Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 594

FUEL SYSTEM 6C – 35

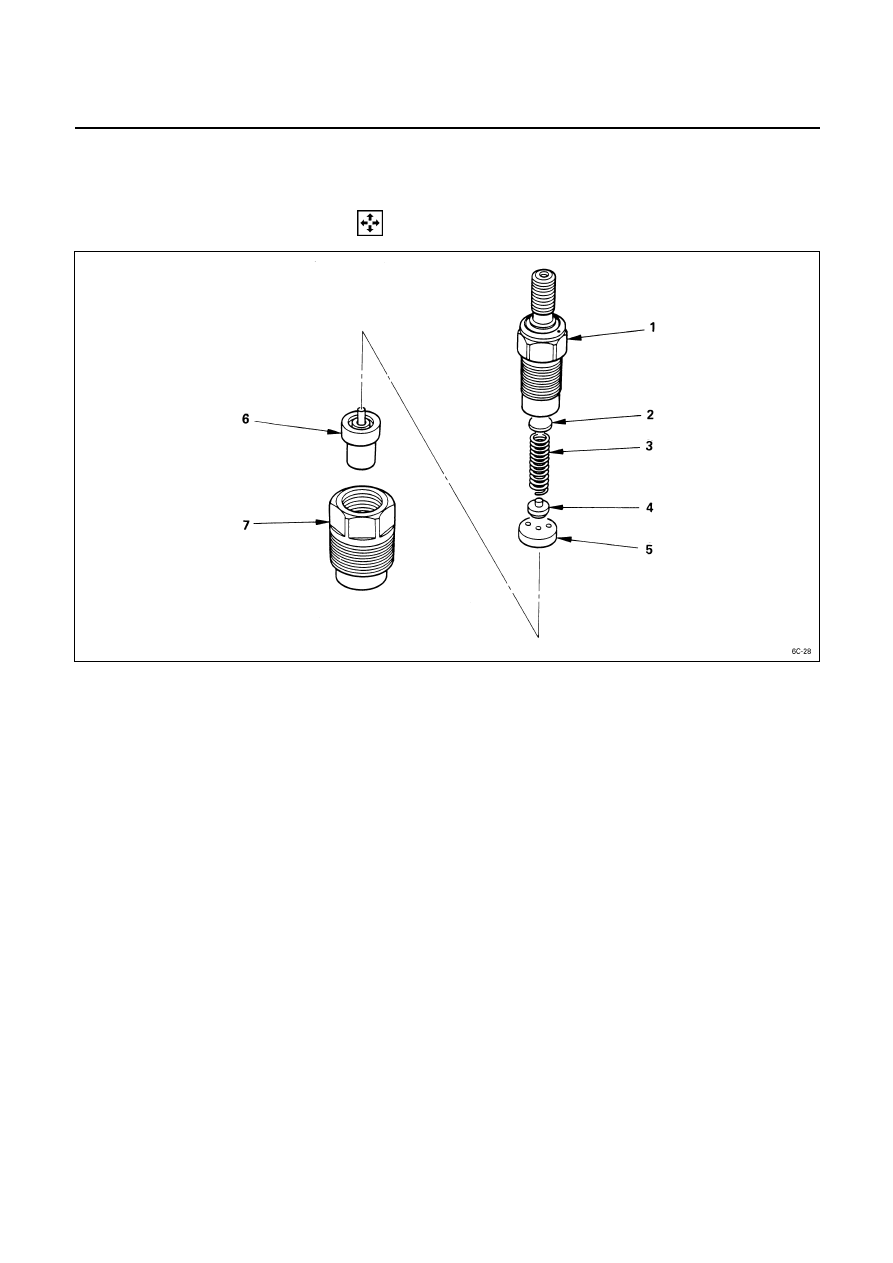

INJECTION NOZZLE

(For 4JG2T Engine)

DISASSEMBLY

Disassembly Steps

J

1.

Nozzle holder body

5.

Distance piece

2.

Adjusting shim

J

6.

Nozzle assembly

3.

Spring

7.

Retained nut

4.

Push rod

6C – 36 FUEL SYSTEM

Important Operations

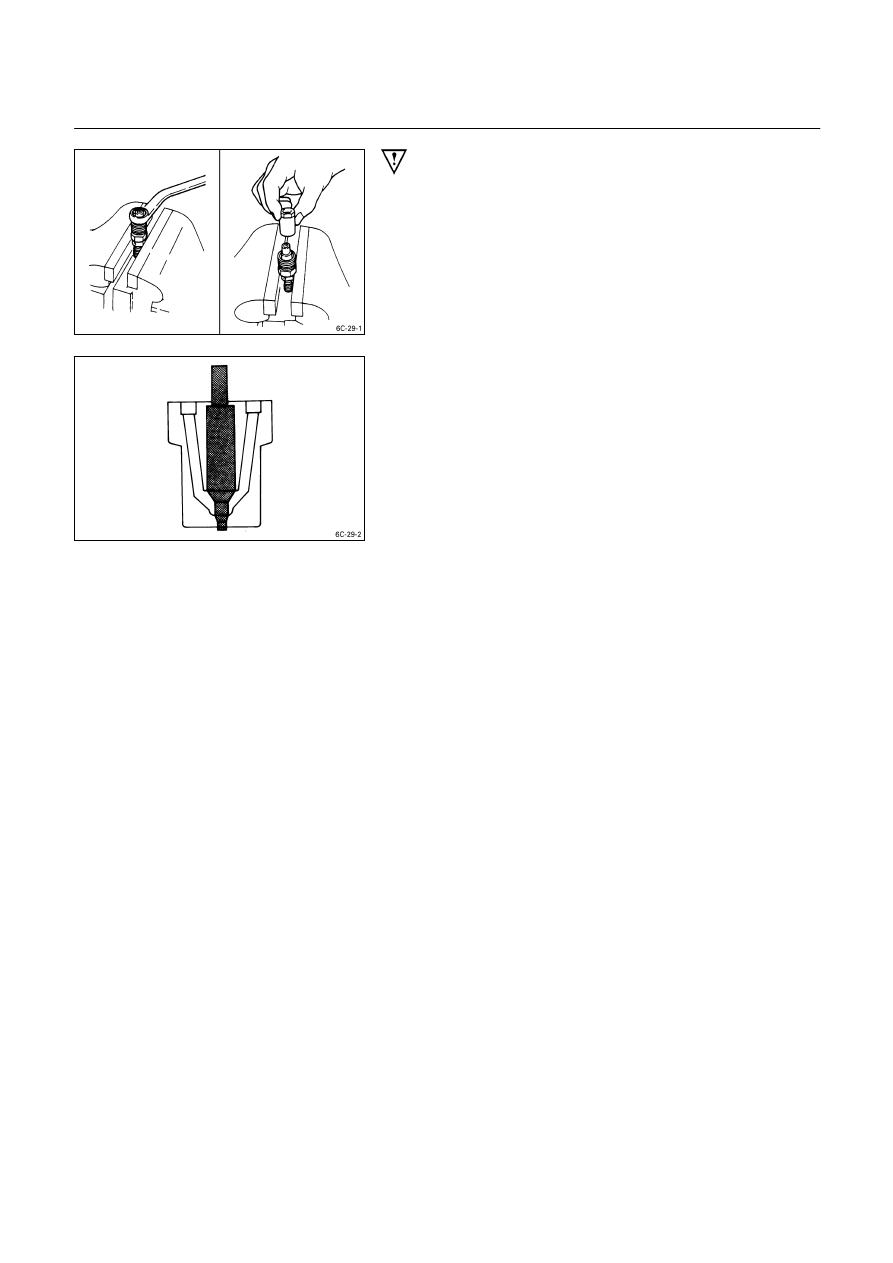

1. Nozzle

holder

body

Clamp the nozzle holder in a vise and remove the

retaining nut.

6. Nozzle

assembly

Keep nozzle assembly removed from the holder body

separated to maintain proper needle valve and body

combinations.

FUEL SYSTEM 6C – 37

INSPECTION AND REPAIR

Make the necessary adjustments, repairs, and part

replacements if excessive wear or damage is discovered

during inspection.

Injection nozzle needle seizure inspection

1) Remove the injection nozzle needle from the injection

nozzle body.

2) Carefully wash the injection nozzle needle and the

injection nozzle body in clean diesel fuel.

3) Check that the injection needle valve moves smoothly

inside the injection nozzle body.

If the injection needle valve does not move smoothly, it

must be replaced.

Injection nozzle body and injection needle

inspection

Check the injection nozzle body and the injection needle

valve for damage and deformation.

The injection nozzle assembly must be replaced if either of

these two conditions are discovered during inspection.

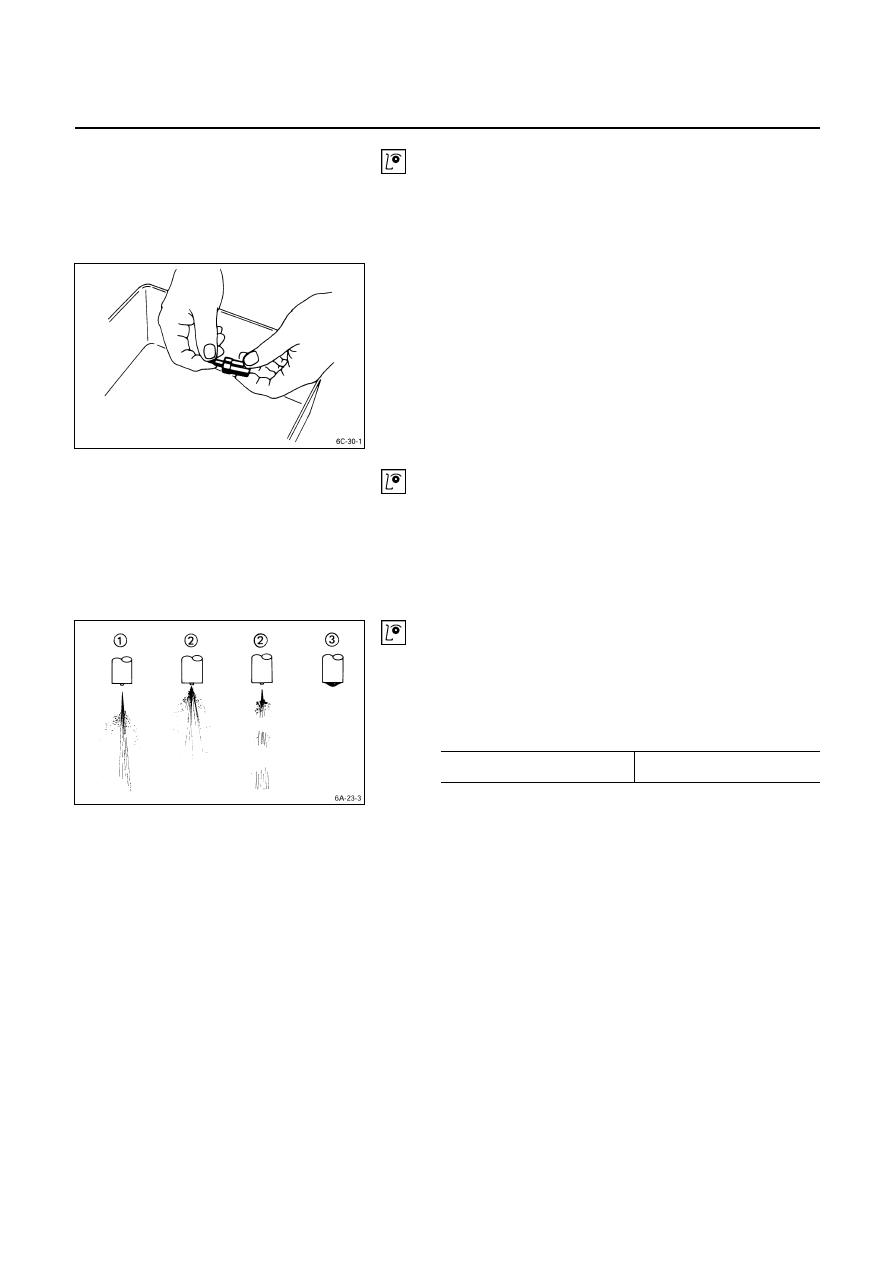

Injection Nozzle Inspection

Use a nozzle tester to check the injection nozzle opening

pressure and the spray condition.

If the opening pressure is above or below the specified

value, the injection nozzle must be replaced or adjusted.

Injection Nozzle Opening Pressure

kg/cm

2

(psi/MPa)

4JG2T 150

(2,133/14.7)

If the spray condition is bad, the injection nozzle must be

replaced or repaired.

Spray Condition

Correct

Incorrect (Restrictions in orifice)

Incorrect (Dripping)

6C – 38 FUEL SYSTEM

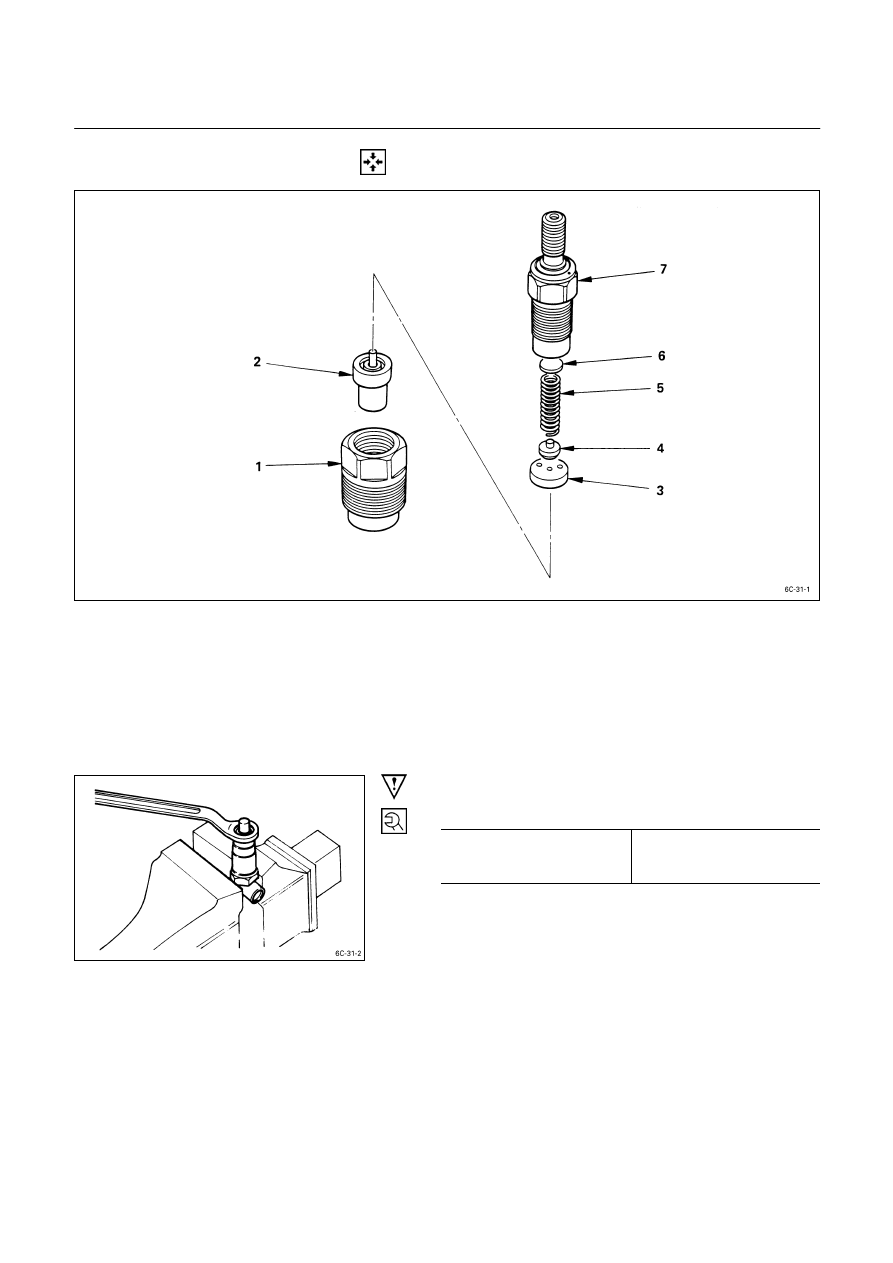

REASSEMBLY

Reassembly Steps

1.

Retaining nut

5.

Spring

2.

Nozzle

6.

Adjusting shim

3.

Distance piece

J

7.

Nozzle holder body

4.

Push rod

Important Operations

7. Nozzle

holder

body

Torque

kg·m (lb.ft/N·m)

3.0 – 5.0

(21.7 – 36.2/29.4 – 49.0)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст