Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 593

FUEL SYSTEM 6C – 31

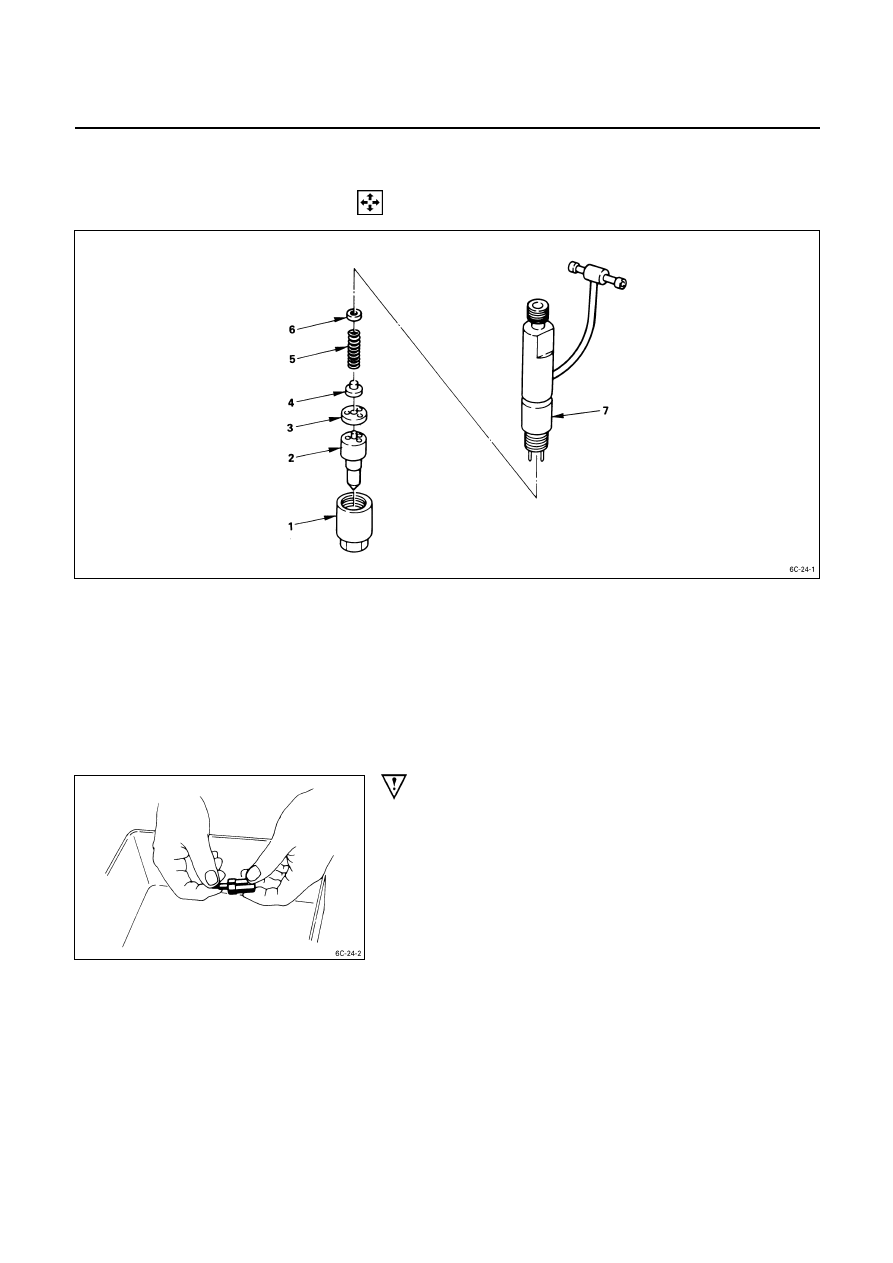

INJECTION NOZZLE

DISASSEMBLY

Disassembly Steps

1.

Retaining nut

5.

Spring

J

2.

Injection nozzle

6.

Adjusting shim

3.

Spacer

7.

Nozzle holder

4.

Spring seat

Important Operations

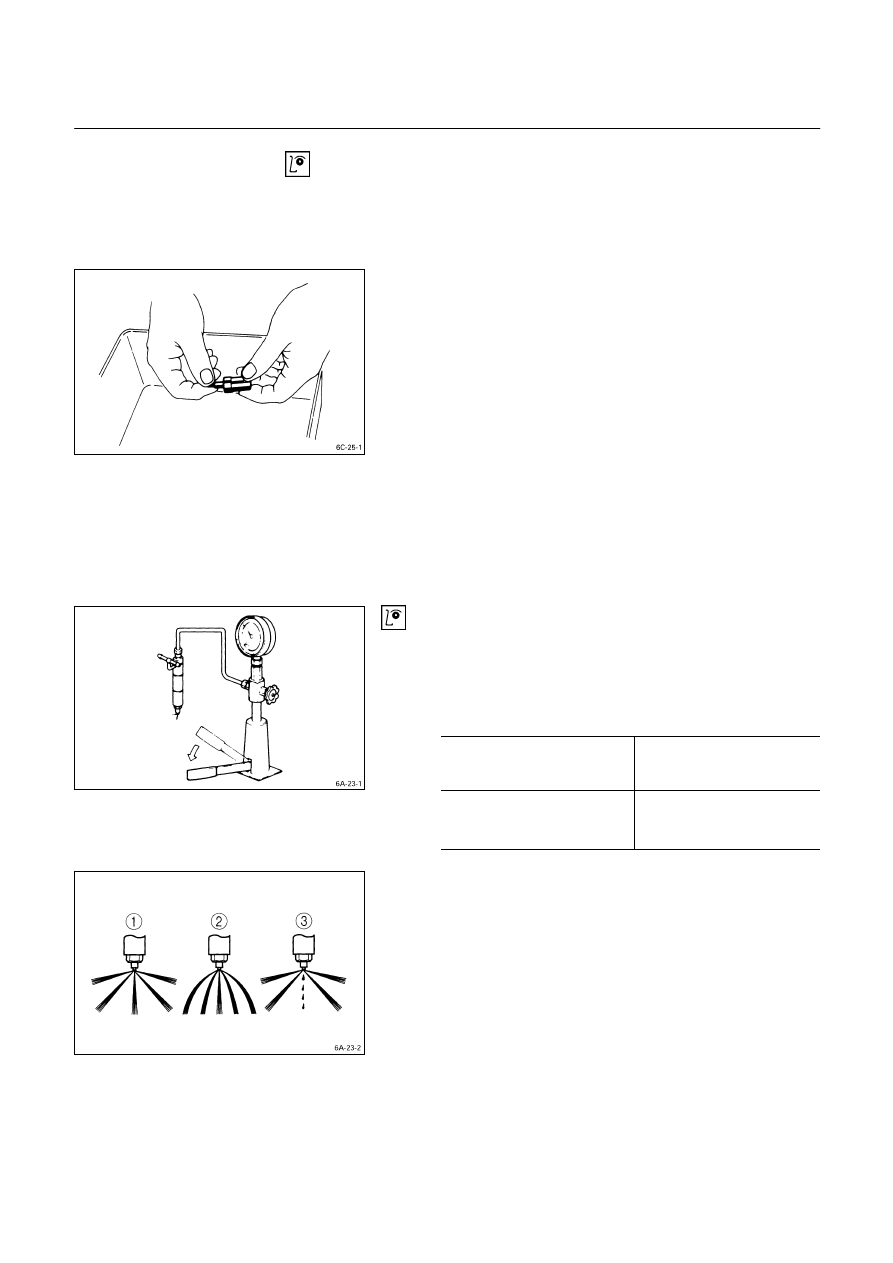

2. Injection

nozzle

1) Remove the nozzle assemblies from the nozzle

holders.

Tag the nozzle assemblies and the nozzle holders to

ensure that they are reinstalled in their original

positions.

The nozzle assembly and nozzle holder combinations

must not be interchanged.

2) Immerse the injection nozzles in a tool tray filled with

clean diesel oil to protect them from dust.

6C – 32 FUEL SYSTEM

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part replacements if excessive wear or damage is discovered during

inspection.

Injection Nozzle Needle Inspection

1. Remove the nozzle needle from the nozzle body.

2. Carefully wash the nozzle needle and the nozzle body

in clean diesel fuel.

3. Check that the nozzle needle moves smoothly inside

the injection nozzle body.

If the nozzle needle does not move smoothly, it must

be replaced.

Nozzle Body and Needle Valve Inspection

Check the nozzle body and the needle valve for damage

and deformation.

The nozzle and body assembly must be replaced if either

of these two conditions are discovered during inspection.

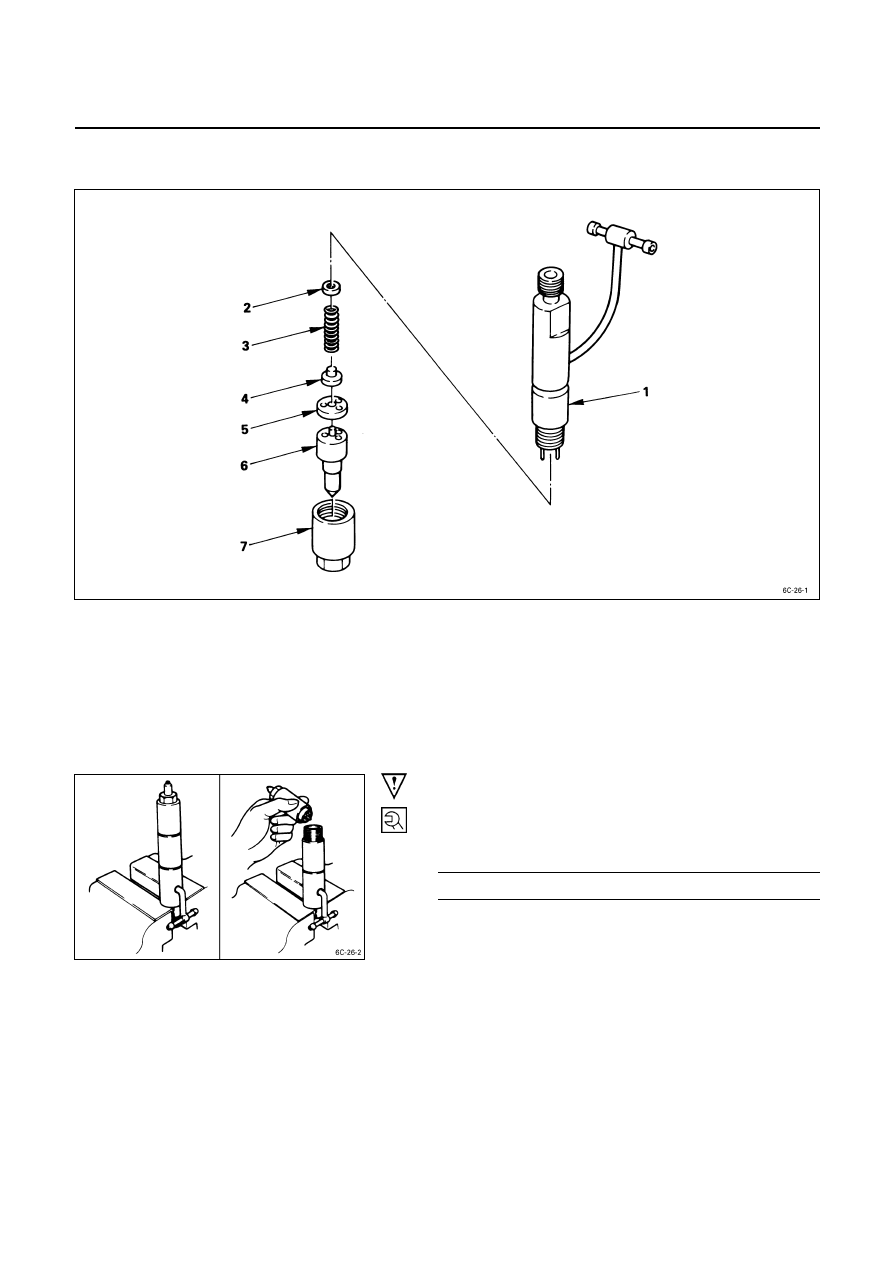

Injection Nozzle Inspection

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or adjusted.

Injection Nozzle Opening Pressure

kg/cm

2

(psi/kPa)

4JA1T, 4JA1, 4JB1T

185 (2,631/18,1)

4JB1T

For ARGENTINA and

MALAYSIA only.

220 (3,128/21,575)

If the spray condition is bad, the injection nozzle must be

replaced or repaired.

Spray Condition

Correct

Incorrect (Restrictions in orifice)

Incorrect (Dripping)

FUEL SYSTEM 6C – 33

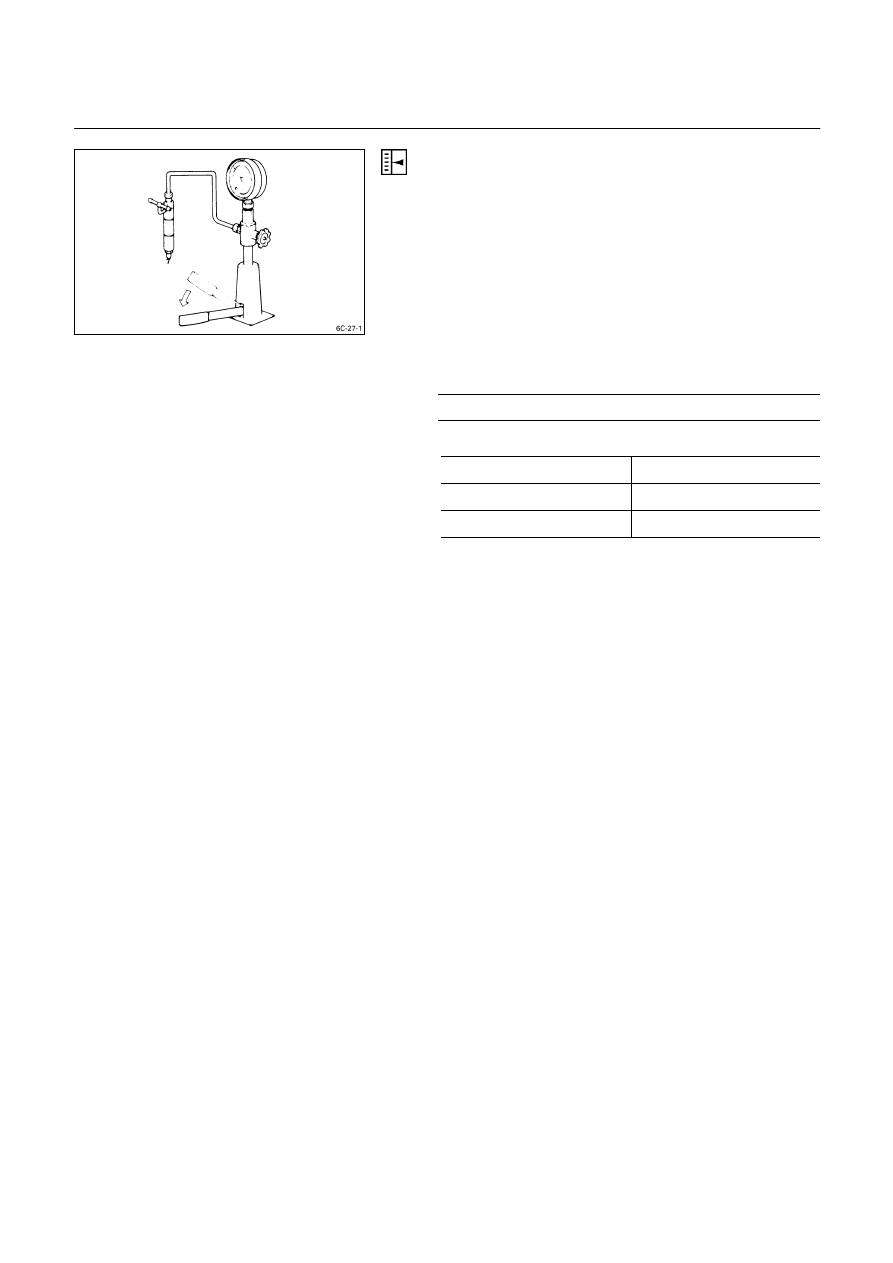

REASSEMBLY

Reassembly Steps

1.

Nozzle holder

5.

Spacer

2.

Adjusting shim

6.

Injection nozzle

3.

Spring

J

7.

Retaining nut

4.

Spring seat

Important Operations

7. Retaining

Nut

Tighten the retaining nut to the specified torque.

Retaining Nut Torque

kg·m (lb.ft/N·m)

3.5

± 0.5 (25.3 ± 3.6/34.3 ± 4.9)

6C – 34 FUEL SYSTEM

Injection Nozzle Adjustment

The fuel injection starting pressure adjustment of this

injection nozzle is done by rereplacing or decreasing or

increasing the number of shims installed.

1) Attach the injection nozzle holder to the injection

nozzle tester.

2) Apply pressure to the nozzle tester to check that the

injection nozzle opens at the specified pressure.

If the injection nozzle does not open at the specified

pressure, install or remove the appropriate number of

ajusting shims to adjust it.

Nozzle Opening Pressure

kg/cm

2

(psi/MPa)

185 (2,631/18.1)

Adjusting Shim Availability

rnm(in)

Range

0.50 – 1.50 (0.02 – 0.06)

Increment 0.025

(0.001)

Total No. of Shims

41

Removing or installing one shim will increase or decrease

the nozzle opening pressure approximately 3.77 kg/cm

3

(53.6 psi/369.46 kPa).

WARNING:

TEST FLUID FROM THE INJECTION NOZZLE TESTER

WILL SPRAY OUT UNDER GREAT PRESSURE. IT CAN

EASILY PUNCTURE A PERSON’S SKIN. KEEP YOUR

HANDS AWAY FROM THE INJECTION NOZZLE

TESTER AT ALL TIMES.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст