Seat Mii (2019 year). Manual in english — page 2

The essentials

Removing ice from the windscreen

The ››› Fig. 38 button is used to remove ice from the windscreen as quickly as possible and to demist it (defrost/demist function).

When the temperature is above +3°C (+38°F), the air is dehumidified and fan speed increases.

Air recirculation

The ››› Fig. 38 button switches that air recirculation on and off ››› page 129.

Heated rear window

The button, located in the upper part of the centre console, switches the heated rear window on and off when the engine is running. The

heated rear window switches off automatically after 10 minutes at most.

››› in Introduction on page 129

››› page 129

How does the manual air conditioning and the heating and fresh air system work?

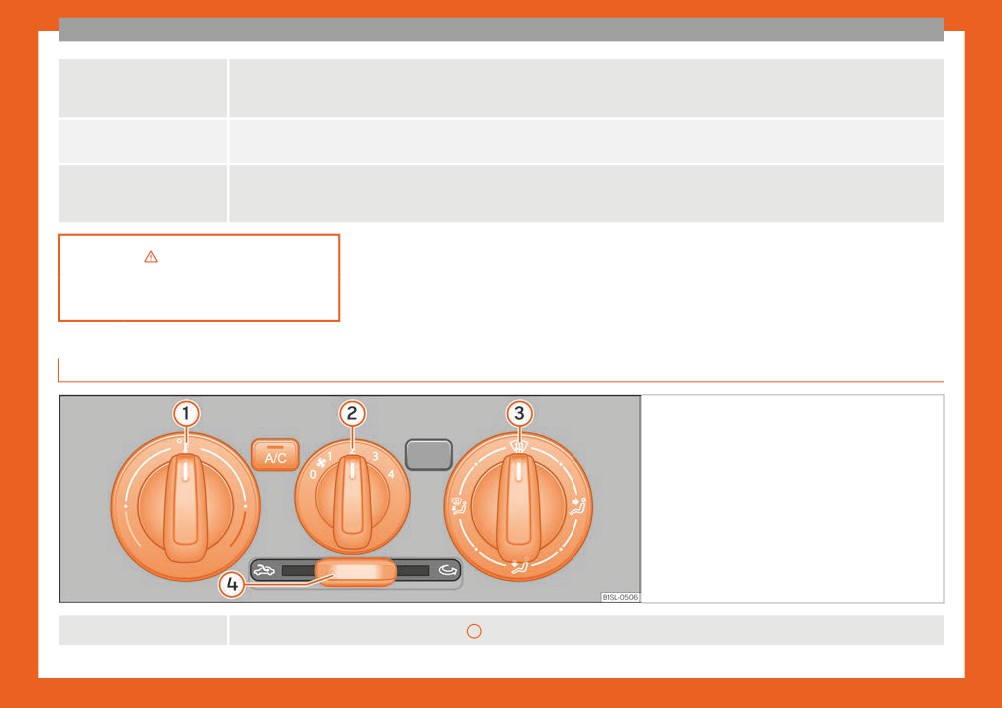

Fig. 39 Centre console, top section: controls for

the manual air conditioning and the heating and

fresh air system.

Switching off

It is switched off by turning the central control

2 to the ››› Fig. 39 position.

30

The essentials

Cooling modea)

The button switches cooling mode on and off.

Temperature

The left rotary adjuster

1

››› Fig. 39 is used to adjust the temperature.

Fan

The central rotary adjuster 2 ››› Fig. 39 is used to adjust fan speed.

The right rotary adjuster 3 ››› Fig. 39 is used to adjust air distribution.

: The air is distributed towards the upper part of the body through the dash panel air vents.

: Air distribution to footwells.

Air distribution

: Air distribution towards the windscreen and the footwell.

: Removing ice from the windscreen. Ice is removed from the windscreen as fast as possible and the windscreen is demisted (defrost

function).

Air recirculation

The slider 4 ››› Fig. 39 is used to switch air recirculation on and off ››› page 129.

Heated rear window

The button, located in the upper part of the centre console, switches the heated rear window on and off when the engine is running. The

heated rear window switches off automatically after 10 minutes at most.

a) Valid for vehicles with manual air conditioning.

››› in Introduction on page 129

››› page 129

31

The essentials

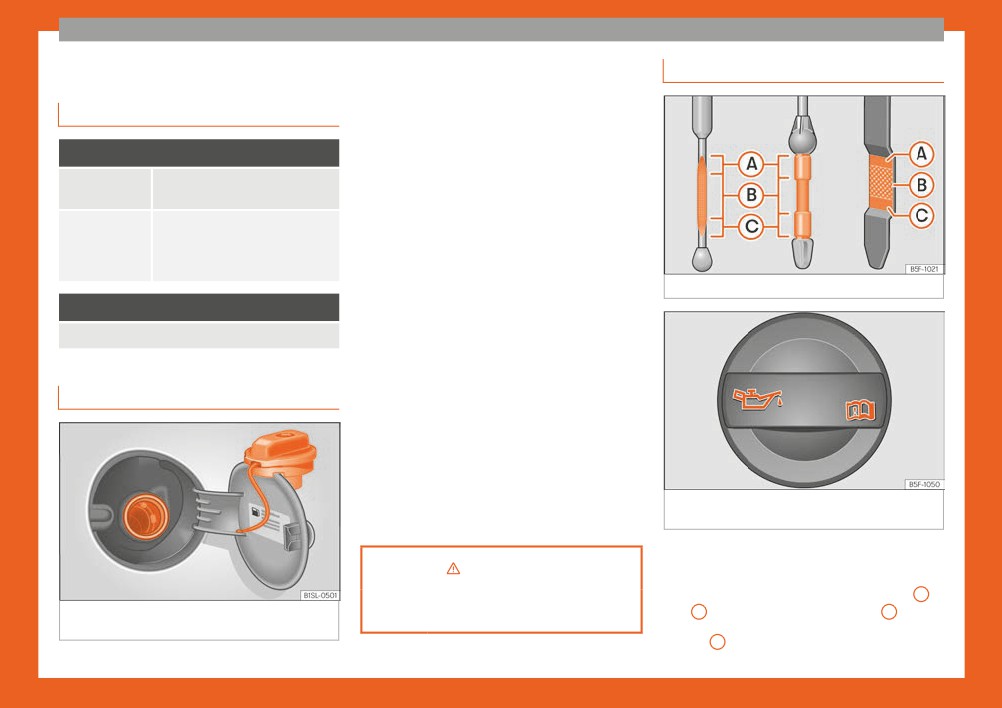

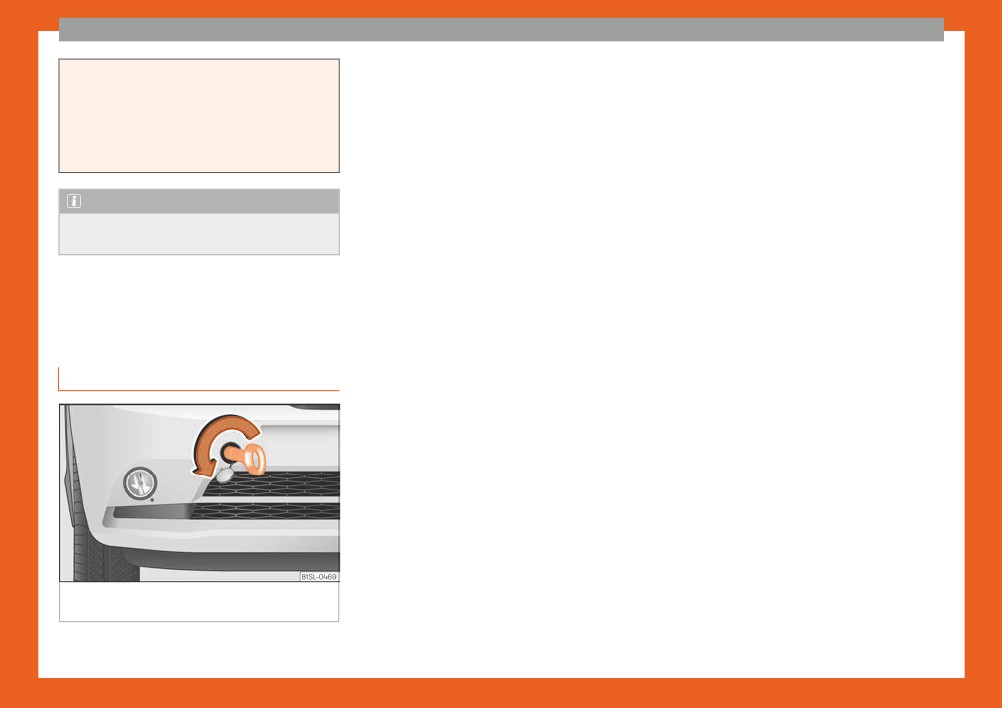

Opening the fuel tank cap

Oil

Fluid level control

The tank flap is at the rear of the vehicle on

Filling the fuel tank

the right.

● Pull the rear zone of the fuel tank flap to

Fuel tank capacity

open.

Around 35.0 l

● Unfold the key shaft if necessary

Petrol engines

of which approx. 4.0 l are reserve.

››› page 92.

Natural gas: approx. 11.0 kg; of

● Insert the vehicle key into the lock cylinder

Natural gas

which max. 1.5 kg are reserve

of the fuel tank plug and turn the key in an

engine

Petrol: approx. 10.0 l; of which ap-

anticlockwise direction.

prox. 5.0 l are reserve

● Take out the fuel tank plug by turning it in an

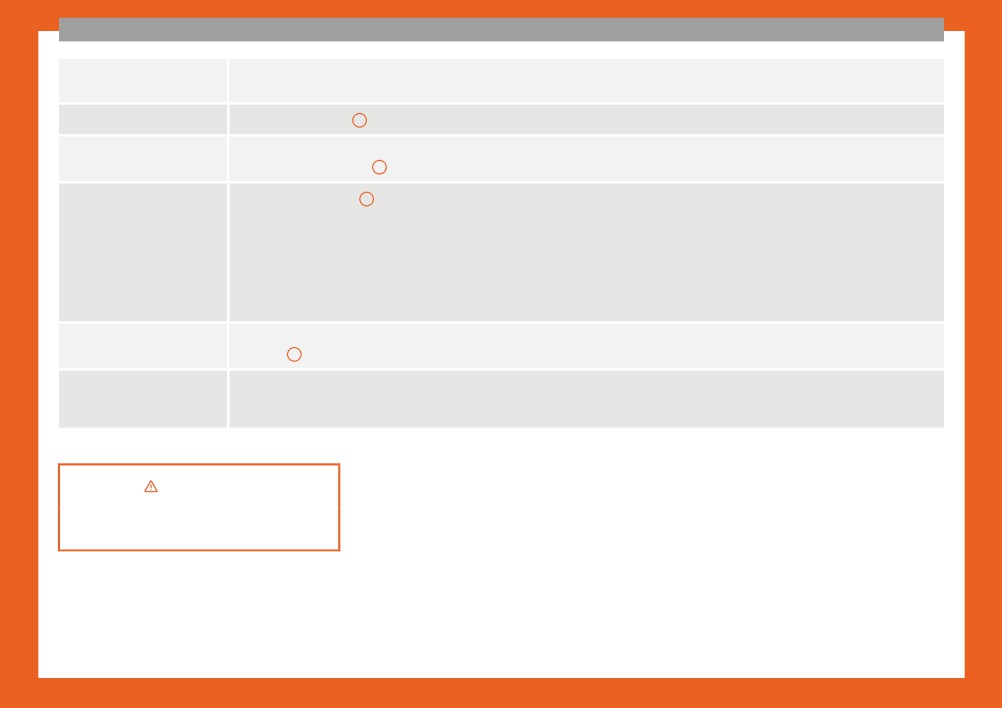

Fig. 41

Engine oil dipstick.

anticlockwise direction and rest it on the up-

Windscreen washer tank capacity

per part of the fuel tank flap ››› Fig. 40.

The washer bottle capacity is approximately 3 litres.

Closing the fuel tank cap

● Screw on the fuel tank filler plug in a clock-

wise direction until it is fully inserted with a

Fuel

click.

● Insert the vehicle key into the lock cylinder

of the fuel tank plug, turn the key in a clock-

wise direction and remove the key.

● Press the tank flap until you hear it click into

Fig. 42 In the engine compartment: Engine oil

place. The tank flap must be flush with the

filler cap.

body contour.

The level is measured using the dipstick loca-

ted in the engine compartment.

››› in Introduction on page 189

The oil indicator must be between zones A

Fig. 40 Open fuel tank flap with tank cap in

and C . It can never go above zone A .

››› page 191

the holder

● Zone A : do not add oil.

32

The essentials

● Zone B : you can add oil but keep the level

Coolant specifications

in that zone.

Recommended by SEAT

The engine cooling system is supplied from

● Zone C : add oil until zone B .

the factory with a specially treated mixture of

SEAT recommends using original SEAT oil to

water and at least 40 % of the additive G13

Topping up engine oil

guarantee high SEAT engine performance.

(TL-VW 774 J), purple. This mixture gives the

necessary frost protection down to -25°C

● Unscrew cap from oil filler opening.

(-13°F) and protects the light alloy parts of

● Add oil slowly.

the engine cooling system against corrosion.

● At the same time, check the level to ensure

p›age

197

It also prevents scaling and considerably rai-

you do not add too much.

ses the boiling point of the coolant.

● When the oil level reaches at least zone B ,

››› page 195

To protect the cooling system, the percent-

unscrew the engine oil filler cap carefully.

age of additive must always be at least 40 %,

even in warm climates where anti-freeze pro-

If the engine oil level is too low

tection is not required.

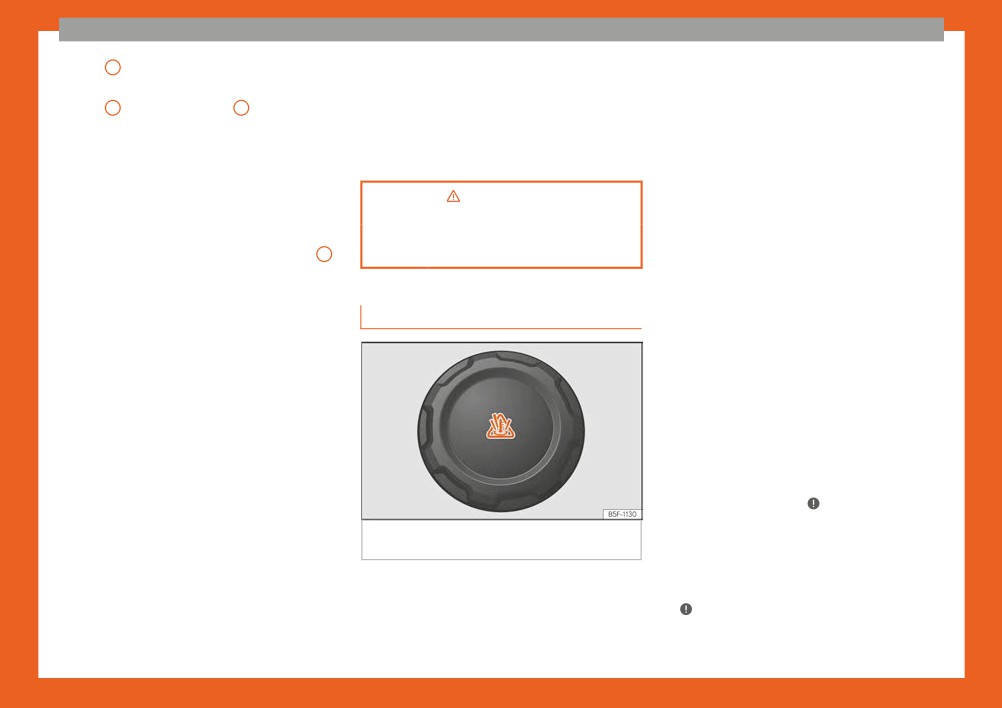

Coolant

You can get information about the correct en-

If for weather reasons further protection is

gine oil for your vehicle in your specialised

necessary, the proportion of additive may be

shop. If you have to change your engine oil,

increased, but only up to 60 %; otherwise an-

use this oil.

tifreeze protection will diminish and this will

If the recommended engine oil is not availa-

worsen cooling.

ble, in the event of an emergency you can

When the coolant is topped up, use a mixture

change the oil once with a maximum of 0.5 L

of distilled water and at least 40 % of the

of the next oil until the next oil change:

G13 or G12 plus-plus (TL-VW 774 G) additive

(both are purple) to obtain an optimum anti-

- Petrol engines: standard VW 504 00,

corrosion protection ››› in Checking the

VW 502 00, VW 508 00, ACEA C3 or

coolant level and topping up on page 200.

API SN.

Fig. 43 Engine compartment: coolant expan-

The mixture of G13 with G12 plus (TL-VW 774

sion tank cap.

Have the oil changed by a specialised work-

F), G12 (red) or G11 (green-blue) engine cool-

shop.

ants will significantly reduce anti-corrosion

The coolant tank is located in the engine

protection and should therefore be avoided

Using engine oil that is compliant with the VW

compartment.

››› in Checking the coolant level and

504 00 standard instead of VW 508 00

When the engine is cold, replace the coolant

topping up on page 200.

»

could increase consumption and the vehicle’s

when the level is below .

CO2 emissions.

33

The essentials

Windscreen washer

Battery

a›nd

opping up on page 199

The battery is located in the engine compart-

ment. It does not require maintenance. It is

››› page 198

checked as part of the Inspection Service.

Brake fluid

››› in Introduction on page 203

››› page 202

Fig. 45 In the engine compartment: cap of the

windscreen washer tank.

The windscreen washer reservoir is located in

the engine compartment.

To top up, mix water with a product recom-

mended by SEAT.

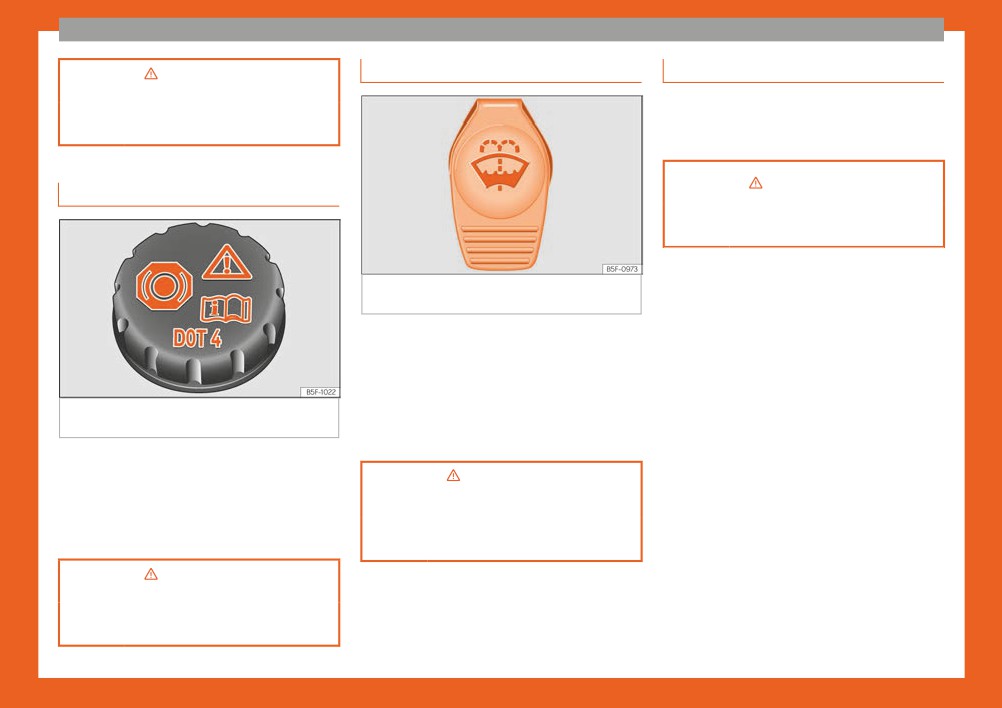

Fig. 44 Engine compartment: brake fluid res-

ervoir cap.

In cold temperatures, add anti-freeze for the

windshield cleaner.

The brake fluid reservoir is located in the en-

gine compartment.

››

in Checking and topping up the

windscreen washer reservoir with

The level should be between the and

›

water on page 202

marks. If it is below , please visit a Technical

Service.

››› page 201

e›lonpna

ge 201

››› page 200

34

The essentials

Underneath the instrument panel

Replacing a blown fuse

Emergencies

The fuse box is located underneath the dash

panel on the driver side ››› Fig. 46.

Fuses

In the engine compartment

Fuse location

Press the locking tabs to release the fuse box

cover ››› Fig. 47.

Identifying fuses situated below the dash

panel by colours

Colour

Amp rating

Fig. 48 Image of a blown fuse.

Purple

3

Preparation

Light brown

5

● Switch off the ignition, lights and all electri-

Brown

7.5

cal equipment.

Fig. 46 On the dashboard on the driver side:

Red

10

● Open the corresponding fuse box

lid of the fuse box.

Blue

15

››› page 79.

Yellow

20

Identifying a blown fuse

White or transparent

25

A fuse is blown if its metal strip is ruptured

››› Fig. 48.

Green

30

Point a lamp at the fuse to see if the fuse has

Orange

40

blown.

To replace a fuse

››› in Introduction on page 78

● Remove the fuse.

Fig. 47 In the engine compartment: lid of the

● Replace the blown fuse by one with an

››› page 78

fuse box.

identical amperage rating (same colour and

markings) and identical size.

»

35

The essentials

● Replace the cover again or close the fuse

Action in the event of a punc-

with a stone or similar to prevent the vehi-

box lid.

cle from moving.

ture

What to do first

Bulbs

Repairing a tyre with the anti-punc-

● Park the vehicle on a horizontal surface and

ture kit

Bulbs (12 V)

in a safe place as far away from traffic as

possible.

Light source used for each function

● Apply the handbrake.

Halogen headlights.

Type

● Switch on the hazard warning lights.

Daytime running light/side

● Manual transmission: select the 1st gear.

W21/5W

light

● Automatic transmission: Move the selector

Dipped beam headlights

H4 LL

lever to position D or R.

● If you are towing a trailer, unhitch it from

Main beam headlights

H4 LL

your vehicle.

Turn signal

PY21W NA

● Have the vehicle tool kit ››› page 71

and the spare wheel* ready

Rear bulb light

Type

››› page 213.

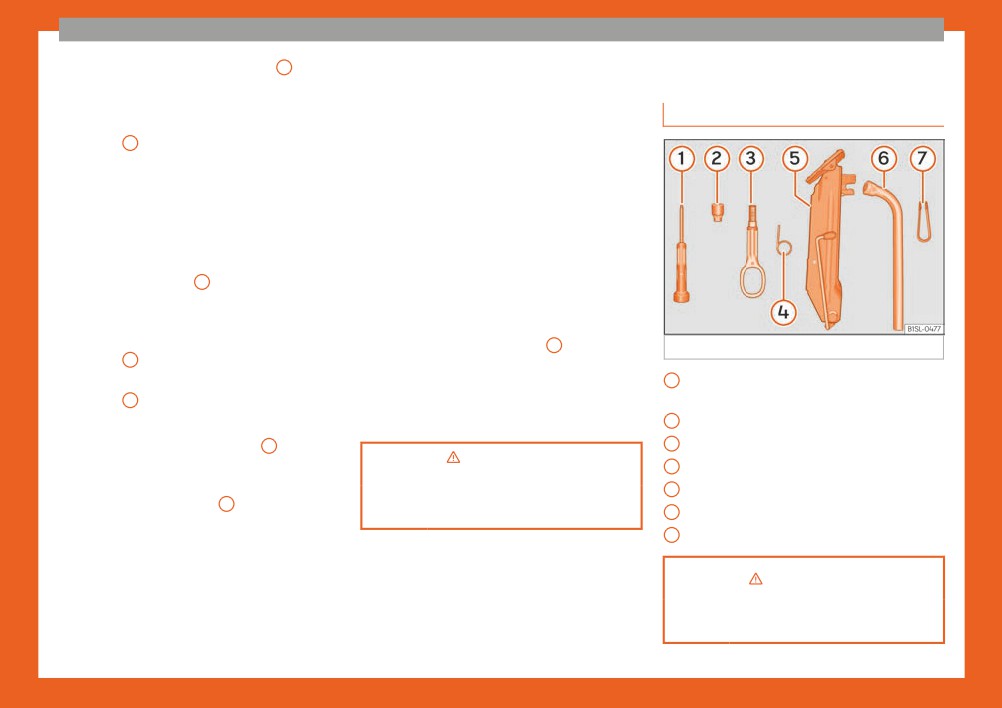

Fig. 49 Standard display: contents of the anti-

Brake/side lights

P21/5W LL

● Observe the applicable legislation for each

puncture kit.

country (reflective vest, warning triangles,

Side lights

P21/5W LL

etc.).

The anti-puncture kit is located under the

Turn signal

PY21W NA LL

● All occupants should leave the vehicle and

floor panel in the luggage compartment.

wait in a safe place (for instance behind the

Retro fog light

P21W

roadside crash barrier).

Sealing the tyre

Reverse lights

R10W

● Unscrew the tyre valve cap and insert. Use

WARNING

the ››› Fig. 49

1 tool to remove the insert.

● Always observe the above steps and pro-

Place it on a clean surface.

tect yourself and other road users.

● Shake the tyre sealant bottle vigorously

● If you change the wheel on a slope, block

››› Fig. 49 10 .

the wheel on the opposite side of the car

36

The essentials

● Screw the inflator tube ››› Fig. 49 3 into

● Move the vehicle 10m so that the sealant is

Changing a wheel

the sealant bottle. The bottle's seal will break

distributed throughout the tyre.

automatically.

● Screw the compressor tyre inflator into the

Vehicle tool kit

● Remove the lid from the filling tube

valve.

››› Fig. 49 3 and screw the open end of the

● Repeat the inflation process.

tube into the tyre valve.

● If the indicated pressure still cannot be

● With the tyre sealant bottle upside down, fill

reached, the tyre is too badly damaged. Stop

the tyre with the contents of the sealant bot-

and request assistance from an authorised

tle.

technician.

● Remove the bottle from the valve.

● Disconnect the air compressor. Unscrew

● Place the insert back into the tyre valve us-

the tyre inflator tube from the tyre valve.

ing the tool ››› Fig. 49

1 .

● When the tyre pressure is between 2.5 and

2.0 bars, continue driving without exceeding

Inflating the tyre

80 km/h (50 mph).

● Screw the compressor tyre inflator tube

● Attach the sticker ››› Fig. 49 2 to the in-

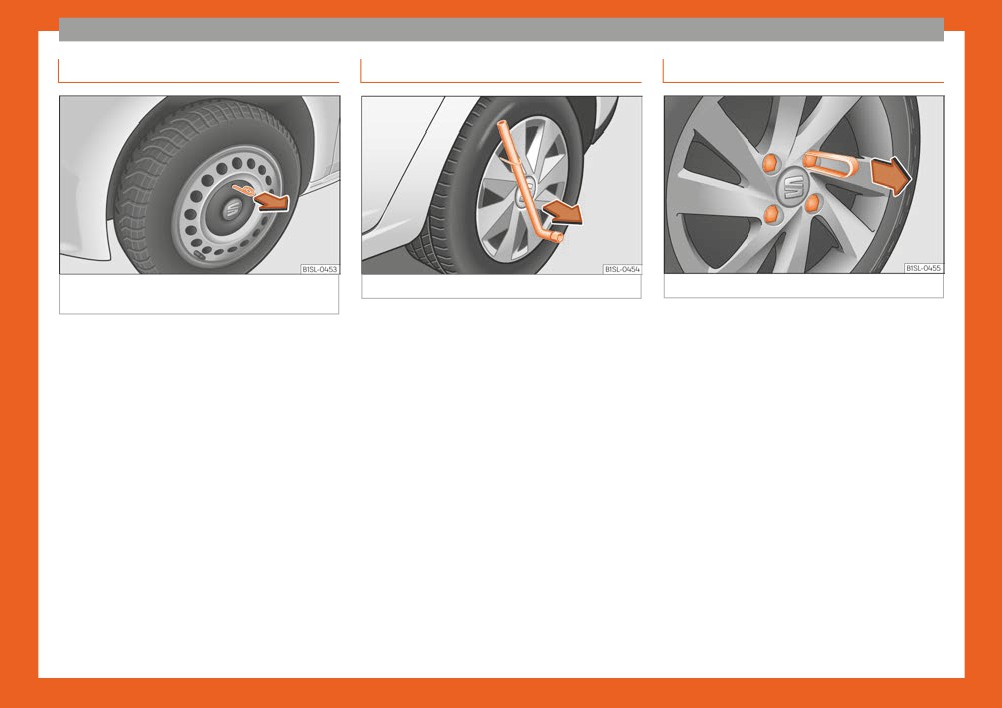

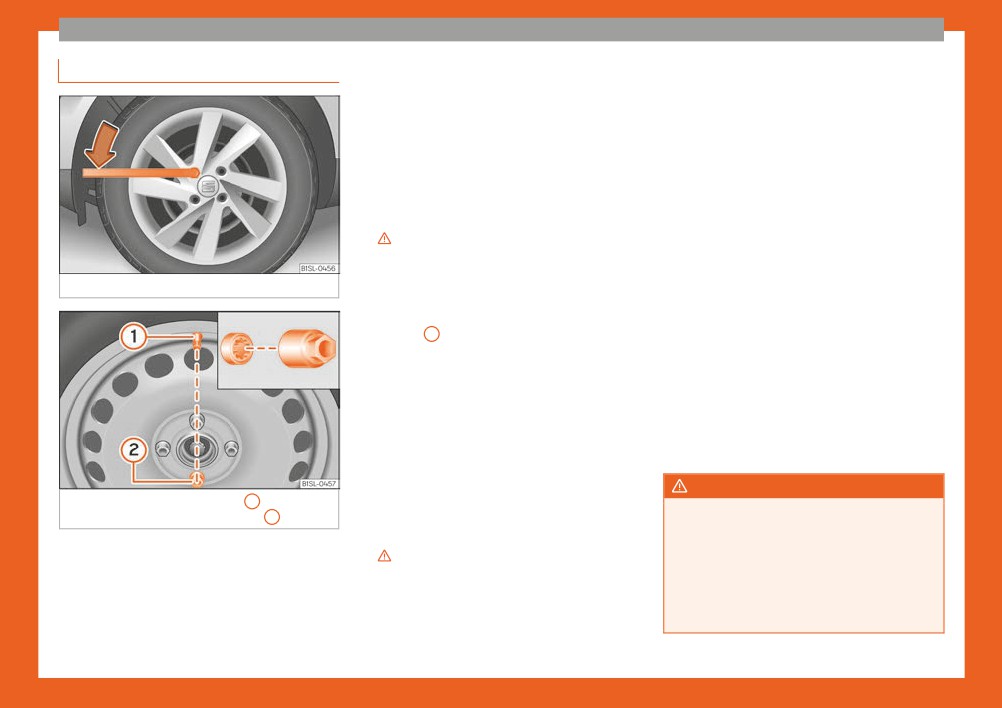

Fig. 50 Components of the vehicle tool kit

››› Fig. 49 5 into the tyre valve.

strument cluster, within the driver's visual

● Check that the air bleed screw is closed

field.

1

Screwdriver with hexagon socket in the

››› Fig. 49

7 .

● Check the pressure again after 10 minutes

handle

● Start the engine and leave it running.

››› page 74.

2

Adapter for anti-theft bolt.

● Insert the connector ››› Fig. 49 9 into the

3

Towline anchorage, removable.

vehicle's 12-volt socket ››› page 120.

4

Wire hook for removing the hub caps.

o›npa

ge 73

● Turn the air compressor on with the

5

Jack.

ON/OFF switch ››› Fig. 49 8 .

››› page 73

6

Wheel spanner.

● Keep the air compressor running until it rea-

7

Wheel bolt cap clips.

ches 2.0 to 2.5 bar (29-36 psi/200-250 kPa).

A maximum of 8 minutes.

● Disconnect the air compressor.

››› in What to do first on page 36

● If it does not reach the pressure indicated,

unscrew the tyre inflator tube from the valve.

››› page 70

37

The essentials

Hubcaps

Full hubcaps

Wheel bolt caps

Fig. 51 Remove the hubcap of the steel wheel

Fig. 52 Removing the full hubcap

Fig. 53 Removing the wheel bolt caps

trim

Removing the full hubcap

Removal

In order to access the wheel bolts, first re-

● Take the wheel brace and the wire hook

● Fit the plastic clip (vehicle tools

move the hubcap.

from the vehicle tool kit ››› page 70.

››› page 70) over the cap until it clicks

into place ››› Fig. 53.

Removing and fitting the hubcap

● Hook the wire through one of the grooves

on the hubcap.

● Remove the cap with the plastic clip.

● To remove, take the vehicle tool kit wire

● Insert the wheel brace onto the wire hook

hook and attach it to the edge of the wheel

The caps protect the wheel bolts and should

››› Fig. 52 and pull the hub cap in the direc-

trim ››› Fig. 51.

be remounted after changing the tyre.

tion shown by the arrow.

● Remove the trim by pulling it in the direction

The anti-theft wheel bolt has a special cap

of the arrow.

which is only compatible with anti-theft bolts

Fitting hubcaps

● To replace the hubcap, press the hubcap

and cannot be used for conventional bolts.

● It is necessary to press the hubcap against

against the trim until it clicks into place.

the wheel so that the space for the valve fits

The caps protect the wheel bolts and should

over the tyre valve.

be remounted after changing the tyre.

● Make sure that the hubcap is correctly fit-

ted all the way around the wheel. If you are

using an anti-theft wheel lock, screw it in the

opposite position to the valve.

38

The essentials

Loosening the wheel bolts

of the wheel brace carefully with your foot.

with the right length and correctly shaped

Hold on to the vehicle for support and take

bolt heads must be used. This ensures that

care not to slip.

wheels are fitted securely and that the brake

system functions correctly.

Loosening wheel bolts

In some circumstances, wheel bolts from the

● Fit the wheel brace as far as it will go over

same model vehicle should not be used.

the wheel bolt ››› Fig. 54.

● Hold the wheel brace at the end and rotate

Wheel bolt tightening torque

the bolt approximately one turn anticlockwise

The prescribed tightening torque for wheel

›››

bolts for steel and alloy wheels is 110 Nm.

Have the tightening torque of the wheel bolts

Loosening anti-theft wheel bolts

checked as soon as possible with a reliable

Fig. 54

Tyre change: slacken the wheel bolts.

For wheels with full hubcap, the anti-theft

torque wrench.

wheel lock must be threaded into position

If wheel bolts are rusty and it is difficult to

››› Fig. 55 2 before mounting the hubcap.

tighten them, the threads should be replaced

Otherwise it will not be possible to mount the

and cleaned before checking the tighten-

entire hubcap.

ing torque.

● Take the adapter for anti-theft wheel bolts

Never grease or lubricate wheel bolts or the

out of the vehicle tool kit.

wheel hub threads. Although they have been

tightened to the prescribed torque, they

● Insert the adapter onto the wheel bolt

could come loose while driving.

››› Fig. 55. Push it on as far as it will go.

● Fit the wheel brace onto the adapter as far

WARNING

Fig. 55

Tyre change: tyre valve

1 and posi-

as possible.

If the wheel bolts are not fitted correctly

tion of anti-theft wheel locking bolt

2 .

● Hold the wheel brace at the end and rotate

they could be released while driving lead-

the bolt approximately one turn anticlockwise

● Only use the tool supplied with the vehicle

ing to loss of vehicle control and serious

›››

damage.

to loosen the wheel bolts.

● Only use wheel bolts which correspond

● Loosen the wheel bolts only about one turn

Important information about wheel bolts

to the wheel rims in question.

before raising the vehicle with the jack.

The wheel rims and bolts have been de-

● Never use different wheel bolts.

»

● If the wheel bolt is very tight, you may be

signed to be fitted to factory options. If differ-

able to loosen it by pushing down on the end

ent rims are fitted, the correct wheel bolts

39

The essentials

● The bolts and threads should be clean,

Raising the vehicle with the jack

free of oil and grease and easy to thread.

● To loosen and tighten the wheel bolts, al-

ways use the wheel brace supplied with the

vehicle.

● Loosen the wheel bolts only about one

turn before raising the vehicle with the jack.

● Never grease or lubricate wheel bolts or

the wheel hub threads. Although they have

been tightened to the prescribed torque,

they could come loose while driving.

● Never loosen the bolted joints of wheel

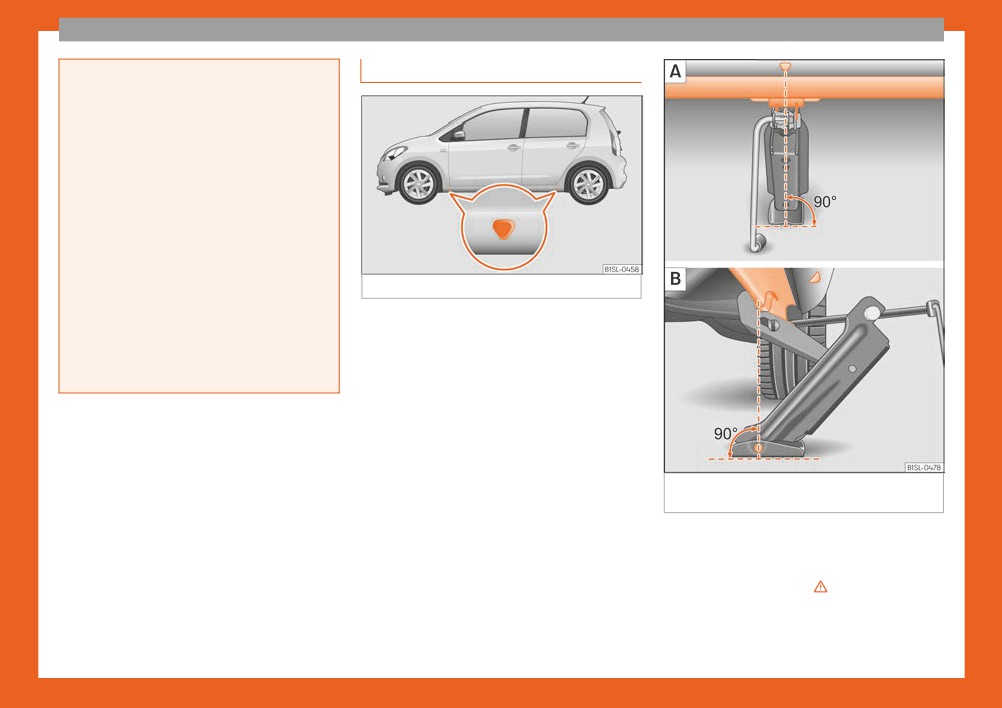

Fig. 56

Jack position points.

rims with bolted ring trims.

● If the wheel bolts are not tightened to the

correct torque, they may come loose while

driving, and the bolts and rims may come

out. If the tightening torque is too high, the

wheel bolts and threads can be damaged.

Fig. 57 Jack mounted on the left rear part of

the vehicle

The jack may be applied only at the jacking

points shown (marks on chassis) ››› Fig. 56.

Always the relevant jacking point for the

wheel to be changed ›››

Raise the vehicle using only the designated

jacking points.

40

The essentials

WARNING

Removing and fitting a wheel

● Place the spare wheel or temporary spare

wheel into position.

If the vehicle is not correctly raised, it could

● Replace the wheel bolts and tighten slight-

fall off the jack causing serious injury.

Please observe the following rules to mini-

ly using the hexagonal socket on the end of

mise the risk of injury:

the wheel brace.

● You should only use a jack approved by

● To tighten the anti-theft locking wheel bolts

SEAT for your vehicle. Other jacks, even

use the corresponding adaptor.

those approved for other SEAT models,

● Lower the car with the jack.

might slip out of place.

● Tighten all of the wheel bolts clockwise

● The ground should be firm and flat. If the

››› . Tighten the bolts in diagonal pairs (not

ground is sloped or soft then the vehicle

in a circle).

could slip and fall off the jack. If necessary,

support the jack on a wide solid base.

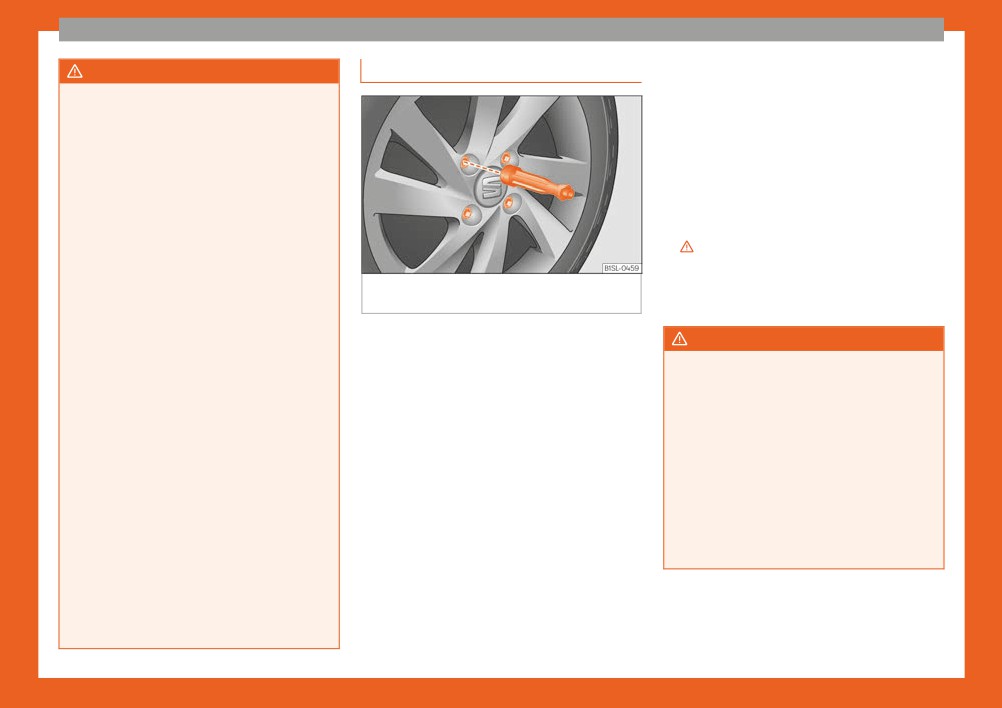

Fig. 58 Changing the tyre: loosen wheel bolts

● Put the caps, trim or full hubcap back on

with the socket at the end of the wheel brace

››› page 38.

● If the ground is slippery, such as tiles,

place a non-slip surface (a floor mat, for in-

Change the wheel after loosening the wheel

stance) beneath the jack to avoid slipping.

WARNING

bolts and raising the vehicle with the jack.

● Only fit the jack at the prescribed jacking

If the wheel bolts are not treated suitably

points. The claw of the jack should grip the

or not tightened to the correct torque then

Removing the wheel

reinforcement nerve on the underbody

this could lead to loss of vehicle control

››› Fig. 57.

● Slacken the wheel bolts ››› page 39.

and to a serious accident.

● You should never place a body limb such

● Raise the vehicle ››› page 40.

● All the wheel bolts and hub threads

as an arm or leg under a raised vehicle that

● Using the hexagonal socket in the wheel

should be clean and free of oil and grease.

is solely supported by the jack.

The wheel bolts should be easily tightened

brace ››› Fig. 58, unscrew the slackened

to the correct torque.

● If you have to work underneath the vehi-

wheel bolts and place them on a clean sur-

cle, you must use suitable stands addition-

face.

● The hexagonal socket in the wheel brace

ally to support the vehicle, there is a risk of

should be used for turning wheel bolts only.

● Take off the wheel.

accident!.

Do not use it to loosen or tighten the wheel

bolts.

● Never raise the vehicle if it is tilting to one

How to use the spare wheel or temporary

side or the engine is running.

spare wheel

● Never start the engine when the vehicle is

Check the direction of rotation of the tyre

raised. The vehicle may come loose from

››› page 214, Tyre code.

the jack due to the engine vibrations.

41

The essentials

Tyres with compulsory direction of

● Have the tightening torque of the wheel

Remove wheel hub covers and trim rings be-

bolts checked as soon as possible with a tor-

fore fitting snow chains ››› . The wheel bolts

rotation

que wrench ›››

page 39.

should be covered with caps for safety rea-

sons. These are available from technical

A directional tread pattern can be identified

● Have the flat tyre replaced as quickly as

by the arrows on the sidewall that point in the

possible.

services.

direction of rotation. Always observe the di-

rection of rotation indicated when fitting the

Temporary spare wheel

wheel to guarantee optimum properties of

For technical reasons, snow chains must not

this type of tyres with regard to grip, noises,

Snow chains

be used on the compact temporary spare

wear and aquaplaning.

wheel ››› page 213.

Use

If it is absolutely necessary to fit the spare

If it is necessary to fit chains with the tempo-

tyre* against the direction of rotation, drive

rary spare wheel in use, install the wheel on

When using snow chains, applicable local

with care as this means the tyre does not of-

the rear axle in the event of a fault in a front

legislation and maximum permitted speed

fer optimum driving properties. This is of par-

wheel. Then, fit the rear wheel that is free, in-

limits must be observed.

ticular importance when the road surface is

stead of the damaged front wheel. In this sit-

wet.

In winter weather, snow chains not only help

uation, observe the rotating direction of the

to improve grip but also improve the braking

wheels. SEAT recommends attaching the

To return to directional tread tires, replace the

capacity.

snow chains before fitting the wheel.

punctured tyre as soon as possible and re-

store the obligatory direction of rotation of all

The fitting of chains is permitted only on

tyres.

front wheels and with the following combi-

WARNING

nations of wheel trims and tyres:

The use of unsuitable or incorrectly fitted

chains could lead to serious accidents and

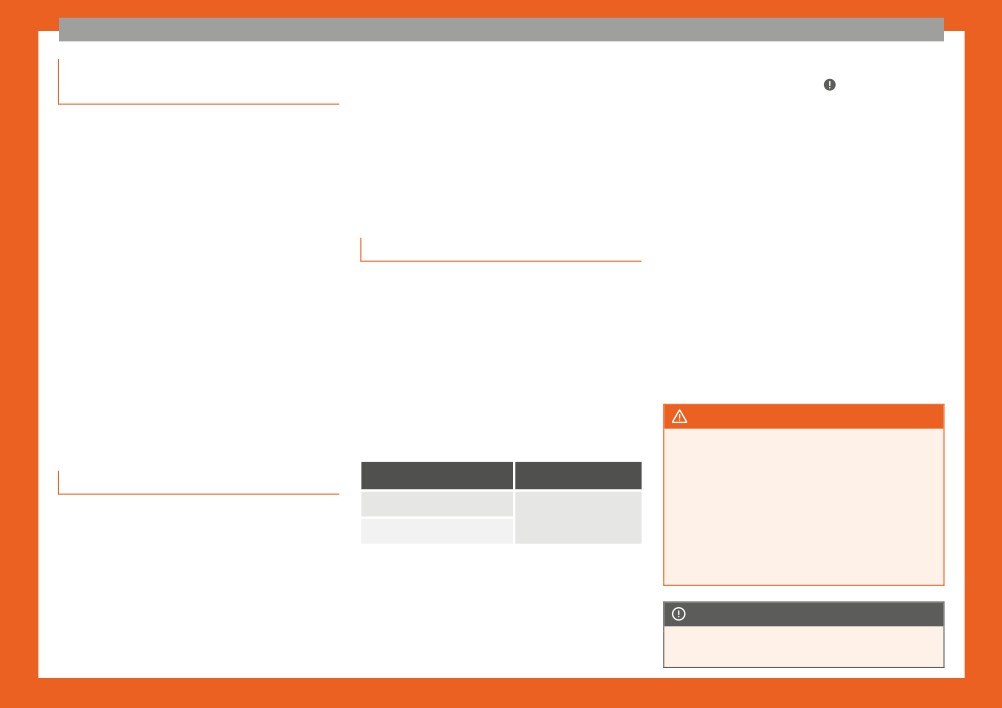

Tyre size

Wheel rim

damage.

After the wheel change

● Always the appropriate snow chains.

165/70 R14

● Clean the vehicle tools, if necessary and

5 J x 14 offset of 35

● Observe the fitting instructions provided

put them away in the luggage compartment

175/65 R14

by the snow chain manufacturer.

foam holder ››› page 70.

● Never exceed the maximum permitted

SEAT recommends you ask a technical serv-

● Store the spare wheel, the temporary spare

speeds when driving with snow chains.

ice for further information on wheel, tyre and

wheel or the changed wheel securely in the

chain sizes.

luggage compartment.

CAUTION

Wherever possible use fine-link chains meas-

uring less than 15 mm including the lock.

● Remove the snow chains to drive on

roads without snow. Otherwise they will

42

The essentials

impair vehicle handling, damage the tyres

Towline anchorages

● The brake must be depressed much harder

and wear out very quickly.

Attach the bar or rope to the towline ancho-

as the brake servo does not operate. Avoid

hitting the towing vehicle.

● Wheel rims may be damaged or scratch-

rages.

ed if the chains come into direct contact

● Note the instructions and information con-

It is located with the vehicle's tools

with them. SEAT recommends the use of

tained in the Instruction Manual for the vehi-

››› page 70.

covered snow chains.

cle to be towed.

Screw the front towline anchorage into the

screw connection ››› Fig. 59 and tighten it

Notes for the driver of the towing vehicle

Note

with the wheel brace.

Snow chains are available in different sizes

● Accelerate gently and carefully. Avoid sud-

according to the vehicle type.

den manoeuvres.

Tow rope or tow bar

● Brake well in advance than usual and brake

When towing, the tow bar is the safest and

gently.

vehicle friendly way. You should only use a

● Note the instructions and information con-

Emergency towing of the ve-

tow rope if you do not have a tow bar.

tained in the Instruction Manual for the vehi-

hicle

A tow rope should be slightly elastic to avoid

cle to be towed.

damage to both vehicles. It is advisable to

use a tow rope made of synthetic fibre or sim-

Driving style

Towing

ilarly elastic material.

Towing requires some experience, especially

● Only secure the tow rope or tow bar to the

when using a tow rope. Both drivers should

towline anchorage or specially designed fit-

realise how difficult it is to tow a vehicle. Inex-

ting.

perienced drivers should not attempt to tow.

Do not pull too hard with the towing vehicle

Notes for the driver of the towed vehicle

and take care to avoid jerking the tow rope.

● Keep the ignition running to prevent the

When towing on an unpaved road, there is al-

steering wheel from locking and also to allow

ways a risk of overloading and damaging the

the use of the turn signals, horn, windscreen

anchorage points.

wipers and washers.

Switch on the ignition so that the turn signals,

● As the power assisted steering does not

windscreen wipers and windscreen washer

Fig. 59 Right side of the front bumper: towline

anchorage screwed in.

work if the engine is not running, you will need

can work. Ensure that the steering wheel is

more strength to steer than normally.

unlocked and moves freely.

»

43

The essentials

Place the gear lever in neutral on vehicles

However, if your vehicle must absolutely

WARNING

with a manual gearbox. With an automatic

be tow-started (manual gearbox):

Incorrect use of jump leads and incorrectly

gearbox, place the lever in N.

● Put it into second or third gear.

jump starting could cause the battery to

To brake, press the brake pedal firmly. The

● Keep the clutch pressed down.

explode resulting in serious injury. Please

brake servo does not work when the engine is

observe the following rules to minimise the

● Switch on the ignition and the hazard warn-

switched off.

risk of a battery explosion:

ing lights.

● The battery providing current must have

The power steering only works when the igni-

● Release the clutch when both vehicles are

the same voltage (12V) and approximately

tion is switched on, provided that the battery

moving.

the same capacity (see markings on bat-

is sufficiently charged. Otherwise, it will need

● As soon as the engine starts, press the

tery) as the flat battery.

more force.

clutch and move the gear lever into neutral.

● Never charge a frozen or recently thawed

Ensure that the tow rope remains taut at all

This helps to prevent a collision with the tow-

battery. A flat battery can also freeze at

times.

ing vehicle.

temperatures close to 0°C (+32°F).

● If a battery is frozen and/or has been fro-

zen then it must be replaced.

o›npa

ge 76

● A highly explosive mixture of gases is re-

How to jump start

leased when the battery is being charged.

››› page 75

Always keep lit cigarettes, flames, sparks

Jump leads

and fire far from the battery. Never use a

mobile telephone when connecting and re-

If the engine fails to start because of a dis-

moving the jump leads.

Tow-starting

charged battery, the battery of another vehi-

● Charge the battery only in well ventila-

cle can be used to start the engine. Before

In general, the vehicle should not be star-

ted areas given that when the battery is

starting, check the magic eye on the battery

charged by outside assistance, it creates a

ted by towing. Jump-starting is much more

››› page 202.

mix of highly explosive gases.

preferable ››› page 44.

For starting assistance, jump lead cables

● Jump leads should never enter into con-

For technical reasons, the following vehicles

conforming to the standard DIN 72553 are re-

tact with moving parts in the engine com-

can not be tow started:

quired (see the cable manufacturer instruc-

partment.

tions). The cable section in vehicles with pet-

● Vehicles with an automatic gearbox.

● Never switch the positive and negative

rol engine must be at least 25 mm2.

poles or connect the jump leads incorrect-

● If the vehicle battery is flat, it is possible that

ly.

the engine control unit does not operate cor-

● Note the instruction manual provided by

rectly.

the manufacturer of the jump leads.

44

The essentials

CAUTION

5.

Connect the other end of the black jump

lead X to a solid metal component bol-

To avoid considerable damage to the vehi-

ted to the engine block or to the engine

cle electrical system, note the following

block itself of the vehicle with the flat

carefully:

battery. Do not connect it to a point near

● If the jump leads are incorrectly connec-

the battery A .

ted, this could result in a short circuit.

6.

Position the leads in such a way that

● The vehicles must not touch each other,

they cannot come into contact with any

otherwise electricity could flow as soon as

moving parts in the engine compart-

the positive terminals are connected.

ment.

Fig. 61 Diagram of connections for vehicles

with Start Stop system

Starting

How to jump start: description

Start the engine of the vehicle with the

7.

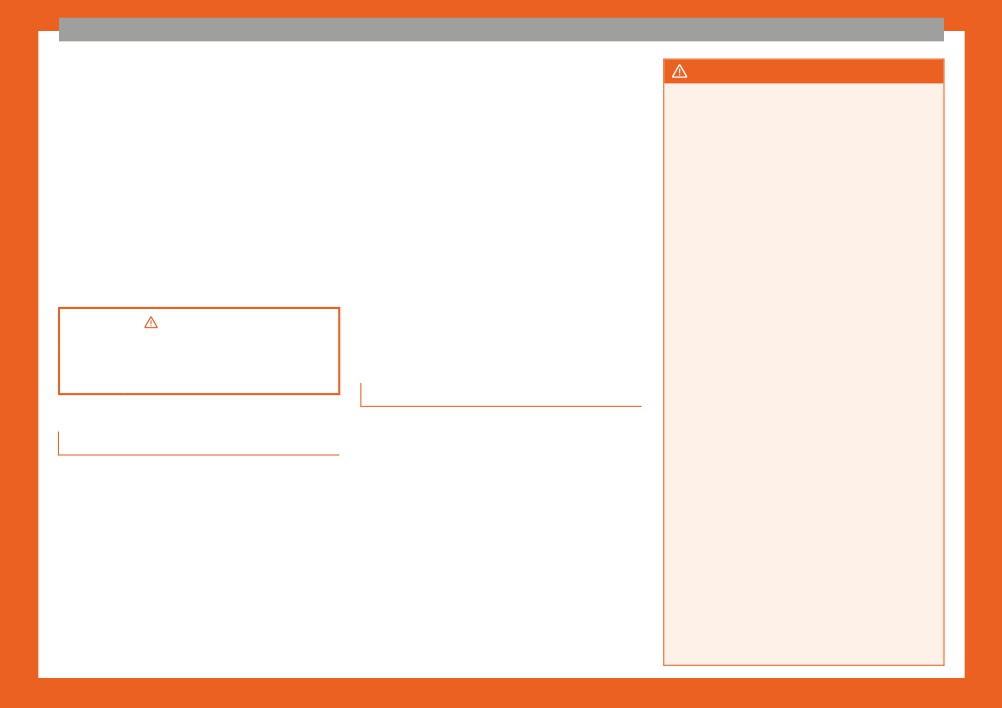

Jump lead terminal connections

boosting battery and let it run at idling

1.

Switch off the ignition of both vehicles

speed.

›››

8.

Start the engine of the vehicle with the

2.

Connect one end of the red jump lead to

flat battery and wait for 2 or 3 minutes

the positive

+ terminal of the vehicle

until the engine is running.

with the flat battery A ››› Fig. 60.

3.

Connect the other end of the red jump

Removing the jump leads

lead to the positive terminal + in the ve-

9.

Before you remove the jump leads,

hicle providing assistance B .

switch off the dipped beam headlights if

4a.

In vehicles without a Start-Stop system:

they are switched on.

Fig. 60 Diagram of connections for vehicles

connect one end of the black jump lead

10.

Turn on the heater blower and heated

without Start Stop system

to the negative terminal - of the vehicle

rear window in the vehicle with the flat

providing the current B ››› Fig. 60.

battery. This helps minimise voltage

4b.

In vehicles with a Start-stop system:

peaks which are generated when the

connect one end of the black jump lead

leads are disconnected.

X to a suitable ground terminal, to a sol-

11.

When the engine is running, disconnect

id piece of metal in the engine block, or

the leads in reverse order to the details

to the engine block itself ››› Fig. 61.

given above.

»

45

The essentials

Make sure the battery clamps have sufficient

● Never attach the negative cable to fuel

Changing the wiper blades

metal-to-metal contact with the battery ter-

system components or the brake lines in

minals.

the other vehicle.

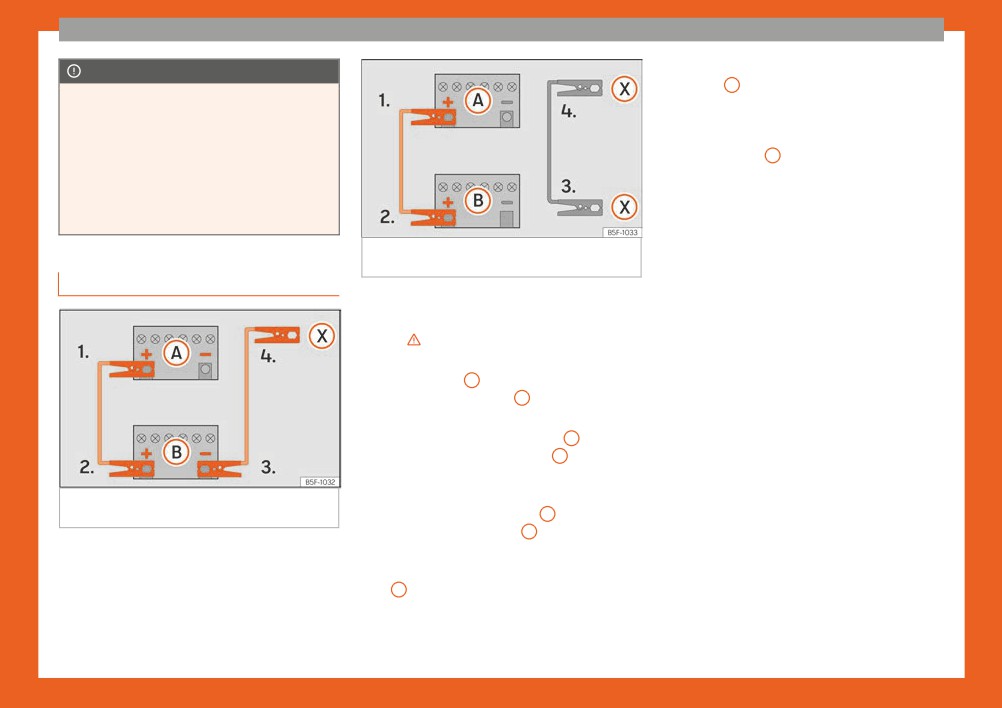

Windscreen wipers service posi-

If the engine fails to start after about 10 sec-

● The non-insulated parts of the battery

tion

onds, switch off the starter and try again after

clamps must not be allowed to touch. The

about 1 minute.

jump lead attached to the positive battery

terminal must not touch metal parts of the

WARNING

vehicle, this can cause a short circuit.

● Position the leads in such a way that they

● Please note the safety warnings referring

cannot come into contact with any moving

to working in the engine compartment

parts in the engine compartment.

››› page 193.

● Do not lean on the batteries. This could

● The battery providing assistance must

result in chemical burns.

have the same voltage as the flat battery

(12V) and approximately the same capaci-

ty (see imprint on battery). Failure to com-

Note

ply could result in an explosion.

The vehicles must not touch each other,

Fig. 62 Wipers in service position.

● Never use jump leads when one of the

otherwise electricity could flow as soon as

batteries is frozen. Danger of explosion!

the positive terminals are connected.

The wiper arms can be raised when the wip-

Even after the battery has thawed, battery

ers are in service position ››› Fig. 62.

acid could leak and cause chemical burns.

If a battery freezes, it should be replaced.

● Close the bonnet ››› page 193.

● Keep sparks, flames and lighted ciga-

● Switch the ignition on and off.

rettes away from batteries, danger of ex-

● Press the windscreen wiper lever down-

plosion. Failure to comply could result in an

wards briefly ››› Fig. 33 4 .

explosion.

● Observe the instructions provided by the

Before driving, always lower the wiper arms.

manufacturer of the jump leads.

When the ignition is switched on, the wind-

● Do not connect the negative cable from

screen wiper arms return to their initial posi-

the other vehicle directly to the negative

tion upon activating the windscreen wiper

terminal of the flat battery. The gas emit-

lever.

ted from the battery could be ignited by

sparks. Danger of explosion.

››› page 75

46

The essentials

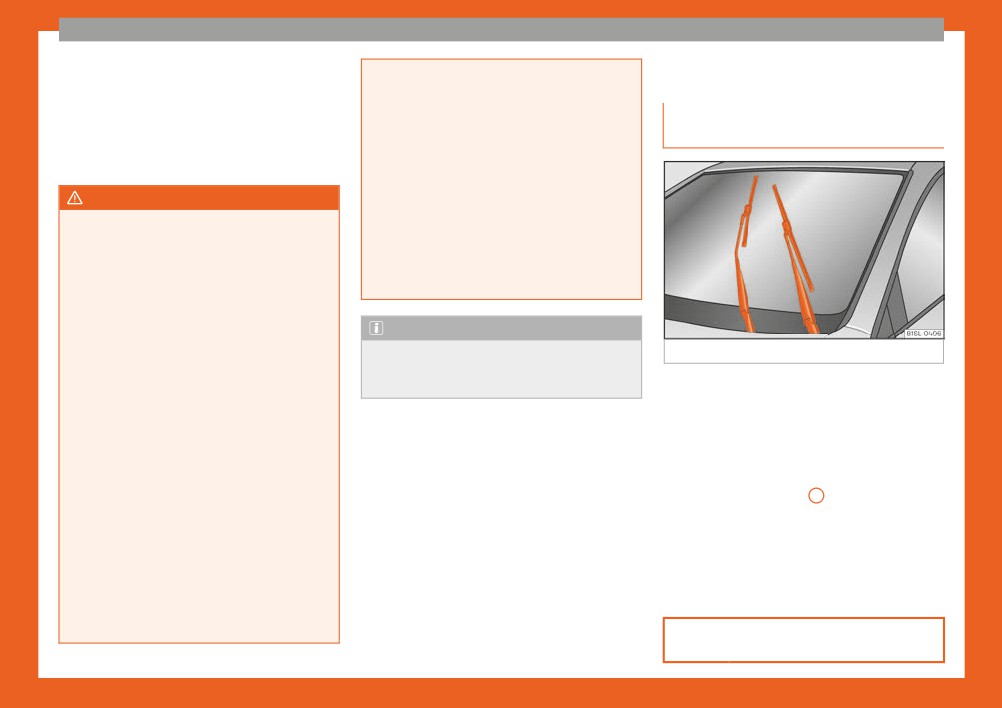

Changing the front wiper blades

Cleaning windscreen wiper blades

posite direction to the arrow B and hook into

place. This feature is operational when the

● Lifting and unfolding the wiper arms.

knob is in position (arrow A ).

● Use a soft cloth to remove dust and dirt

● Return the windscreen wiper arm to the

from the windscreen wiper blades.

windscreen. Do not let it simply drop down!

● If the blades are very dirty, a sponge or

damp cloth may be used ››› in Changing

›››

in Changing the windscreen

the windscreen and rear window wiper

and rear window wiper blades on

blades on page 75.

page 75

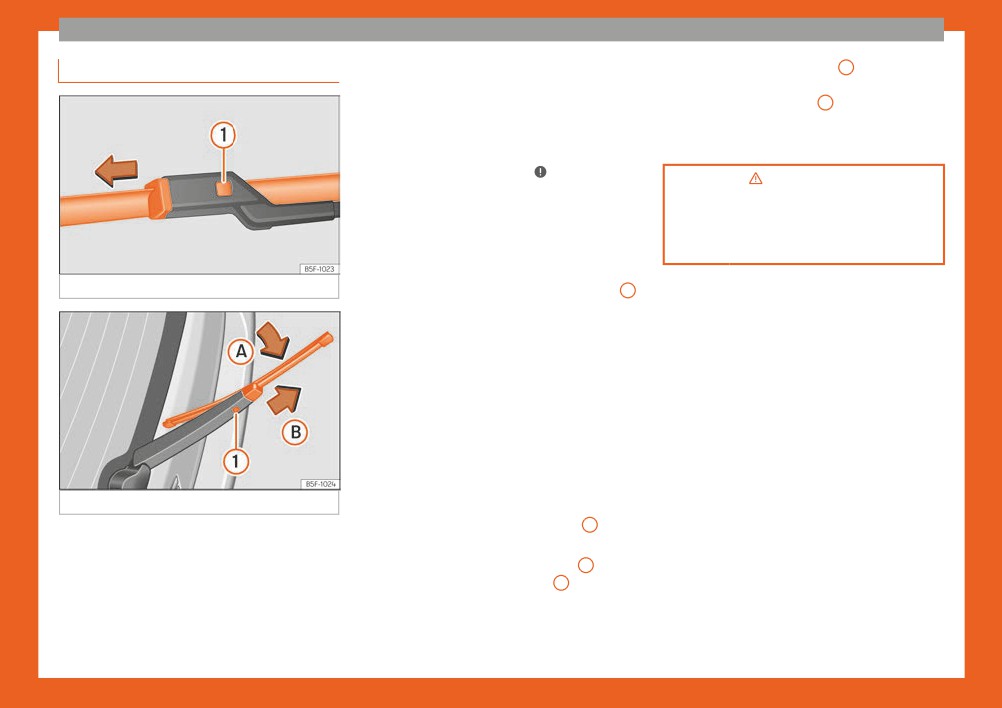

Changing the windscreen wiper blades

››› page 75

● Lifting and unfolding the wiper arms.

Fig. 63

Changing the front wiper blades

● Hold down the release button ››› Fig. 63 1

while gently pulling the blade in the direction

of the arrow.

● Fit a new wiper blade of the same length

and design on to the wiper arm and hook it

into place.

● Rest the wiper arms back onto the wind-

screen.

Changing the rear wiper blade

● Lift the windscreen wiper arm and fold it at

Fig. 64

Changing the rear wiper blade

an angle of approximately 60° ››› Fig. 64.

● Press and hold the release button

1 .

Lifting and unfolding the wiper arms

● Fold the wiper blade towards the wind-

The wiper arm may only be lifted at the point

screen wiper arm ››› Fig. 64 (arrow A ) while

where it is fastened to the blade.

pulling in the direction of arrow B . You might

The wiper should be in service position before

have to apply a lot of force.

unfolding it ››› page 108.

● Insert a new blade of the same length and

type in the windscreen wiper arm in the op-

47

Safety

Before driving

- Fasten your seat belt securely. Instruct your

Safety

passengers also to fasten their seat belts

For your own safety and the safety of your

properly ››› page 53.

passengers, always note the following points

Safe driving

before every trip:

- Make sure that the vehicle's lights and turn

What affects driving safety?

Driving advice

signals are working properly.

As a driver, you are responsible for yourself

Safety first!

- Check tyre pressure.

and your passengers. When your concentra-

- Ensure that all windows provide a clear and

tion or driving safety is affected by any cir-

WARNING

good view of the surroundings.

cumstance, you endanger yourself as well as

others on the road ›››

, for this reason:

● This manual contains important informa-

- Make sure all luggage is secured

tion about the operation of the vehicle,

- Always pay attention to traffic and do not

››› page 114.

both for the driver and the passengers. The

get distracted by passengers or telephone

other sections of the on-board documenta-

- Make sure that no objects can interfere with

calls.

tion also contain further information that

the pedals.

- Never drive when your driving ability is im-

you should be aware of for your own safety

- Adjust front seat, head restraint and mirrors

paired (e.g. by medication, alcohol, drugs).

and for the safety of your passengers.

properly according to your size.

● Ensure that the on-board documentation

- Observe traffic laws and speed limits.

is kept in the vehicle at all times. This is es-

- Ensure that the passengers in the rear seats

pecially important when lending or selling

always have the head restraints in the in-

- Always reduce your speed as appropriate

for road, traffic and weather conditions.

the vehicle to another person.

use position ››› page 52.

- Instruct passengers to adjust the head re-

- When travelling long distances, take breaks

WARNING

straints according to their height.

regularly - at least every two hours.

Driving under the influence of alcohol,

- Protect children with appropriate child

- If possible, avoid driving when you are tired

drugs, medication or narcotics may result

seats and properly applied seat belts

or stressed.

in severe accidents and even loss of life.

››› page 65.

● Alcohol, drugs, medication and narcotics

WARNING

- Assume the correct sitting position. Instruct

may significantly alter perception, affect

When driving safety is impaired during a

your passengers also to assume a proper

reaction times and safety while driving,

trip, the risk of injury and accidents increa-

which could result in the loss of control of

sitting position ››› page 49.

ses.

the vehicle.

48

Safe driving

Safety equipment

If your physical constitution prevents you

Correct position of the vehi-

from maintaining the correct sitting position,

Never put your safety or the safety of your

cle occupants

contact a specialised workshop for help with

passengers in danger. In the event of an acci-

any special devices. The seat belt and airbag

dent, the safety equipment may reduce the

Correct sitting position

can only provide optimum protection if a cor-

risk of injury. The following points cover part

rect sitting position is adopted. SEAT recom-

of the safety equipment in your SEAT:

mends taking your car in for technical serv-

ice.

● three-point seat belts,

For your own safety and to reduce the risk of

● belt tension limiters for the front seats,

injury in the event of an accident or sudden

● belt tensioners for the front seats,

braking or manoeuvre, SEAT recommend the

● front airbags,

following positions:

● side airbags in the front seat backrests,

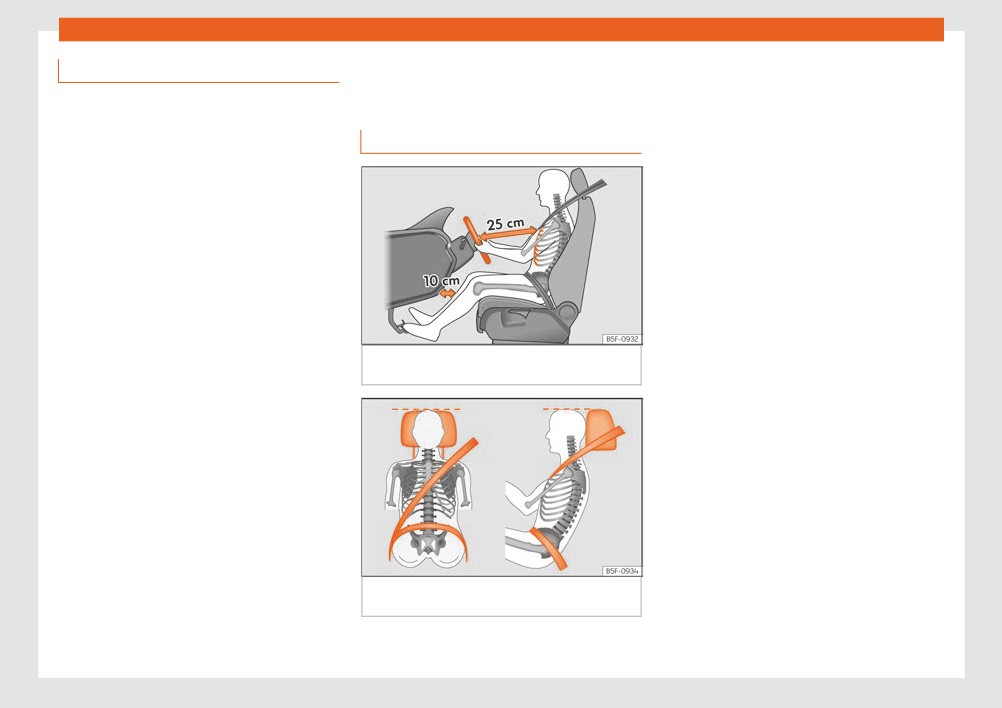

Valid for the driver:

● “ISOFIX” anchor points for child seats in the

● Adjust the seat backrest to an upright posi-

rear side seats with the “ISOFIX” system,

tion so that your back rests completely

● rear head restraints with in-use position and

Fig. 65 The proper distance between driver

against it.

non-use position,

and steering wheel.

● Adjust the seat so that there is a distance of

● adjustable steering column.

at least 25 cm between the steering wheel

and your chest ››› Fig. 65 and so that you

The safety equipment mentioned above

can hold the steering wheel with both hands

works together to provide you and your pas-

on the outside of the ring at the 9 o'clock and

sengers with the best possible protection in

3 o'clock positions with your arms slightly

the event of an accident. However, these

bent.

safety systems can only be effective if you

and your passengers are sitting in a correct

● The adjusted steering wheel must face your

position and use this equipment properly.

chest and not your face.

Safety is everyone's business!

● Adjust the driver seat forwards or back-

wards so that you are able to press the ac-

Fig. 66 Correct belt web and head restraint

celerator, brake and clutch pedals to the floor

positions

with your knees slightly angled and the dis-

tance between your knees and the dash pan-

The correct sitting positions for the driver and

el is at least 10 cm ››› Fig. 65.

»

passengers are shown below.

49

Safety

● Adjust the height of the driver seat so that

● Short people must lower the head restraint

● Never adjust the steering wheel while the

you can easily reach the top of the steering

to the first anchorage position, even if your

vehicle is in motion. If you need to adjust

wheel.

head is below its upper edge.

the steering wheel while the vehicle is in

● Keep both feet in the footwell so that you

● Tall people must raise the head restraint

motion, stop safely and make the proper

have the vehicle under control at all times.

completely.

adjustment.

● Adjust and fasten your seat belt correctly

● Always keep your feet in the footwell while

● The adjusted steering wheel should be

facing your chest and not your face so as

››› page 53.

the vehicle is in motion.

not to hinder the driver's front airbag pro-

● Adjust and fasten your seat belt correctly

tection in the event of an accident.

Valid for the passenger:

››› page 53.

● When driving, always hold the steering

● Adjust the seat backrest to an upright posi-

wheel with both hands on the outside of the

tion so that your back rests completely

ring at the 9 o'clock and 3 o'clock positions

against it.

Adjusting the steering wheel posi-

to reduce injuries when the driver's front

● Move the front passenger seat back as far

tion

airbag deploys.

as possible for optimum protection should the

● Never hold the steering wheel at the 12

airbag deploy.

Read the additional information carefully

o'clock position or in any other manner

››› page 15.

(e.g. in the centre of the steering wheel). In

● Always keep your feet in the footwell while

such cases, if the driver's airbag deploys,

the vehicle is in motion.

Adjust the steering wheel before your trip and

you may sustain injuries to your arms,

● Adjust and fasten your seat belt correctly

only when the vehicle is stationary.

hands and head.

››› page 53.

Adjust the correct distance between the driv-

er and the steering wheel ››› Fig. 65 using the

Valid for the passengers in the rear sec-

controls on the driver seat ››› page 14.

Danger of injuries due to an incor-

tion:

rect sitting position

● Adjust the head restraint so that its upper

WARNING

edge is at the same level as the top of your

Incorrect use of the steering wheel adjust-

Number of seats

head, or as close as possible to the same lev-

ment function and an incorrect adjustment

The vehicle has a total of 4 seats: 2 front

el as the top of your head and under no cir-

of the steering wheel can result in severe or

cumstances below eye level. Keep the back

fatal injury.

seats and 2 rear seats. Each seat is equipped

with a seat belt.

of your neck as close as possible to the head

● After adjusting the steering column, push

restraint ››› Fig. 65 and ››› Fig. 66.

the lever firmly upwards to ensure the

If the seat belts are worn incorrectly or not at

steering wheel does not accidentally

all, the risk of severe injuries increases. Seat

change position while driving.

belts can provide optimal protection only if

the belt web is properly worn. Being seated in

50

Большое спасибо!

Ваше мнение очень важно для нас.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст