SsangYong Korando II (1996-2006 year). Manual — part 129

1F2 -- 96 M161 ENGINE CONTROLS

DAEWOO MY_2000

YAA1F550

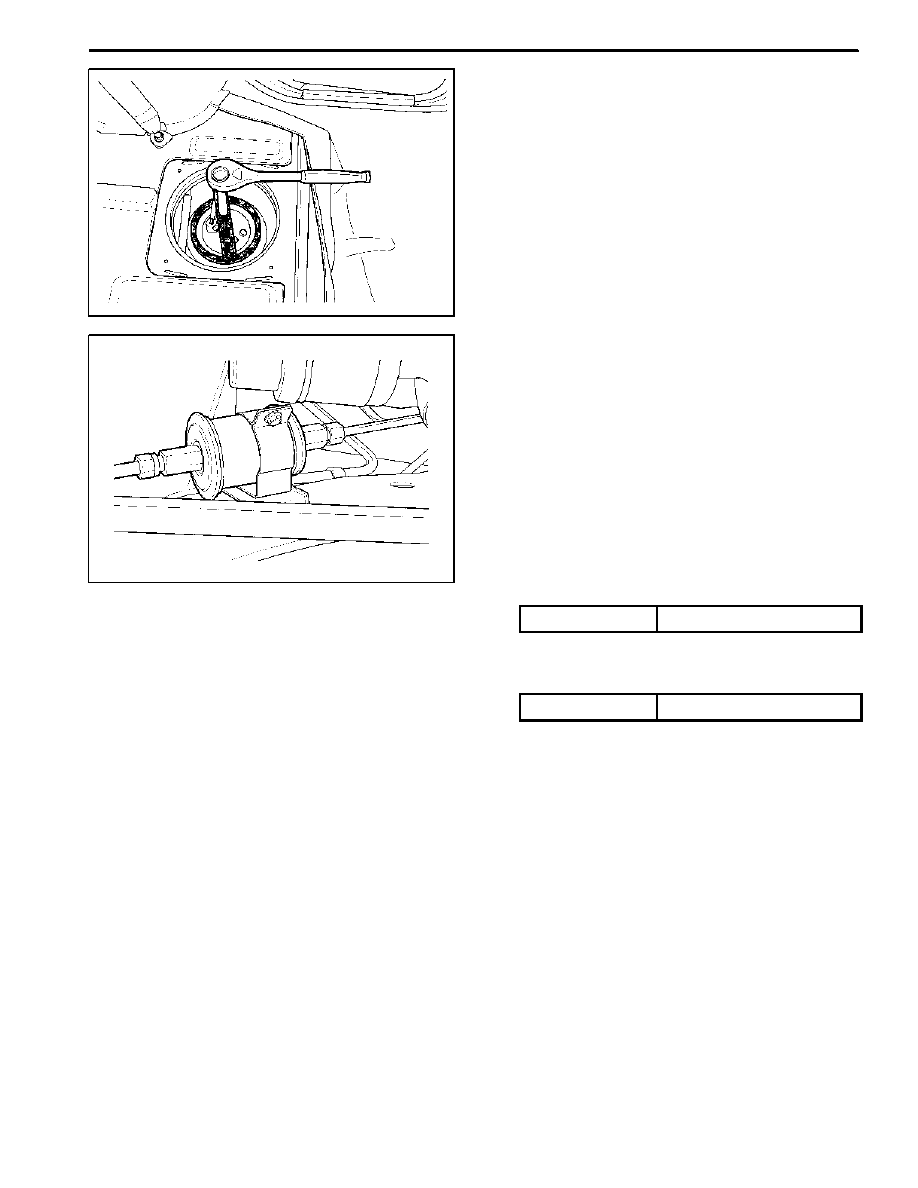

8. Using the fuel tank cap wrench 661 589 00 46 00,

remove the locking cap.

9. Remove the pump from the fuel tank.

Notice: Check the condition of the seal and replace if

necessary. Drain the fuel before removing the pump.

10. Perform an operational check of the fuel pump.

11. Installation should follow the removal procedure in

the reverse order.

YAA1F190

FUEL FILTER

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres-

sure before disconnecting the fuel lines.

2. Relieve the fuel system pressure. Refer to “Dis-

charging the Pressure in Fuel System” in this sec-

tion.

3. Disconnect the fuel lines from the fuel filter.

Installation Notice

Tightening Torque

28 NSm (21 lb-ft)

4. Remove the fuel filter mounting bracket bolt .

Installation Notice

Tightening Torque

6 NSm (53 lb-in)

Notice: Place the fuel pump pad. There may be a corro-

sion due to the contact between the fuel filter and the

bracket.

5. Remove the fuel filter.

6. Install the fuel filter.

7. Perform a leak test of the fuel filter.

8. Installation should follow the removal procedure in

the reverse order.

M161 ENGINE CONTROLS 1F2 -- 97

DAEWOO MY_2000

KAA1F370

FUEL TANK

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres-

sure before disconnecting the fuel lines.

1. Relieve the fuel pressure. Refer to “Discharging the

Pressure in Fuel System” in this section.

2. Disconnect the negative battery cable.

3. Drain the fuel tank.

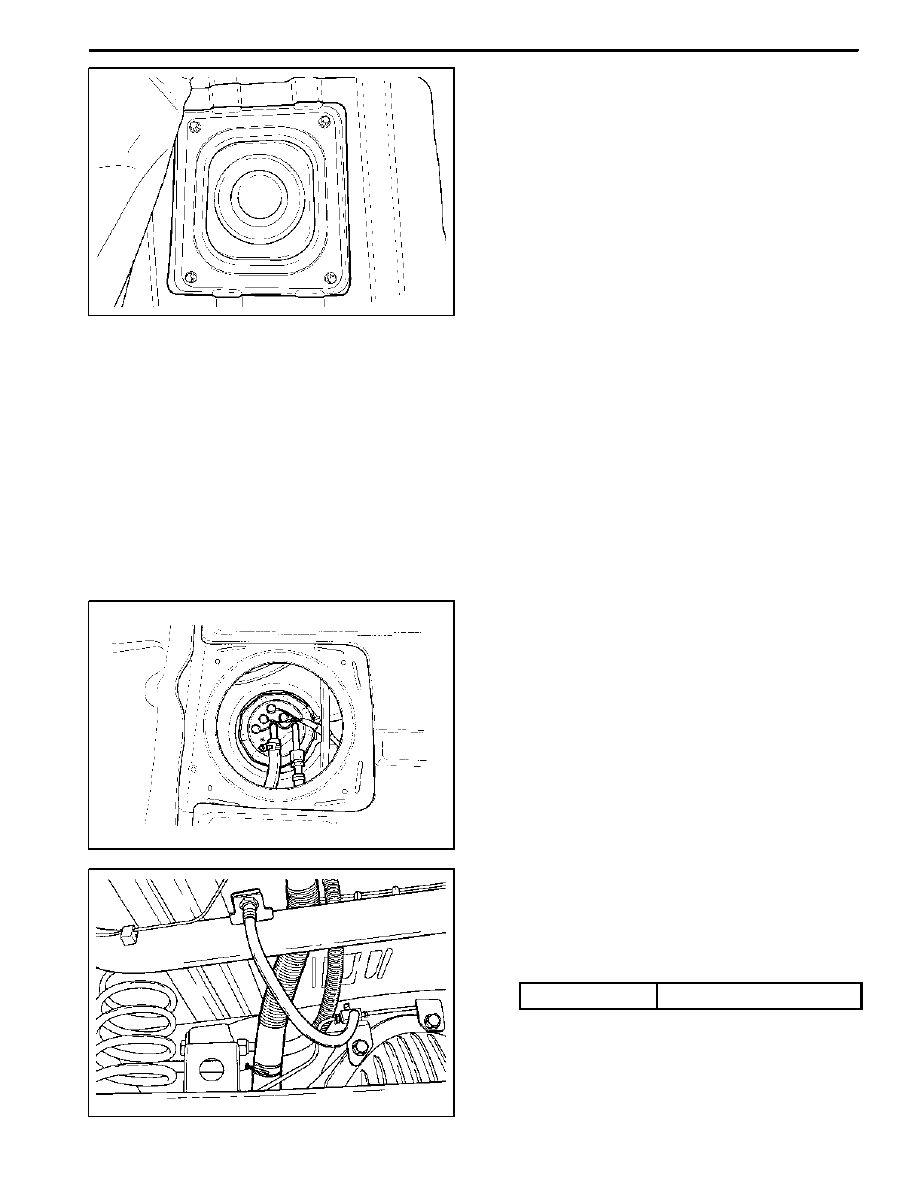

4. Put aside the floor carpet to remove the fuel pump

access cover.

5. Remove the fuel pump access cover.

YAA1F170

6. Disconnect the return line.

7. Disconnect the supply line.

8. Disconnect the fuel tank-to-canister hose from the

fuel tank.

9. Disconnect the fuel pump wiring connector.

KAB1F370

10. Disconnect the fuel filler hose and air vent hose from

the fuel tank.

11. Support the fuel tank.

12. Remove the fuel tank retaining nuts.

Installation Notice

Tightening Torque

38 NSm (28 lb-ft)

13. Carefully lower the fuel tank.

1F2 -- 98 M161 ENGINE CONTROLS

DAEWOO MY_2000

YAA1F180

14. Turn the roll over valves counterclockwise at an

angle of 90 degrees.

15. Turn the lock ring counterclockwise.

16. Remove and discard the gasket.

17. Installation should follow the removal procedure in

the reverse order.

YAA1F700

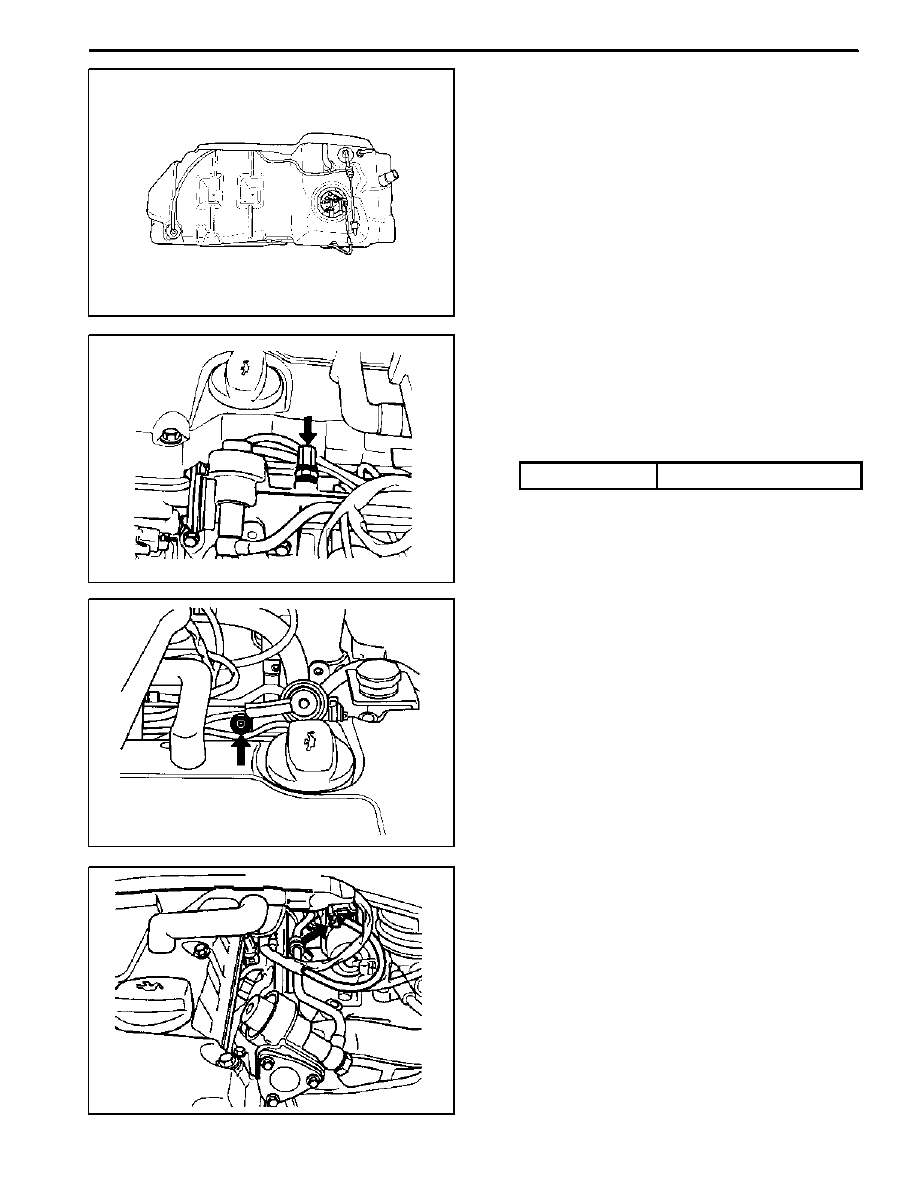

FUEL PRESSURE REGULATOR

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Remove the fuel pressure test connector.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

YAA1F720

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres-

sure before disconnecting the fuel lines.

3. Relieve the fuel pressure in fuel supply system by

pressing the service valve.

YAA1F730

4. Disconnect the vacuum hose.

5. Disconnect the circlip and remove the fuel pressure

regulator.

6. Apply the oil to O-ring lightly and then replace it.

7. Perform a leak test of the fuel pressure regulator

with the engine off and the ignition on.

8. Installation should follow the removal procedure in

the reverse order.

M161 ENGINE CONTROLS 1F2 -- 99

DAEWOO MY_2000

YAA1F710

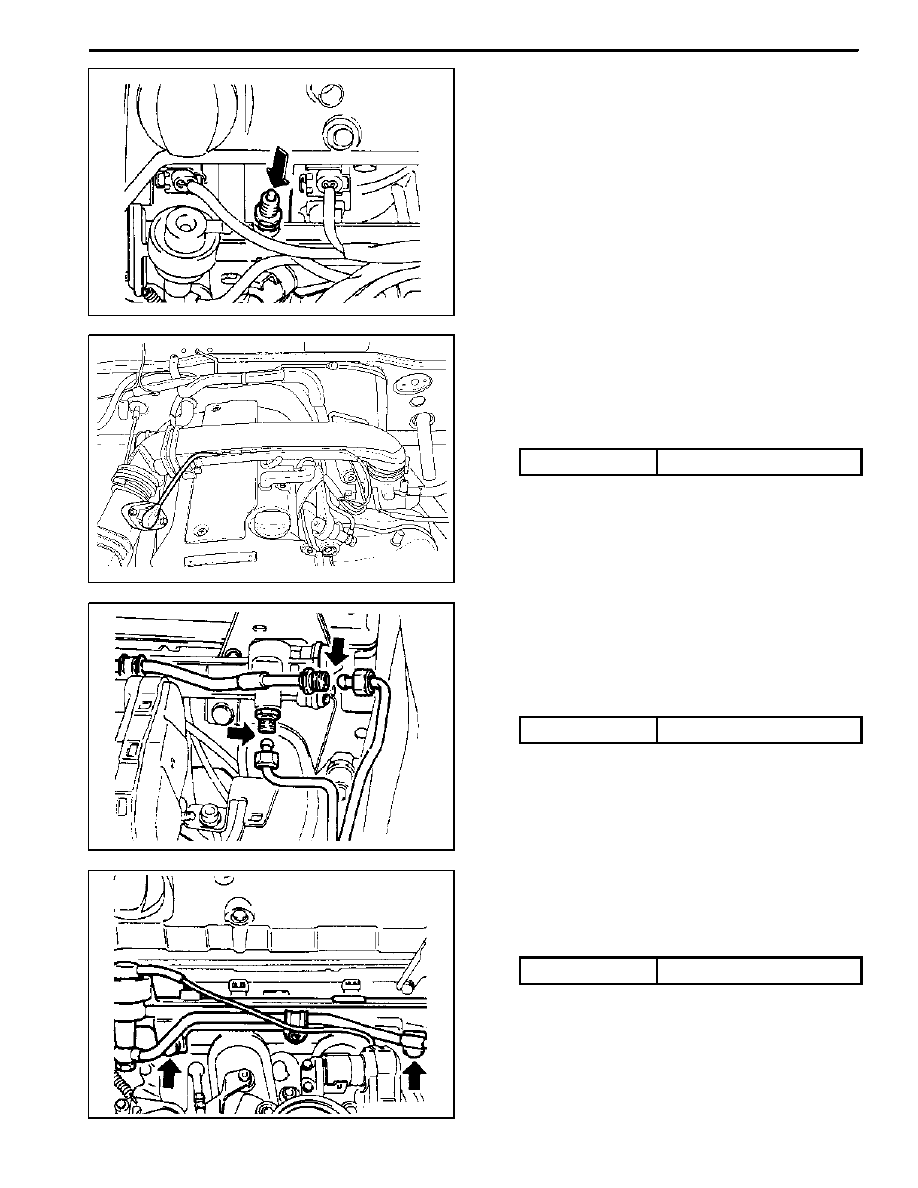

FUEL RAIL AND INJECTORS

Removal and Installation Procedure

Caution: The fuel system is under pressure. To

avoid fuel spillage and the risk of personal injury or

fire, it is necessary to relieve the fuel system pres-

sure before disconnecting the fuel lines.

1. Discharge the fuel pressure from the fuel pressure

test connector.

2. Disconnect the negative battery cable.

3. Disconnect the vacuum hose from the fuel pressure

regulator.

YAA1F740

4. Remove the cable guide.

5. Disconnect the Hot Film Air Mass (HFM) sensor

connector.

6. Remove the intake air duct mounting bolts.

Installation Notice

Tightening Torque

9 NSm (80 Ib-in)

7. Remove the intake air duct clamps.

8. Remove the intake air duct.

YAA1F750

9. Remove the fuel return and supply line.

Notice: For removal, cover around parts with cloths not

to be stained by fuel. In case of checking the injector

only, do not remove the fuel return and supply line.

Installation Notice

Tightening Torque

23 NSm (17 Ib-ft)

10. Remove the six injector connectors.

YAA1F760

11. Remove the two left and two right bolts and one cen-

ter bolt of the fuel rail assembly from the intake man-

ifold.

Installation Notice

Tightening Torque

25 NSm (18 Ib-ft)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст