Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 546

6A – 22 ENGINE MECHANICAL

RECOMMENDED LIQUID GASKET

Type Brand

Name

Manufacturer

Remarks

RTV*

Silicon Base

ThreeBond 1207B

ThreeBond 1207C

Three Bond

Three Bond

Water Base

ThreeBond 1141E

Three Bond

Solvent

ThreeBond

1104

BelcoBond 4

BelcoBond 401

BelcoBond 402

Three Bond

Isuzu

Isuzu

Isuzu

Anaerobic

LOCTITE

515

LOCTITE 518

Loctite

Loctite

Recommended for

transaxle repairs

* RTV : Room Temperature Vulcanizer

Note:

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacturer’s instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of

greater than 0.25 mm (0.01 in). Poor adhesion will result.

ENGINE MECHANICAL 6A – 23

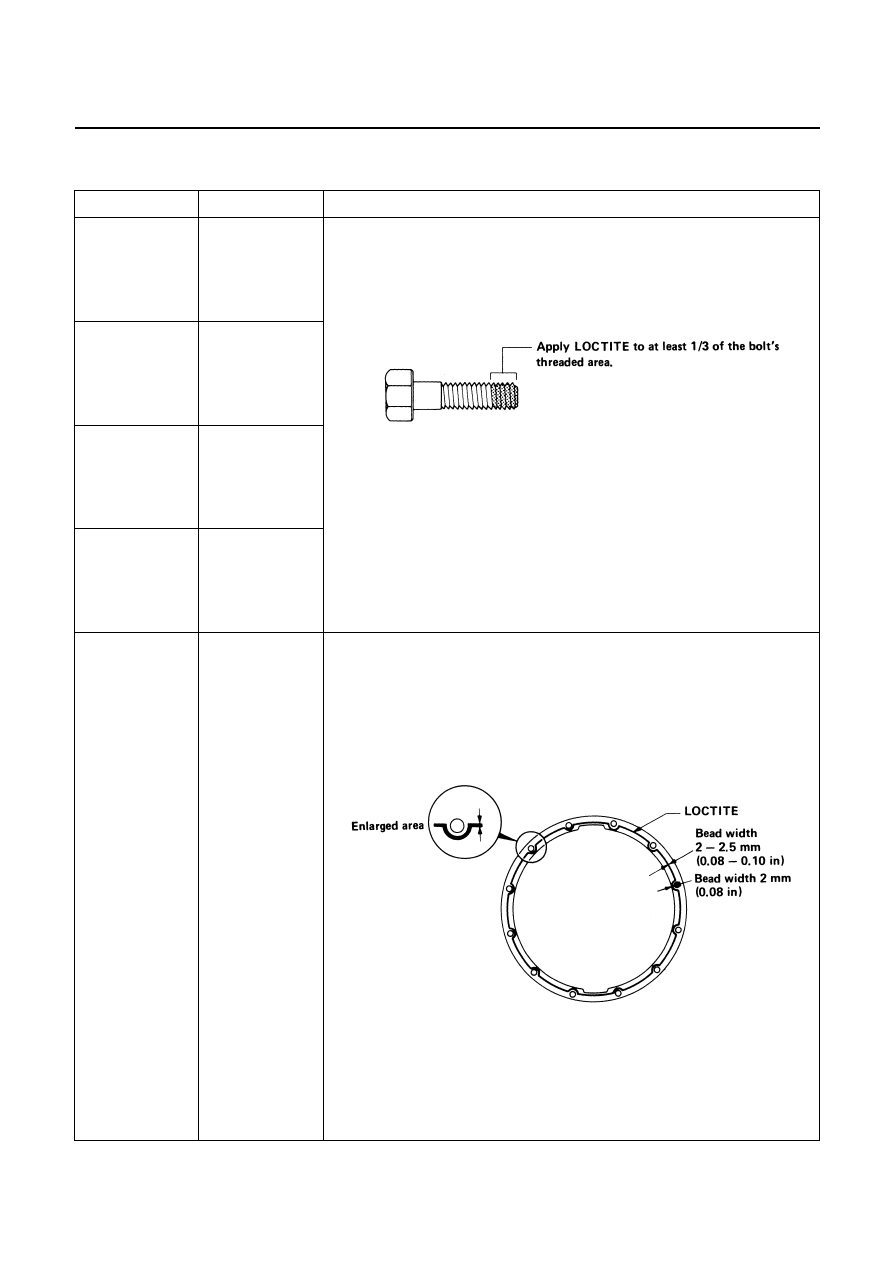

LOCTITE APPLICATION PROCEDURE

LOCTITE Type

LOCTITE Color

Application Steps

LOCTITE 242

Blue

LOCTITE 262

Red

LOCTITE 270

Green

LOCTITE 271

Red

1. Completely remove all lubricant and moisture from the bolts and the

female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

3. Tighten the bolts to the specified torque.

4. Wait at least one hour before continuing the installation procedure.

LOCTITE 515

Violet

1. Completely remove lubricant and moisture from the connecting

surfaces.

The surfaces must be perfectly dry.

2. Apply a 2.0 – 2.5 mm bead of LOCTITE to one of the connecting

surfaces.

There must be no gaps in the bead.

3. Tighten the bolts to the specified torque.

4. Let the joined parts set for at least thirty minutes.

6A – 24 ENGINE MECHANICAL

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

MODEL IDENTIFICATION

Engine Serial Number

The engine number is stamped on the front left hand side

of the cylinder body.

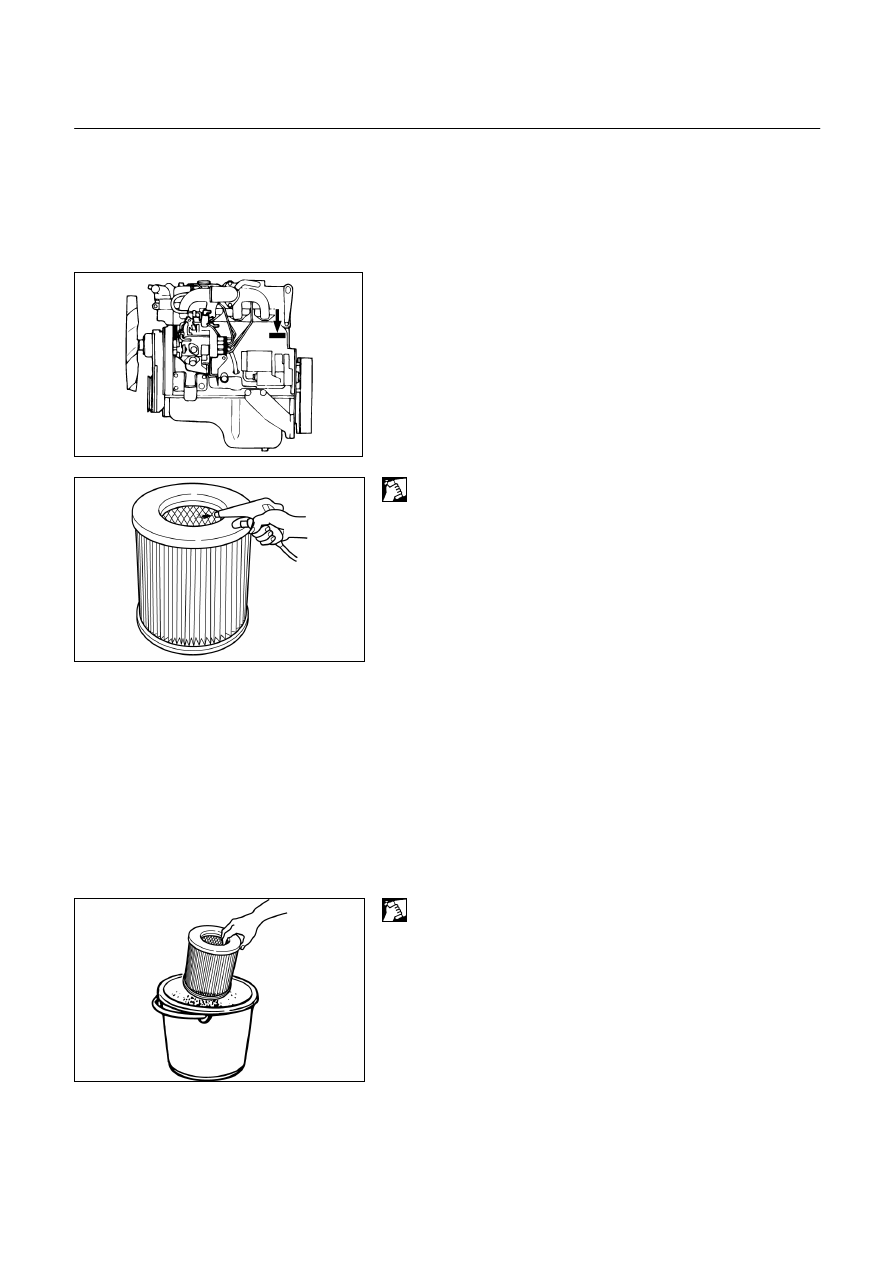

AIR CLEANER

Element cleaning procedures will vary according to the

condition of the element.

Oil Wetted (Viscous Type) Paper Element

The air cleaner has an oil wetted paper element. No

servicing is required until the replacement interval is

reached. Never attempt to clean the element, no matter

how dirty may appear. The element is designed to provide

normal filtering efficiency until it becomes due for

replacement. Refer to the Item “Service and Maintenance”

in the Owner’s and Driver’s Manual for general service

information.

Dust Fouled Element

Rotate the element with your hand while applying

compressed air to the inside of the element. This will blow

the dust free.

Compressed air pressure must not exceed 7 kg/cm

2

(100

psi/690 kPa).

Carbon and Dust Fouled Element

1. Prepare a cleaning solution of Isuzu Genuine Element

Cleaner (Donaldson D1400) diluted with water.

2. Submerge the element in the solution for twenty

minutes.

A06RY00006

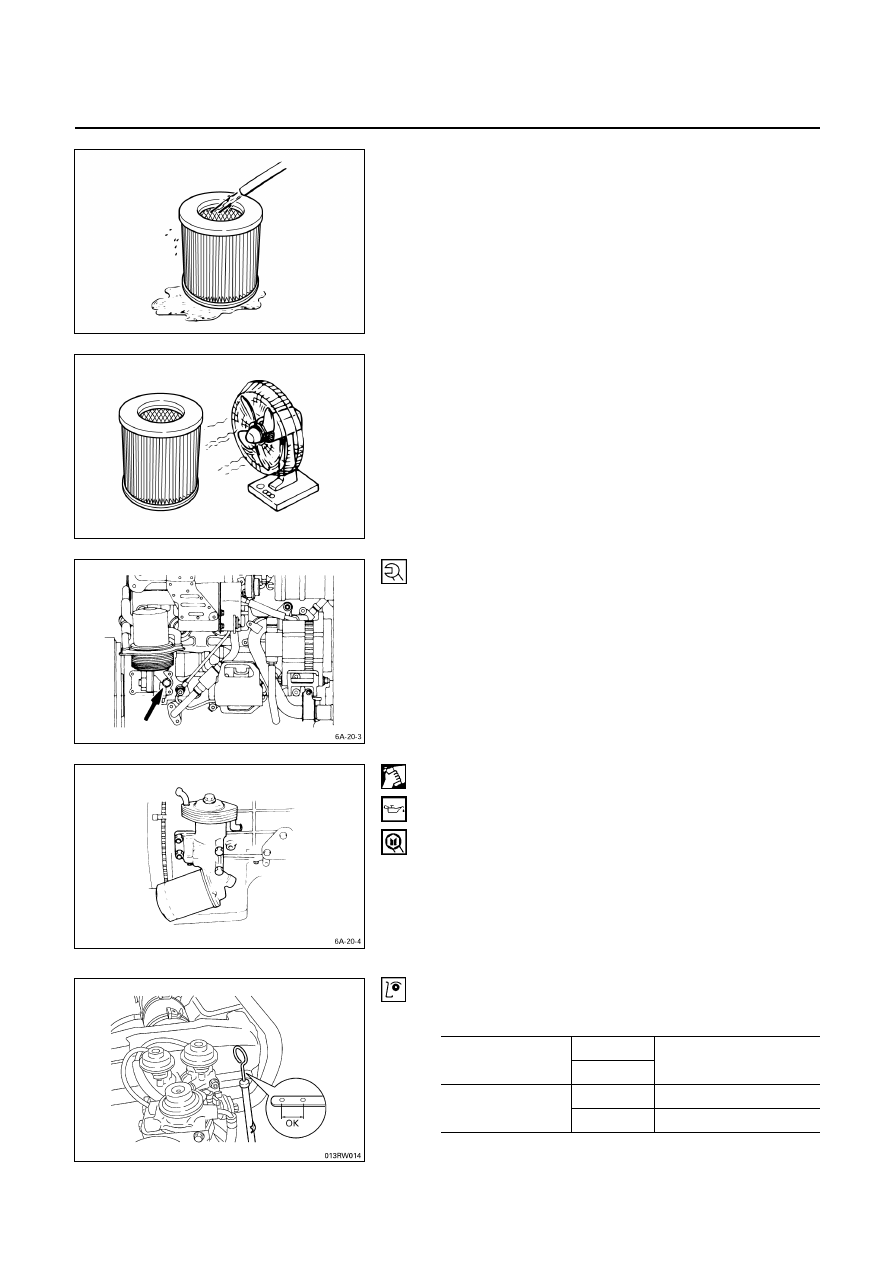

ENGINE MECHANICAL 6A – 25

3. Remove the element from the solution and rinse it well

with running water.

Water pressure must not exceed 2.8 kg/cm

2

(40

psi/270 kPa).

4. Dry the element in a well ventilated area.

An electric fan will hasten drying.

Note:

Do not use compressed air or an open flame to dry the

element quickly. Damage to the element will result.

It will usually take two or three days for the element to

dry completely. Therefore, it is a good idea to have a

spare on hand to use in the interim.

LUBRICATING SYSTEM

Main Oil Filter (Cartridge Type Paper Element)

Replacement Procedure

1. Loosen the drain plug to drain the engine oil.

2. Wait a few minutes and then retighten the drain plug.

3. Loosen the used oil filter by turning it counterclockwise

with a filter wrench.

4. Clean the oil cooler fitting face. This will allow the new

oil filter to seat properly.

5. Apply a light coat of engine oil to the O-ring.

6. Turn in the new oil filter until the filter O-ring is fitted

against the sealing face.

7. Use the filter wrench to turn in the filter an additional 1

and 1/8 turns.

Filter Wrench: 5-8840-0200-0 (4JB1T, 4JG2T, 4JA1T,

4JA1TC, 4JH1TC)

: 5-8840-0201-0 (4JA1)

8. Check the engine oil level and replenish to the

specified level if required.

Replenished Engine Oil

lit (US/UK gal)

4

× 2

4JA1, 4JA1T

4JB1T

4

× 4

6.5 (1.7/1.4)

4

× 2

6.5 (1.7/1.4)

4JG2T, 4JA1-TC

4JH1TC

4

× 4

7.3 (1.9/1.6)

9. Start the engine and check for oil leakage from the

main oil filter.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст