SsangYong Musso. Manual — part 406

1B3-186 OM600 ENGINE MECHANICAL

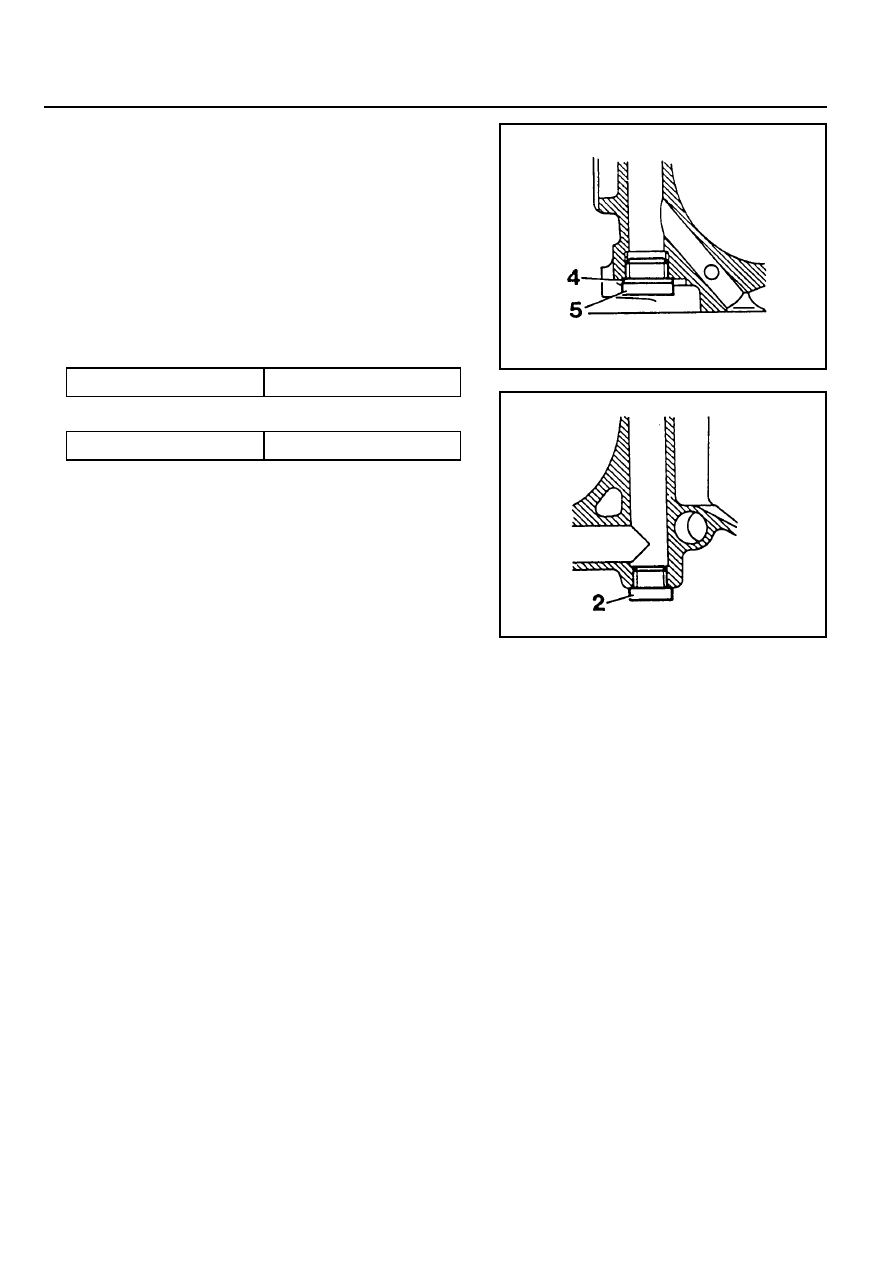

Installation of Screw Plug

Notice

If steel ball leaks again, install the screw plug.

1. Remove the steel ball.

2. Tap thread into the bores of the oil gallery.

Notice

Front bore : M18 ´ 1.5, depth 10mm

Rear bore : M16 ´ 1.5, depth 14mm

3. Thoroughly clean the oil gallery.

4. Tighten the front plug (5) with seal (4).

5. Apply Loctite 241 and then tighten the rear plug (2).

Tightening Torque

50 Nm

Tightening Torque

50 Nm

OM600 ENGINE MECHANICAL 1B3-187

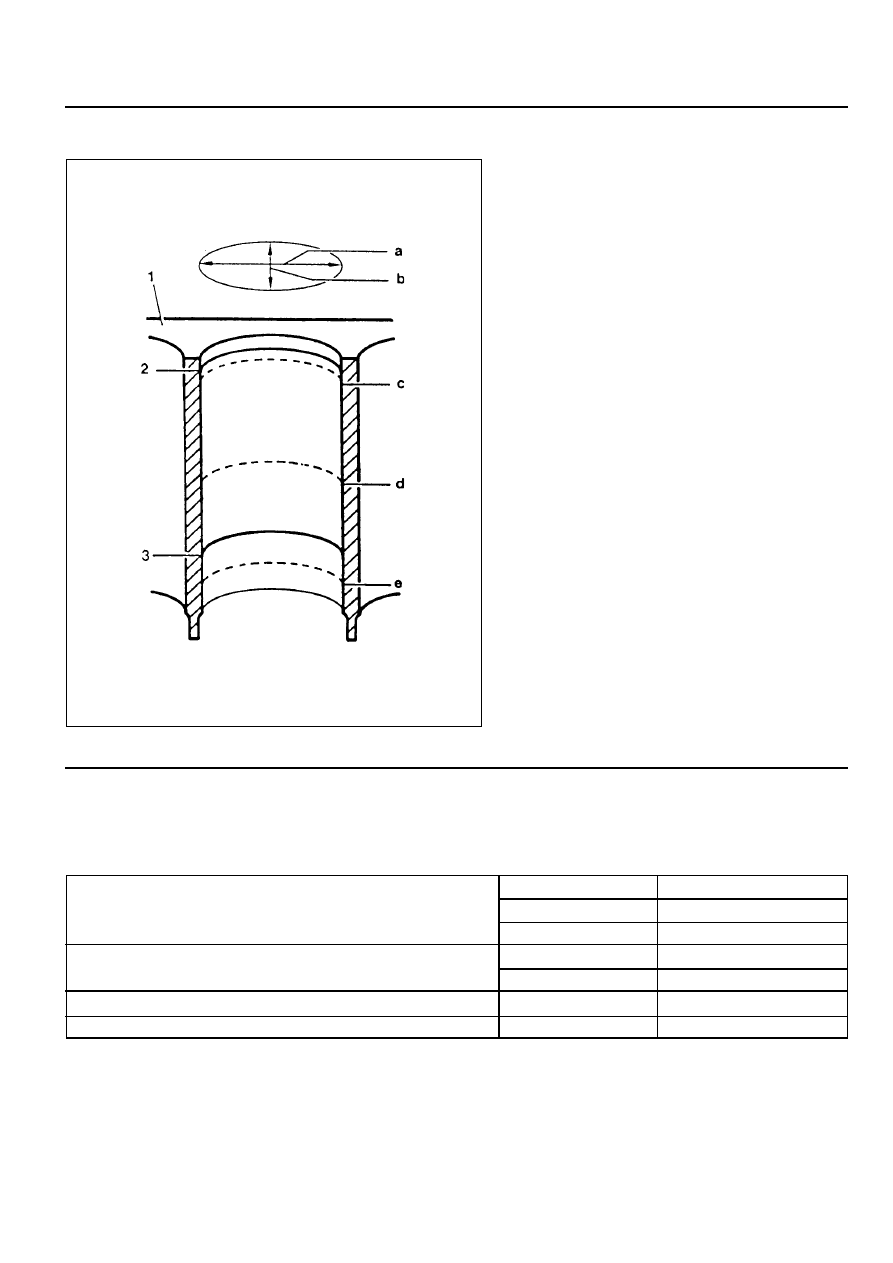

Standard size

Wear limit in direction of travel and in transverse direction

Permissible deviation of cylinder shape

Honing angle

CYLINDER BORE MEASUREMENT

a

Longitudinal Direction

b

Transverse Direction

c, d, e. Measuring Point

1

Crankcase Contacting Surface

2

TDC of 1st Piston Ring

4

BDC of Ring

Service Data

Code letter ‘A’

Code letter ‘X’

Code letter ‘B’

When new

Wear limit

89.000 - 89.006mm

89.006 - 89.012mm

89.012 - 89.018mm

Max. 0.20mm

0.01mm

0.05mm

50° ± 10°

SECTION 1D3

OM600 ENGINE COOLING

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1D3-1

General Specifications . . . . . . . . . . . . . . . . . 1D3-1

Fastener Tightening Specifications . . . . . . . . 1D3-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-2

Cooling Circulation . . . . . . . . . . . . . . . . . . . . 1D3-2

Thermostat Operation . . . . . . . . . . . . . . . . . 1D3-3

Cooling System Leakage Test . . . . . . . . . . . 1D3-4

Maintenance and Repair . . . . . . . . . . . . . . 1D3-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1D3-5

Drain and Filling of Coolant . . . . . . . . . . . . . 1D3-5

Coolant Pump . . . . . . . . . . . . . . . . . . . . . . . . 1D3-6

Coolant Pump Housing . . . . . . . . . . . . . . . . . 1D3-8

Cooling Fan Clutch . . . . . . . . . . . . . . . . . . . 1D3-10

Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-12

Cooling Sub-System . . . . . . . . . . . . . . . . . . 1D3-14

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . 1D3-16

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Application

Coolant

Mixing Ratio (Water : anticorrosion)

Capacity

Description

ALUTEC P- 78

50 : 50

10.5L - 11L

9.5L - 10L

SPECIFICATIONS

GENERAL SPECIFICATIONS

Application

Coolant Pump Bolt

Belt Pulley Bolt

Coolant Pump Housing Return Pipe Bolt

Thermostat Bolt

Cooling Fan Clutch Socket Bolt (Center)

Cooling Fan Clutch Socket Bolt (Side)

Radiator Bolt

Coolant Sub-tank Bolt

N

•••••

m

10

10

10

10

45

10

3 - 7

3 - 7

FASTENER TIGHTENING SPECIFICATIONS

662LA

661LA

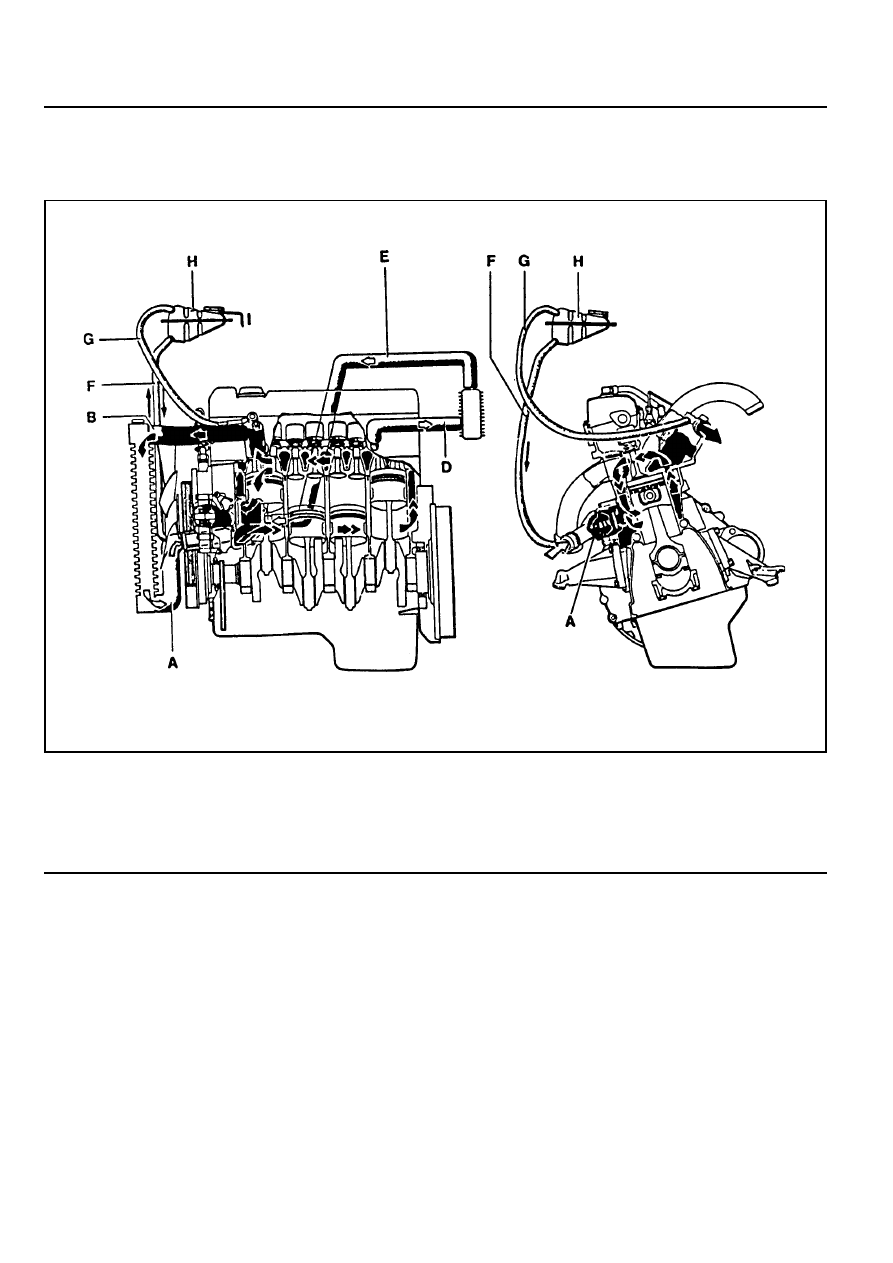

1D3-2 OM600 ENGINE COOLING

COOLING CIRCULATION

A Thermostat

B Radiator

D From Heater

E Hose

G Deaeration Line

H Reservoir

DIAGNOSIS

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст