SsangYong Actyon Sports II. Manual — part 56

15-21

0000-00

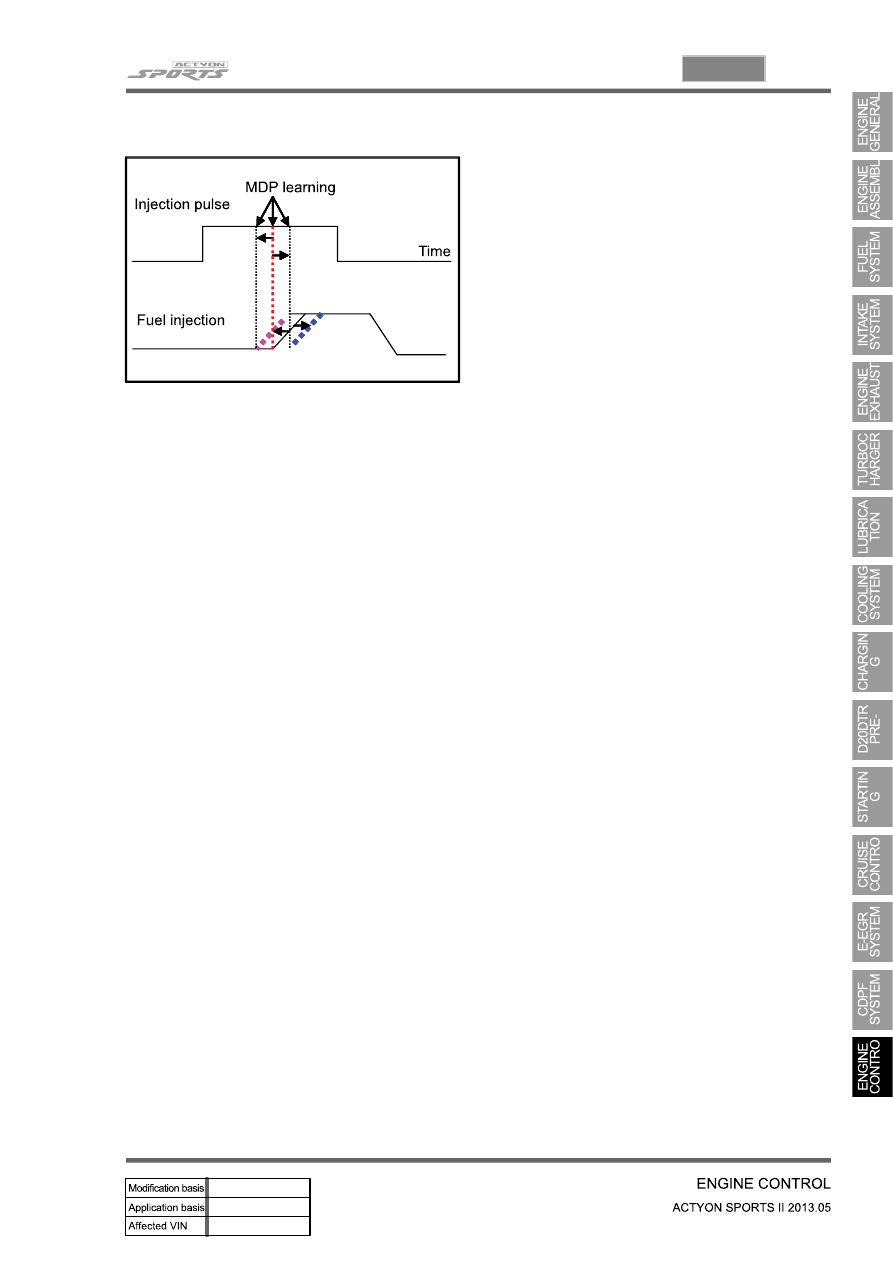

MDP (Minimum Drive Pulse ) refers to the

minimum power supply pulse for injection which

the injector can perform. It is possible to control

the fuel volume for each injector accurately

through correct learning for the MDP value. The

basic process of MDP learning is that the pulse

slightly higher than MDP is supplied and then (b)

the vibration generated from the cylinder is

detected. The knock sensor detects the vibration

from the engine after a small volume of fuel is

injected. And the time interval between the points

of injection and vibration is measured so that

MDP can be learned. MDP learning is helpful to

prevent engine vibration, high emission and

power reduction through performing calibration

for the old injectors. During MDP learning, a little

vibration and noise can be occur for a while. This

is because the fuel pressure is increased

instantaneously and the exact injection value is

not input, so that the exact engine vibration

timing can be detected.

(6) MDP Learning Control

A. MDP Learning

When the pulse value that the injector starts injection is measured, it is called minimum drive pulse

(MDP). Through MDP controls, can correct pilot injections effectively. Pilot injection volume is very small,

1 to 2 mm/str, so precise control of the injector can be difficult if it gets old. So there needs MDP learning

to control the very small volume precisely through learning according to getting older injectors.

Control the fuel injection volume precisely by MDP learning even for the old injector.

ECU corrects the pilot injection effectively by MDP control.

MDP learning is performed by the signal from knock sensor.

-

-

-

The system measures the pulse at initial injection to reduce the engine vibration.

B. Purpose of MDP learning

15-22

C. Learning Conditions

Idle MDP learning

Drive MDP learning

Coolant temperature

over 60℃

over 60℃

Vehicle speed

Idling

over 50km/h (over 5 seconds)

Engine rpm

2,000 to 2,500 rpm

Fuel temperature

0 < Fuel temperature < 80℃

Learning

2 times for each cylinder (every 5

seconds)

2 times for each cylinder

(every 5 seconds)

If MDP learning is not properly performed, engine vibration and injection could be occurred.

MDP learning should be performed after replacing ECU, reprogramming and replacing injector.

-

-

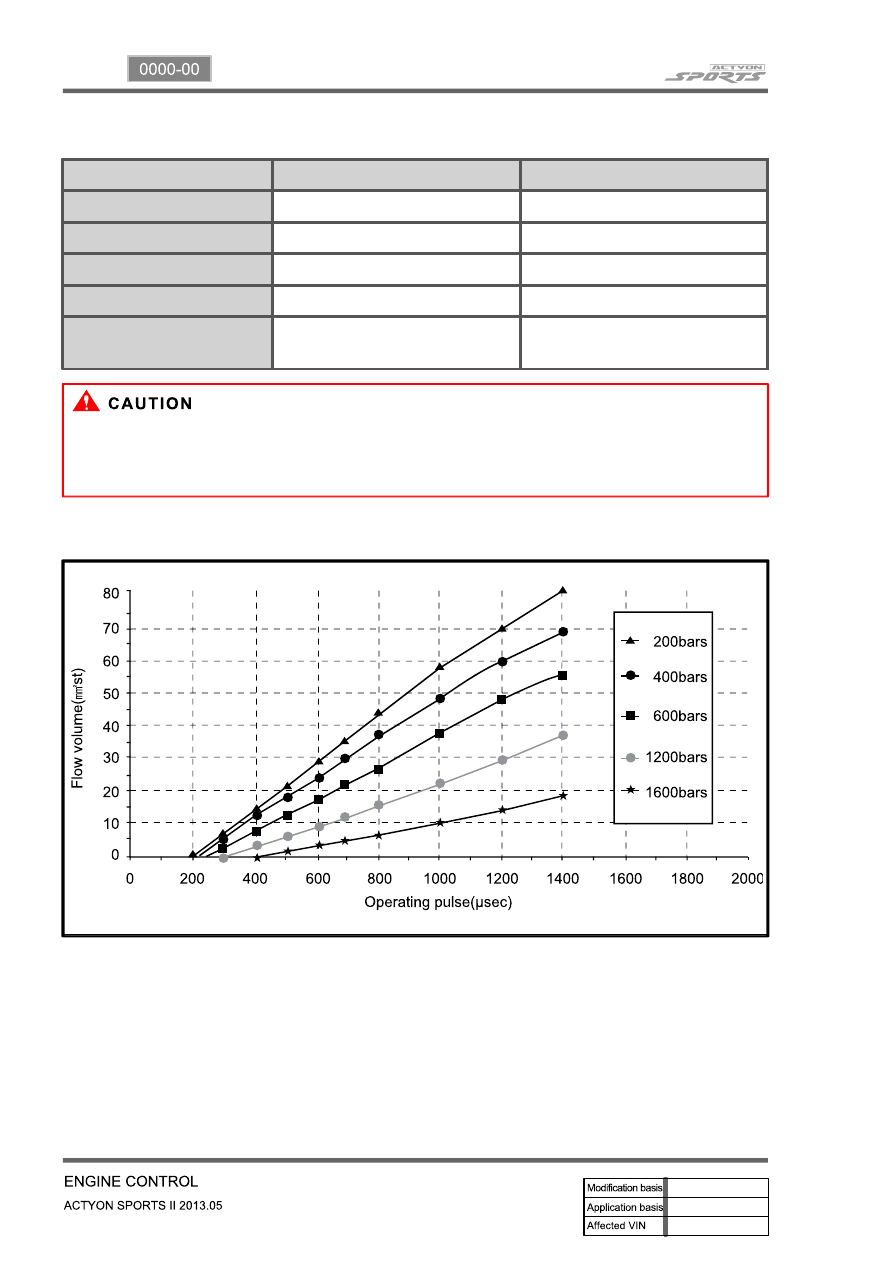

D. Injector characteristic curve for rail pressure

15-23

0000-00

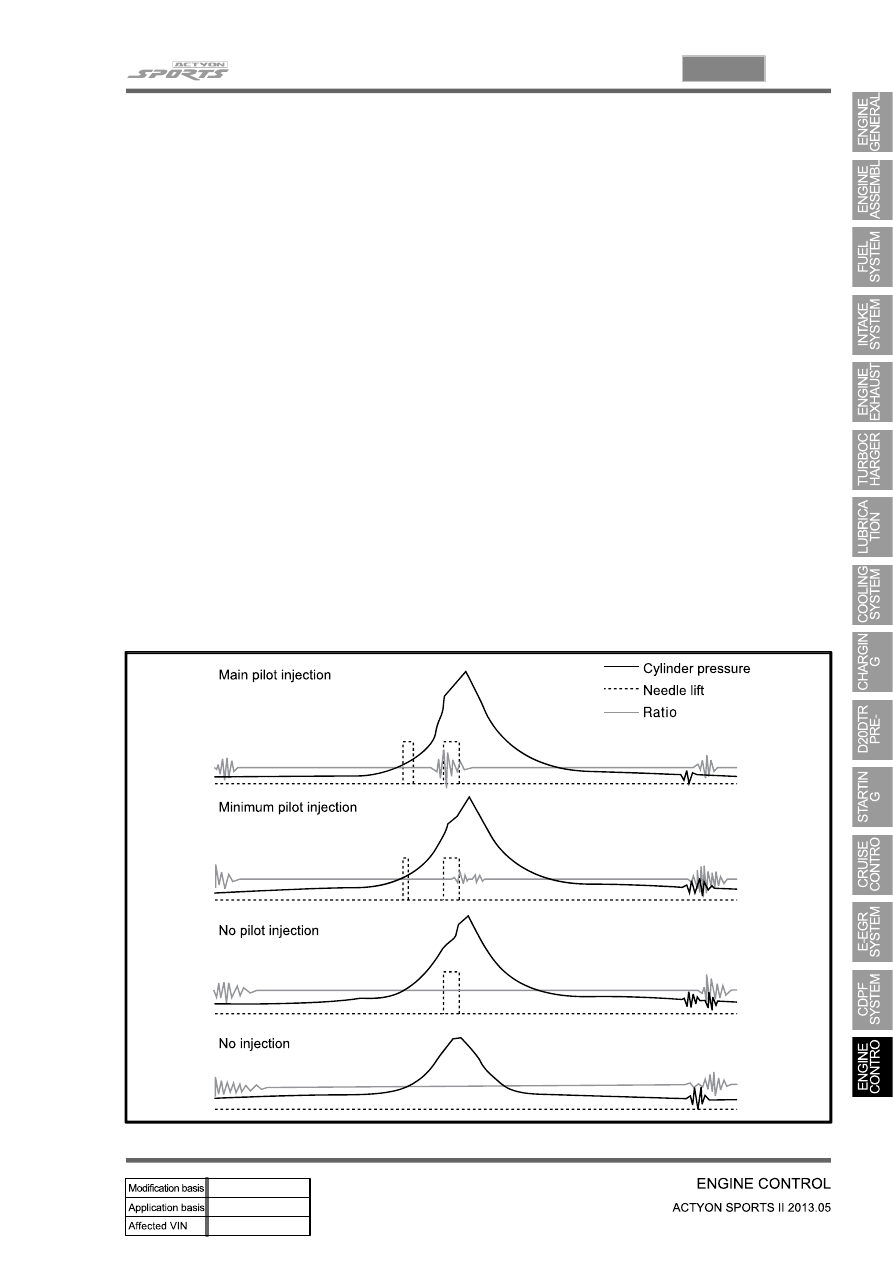

(7) Knocking Control

A. Resetting the pilot injection

The knocking control is used to reset the pilot injection flow in closed loop for each injector. This method

allows the correction of any injector deviations over a period of time. The principle of use of the knocking

control is based on the detection of the combustion noises.

The sensor is positioned in such a way as to receive the maximum signal for all the cylinders. The raw

signals from the knock sensor are processed to obtain a variable which quantifies the intensity of the

combustion. This variable, known as the ratio, consists of the ratio between the intensity of the

background noise and the combustion noise.

A first window is used to establish the background noise level of the knocking control signal for each

cylinder. This window must therefore be positioned at a moment when there cannot be any

combustion.

The second window is used to measure the intensity of the pilot combustion. Its position is such that

only the combustion noises produced by the pilot injection are measured . It is therefore placed just

before the main injection.

1.

2.

The knock sensor does not allow any evaluation of the quantity injected. However, the pulse value will

be measured when the injector starts injection and this pulse value is called the MDP (Minimum Drive

Pulse). On the basis of this information, it is possible to efficiently correct the pilot flows. The pilot

injection resetting principle therefore consists of determining the MDP, in other words the pulse

corresponding to the start of the increase in value of the ratio (increase of vibration due to fuel

combustion).

15-24

This is done periodically under certain operating conditions. When the resetting is finished, the new

minimum pulse value replaces the value obtained during the previous resetting. The first MDP value is

provided by the C3I. Each resetting then allows the closed loop of the MDP to be updated according to

the deviation of the injector.

B. Detection of leaks in the cylinders

The accelerometer is also used to detect any injector which may have stuck open. The detection

principle is based on monitoring the ratio. If there is a leak in the cylinder, the accumulated fuel self-

ignites as soon as the temperature and pressure conditions are favorable (high engine speed, high load

and small leak).

This combustion is set off at about 20 degrees before TDC and before main injection.

The ratio therefore increases considerably in the detection window. It is this increase which allows the

leaks to be detected. The threshold beyond which a fault is signaled is a percentage of the maximum

possible value of the ratio.

Because of the severity of the recovery process (engine shut-down), the etection must be extremely

robust.

An increase in the ratio can be the consequence of various causes:

Pilot injection too much

Main combustion offset

Fuel leak in the cylinder

-

-

-

If the ratio becomes too high, the strategy initially restricts the pilot injection flow and retards the main

injection. If the ratio remains high despite these interventions, this shows that a real leak is present, a

fault is signaled and the engine is shut down.

C. Detection of an accelerometer fault

This strategy permits the detection of a fault in the sensor or in the wiring loom connecting the sensor to

the ECU.

It is based on detection of the combustion. When the engine is idling, the detection window is set too low

for the combustion caused by the main injection. If the ratio increases, this shows that the knock sensor

is working properly, but otherwise a fault is signaled to indicate a sensor failure. The recovery modes

associated with this fault consist of inhibition of the pilot injection and discharge through the injectors.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст