Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 588

FUEL SYSTEM 6C – 11

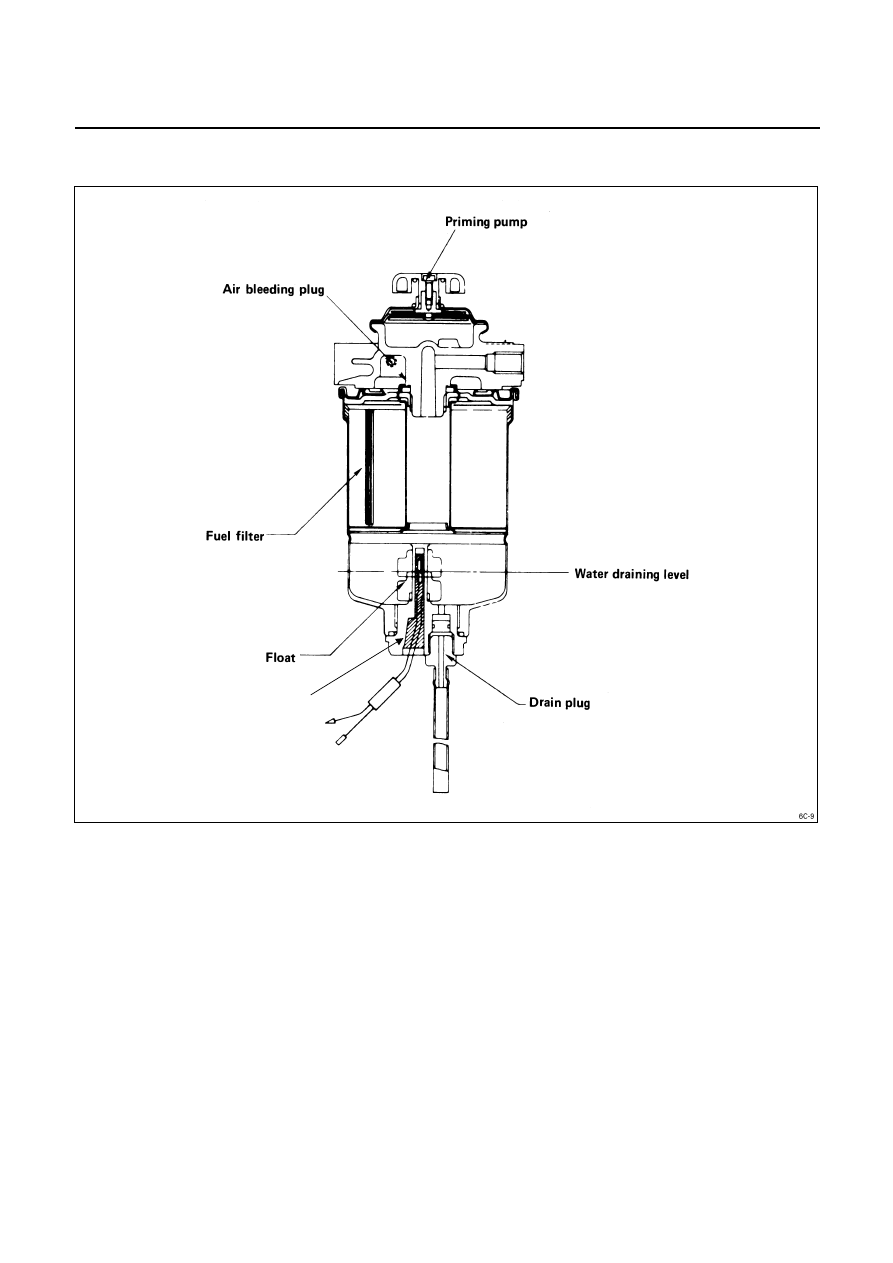

FUEL FILTER WITH BUILT-IN WATER SEPARATOR

A fuel filter with a built-in water separator is used along with the VE type injection pump.

As the inside of the injection pump is lubricated by the fuel which it is pumping, the fuel must be perfectly clean. The

fuel filter and the water separator remove water particles and other foreign material from the fuel before it reaches

the injection pump.

The water separator has an internal float. When the float reaches the specified level, a warning light comes on to

remind you to drain the water from the water separator.

A diaphragm type priming pump is installed at the top of the water separator. It is used during the water draining

and the air bleeding procedures.

Level Sensor

6C – 12 FUEL SYSTEM

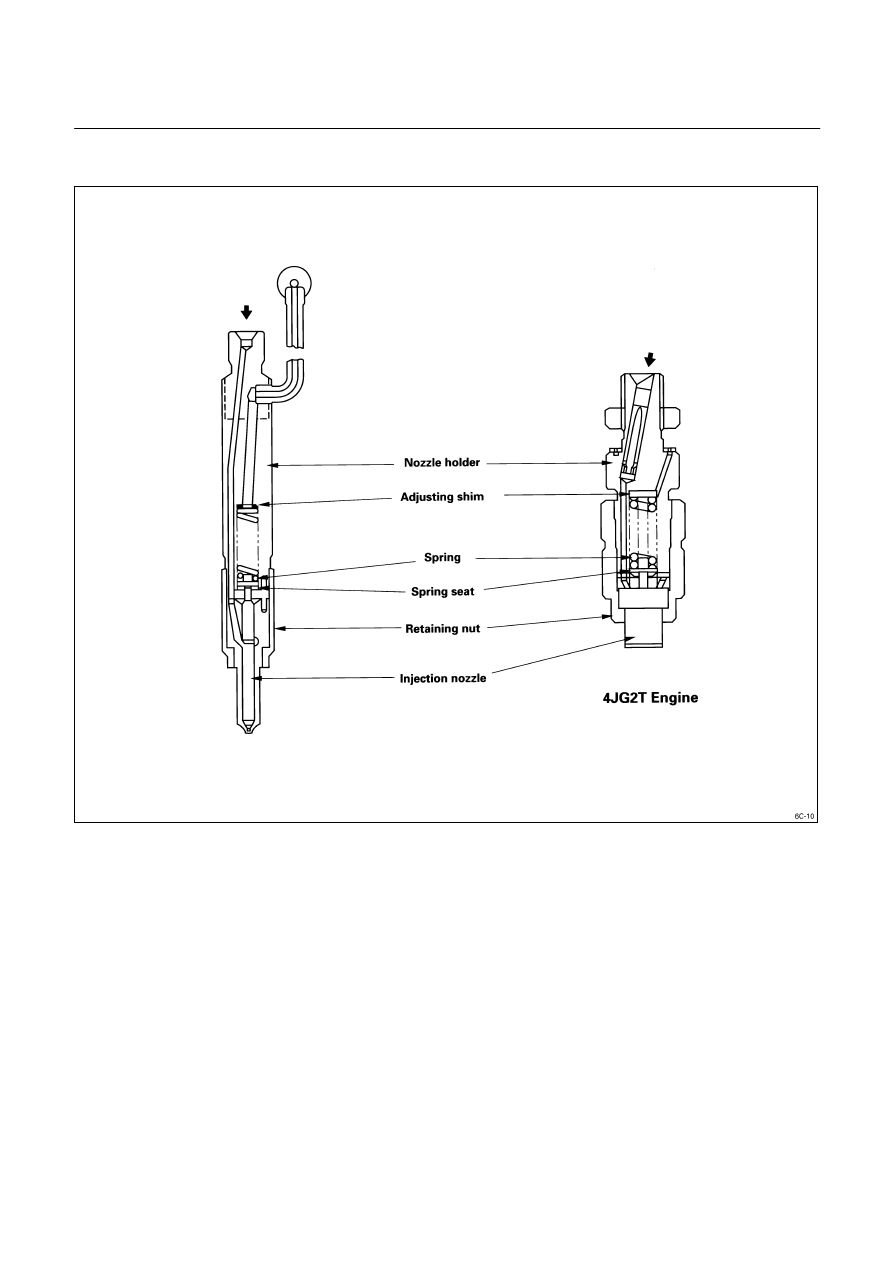

INJECTION NOZZLE

A hole (with 5 orifices) type injection nozzle is used for 4JA1T, 4JA1, 4JB1T Engine and a throttle type injection is

used for 4JG2T Engine. It consists of the nozzle body and the needle valve assembly.

The injection nozzle assembly sprays pressurized fuel from the injection pump into the combustion chamber

through the nozzle body injection orifice.

FUEL SYSTEM 6C – 13

INJECTION PUMP

REMOVAL AND INSTALLATION

Read this Section carefully before performing any removal and installation procedure. This Section gives you

important points as well as the order of operation. Be sure that you understand everything in this Section before you

begin.

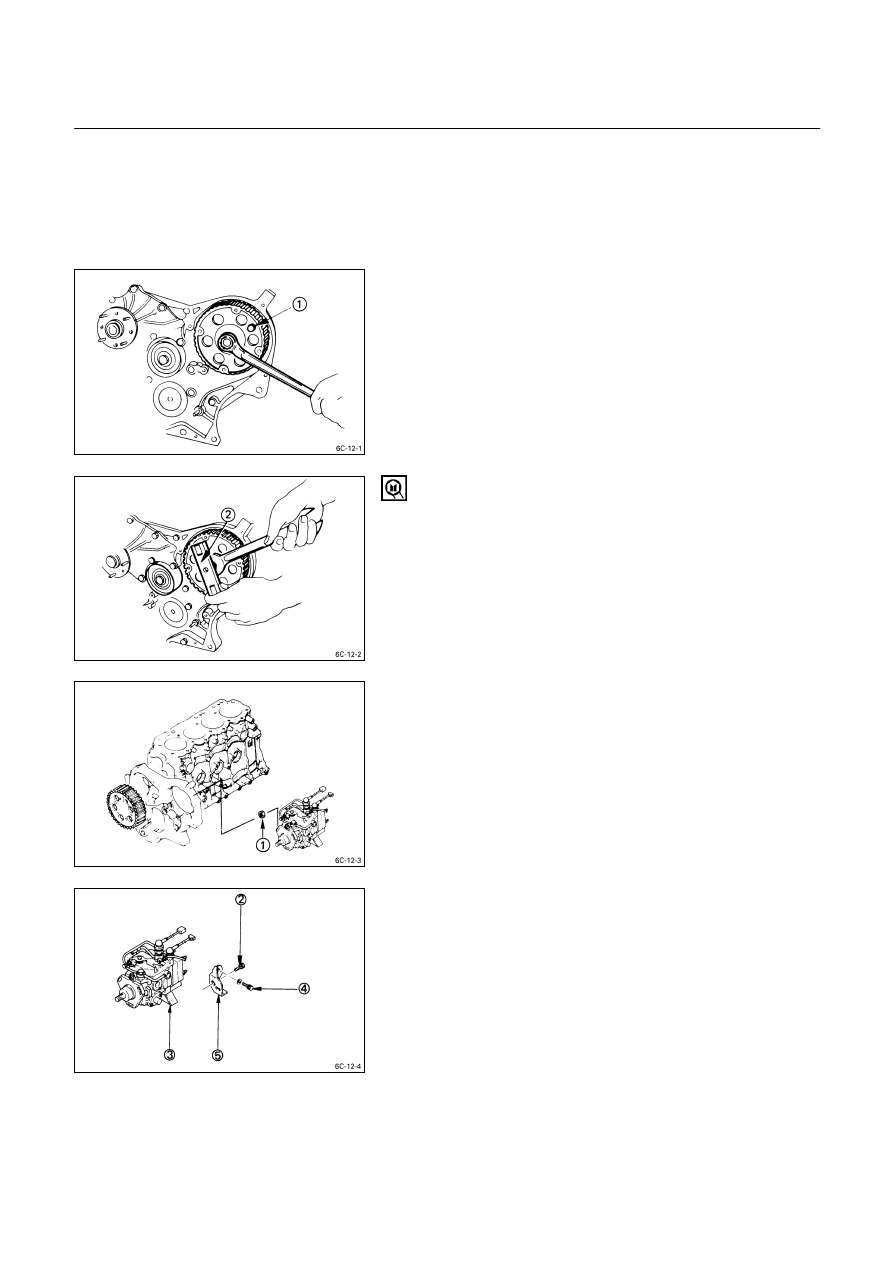

BELT DRIVE MODEL (4JA1T, 4JG2T)

Removal Steps

1. Cooling

Fan

Drain the engine coolant.

The following parts must be removed before the cooling

fan can be removed.

Battery, Air cleaner duct, Radiator

Additionally, all piping, wiring, and hoses which will

interfere with the removal of the cooling fan must be

disconnected.

Refer to Section 6A, “REMOVAL AND INSTALLATON” of

this Manual for detailed information on part removal.

2. Crankshaft Damper Pulley

Turn the crankshaft to align the damper pulley mark with

the timing pointer.

This will bring the No. 1 piston to TDC on the compression

stroke.

3. Fuel Injection Pipe with Clip

1. Loosen the injection pipe sleeve nuts at the delivery

valve side

.

Do not apply excessive force to the injection pipes.

2. Loosen the injection pipe clips

.

3. Remove the injection pipes

.

Note:

Plug the delivery holder ports with the shipping caps

to prevent the entry of foreign material.

6C – 14 FUEL SYSTEM

4. Timing Case Cover Upper

5. Timing Case Cover Lower

6. Timing

Belt

1. Loosen the timing belt tensioner bolt and remove the

timing belt.

7. Injection Pump Timing Pulley

1. Install the stopper bolt

to the timing pulley to

prevent it from turning.

2. Use the timing pulley remover

to remove the

injection pump timing pulley.

Timing Pulley Puller: 5-8840-0086-0

3. Remove the stopper bolt.

8. Injection

Pump

1. Remove the three injection pump bracket nuts

at

the rear of the timing pulley housing.

2. Remove the injection pump rear bracket bolts

from

the injection pump bracket

.

3. Remove the injection pump rear bracket bolts

and

the bracket

from the cylinder body.

4. Pull the injection pump free toward the rear of the

engine.

Note:

Plug the injection pump delivery holder ports with the

shipping caps (or the equivalent) to prevent the entry

of foreign material.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст