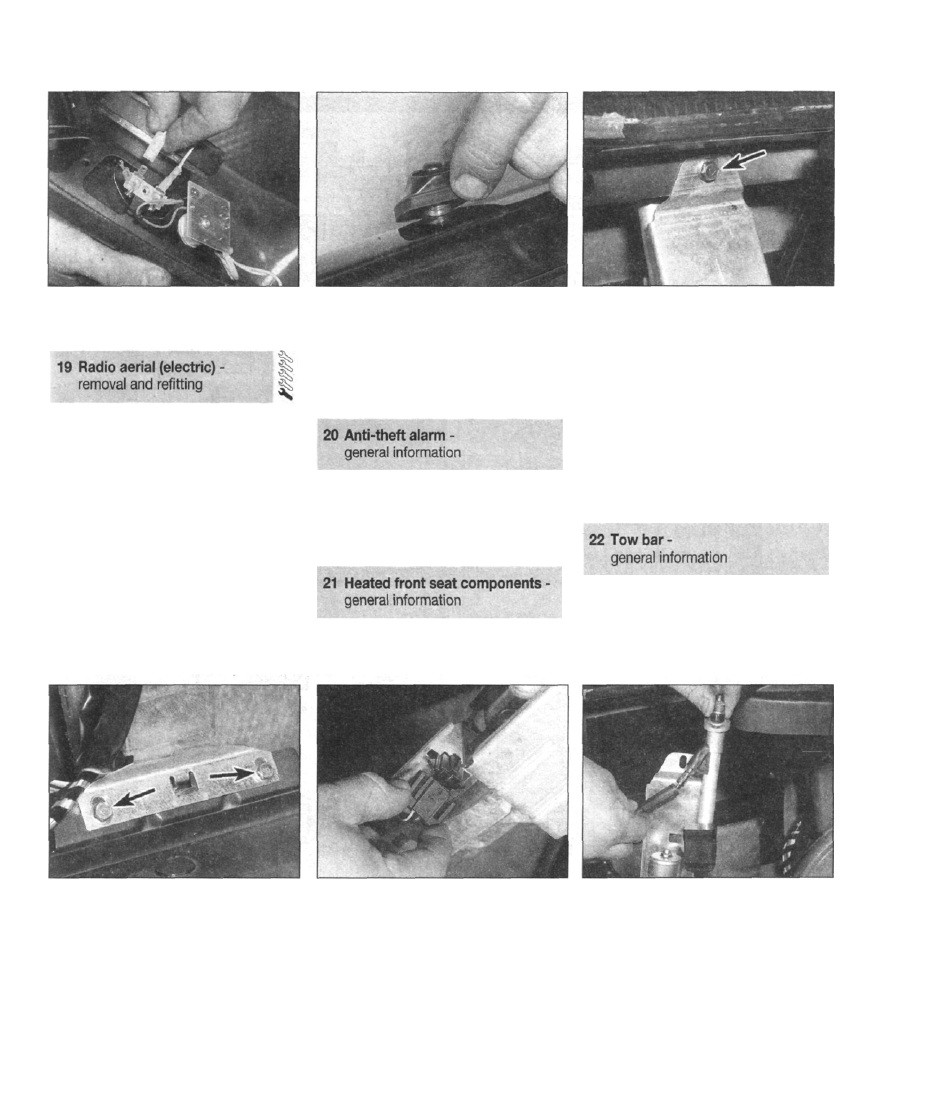

Front speakers

Removal

1 Ensure that the radio/cassette/CD player is

switched off.

2 With reference to Chapter 11, Section 27,

remove the top panel from the facia. Lift off

the grille, and recover the rubber spacer

beneath.

3 Remove the screws and lift out the speaker

units, unplugging the cables and labelling

them to aid refitting later.

Refitting

4 Refitting is a reversal of removal.

Rear speakers

Removal

5 Working from Chapter 11, remove the trim

panel from side of the loadspace.

6 Remove the retaining nuts, and lower the

speaker unit away from the parcel shelf

support.

7 Unplug the cables, labelling them to aid

refitting later (see illustration).

Refitting

8 Refit the speaker unit by reversing the

removal procedure.

Body electrical systems 12•15

18.7 Unplug the speaker cables, labelling

them to aid refitting later

19.3 Remove the locknut from the top of

the aerial, then lift off the grommet

19.4a Remove the upper...

Removal

1 Switch off the radio, and ensure that the

aerial returns to its fully-retracted position.

Disconnect the battery negative cable, and

position it away from the terminal.

2 Refer to Chapter 11 and remove the inner

trim panel from the left-hand side of the

loadspace.

3 Remove the locknut from the top of the

aerial using a spanner, then lift off the

grommet (see illustration).

4 Remove the upper and lower retaining

screws, and lift out the aerial assembly (see

illustrations).

5 Disconnect the power and coaxial cables

from the aerial assembly (see illustrations).

Refitting

6 Refit the aerial assembly by reversing the

removal procedure.

At the time of writing, very little detailed

information was available regarding the anti-

theft alarm. It is recommended that any

problems or queries with the system should be

referred to a Saab dealer.

All models are fitted with thermostatically-

regulated heated front seats. Individual control

switches are provided for each seat, which

allow the heating element temperature to be

set to one of three levels, or switched off

completely.

Two heating elements are fitted to each seat

- one in the backrest, and one in the seat

cushion. Access to the heating elements can

only be gained by removing the upholstery

from the seat - this is an operation which

should be entrusted to a Saab dealer.

All models have a wiring connector already

wired up for a tow bar located in the luggage

compartment. For further information

regarding this component contact your local

Saab dealer.

19.4b .. .and lower aerial assembly

retaining screws

19.5a Disconnect the power cable ...

19.5b . . . and coaxial cable from the aerial

assembly

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст