SsangYong Actyon Sports II. Manual — part 70

03-3

1713-08

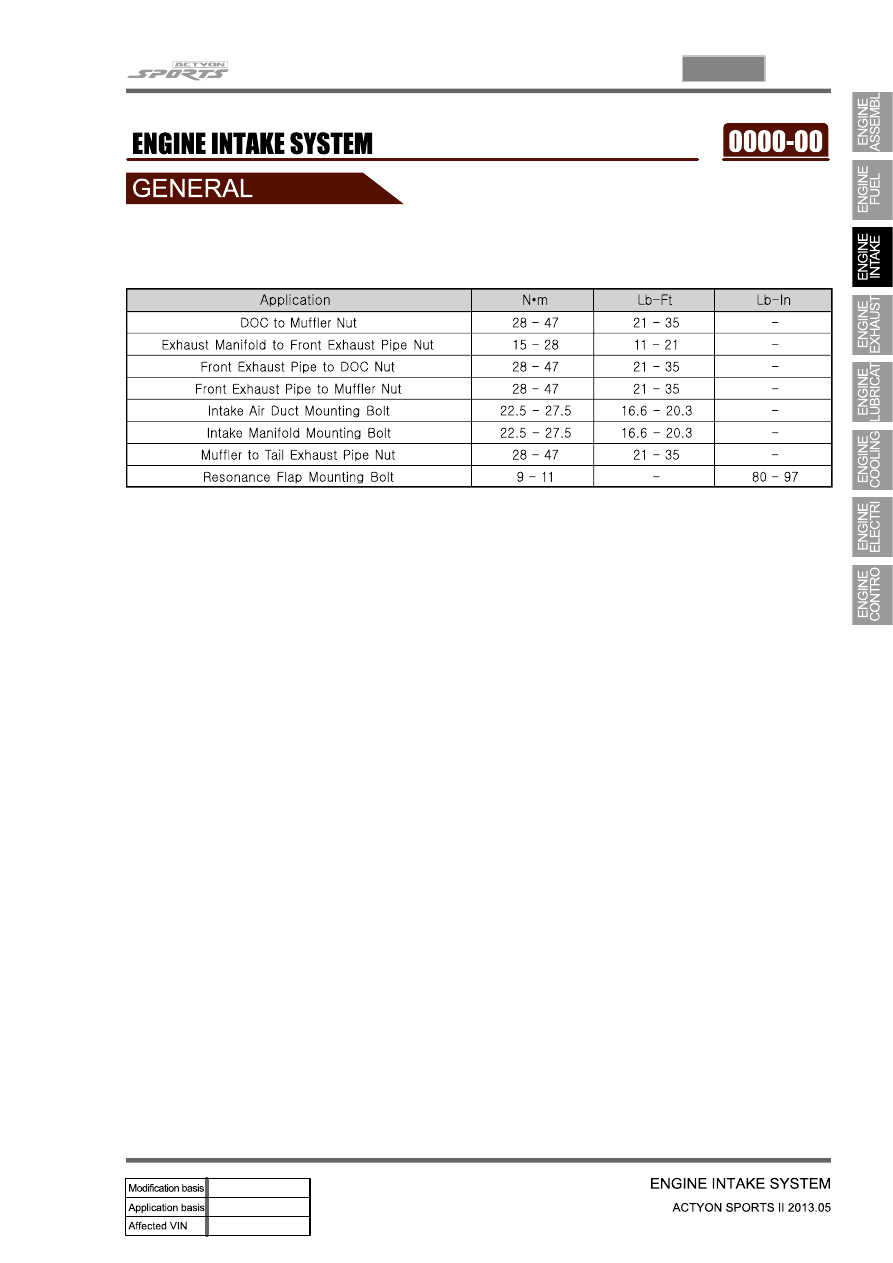

1. SPECIFICATIONS

(1) Fastener Tightening Specifications

04-3

2420-01

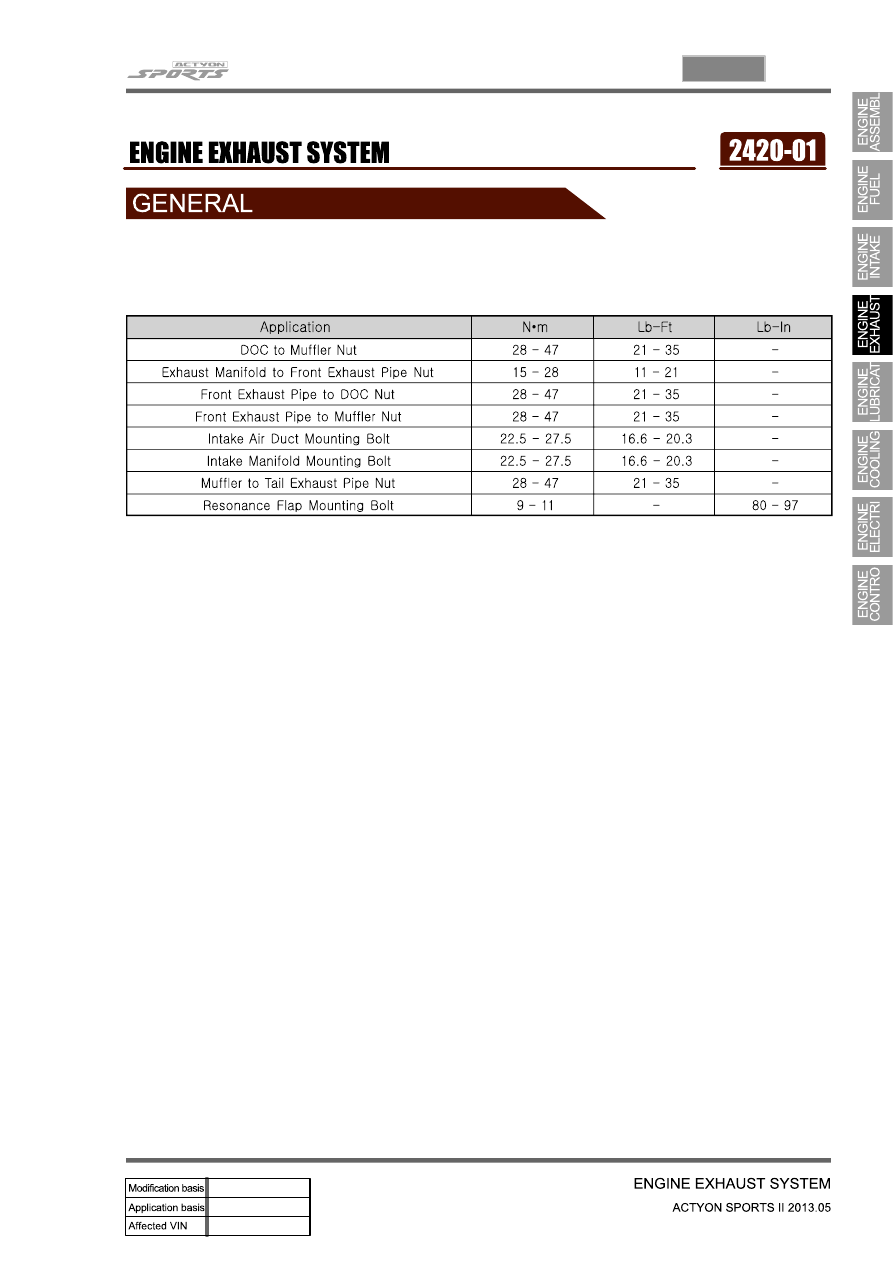

1. SPECIFICATION

(1) Fastener Tightening Specifications

04-4

1. DESCRIPTION AND OPERATION

1) Exhaust System

When you are inspecting or replacing exhaust system components, make sure there is adequate

clearance from all points on the underbody to avoid possible

overheating of the floor panel and possible damage to the passenger compartment insulation and trim

materials.

Check the complete exhaust system and the nearby body areas and trunk lid for broken, damaged,

missing or mispositioned parts, open seams, holes, loose connections, or other deterioration which

could permit exhaust fumes to seep into the trunk may be an indication of a problem in one of these

areas. Any defects should be corrected immediately.

2) Catalytic Converter (Gasoline Engine)

When jacking or lifting the vehicle from the body side rails, be certain that the lift pads do not contact

the catalytic converter, as this could damage the catalytic converter.

Use of anything other than unleaded fuel will damage the catalyst in the catalytic converter.

1.

2.

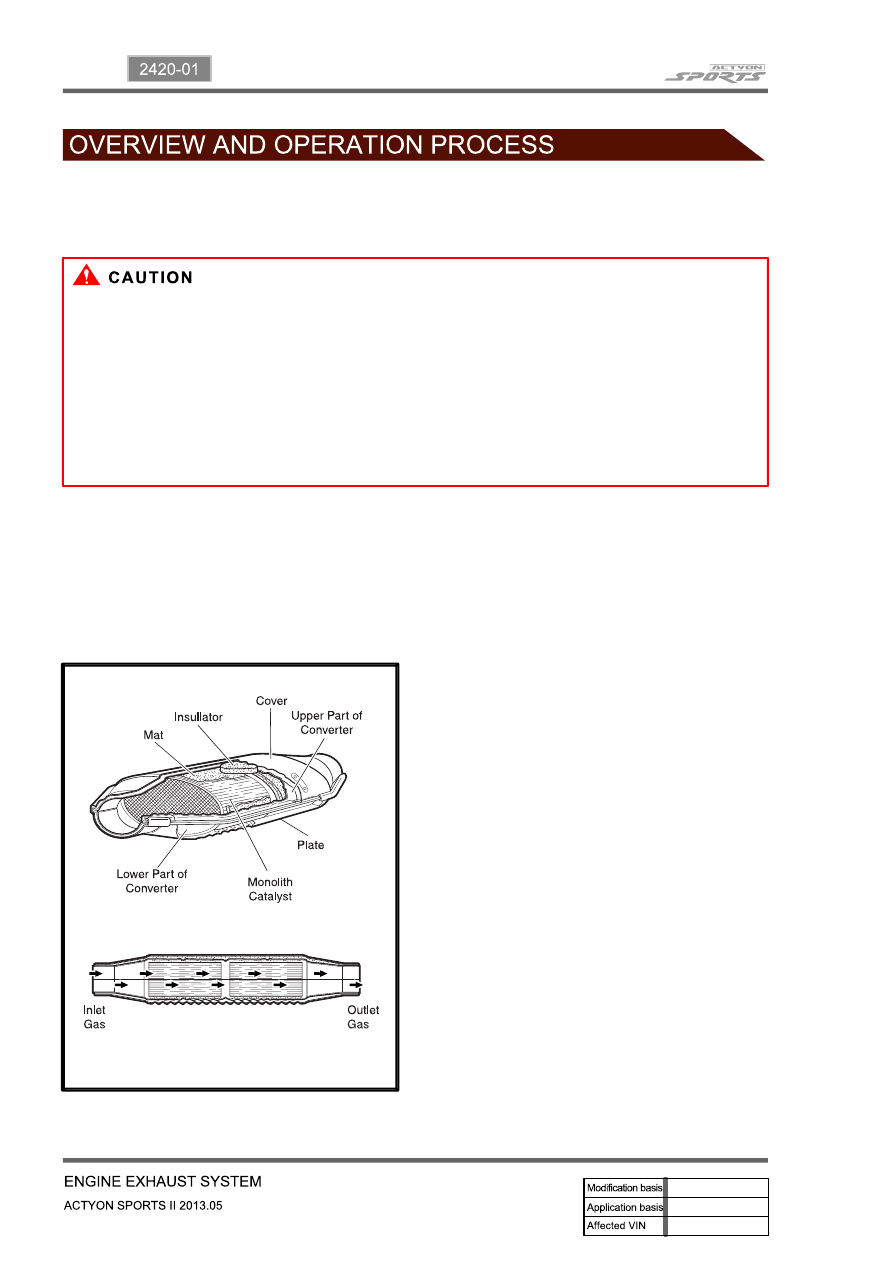

Catalytic Converter Structure

▶

The Catalytic converter of monolith type consists of 2

walled metal bodies which is made of Cordierite. The

principal element of converter consists of the materials

like Alumina or oxidized Serume in order to apply to

Ceramic Monolith. Washer coat operates first, and

catalytic metal elements (Pt, Pd, Rh) operates to

washer coat next.

Monolith type is lighter than other types, easy to

manufacture and quickly approaches to proper

temperature. Washer coat is used to make a contact

surface with exhaust gas bigger by adhering closely to

small holes

of inner layer. If a lead compound or phosphorus

adheres to the surface and the temperature rises, its

surface is decreased. The total area of general

monolith converter is about 45, 000~500,000ft3. (10

times of a football field) Generally Alumina (AL2 O3) is

used as a raw materialand its 7 phases of gamma,

delta, theta have big areas and high stability for the

temperature, and nowadays gamma Alumina is used

usually.

04-5

2420-01

Catalytic Converter and Temperature

▶

Catalytic converter has the normal function of

purification at a range of the temperature.

Because it has a weak point of decreasing of the

purification rate in the condition of continuous

high temperature, it should keep the temperature

range of 400 to 500°C for normal condition.

HC purification rate becomes better according to

the increase of temperature in the normal range

of temperature. CO purification rate becomes the

best near the temperature of 450°C, and NOx

does so near the temperature of 400 to 500°C.

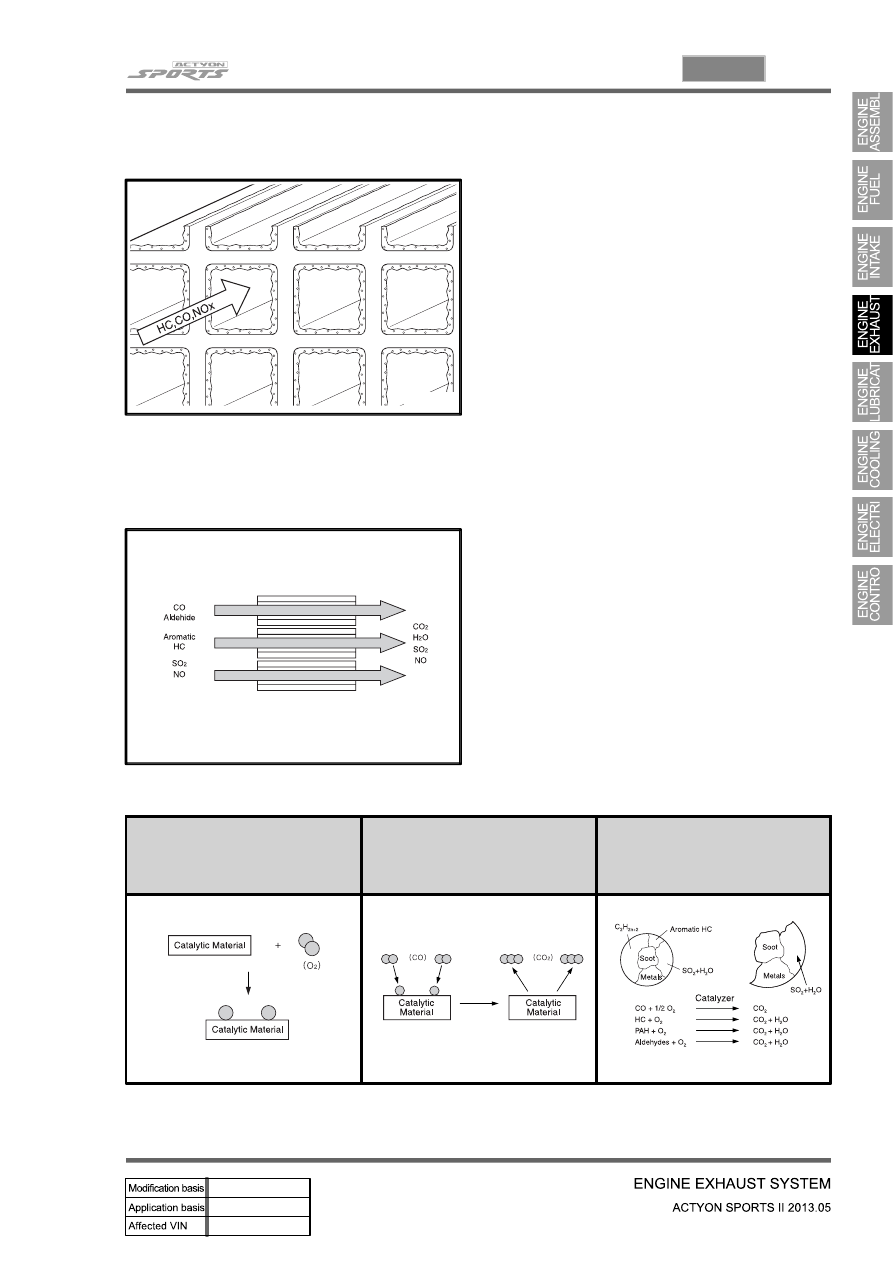

Purification of Catalytic Converter

▶

Adhesion of soluble organic fraction (SOF)

below 180°C

Purification of soluble organic fraction (SOF)

over 180°C

Chemical reaction formula

-

-

SOF(HC)+O2 → CO2+H2O

2CO+O2 → 2CO2

2C2H6+7O2 → 4CO2+6H20

By catalytic action of two primary catalytic

converter, oxidation occurs in order to

decrease HC and CO.

-

Oxygen adheres to catalytic

material : below 180°C

Catalytic material supplies each

CO and HC with O2 for their

oxidation : above 180°C

Catalytic material conversion

process by DOC

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст