SsangYong Actyon Sports II. Manual — part 69

02-4

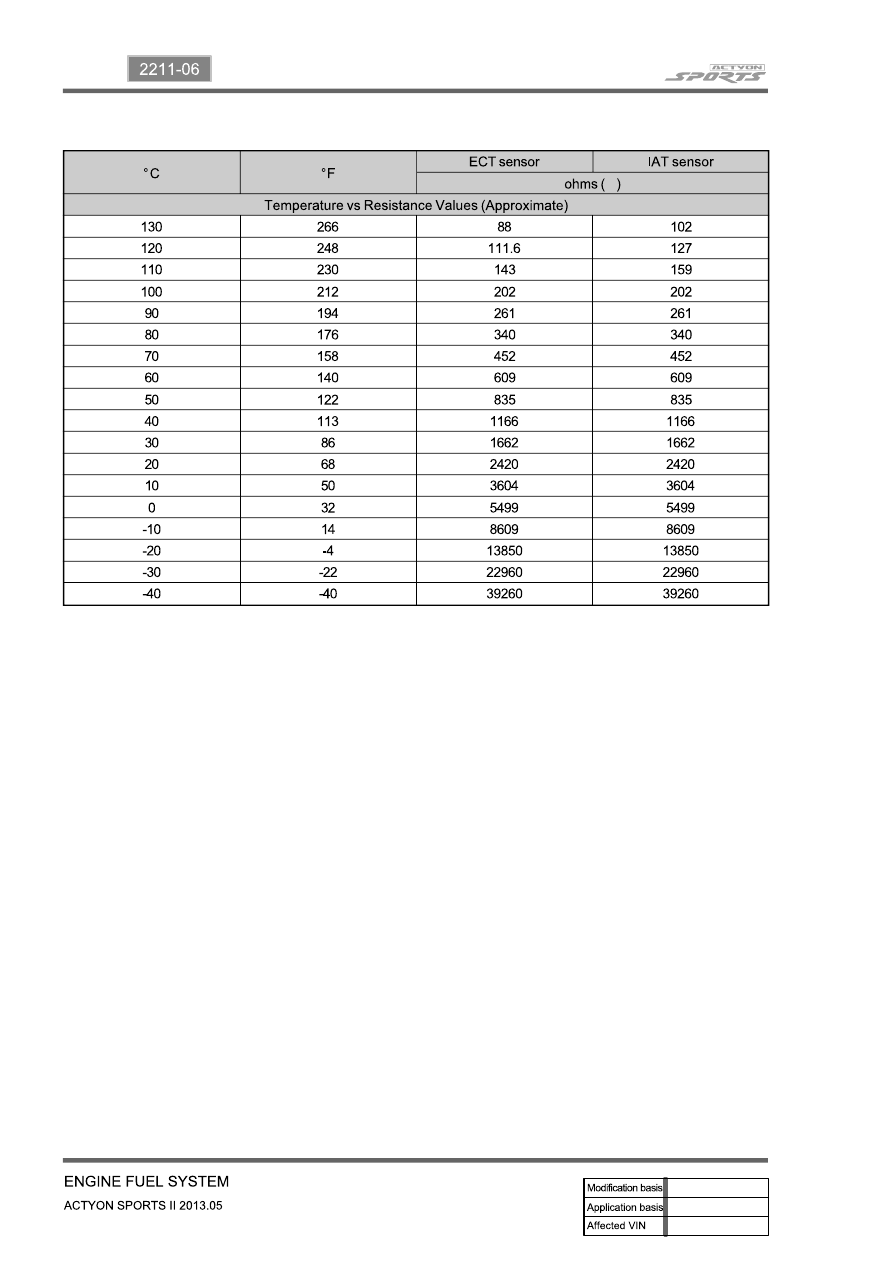

Temperature VS Resistance

▶

02-5

2211-06

1. FUEL SYSTEM

The function of the fuel metering system is to deliver the correct amount of fuel to the engine under all

operating conditions.

The fuel is delivered to the engine by the individual fuel injectors mounted into the intake manifold near

each cylinder.

The main fuel control sensors are the Mass Air Flow (MAF) sensor and the oxygen (O2) sensors.

The MAF sensor monitors the mass flow of the air being drawn into the engine. An electrically heated

element is mounted in the intake air stream, where it is cooled by the flow of incoming air. Engine Control

Module (ECM) modulates the flow of heating current to maintain the temperature differential between the

heated film and the intake air at a constant level. The amount of heating current required to maintain the

temperature thus provides an index for the mass air flow. This

concept automatically compensates for variations in air density, as this is one of the factors that

determines the amount of warmth that the surrounding air absorbs from the heated element. MAF

sensor is located between the air filter and the throttle valve.

Under high fuel demands, the MAF sensor reads a high mass flow condition, such as wide open throttle.

The ECM uses this information to enrich the mixture, thus increasing the fuel injector on-time, to provide

the correct amount of fuel. When decelerating, the mass flow decreases. This mass flow change is

sensed by the MAF sensor and read by the ECM, which then decreases the fuel injector on-time due to

the low fuel demand conditions.

The O2 sensors are located in the exhaust pipe before catalytic converter. The O2 sensors indicate to

the ECM the amount of oxygen in the exhaust gas, and the ECM changes the air/fuel ratio to the engine

by controlling the fuel injectors. The best air/fuel ratio to minimize exhaust emissions is 14.7 to 1, which

allows the catalytic converter to operate most efficiently. Because

of the constant measuring and adjusting of the air/fuel ratio, the fuel injection system is called a "closed

loop" system.

The ECM uses voltage inputs from several sensors to determine how much fuel to provide to the engine.

The fuel is delivered under one of several conditions, called "modes".

02-6

1) Starting Mode

When the ignition is turned ON, the ECM turns the fuel pump relay on for 1 second. The fuel pump then

builds fuel pressure. The ECM also checks the Engine Coolant Temperature (ECT) sensor and the

Throttle Position (TP) sensor and determines the proper air/fuel ratio for starting the engine. This ranges

from1.5 to 1 at -36 °C

(-33 °F) coolant temperature to 14.7 to 1 at 94 °C (201 °F) coolant

temperature. The ECM controls the amountof fuel delivered in the starting mode by changing how long

the fuel injector is turned on and off. This is done by ''pulsing" the fuel injectors for very short times.

2) Run Mode

The run mode has two conditions called ''open loop" and ''closed loop".

3) Open Loop

When the engine is first started and it is above 690 rpm, the system goes into "open loop" operation. In

"open loop", the ECM ignores the signal from the HO2S and calculates the air/fuel ratio based on inputs

from the ECT sensor and the MAF sensor. The ECM stays in "open loop" until the following conditions

are met:

The O2 has a varying voltage output, showing that it is hot enough to operate properly.

The ECT sensor is above a specified temperature (22.5 °C).

A specific amount of time has elapsed after starting the engine.

-

-

-

4) Closed Loop

The specific values for the above conditions vary with different engines and are stored in the

Electronically Erasable Programmable Read-Only Memory (EEPROM).

When these conditions are met, the system goes into "closed loop" operation. In "closed loop", the ECM

calculates the air/fuel ratio (fuel injector on- time) based on the signals from the O2 sensors. This allows

the air/fuel ratio to stay very close to 14.7 to 1.

5) Acceleration Mode

The ECM responds to rapid changes in throttle position and airflow and provides extra fuel.

6) Deceleration Mode

The ECM responds to changes in throttle position and airflow and reduces the amount of fuel. When

deceleration is very fast, the ECM can cut off fuel completely for short periods of time.

02-7

2211-06

7) Battery Voltage Correction Mode

When battery voltage is low, the ECM can compensate for a weak spark delivered by the ignition

module by using the following methods:

Increasing the fuel injector pulse width.

Increasing the idle speed rpm.

Increasing the ignition dwell time.

-

-

-

8) Fuel Cut-Off Mode

No fuel is delivered by the fuel injectors when the ignition is off. This prevents dieseling or engine runon.

Also, the fuel is not delivered if there are no reference pulses received from the CKP sensor. This

prevents flooding.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст