SsangYong Musso. Manual — part 213

1F-436 ENGINE CONTROLS

SSANGYONG Y158

KAA1F006

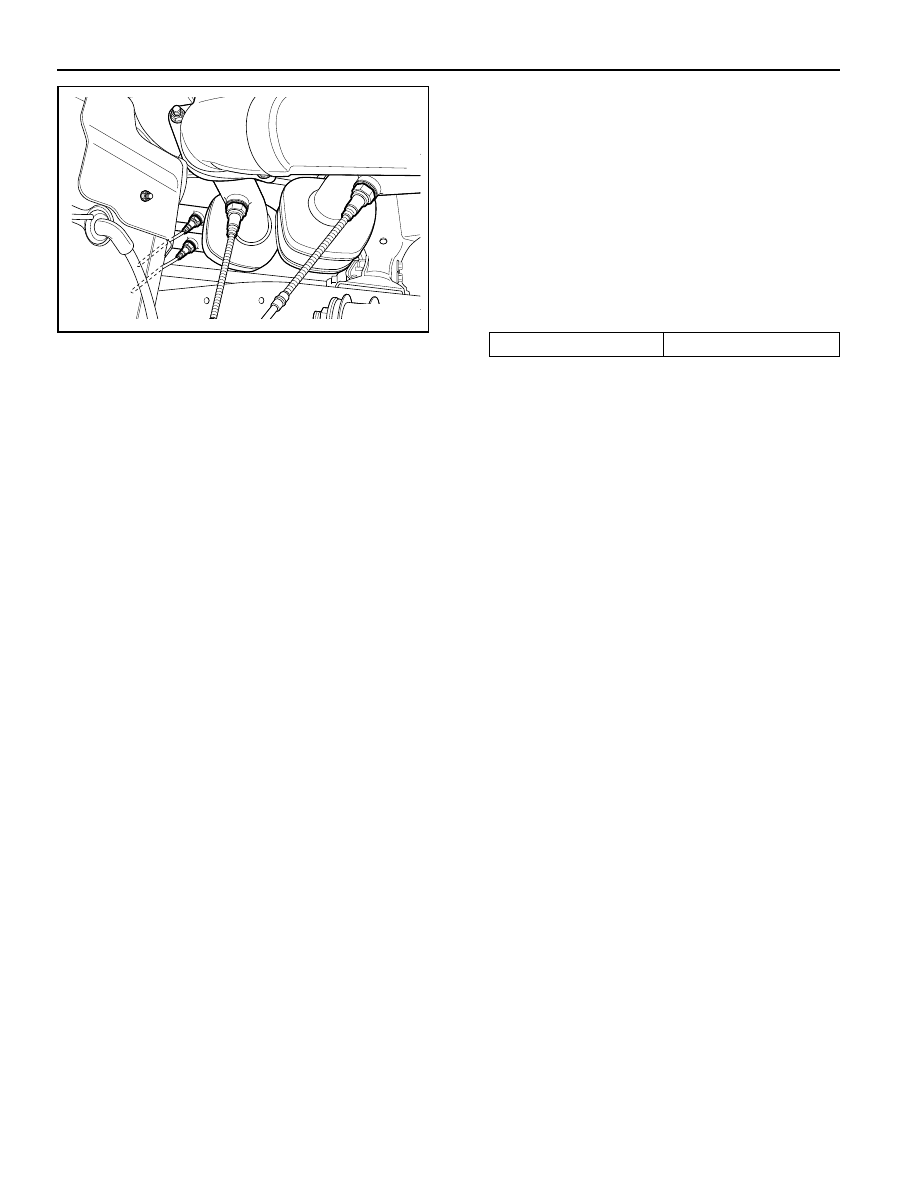

OXYGEN SENSOR (3.2L DOHC)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

Notice: The Oxygen (O2) sensor uses a permanently

attached pigtail and connector. This pigtail should not be

removed from the O2 sensor. Damage or removal of the

pigtail or the connector could affect proper operation of the

O2 sensor. Do not drop the O2 sensor.

2. Disconnect the electrical connector.

3. Carefully remove the O2 from the exhaust pipe.

Installation Notice

Important: a special anti-seize compound is used on the

O2 sensor threads. This compound consists consists of a

liquid graphite and glass beads. The graphite will burn

away, but the glass beads will remain, making the sensor

easier to remove. New or serviced sensors will already

have the compound applied to the threads. If a sensor is

removed from any engine and is to be reinstalled, the

threads must have an anti-seize compound applied before

reinstallation.

4. Coat the threads of the O2 sensor with an anti-seize

compound, if needed.

5. Installation should follow the removal procedure in

the reverse order.

Tightening Torque

55 N•m (41 lb-ft)

KAC1F300

ENGINE CONTROLS 1F-437

SSANGYONG Y158

YAB1F250

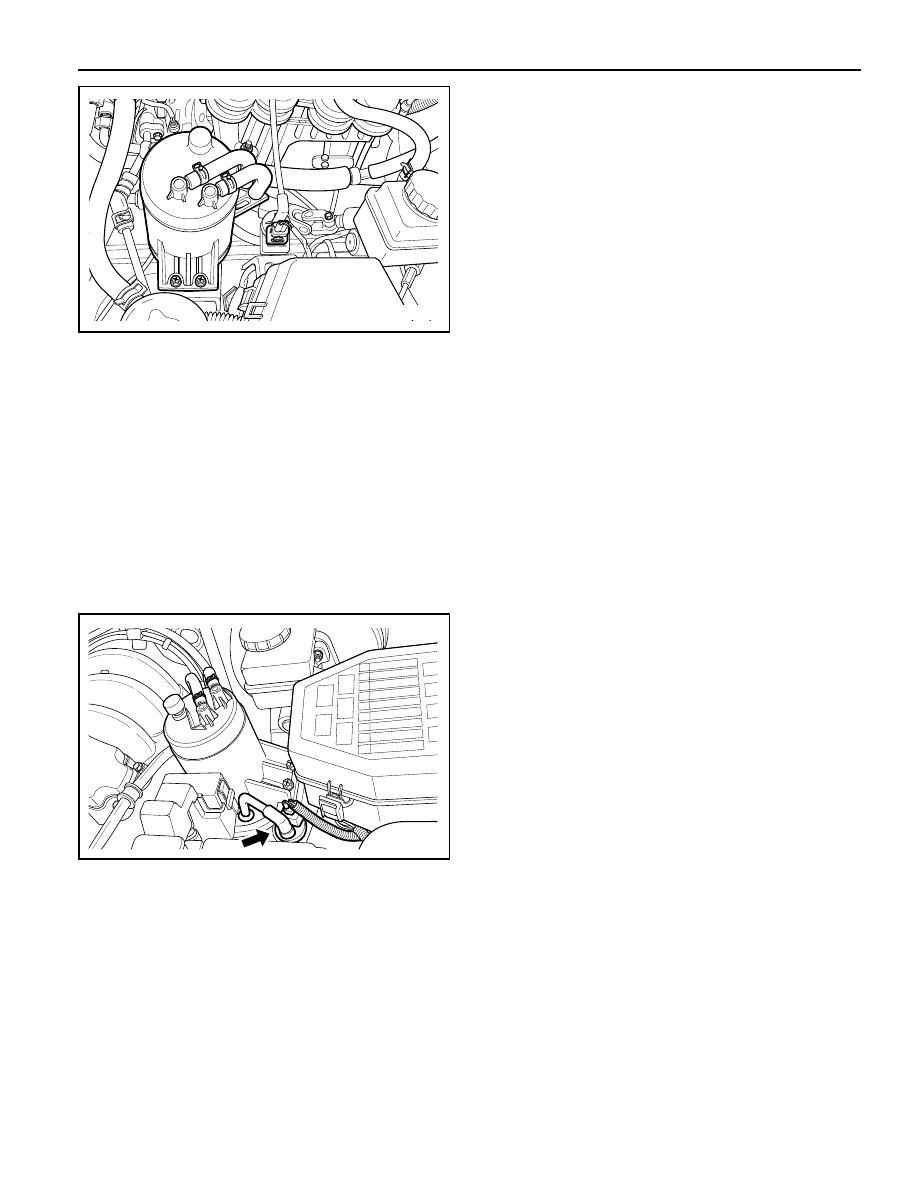

PURGE CONTROL VALVE

(2.3L DOHC)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the purge control valve connector.

3. Disconnect the throttle body-to-purge control valve

hose from the purge control valve.

4. Disconnect the canister-to-purge control valve hose

from the purge control valve.

5. Remove the purge control valve.

6. Installation should follow the removal procedure in

the reverse order.

YAB1F250

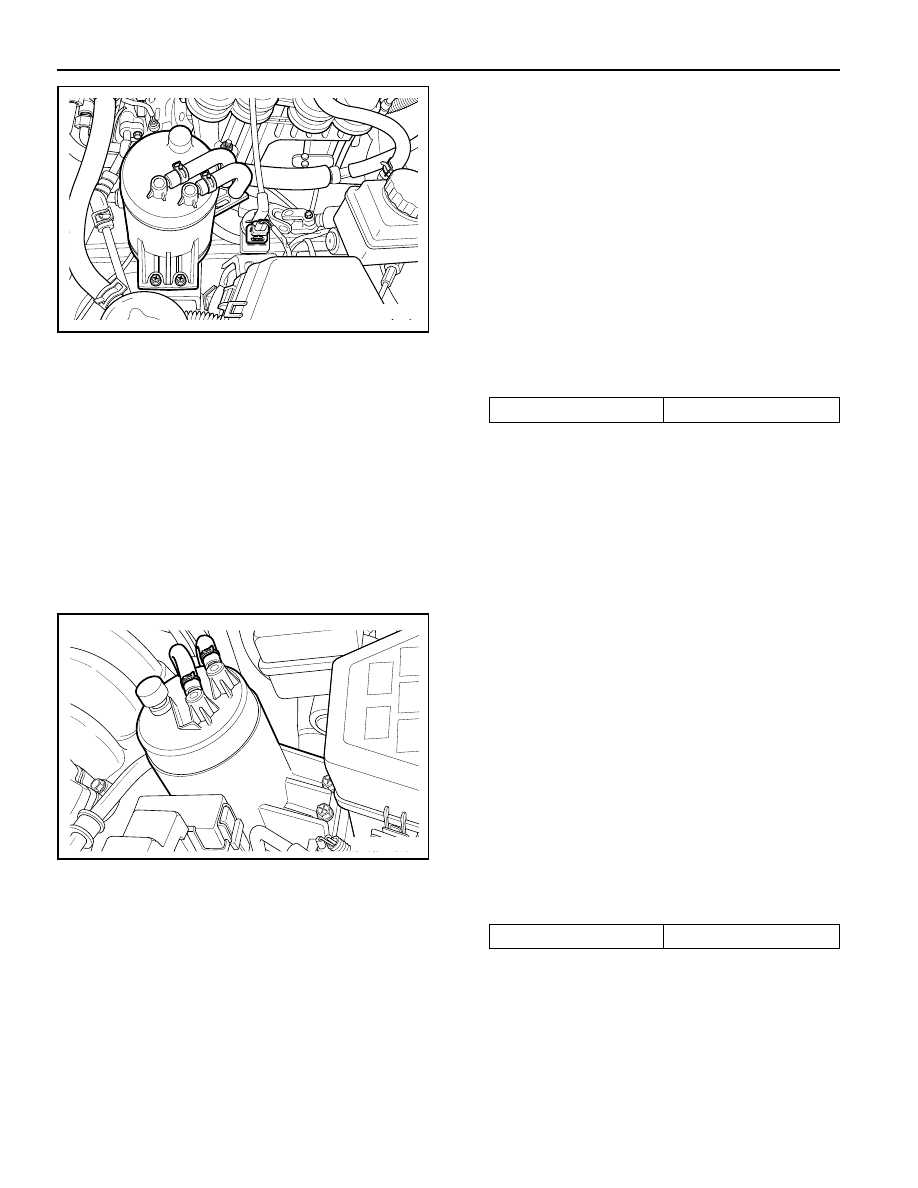

PURGE CONTROL VALVE

(3.2L DOHC)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the purge control valve connector.

3. Disconnect the throttle body-to-purge control valve

hose from the purge control valve.

4. Disconnect the canister-to-purge control valve hose

from the purge control valve.

5. Remove the purge control valve.

6. Installation should follow the removal procedure in

the reverse order.

YAA1F210

1F-438 ENGINE CONTROLS

SSANGYONG Y158

YAB1F250

3. Remove the canister mounting bolts.

Installation Notice

4. Remove the canister.

5. Installation should follow the removal procedure in

the reverse order.

CANISTER (3.2L DOHC)

Removal and Installation Procedure

Caution: Canister and vacuum hoses contain fuel

vapors. Do not smoke in the area or permit an open

flame.

1. Disconnect the fuel tank-to-canister hose form the

canister.

2. Disconnect the canister-to-purge control valve hose

form the canister.

Tightening Torque

6 N•m (53 lb-in)

YAA1F200

3. Remove the canister mounting bolts.

Installation Notice

4. Remove the canister.

5. Installation should follow the removal procedure in

the reverse order.

CANISTER (2.3L DOHC)

Removal and Installation Procedure

Caution: Canister and vacuum hoses contain fuel

vapors. Do not smoke in the area or permit an open

flame.

1. Disconnect the fuel tank-to-canister hose form the

canister.

2. Disconnect the canister-to-purge control valve hose

form the canister.

Tightening Torque

6 N•m (53 lb-in)

YAB1F250

ENGINE CONTROLS 1F-439

SSANGYONG Y158

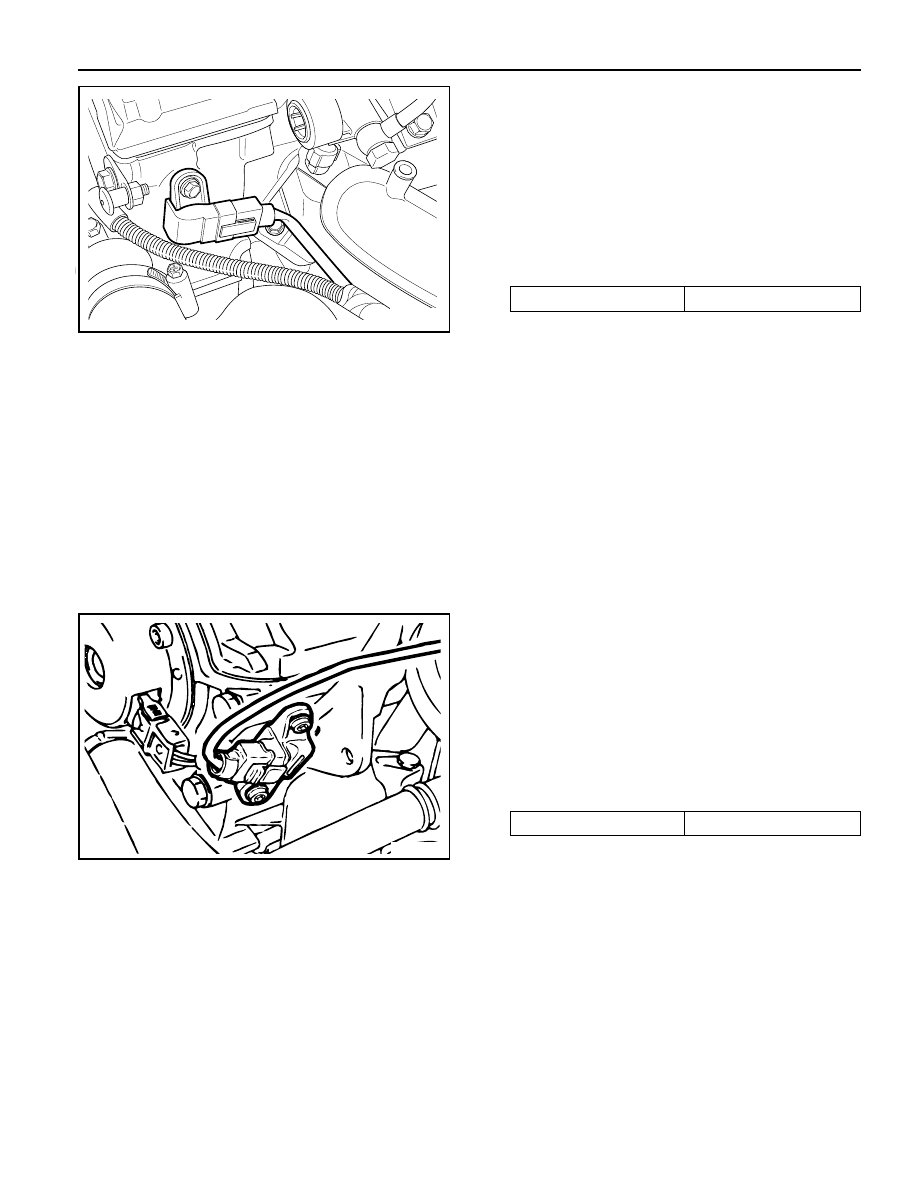

CAMSHAFT POSITION SENSOR

(2.3L DOHC)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the

Camshaft Position (CMP) sensor.

3. Remove the CMP sensor retaining bolt.

Installation Notice

4. Check the O-ring for damage and replace it if

necessary

5. Installation should follow the removal procedure in

the reverse order.

Tightening Torque

10 N•m (89 lb-in)

YAA1F810

CAMSHAFT POSITION SENSOR

(3.2L DOHC)

Removal and Installation Procedure

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the

Camshaft Position (CMP) sensor.

3. Remove the CMP sensor retaining bolt.

Installation Notice

4. Check the O-ring for damage and replace it if

necessary

5. Installation should follow the removal procedure in

the reverse order.

Tightening Torque

10 N•m (89 lb-in)

KAA1C170

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст