SsangYong Actyon Sports II. Manual — part 57

15-25

0000-00

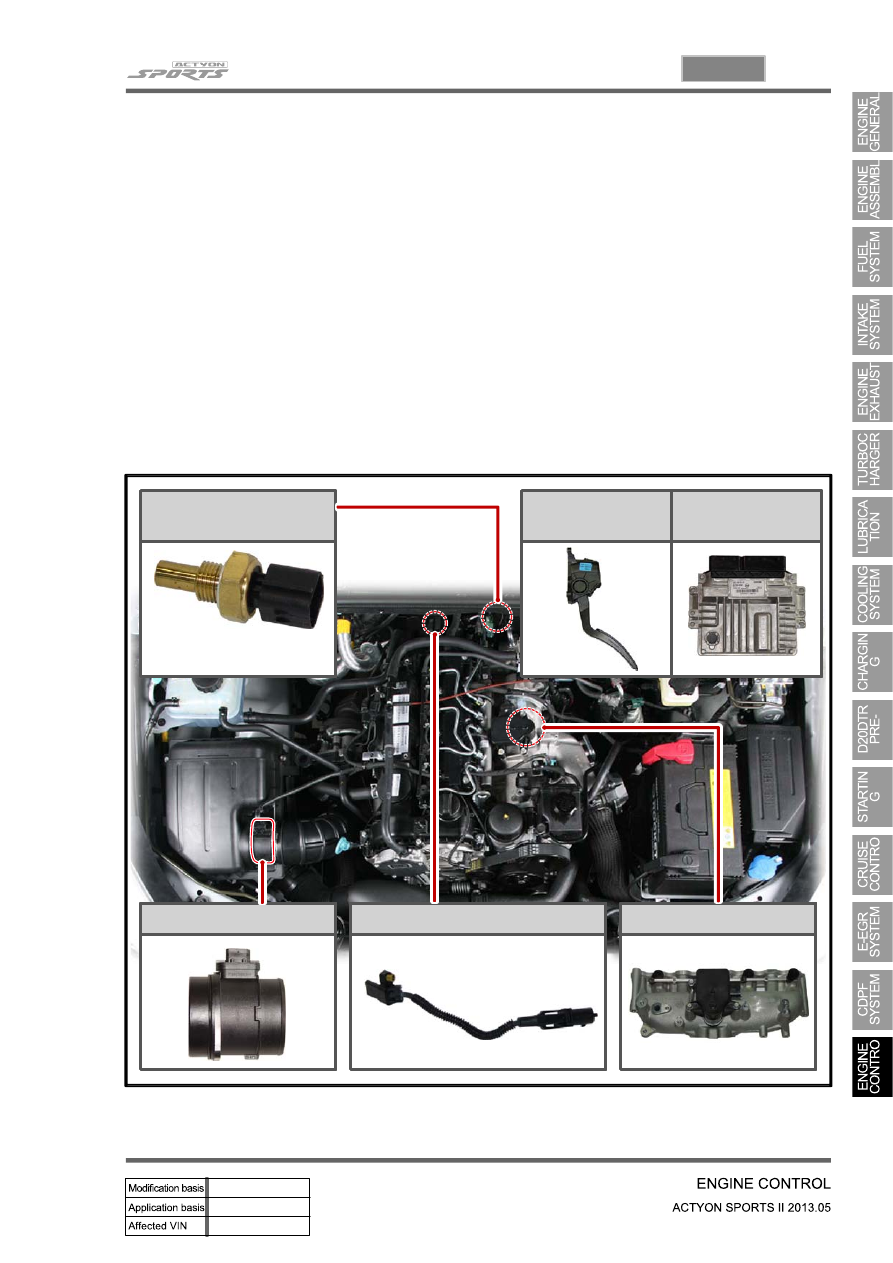

(8) Swirl control

A. Overview

Variable swirl valve

▶

The strong swirl caused by intake air is important element for anti-locking function in diesel engine. The

swirl control valve partially closes the intake port to generate the swirl according to the engine conditions.

When the engine load is in low or medium range, the swirl could not be generated because the air flow is

slow. To generate strong swirl, there are two passages in intake manifold, and one of them has the valve

to open and close the passage. When the valve closes the passage, the air flow through the another

passage will be faster, and the strong swirl will be generated by the internal structure of the passage. This

swirl makes the better mixture of air and fuel, eventually the combustion efficiency in combustion

chamber could be improved. This provides the enhanced fuel consumption, power and EGR ratio.

Components

▶

HFM

Crankshaft position sensor

Variable swirl valve

Coolant temperature

sensor

Accekerator pedal

module

D20DTR ECU

15-26

B. Input/Output for variable swirl valve

15-27

0000-00

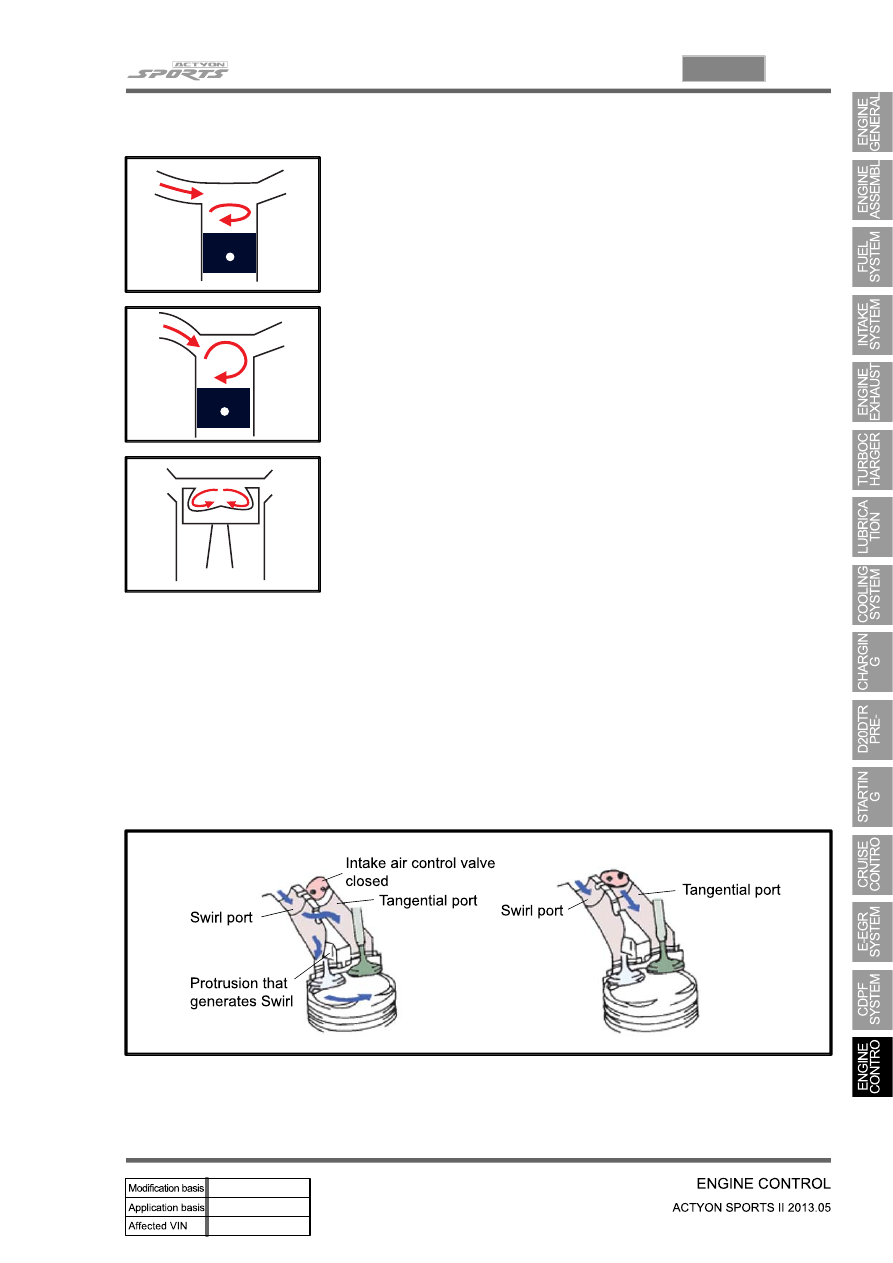

C. Types of swirl

Swirl: One cylinder has two intake air ports, one is set horizontally and

the other one is set vertically. Swirl is the horizontal air flows in cylinder

due to the horizontal intake air ports.

Tumble: Tumble is the vertical air flows in cylinder due to the vertical

intake air port

Tumble: Tumble is the vertical air flows in cylinder due to the vertical

intake air port

D. Swirl control

In DI type diesel engine, the liquefied fuel is injected into the cylinder directly. If the fuel is evenly

distributed in short period, the combustion efficiency could be improved. To get this, there should be

good air flow in cylinder. In general, there are two intake ports, swirl port and tangential port, in each

cylinder. The swirl port generates the horizontal flow and the tangential port generates the longitudinal

flow. In low/mid load range, the tabgential port is closed to increase the horizontal flow. Fast flow

decreases the PM during combustion and increases the EGR ratio by better combustion efficiency.

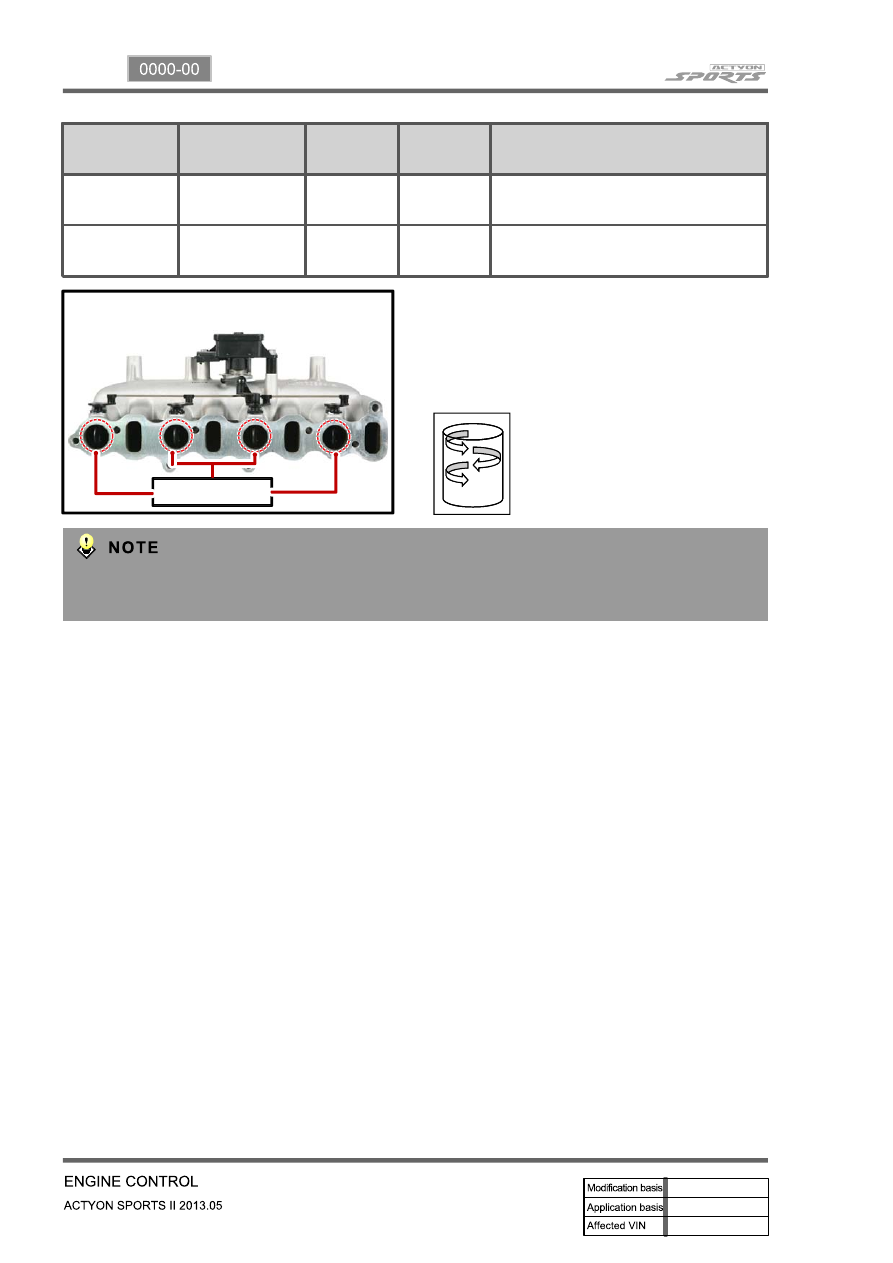

15-28

Load

Engine speed

Swirl valve Amount of

swirl

Remarks

Low speed,

Low load

below 3,000 rpm

Closed

Heavy

Increased EGR ratio, better air-fuel

mixture (reduce exhaust gas)

High speed,

High load

over 3,000 rpm

Open

Light

Increase charge efficiency, higher

engine power

The variable swirl valve actuator operates when

turning the ignition switch ON/OFF position to

open/close the swirl valve. In this period, the soot

will be removed and the learning for swirl valve

position is performed.

Swirl: This is the twisted (radial) air flow along the cylinder wall during the intake stroke. This

stabilizes the combustion even in lean air-fuel mixture condition.

Swirl valve

E. Features

Swirl and air intake efficiency

To generate the swirl, the intake port should be serpentine design. This makes the resistance in air

flow. The resistance in air flow in engine high speed decreases the intake efficiency. Eventually, the

engine power is also decreased, Thus, the swirl operation is deactivated in high speed range to

increase the intake efficiency.

Relationship between swirl and EGR

To reduce Nox, it is essential to increase EGR ratio. However, if EGR ratio is too high, the PM also

could be very higher. And, the exhaust gas should be evenly mixed with newly aspired air. Otherwise,

PM and CO are dramatically increased in highly concentrated exhaust gas range and EGR ratio

could not be increased beyond a certain limit. If the swirl valve operates in this moment, the limit of

EGR ratio will be higher.

-

-

F. Relationship between swirl and fuel injection pressure

The injector for DI engine uses the multi hole design. For this vehicle, there are 8 holes in injector. If the

swirl is too strong, the injection angles might be overlapped and may cause the increased PM and

insufficient engine power. Also, if the injection pressure is too high during strong swirl, the injection

angles might be overlapped. Therefore, the system may decreases the fuel injection pressure when the

swirl is too strong.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст